0 ratings0% found this document useful (0 votes) 761 views26 pagesProject Quality Plan - Part 2

PQP Part 2 for SGEW Project

Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content,

claim it here.

Available Formats

Download as PDF or read online on Scribd

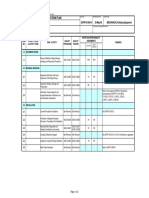

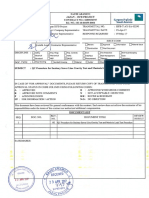

‘SAUDI ARAMCO OIL COMPANY

en |

ABDUL MOHSEN AH AL-TAMI

rare conan

saadiAtme

vocwowirawrscevan [met

PROJECT QUALITY PLAN ra ais

ATTACHMENT ‘2

su In SYSTEM DELIVERABLES

a TARTS

Tene iad de

Reaitey Fore after the effective date of “Within 7 calendar days of

1 Jew azotseaue ar |eenntand tron sent [enh ron regener

oes

aa FA] Tne nanan

, OGRRERIEN ESS) acing ran ital | wench

Sense a

Personnel arene)” | OTOH

Qualifications: rofto assignment Personnel | quaity personnel on the

3 Paragraph 5.6 of entegiee project.

Senco

Taiyo Gary oe a) ae

sn wrens) ant | a cedar deo

Aitepore aren 795_| ini ures TT ena

fuer Airoonpton he md

5 srsresot

COTRRCTOR Vea

Ssh wana st | ntti f ean

«| soumiten tonpmph752 |rpertgescnen snare | aed

tseaue"e

Non donformence Susenary ‘the first non-conformance is

Paragraph 7.55 of Schedule | Mtr th i es ‘Weekly for the Project

a |g toed Progress Meeting

‘Management Review results

Paragraph 4 of Schedule Q

Within two 2) weeks after

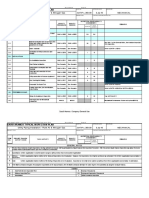

scheduled review�SAUDTARAMCO OIL COMPANY

Ea ABDUL MOHSEN AN AL-TAMIME

1 9So4) PARTNERS COMPANY

BOC. NOAM.9QR SW. mot

PROJECT QUALITY PLAN ans ws

Title cst Submittal to COMPANY

‘Subsequent submitalsto

‘COMPANY

‘Guay Management Report | Shy (6) calendar days after the

9, | Paraeranh 7.7 ofschedle“a* | effective date ofthe Convact | MO"

‘evidence of manufacturer

Prequalification “Two (2} weeks prio to placement

10, | Paragraph .2.1 of attachment | of Purchase order

W

Tnepecton Fabrication Status

‘one week after the fst purchase

port: Paragraph 2.4 of el

Fri pescreedndetlareal order's awarded forthe Contract | W**HY

attachment it

Inspection Assignment “Twenty one (2) calendar days

Package; Paragraph 3.18 of | prior topreinspection meeting or

ta, | Attachment (incuding fourteen days prior to final

Procurement P's) Inspection for Level inspection,

Pre-nspection Meeting and | ren (40) calendardaysafter the | Ten (10) calendar dys

‘endor inspection Reports | sreinspection meeting or fst | after each inspection vist

23, | Paruapn S2z ofAtachment | ngpection vit foreach supplier | an week for Level

Tavineeh lobebeae Fourteen (14) calendar days

sere before the start of any inspection

activity ffist purchase orderor | “SKY

14 | paragraph 3.3 of Attachment i | tty of ist

Paragrapa 1.6 0 ttacnment1V

start of construction acter

1s.

