Professional Documents

Culture Documents

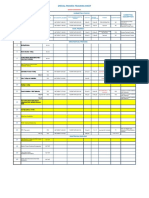

Organization Chart, Formats & Mobilization-Demobilization Plan PDF

Uploaded by

moytabura96100%(1)100% found this document useful (1 vote)

627 views74 pagesOriginal Title

4. Organization Chart, Formats & Mobilization-Demobilization Plan.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

627 views74 pagesOrganization Chart, Formats & Mobilization-Demobilization Plan PDF

Uploaded by

moytabura96Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 74

‘SAUDI ARAMCO OIL COMPANY

ABDUL MOHSEN AH AL-TAMIM

ay ES sits

OC. NO-AMTEPSGEW-0 vot

PROJECT QUALITY PLAN . _

SOUTH GHAWAR UR EARLY WORKS & TCF

BI: 10-1431 CONTRACT NO : 6500045093

PROJECT QUALITY PLAN

DISCIPLINE: CIVIL DEPT.

Clareroven (1 ArpRoveD w/coMMENTS

REMARKS:

= | = [Coe ee 2Az..,

Ex fare eteae ae

ren sou aaa

el

PROJECT QUALITY PLAN ine ia

‘Table of Contents

Section

Tie

Page

Introduction

56

TLL Normative References

Conficts and Deviations

‘Scope of Work

‘Terms / Abbreviations and Definitions

18

‘Quality Management System

97

5.1 General

52 Poly

53 Objectives

SA Process Approach

55 Quality Plan

56 Contol of Quality Records

5.7, Prooedures|

Cent / Costumers Foss

1719)

(Organizational ad Responsibiies

19-27

7.1 Responsibilities and Authorities

Resource Management

2728

Quality Sytem

2833

9.1 Generat

9.2 Purpose |

9.3 Responsibilies

SAUDI ARAMCO ON, COMPANY

sane El

ABDUL MOHSEN AH AL-TAMEML

PARTNERS COMPANY

PROJECT QUALITY PLAN

DOC, NOAMT-NQP-SGEW-00

94 Development, Maintonace and Control of Quality Plan

Sunny OF Quy Deliverables

0

Mobilization & Demobilzation Plan

33.4

104

Management Review

35

2

Contract Review

35.36

12 Soope

122. Genel

13

Documents and Data Control

3637

4

‘Major Facilites and Data Control

37

Mt General

142 Test Procedre

15

Quality Control Activites

3844

15.1 General

152 _ QAIQC Aetivtes and Field Reports

1533 Inspection and Test Plans

15 Level of Inspections

1535 Method Statements

15.6 _ Request for Inspection

15.7 Testing and Inspection Prosedure

158 Excavation, Backiling and Compaction

159 Coneret Works

15.10. Survey Wonks

15.11 Mat

1 Revsiving and Storage

‘SAUDI ARAMCO OIL COMPANY

ves

ABDUL MOHSEN AH AL-TAMIMI

PARTNERS COMPANY,

DOC. NO-AMT-PQP-SGEW.ON, neo

PROJECT QUALITY PLAN _ a

15.12. Hand Over Work

1513 Rewind Reaping

15.14 Contol of Non-Conformance

15:15 Quality Audit

15.16 Inspection and Testing Equipment

16 | Procurement Cycle

“

17 | Attachments

45

[Site Organization Chart

[La Histogram / Costuction Schedule

Inspection & Test Plan

‘Request for Inspection

Survey Report

2

3

4 Pour Conerete Card

5

6

“Material Receiving Inspection

7 Conerete Pouring Log

8 Non: Conformance Report

‘9 Non- Conformance Log

10 Request For Inspection log

Quality Aut Schedule

TZCAK - Corretve Action Report

13 Technical Query Form

‘SAUDI ARAMCO OIL COMPANY =

ARDUL MOHSEN AH AL-TAMIMI

a sta

‘BOC: NO-ANE-PQP-SGEW01 reo

PROJECT QUALITY PLAN

Fae rast

1, INTRODUCTION

Abul Mohsen AH Al-1!amimi Partners Company has for many years completed construction

projects at many locations within and out of the Kingdom of Saudi Arabia and has established

themselves as an industrial leader duc to their experience and by following Quality Management

principles. This approach has resulted in the completion of its past project, meeting its client

satisfaction despite sometimes has stringent time and budget constraints Sil, the completed works

‘have met the quality standard imposed, even under difficult situations

‘The continuances of these concepts have been given top priority and carry the full support and

committment of the Company Executive Management.