Tnspection/Shiping Release;

Within forty eight (48) hours oF

Paragraph 3.26 of tachment | issue�‘SAUDI ARAMGO OIL COMPANY

Ea ABDUL MOHSEN AH AL-TAMIME

@.ggouustgSoyt PARTNERS COMPANY

‘Saudi Aramco

DOC. NO-AMT-PQP-SGW.001 rev

PROJECT QUALITY PLAN = —a

‘Subsequent submittals t

Qo. 5 ist Submittal to COMPANY

N Tt Fist Submittal to COMPANY Ea

Inspection Disposition Report | Two (2) weaks afer equipment

Paragraph 3.27 of Atachment | and materials are released for

16. fa shipment

“Special Process Procedures and

Personnel Qualification

ce Twenty one (ah calendar days | 45 execution

7. | Paragraph3.11 and 3.13 of | Prior operation or test

‘tachment il Paragraph 2.4

of attachment V

onstruction inspection and | One month prior to start of Revision Approval prior to

Test Pans: Paragraph 1.1 of

a [eae construction WORK. execution

Hydrostatic Test Package cocach hydrostatic tens | Prot To cach hyrostate

a, | Paragraph 2.1, attachmentiv, | Pert eaeh Werostase test. | ray

10, MOBILIZATION® DEMOLIZATION PLAN

101 Mobilization

o1t Key Projeet Personne!

Project Manager

Construction Manager's

QAIQC Personnel (ll discipline)

Project Quality Control Supervisor

Document Controller

Safety Manager & Officer

Site Engineer / Land Surveyor

Civil Supervisor / Foreman�‘SAUDI ARAMCO OIL, COMPANY

A | ABDUL MONSEN Art AL-TAMIN

gocust 9500 PARTNERS COMPANY

aa cameo

poc woAuregpsaswoor | weak

PROJECT QUALITY PLAN

ae naa

ma

Upon conclusion of the Project Kick off meeting, the above Key personnel

shall be immediately mobilized to projec site to asses initial urgent activities

to be done on the project site the balance manpower needed will follows as

required.

‘Temporary Officelmaterial lay down area will be established and the

needed Office portables will be purchased and prepared as required,

te office underground uilitis shall likewise be prepared in parallel.

Portable electrical Generator set will be provided since the area is remote and

‘power Connection is no possibilty.

Site office & material lay down perimeter area willbe fenced and security shall

be designated during night time. Additional portable tower light for night

lamination shall be provided.

Equipment

List of equipment to mobilize but not limited to:

Grader?

Mobile Crane 1

Dump Trucks 2

Water Tanker 2

Pay Loader 4

Backhoe/Exeavator 2

JCB Backhoe / Loader 1

Roller Compactor 3

Low Bed Trailer | (or Hauling of Eauipment)

Flat bed Trier Transporter (fr mobilization uf Cin & Equipment)

Bulldozer 2

102 DEMOBILIZATION PLAN

oat

022

Upon completion of projec, all Contractor mobilized temporary Facilities

will be demobilize as required.

Used site areas willbe cleaned, restored tothe satisfaction of Saudi Aramco

and as stipulated in the signed contract.�SAUDIARAMCO OIL COMPANY

zonuut sSopn i} [PARTNERS COMPANY.

ABDUL MOHSEN AM AL-TAMIML

PRomcrQuAumyrLaN | | —— =

11 MANAGFMENT REVIEW

na

n2

13

‘The Project Manager with the aid the Quality Manager/QC Engineer shall lead the

‘management team to review Contractor's Quality Management System on an annual

basis. The review shall include assessing opportunities for improvement and the need

for changes to the Project Management System,

CCient shall be communicated with the results of Management Review within two

weeks of the review.

Review Inputs shall include:

Status and results of quality objectives

Results of audits

Feedback and complains from client

Process performance and product conformity

Status of nonconforming items and corrective aetions

Status of preventive and corrective actions

Followup actions pertaining to former Project Management Reviews

Changes affecting the Projet Quality Management System,

Recommendation for improvements

Improving the effectiveness of Project Quality Management System and its|

processes

Intensive education or teaning pertaining toa specialty or skill

‘© Programs for resource needs

12, CONTRACT REVIEW

ma

Scope

‘This chapter describes the requirement for the Construction of the diferent opinions

between Al-Tamimi Partners & Co. and Arameo.

General

2d Contract review shal be taken to include te formalized and planned review

of invitation to bid documentation and any subsequent correspondence of|

‘communication between Al-Tamimi and Aramco during contract

regulations and the resultant signed contract documents,�‘SAUDI ARAMCO OIL COMPANY

dipgnant gSot Ga PARTNERS COMPANY,

ARDUL MOHSEN AH AL-TAMIME

PROJECT QUALITY PLAN

ac, No-AMT-PQPSGEW-001 reo

Ta Tag

ris

m6

Each discipline lend engineer and Site Manager who were assigned at the

bidding stage have performed the contract reviews.

‘The contact details have been agreed between Aramco and Al-Tamim

during the contract award.

“The Project Conteol group is responsible for communicating with various

projects departments for any scope changes, contract clarifications et.

At commencement of the project, each discipline Engineers and Project

Manager shall review the Contract requirements to. confirm theit

understanding and interpretation of the seope of work. Particular risk,

penalties, guarantees, milestones and other such commitments shall be

highlighted. Missing information and any necessary clarifications shall be

resolved with Aramco and documented,

‘The contract review shall confirm as a minimum the following criteria

© Contract documents are properly distributed to the concemed

departments.

‘+ Precise seope of works (documenting any differences between the bid

and the Contract)

‘© Aramco input data to Contractor

‘© Schedule of submittals of data to Arameo as per contract including

Final records turnover and the number of copies.

13, DOCUMENT & DATA CONTROL

‘The Task of Engineering information contol, simply, are too systematically and efficient receive

records and distribute the engineering information to the points it is to be used and ensure that

the user has the latest information available. The user, of course, ist

vidual eratsman oF

‘raft foreman, the engineering and the superintendent. The QA/QC shall verify that they have

the proper drawing and specification for their ile

L

2

3

‘The construction drawings are received in one of the two ways oF

combination of to,

‘They may be received in the form of any updated system accordingly (in

the agreed upon number of copies).

‘The consteuetion drawings are received in the field withthe following data;

‘© Project identification

‘© Drawing identification (title & number)

‘+ Revision number and date of receipt

‘© Distribution�SAUDIARAMCO OIL COMPANY

ABDUL MOHSEN AH AL-TAMIME

a oT

‘Doc, No-ANT-POP-SaEW.001 ret

PROJECT QUALITY PLAN = —

‘© Drawing Transmittal is kept on file in chronological order.

‘he master file of copies of construction drawings is maintained onthe same system, as are

the engineering drawings

14, MAJOR FACILITIES FOR QUALITY CONTROL,

General

Personnel and Construction Equipment are major factors in performing works.

‘Test Equipment or facilities and procedures shall be done in conformity with Saudi

Aramco standards and specifications. Contract documents are carefully sereened t0

make sure that eoneet procedures and instructions are prepared. Independent

laboratory with facilities is equipped for sampling and testing of soil, agurepate,

‘cement and concrete, Survey equipment for setting outlines and grades, control of

‘equipment installation of fencing, roads, asphalting works, boundaries, drainage

system, elevation, datum etc

‘Non-Destructive and Destructive Test Equipment to Contl

Calibration facilities for instruments to be earied out by Arameo approved testing

laboratory

‘Test Procedure

1424 Quality Cheek on all materials approved all materials that are being used oF to be

used will be subjected to Quality testing. For eonerete, compaction ete, Field

technician will do the testing as witness by the Aramco Inspector/Representative

and the QC Inspector. Testing will e cartied out on all finished product and to

be accomplished by the quality contol team,

1422 Routine & Frequency Testing This will be made to ensure thatthe materials shall

comply with the project specifications,

1423 Reporting all tests performed. Test and all inspection made will be reported to the

‘Quality department, The approved third party technicians shall submit the test

reports and responsible QC Inspector or supervisor will do reviews.