Quality Awarenes and conto are at the heat of ll the processes involved in the execution of

construction project and itis the intent that this Quality Control and Assurance Plan shal deseribe

and define in detail how these iden

the project completion. The activites included inthis project are defined inthe seope of work

prepared and issued to Al-Tamimi by Saudi Arameo under BI No: 10-14331.The work shall be

executed under the operational and technical management of Saudi Aramco.

1 Normative References

ied quality levels are to be achieved at defined stages during

'$0900-201556 oui Mammen Sens eames

$0 bats | oes Quay Ps

‘Schedule ‘Q" Procurement and Special Quality Requirements

sams | btn cose Gad Pa

Sete) [setts

Sethe [ie en aie

SAUDI ARAVICO O1L, COMPANY

Ea {nc MOMSEN Ait at-TAMIM

aga 95 PARTNERS COMPANY

Sui Ata

voc noawrescewent | wat

PROJECT QUALITY PLAN

cairo, s0n001 | Quatiy Management Roles & Resposil

Dros cciion Plan

SABP.I22 Project Records

on Inston fr Obtaining a Waiver ofa Mandatory Sadi Aramco

Enginerng Rumen

SAE20 Project Cos Ou Report

SAEP.1150 Inspection Coverage on Projets

SAEP.1161 Testing ad inspection 781) Reporting Procadine

SAFS-Q-001 Cte for design and conerete Svture

SABS.Q.06 Asphalt & Slr Extended Asphalt Concrete Paving

SABS.M.006 Saudi Armco General Purpose Feeing

SAFS.A-IIL Excavation and Bacfiing

SAES-A-IL Bomow Fit Regiremens

SAES-ATO0| Survey Coots and Datu

thor Site Preparation, Exsavaon and Backing ding

sarip-a.1i401 | eontruction

SATIP.0.01-01 | Ready Mix Concrete Batch Plant and 3 Pay Laboratory Management

SATIP.Q.01-02 | Cast in Place Portand Cement Concrete

SATIP-M-IO0-O4_—| Pre-Engineered Metal Building

SATIP-M.006-01 | Securiyand General Purpose Fenn

All works carted out by Al-Tarims shall comply with the requirements of Saudi Aramco

standards and project specifications.

2, CONFLICTS and DEVIATIONS,

‘any conflicts or deviations is observed between POP or any referred Quality procedures,

Dravvngs and the Schedule Q, Sault Aramco standards procedure, specifications and

contracts, then this Saudi Aramco requirements will be followed.

SAUDI ARAMCO OIL COMPANY

MOMSEN AME AL-TAMIME

PARTNERS COMPANY

oe, No-T-FOP-SEW- revo

PROJECT QUALITY PLAN z

Ta Tara

3. SCOPE OF WORK

"The work includes but net limited to procurement, supply and delivery of all materials for South

Ghawar UR Early Works & Temporary Facilites (TCR), Herewith the Following summary activities

listed below but wot limited to,

31 Client’s Support Office

32 Survey Works

33. Earthworks

34 Perimeter Fence Works

35 Access Roads & Asphalting Works

36 Sanitary Treatment Plant

37 _Bvaporation Ponds

28 Main Roads

4, ‘TERMS’ ABBREVIATIONS AND DEFINITION

CLIENT- Saudi Arameo

CONTRACTOR AMT: Abdul Mohsen Al-Tamimig Partners Co.

Pap Project Quality Plan

PQL Project Quality Index

PPL Project Progress Index

rrp Inspection and Test Pan

Ms Method Statement

THIRD PARTY LAB Third Panty Independent Testing Laboratory

NCR 'Non-Conformance Report

RFI Request for Inspection

RMI ‘Request for Material Inspection

MRR ‘Materials Receiving Report

PPM Parts per million

SAUDI ARAMCO OIL COMPANY

El ara so inn

PROJECT QUALITY PLAN. ss er

TDs

Conformity

Non-Confoemity

Defect

Corrections Aetions

Re-work

Repair

Appraisal

Certification

Compliance

‘Total Dissolve Solids

Fulfillment of Requirements

[Non-Fulillment of Requirements

Distinetion between the concepts of defects and Non-

conformity is important as it has legal connotations,

particular those associated with product liability issues

intended use by costumer can be affected by the nature ofthe

information such as operating or maintenance instructions

Preventive Actions- Actions to eliminate the causes of

potential Non-Conformity or ather undesirable potential

situations

To eliminate a defected non conformity a correction can be

made in conjunctions with corrective actions. (ie, re-works)

Action of non-conformity product to make it conform tothe

requirements unlike, repair ean affet or change pars ofthe

‘non- conformance product

[Actions on Non- conformity product to make itaeceptanee

for intended use include remedial action taken toon

previously conforming product to restore tous

s capa

carried out before placing orders,

Assessment of suppl ty of controlling quality

“The authoritative act of documenting compliance with

requitements The requirements can relate to personnel,

processes, products, organizations and services.