424 Recording and Keeping, All test related inspection and quality control operation

should be kept for records approximately for future references,

1425 They should be easily available to the QA/QC Supervisor. Submittal receiver will

be assigned to maintain and keep all records�‘SAUDI ARAMCO OIL COMPANY

‘pga! gsout fg PARTNERS COMPANY.

PROJECT QUALITY PLAN: ones “ we

ae rere

ABDUL MOHSEN AN AL-TAMIME

15, QUALITY CONTROL ACTIVITIES

st

General

Below are brief generalized activites, some of whish may have been done prior

commencing the projec.

1) Training & Testing of Craftsman

1) Preparation of procedures and job instoctions

©) Consrvetion equipment maintenance’matral contol

4) hocking & Verifying contact documents

6) Seleton of Recording and Reporting form

#) Verity sting outlines and grades

2) Verify and maintain bench mark

1) Verification ofall conrets works sgsinst drawings and standards and

specitiaton.

QAIQC Activites & Field Reports

‘The following are detailed activities and QA/QC report documents necessary to ensure

the quality and compliance of the installation with contractual requirements. Parts of

these activities may be performed by the owner or others on behalf of the owner,

‘whereby provides only supporting personnel and facilities. Most of itis however done

1s routine matter by the contractor's inspectors and supervisors. Records and reports

‘on the result of the test and inspection are made and kept as history

Inspection and Test Plan

‘The Al-Tamimi Q4/QC shall adopt the Inspection and Test Plans of Saudi Arameo

Project Inspection Division. (See Attachment of TTP SA-sample) to submit and subject

for SA approval Or AMT willrequest to SAPMT latest and updated SATIPISAIC applicable

to the SGEW project respectively

Level of Inspection

With reference to SAEP 11S, the below inspection levels shall bo established and performed.

Hold point�‘SAUDI ARAMCO OIL COMPANY

| ABDUL MOHSEN AH AL-TAMIME

azonuut gsou) PARTNERS COMPANY

‘Stud Ameo *

0G NOAM FQRSGEW-1 teat

PROJECT QUALITY PLAN ;

ae err

‘The Al-Tamimi QC shall perform the inspeetin or test under the witness of Arameo

Inspector? Representative, Subsequent activity shall not proceed until reesiving

acceptance of the Fleld Inspection Report and signed by the Arameo Inspector!

Representative

Witness point

‘The Al-Tamimi QC shall perform the inspeetion or test under the witness of Arameo

Inspector/Representative. However, in the event thatthe Arameo inspector does not

‘witness the Al-Tamimi QC shall do the inspection by himself and record the result

Subsequent activity may proceed upon approval by the Al-Tamimi QC as long as the

results confirm with the acceptance criteria. Record ofthe inspection or test shall be

submitted to Aramco for review and signing,

Surveillance

Al Tamim Quality Control Inspector will take advance inspection and check possible

violation on the execution by construction team. Keep reminding all involve

‘construction personnel on the item of work to avoid potential violations and inquire

‘construction team to execute and raise RFI in able to arrange by QC Inspector involve

ina particular item of work. Checking the materials, they will install if tis coming

from approved SA vendor(supplier and other related documents required in

processing for Request For Inspection.

Document Review Point

‘The Al-Tamimi QC Inspector may perform the inspection or test by himself without the

‘witness of the Aramco inspector as. Subsequent activity may proceed upon approval by

the Al-Tamimi Inspector as long as the inspection results confirm with the acceptance

criteria. Record of the inspection or test shall be submitted to Arameo for review and

signing,

METHOD STATEMENTS

Method Statements describing the work procedures to follow in the construction of

various evil facilites and structures shall be prepared. These Method Statements shall,

bbe made in accordance with the requirements of Project Specifications, and shall be

submitted to Arameo for thei review and approval, Method Statement/ work procedure

shall be prepared accordingly 2s for specific activity or work as maybe required by the

client depending on the complexity and nature of the work.�‘SAUDI ARAMCO OIL COMPANY

Ea ABDUL MOHSEN AN AL-TAMIME

19504) PARTNERS COMPANY

oc, No-AM-PgPSW-001 root

PROJECT QUALITY PLAN = —

6

17

159

REQUEST FOR INSPECTION.