‘An indication or judgment that the product or service meets

the requirements ofthe relevant specification or regulation;

also, the state of meeting the requirements.

SAUDI ARAMCO OIL COMPANY

[ABDUL MOHSEN A AL-TAMIME

zgnutt gsout Ex PARTNERS COMPANY.

PROJECT QUALITY PLAN = = ne

Fae ras

Customer Recipient of a product provided by the supplier.

Improvement ‘Action taken by Al-Tamimi Partners Co. to increase the

effectiveness and efficiency of activities and processes in

‘order to provide added benefits to AL-Tamimi & its sub-

contractor,

5. QUALITY MANAGEMENT SYSTEM

51 General

Abdul Mohsen Abdullah AL Hurish AL Tamir

to the requirements of ISO 9001-2015 by establishing:

Partners Co, will follow according

‘+ Defining the purpose ofthe company and should identify its users and other interested

parties as wel a their requirements, needs, and expectations in order to determine its

intended output elements.

‘+ Defining policy and objective sof the company. The company policy should be based

‘the analysis of requirements, needs and expectation. The policy should provide the

framework for establishing the organization's objective and implementation of Quali

“Management System.

52. Policy

Iis the policy of ABDUL MOHSEN Abdullah AL Hurish AL TAMIMI & Partners

Co. in terms of services related contracting (Road Works, Civil, Electrical and Mechanical),

“Transportation & Real Estate to:

1, Promoting excellenc

satisfy customer needs by sp

‘organization,

performance of its services itis AL-Tamimi’s Quality Poly to

ng them in the form of defined requirements for the

2, Provide services ofthe highest possible standards, expectations of quality, safety, and

reliability services and customers satisfaction

gage

nae a

PROJECT QUALITY PLAN aa ee

sa

3. Accomplish quality objectives by establishing, implementing and maintaining a

documented. effective Quality Assurance System which eomplies with the requirements

‘oF ISO 9001

4. Timely delivery of serves to mest our customer's requirements.

Ensure our employees are competent and properly trained so they are better able to serve

cour customers.

6. Require adherence to agreed and approved procedures.

7. Provide the necessary resources for productive environment

8. Encourage quality performance above the minimum require.

Our policy requires our employees to be aware of and contbute to then

improvements ofthe Quality Management Systems .

c AE Manager

OBJECTIVES

AL Tamimi Quality Objectives

‘The main objective of this plan isto achieve successful completion ofthe seope of work.

according to contract conditions, requirements and all other acceptable standards set forth

in the project design specification.

Adapt Al-Tamimi’s Quality Management System to meet the eustomer's procedural

requirements with due regard to company’s already established procedures thereby serving

the project's quality requirements with speed. The quality objectives for South Ghawar

UR Early Works & TCF project is SMART Set, Measurable, Attainable, Result-

Criented and Time-Bounded and identified as follow:

1, Implement all established processes and procedures at all levels, doing the right

thing.

‘SAUDI ARAMCO OIL COMPANY

ABDUL MOHSEN AH AL-TAMIML

zona esout Ga ‘PARTNERS COMPANY

memory men | | ae ne

Plan and execute all activites affecting quality ofthe project Deliverables to ensure

that products deliverables are defect and contract complaint by doing itright the

fist time.

3. Record and maintain progressively all qualify verifications documentation for

‘completeness and correctness.

4, Ensure the repeated violations shall not be more than 5% of total violations

recorded in NNCINCRISA non-conformance.

5, RF acceptance rate shall not be less than 95%

6, Quality deliverables rejection will not be more 2%

7. Keep responding to the SA non-conformance within 48 hours

8, Maintain the PQL or PPI (Project Progres Index) above 94%

9 Establish and communicate clear quality control procedures for project execution in

relation to other departments” involvement.

10. Plan, carty out, monitor and adapt the service realization processes.

11, Expand the range of corporate experience & expertise by continuously developing

‘his Quality Management (Plan) System.