Al-Tamiml QC Inspector shall ofticiallyinforun Aratucy 24shouty it aalvance for any

scheduled inspection activites requiring witnessing or inspection by Savdi Aramco by

-submiting sft copies thu e-mail or in QMIS system required available in the project.

‘TESTING AND INSPECTION PROCEDURE

‘The Al-Tamimi QC Inspector shall dizcetly carry out the necessary inspections and

tests required. The Arameo Inspector/Representative participation inthe inspection

and tests shall be as per the ITP requirement. Testing and inspection shall be eared

fut in accordance with the approved ITPs and relevant Project specifications

requirements

EXCAVATION, BACKBILLING AND COMPACTION

Excavation, backfilling and compaction works shall be done in accordance withthe

Method Statement for Ordinary Excavation and Deep Excavation. The independent

Third Party, Geotechnical and Materials Specialists shall perform all the required

quality tests pertaining to compaction of sub grade and backfill, and on materials used

for backfilling. All tests and inspections shall be in aecordance withthe requirement of

the Project Specification.

CONCRETE WORKS

‘Concrete works shall be in accordance with the Method Statement for General

Concrete Works. Al-Tamimi QC shall conduct quality check prior to any pouring of

‘eonerete and shall be witnessed by Aramco inspector. Upon atival on site, the conerete

delivery ticket shall be checked to verify the type of concrete, design mix andthe time

the concrete is batched. Al-Tamimi QC and Aramco inspectoe/Representative shall

‘monitor testson fresh concrete on site. The independent Third Party Office Geotechnical

and Materials Specialist in accordance with the Project Specification shall perform all

relevant tests required of concrete.

The Al-Tamimi QC and Aramco Inspector/Representative shall review reports on

compressive strength tests of hardened conereteeylinder specimen.

‘After every conerete pouring work, the concrete pour card shall be prepared and signed,

bby AL-Tamimi QC and Arameo Inspector as shown (Attachment)�‘SAUDI ARAMCO OIL COMPANY

Ea ABDUL MOHISEN AM AL-TAMIME

gnu gSou PARTNERS COMPANY

|__ Acamcn

DOC. NO-ANT-PQP-SEW-1 van

PROJECT QUALITY PLAN = —

isp SURVEY WORKS

Al survey works shall be done according to the procedures & Method Statement for

Survey Work and reference o Projet Speciation Surveyors sal have ob gad

and approved by Arameo. Survey Report shall be prepared and attached to every

Inspection Report for record and review

by Al-Tamimi QC and Aramco Inspector! Representative, (Attachment). Al-Temimi

‘QC shall conduct coordinate and elevation checks and to be witnessed by Aramco

Inspector. Tolerances shall be within the requirement of the relevant approved ITP and

in accordance to Project Specification,

Isl MATERIAL RECEIVING & STORAGE

vsan. SUPPLIED MATERIAL

‘The materials shall be inspested upon delivery atthe site only to verify the

condition as well as to determine the quantities of the materials delivered, Any

materials found defective or in bad condition or damaged shal be noted on the

Material Equipment Receiving Report and shall be reported to Aramco for their

information. (Attachment). The Al-Tamimi shall be responsible forthe proper

storage and control of materials upon issuance by Aramco,

112 AKTAMIMLPROCURED MATERIALS.

Abdul Mohsen AH Al Tamimi Partners Company shall supply, procure, install

all required materials under the contract and scope of works accordingly,

procared materials to approved Vendor and Supplier by Saudi Aeameo, shall he

‘heck upon delivery othe sit. Delivery notes shall be check to verify the grade

and quantities of such materials and signed off to confirm the receipt of the

materials. Certificates and or Warranty Certificates for deviees, machinels shall

follow and shall also be checked to ensure compliance of the materials tothe

project specification requirement.