12, Optimize effcieney and bring forth improvements

Process Approach —General

‘Abul Mohsen AH Al Tati

cyele

Partners Company will execute and implement the PDCA,

‘SAUDI ARAMCO OIL COMPANY

reson [ad

Gpgaussl gSolyh

ARDUL MOHSEN AH AL-TAMIMIL

PARTNERS COMPANY

OC. NO-AMT:AQPSGEW-01 nwa

PROJECT QUALITY PLAN = —

SS

/

55.1 The Quality Plan ideties the Quality system /atvites necessary for Al-Tamimi

to execute the requirements of the contract on the Site preparation and fencing at

South Ghawar Project. Hence serves asa reference document forthe preparation of

Inspection & Test Plans and Project Procedures. The Inspection & Test Plans detail

the “Review”, *Hold” and “Witness” points during manufacturing and construction,

5.52. The Quality Plan and Inspection & Test Plans shall be applicable toll quality-related

activites forthe exceution of the Contract,

5.53 This Quality Plan includes al activities associated with implementation of Contract

quality requirements. Such activites include Procurements and Construction. The

following project manual procedures shall be compifed throughout the duration of

this projet

SAUDI ARAMCO OIL COMPANY

ABDUL MOHSEN AH AL-TAMIME

zona aso! Ex [PARTNERS COMPANY.

PROJECT QUALITY PLAN | "SNES

554 Abdul Mohsen AH Al Tamim Partners Company and South Ghavar Project

Management Team shall maintain the all documents information during and after the

construction Phase until delivered all necessary and required according to scope of

‘works, specification as well as approved IFC and shop drawing respectively until

close out and handing over to client. And to deliver the following requirements,

standards but not limited

Coordination Procedure

Document Control Procedure

Field Inspection & Test Pan

Field Safety Procedure

Field Security Procedure

Field Material Contol Procedure

‘Vendor/Supplier Control Procedure

Specialty sub-contractor Control Procedure

Control of Quality Records

S61 Purpose

(Quality ecords are maintained to demonstrate conformance ta specified

‘requirements and effective operation of the Quality System. The purpose of this

procedure is to provide fora system and instructions, and to assign responsibilities

for establishing and storage of quality records

562 Scope

This procedure applies to all records generated, handwritten, hardcopy and

clectronc, that serves to record Al-Tamimi activities related to quality or required

to demonstrate implementation of and conformance to Our Company's quality

system,

SAUDI ARAMCO OIL COMPANY,

gga sot ES PARTNERS COMPANY.

ADUL MOHSEN AN AL-TAMIME

mererquurrman |e evan

Pag Tage as

Definitions

Record: A written statement of facts pertaining to a specific event, person,

records)

proces, product, service ete, (Also includes electron

‘Quality System documentation: Quality Manual, Core Services Policy Manuals,

Procedures, Work instructions, Forms etc.

Work Instructions: Instructions were deemed necessary pertaining to individual

tasks explaining how to perform a certain job by following an

appropriate sequence of steps.

Forms: Documents used to enter data ot information generated asa result of certain

activities

Process Owner: ‘The person with designated responsibility for the formulation,

‘maintenance, implementation and keeping records of documents.

ity

Process Owner: The Quality Management Representative (QMR) is the process

owner of this procedure, He is responsible for ensuring that all records

Responsi

are maintained as per this procedure.

“Managers of departments maintaining Quality Records are responsible for ensuring

hose records are maintained according to this procedure.

57 Procedure

sa

Identifieation

‘Records are identifiable tothe product, person, or event to which they pertain,

Records are dated, and identify the person who established the record. Records are

indexed or grouped to facilitate thei retrieval.

~ SAUDI ARAMCO OIL COMPANY,

oscars Ml

ABDUL MOHSEN At AL-TAMIME

‘PARTNERS COMPANY

DOC. NO-AMT-FQP-SCEW-001 ot

PROJECT QUALITY PLAN

Ti as

s73

(Our Company requires documentation for every aspect of our business. Each

department is responsible for maintaining adequate records to demonstrate effective

system operations as defined specficll

cach procedure.

Record Generation

S728

saa

All quality personnel, 0070€ Manager, OCSiperiors: OC ypector,ate

responsible for ensuring records they generate ae legible.

Written quality records should be complete in ink to help ensure

legibility and to protect them from unauthorized change.

(Changes or corrections to records should be made with a single line

through the incorrect entry, dated and initialed by the person making the

change, White Out or correction tape should not be use

Record Maintenance

S738

saa

5933,

s734

‘The authority associated with a particular quality record is responsible for

assuring the records are maintained in a suitable environment that

prevents damage or deterioration and also prevents loss ofthe ecords,

‘The methods used to prevent loss of hardcopy records may include

controlling access, use of checkout cards, of auditing of records as

appropriate for the particular recor.

Electronic records are protected fom damage, deterioration, loss, or

‘unauthorized change by use of password control 10 computer systems,

‘computer systems backups, and virus protection.

Active quality records must be stored such that they are readily

retrievable, Active records are those that have not yet met their minimum

‘SAUDI ARAMCO OIL, COMPANY

Ea ANDUL MOHSEN A AL-TAMMIML

Sapam goin "PARTNERS COMPANY

‘Studi Atsmeo

Oe: NO-AMT-PGP S401 vot

PROJECT QUALITY PLAN =

s735

574 Storage

retention times. Inactive quality records may be archived. Archived

records are retrievable, but not necessarily readily retrievable,

44.6.5 Unless otherwise indicated, quality records are destroyed after

their minimum retention time i attained.

"The department that initially established the record normally stores records. Records

are stored in dry and clean rooms, Cabinets containing records are cleay labeled to

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MS Traffic Signs Installations (Rev. 01)Document6 pagesMS Traffic Signs Installations (Rev. 01)moytabura96100% (1)

- Control Calibrated EquipmentDocument11 pagesControl Calibrated Equipmentmoytabura96100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- South Ghawar Unconventional Resources Project MonitoringDocument1 pageSouth Ghawar Unconventional Resources Project Monitoringmoytabura96No ratings yet

- Field Engineering Change Control ProcedureDocument9 pagesField Engineering Change Control Proceduremoytabura9675% (4)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Saudi Aramco Hydrostatic Testing ProcedureDocument18 pagesSaudi Aramco Hydrostatic Testing Proceduremoytabura96No ratings yet

- Field Engineering Change Control FormDocument1 pageField Engineering Change Control Formmoytabura96No ratings yet

- Project Quality Plan For South GhawarDocument48 pagesProject Quality Plan For South Ghawarmoytabura96No ratings yet

- Materials Quarantine LogDocument1 pageMaterials Quarantine Logmoytabura96No ratings yet

- Saes A 005Document34 pagesSaes A 005Elie AouadNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Project Deliverables TrackingDocument5 pagesProject Deliverables Trackingmoytabura96No ratings yet

- Saudi Aramco Concrete Coating ProcedureDocument10 pagesSaudi Aramco Concrete Coating Proceduremoytabura96100% (1)

- Saep 12 PDFDocument42 pagesSaep 12 PDFYuda SatriaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- RTR - Nonmetallic Pipng ProcedureDocument16 pagesRTR - Nonmetallic Pipng Proceduremoytabura96No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Kho Geo PR 18 80 03 PDFDocument1,387 pagesKho Geo PR 18 80 03 PDFmoytabura96No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- JSA For Traffic Signages Activity (Rev. 00)Document8 pagesJSA For Traffic Signages Activity (Rev. 00)moytabura96No ratings yet

- Saudi Arabian Oil Company: GEN-E0004 A Construction Specifications J95Document4 pagesSaudi Arabian Oil Company: GEN-E0004 A Construction Specifications J95moytabura96100% (1)

- Amt PQP - SgewDocument19 pagesAmt PQP - Sgewmoytabura96No ratings yet

- Traffic Signage Installation ITPDocument1 pageTraffic Signage Installation ITPmoytabura96No ratings yet

- Organization Chart, Formats & Mobilization-Demobilization Plan PDFDocument74 pagesOrganization Chart, Formats & Mobilization-Demobilization Plan PDFmoytabura96100% (1)

- Project Quality Plan - Part 1Document30 pagesProject Quality Plan - Part 1moytabura96100% (5)

- Audit AgendaDocument3 pagesAudit Agendamoytabura96No ratings yet

- Method Statements For Termite Control ApplicationDocument7 pagesMethod Statements For Termite Control Applicationmoytabura96No ratings yet

- Project Quality Plan - Part 2Document26 pagesProject Quality Plan - Part 2moytabura96No ratings yet

- Method Statement ForDocument6 pagesMethod Statement Formoytabura96No ratings yet

- Linolium Sheet Pre-Inspection ChecklistDocument1 pageLinolium Sheet Pre-Inspection Checklistmoytabura96No ratings yet

- Coordinates & DrawingsDocument5 pagesCoordinates & Drawingsmoytabura96No ratings yet

- Linolium Sheet Pre-Inspection ChecklistDocument1 pageLinolium Sheet Pre-Inspection Checklistmoytabura96No ratings yet

- Inspection and Test Plan: Linolium Sheet InstallationDocument1 pageInspection and Test Plan: Linolium Sheet Installationmoytabura96No ratings yet

- 01-SAMSS-025 Plastic-Lined Ferrous Metal Pipe, Fittings, and FlangesDocument9 pages01-SAMSS-025 Plastic-Lined Ferrous Metal Pipe, Fittings, and Flangesmoytabura96No ratings yet