Handling and storage of all materials shall be in accordance with the project

specification and standard which is tobe issued by the client

Al other essential materials that were received to site shall be check to ensure

compliance to Project Specification and Standard,�SAUDIARAMCO OIL COMPANY

Ea ABDUL MOHSEN Alt AL-TAMIME

1 9So4 [PARTNERS COMPANY

OC NO-ANTERQPSGEWA eon

PROJECT QUALITY PLAN

a rears

19113 MATERIAL APPROVAL

Materials, which are tobe used in the construction and become permanently part

of any civil structure, shall have to be approved by the Aramco, A Material

Approval Request along with the echnical Specification(Catalogue for the

material shall be prepared and submitted to the Arameo for their review and

approval

1114 CONTROL OF MATERIALS FOR TESTING

‘The use of materials that required periodic tests shall be monitored and

controlled to ensure compliance to the requirement of the Project Specification.

For soil, the quantity of materials used for backfilling shall be monitored 10

ensure that tests are done accordingly for every required quantity used.

Likewise, for rebar, shall be used to monitor the quantity delivered tothe site so

test ean be done accordingly in accordance tothe project specification.

‘A conerete pouring log shall be prepared to monitor the 7 days and 28-days,

compressive test for concrete, asin (Attachment)

Isi2 HAND- OVER OF WORK

Prior to start of any subsequent activity by another discipline, ic, stracturl,

‘mechanical, piping and electrical, Al-Tamimi QC shall prepare a Work Transfer

‘Sheet for any completed civil activity and submit t Arameo for notification and

acceptance by the eoneemed discipline’s authorized person,

Hua) RECORD KEEPING

Al-Tamimi QN/QC Manager shall maintain all QAVQC related documents,

including but not limited to the following, for subsequent tumover to Aramco.

‘Request for Inspection Report

' Survey Reports

+ Conerete Compressive Strength Test Report (from Third Party)

‘Soil Compaction Test Reporting

+ Rebar Mill Certificates�‘SAUDI ARAMCO OIL COMPANY

ABDUL MOHSEN AH AL-TAMIME

PARTNERS COMPANY

OC. No-AMT-PQP-SGEW-01 ovo

PROJECT QUALITY PLAN - —

+ Epoxy-coating Certificates (i applicable)

Non-Conformance Report

# Method Statements

Inspection and Test Plan

1514 CONTROL OF NON-CONFORMITIES

15.1.1, Product that doesnot conform to specified requirement should not be released

subsequent activity unless the non-conforming condition is rectified in

tceordance with disposition approved by Aramco

1542 Any non-conformity found by Al-Tamimi QC that requires repair, or that

requires Aramco disposition to “use as is” or “use as built“, shall be reported to

‘Aramco using the Nou-Conformance Report (NCR) form as shown in

(Attachment)

15143 Non-conformance report shall state the non-conforming condition and the

proposed rectification procedure together with technical justification

Rectification work shall only proceed alter the proposed rectification procedure

hhas been approved by Saudi Aramco,

isis QUALITY AUDIT

Al-Tamin shall follow item 7.3 stated in Schedule Q Intemal Aucit, AMT shall submit,

‘2 quality audit schedule for 15% and 60% completion stage for Design, Procurement

«and Construction work phases as a minimum requirements by Aramco to be conduct by

SA approved Third Party Auditor. He shall verify whether quality activities comply with

‘this Quality Pan, Method Statements, Inspection and Test Plans, RFT's, RMI’, of Saudi

Arameo requirements, Any request for corrective action during quality audit, Al-

‘Tamiml shall take the necessary corrective steps and offically inform the Saudi Aramco

‘of the corrective actions dane. Schedule for conducting the quality auit shall be set by’

AMT and shall inform or notify Client’s representative respectively. Contractor Internal

‘uit shall be done on a Bi-annual basis. All audits shall be executed by quality system

auditor qualified not directly forthe area being audited. For Internal Audit schedule (see

attachment).

sie INSPECTION AND TESTING EQUIPMENTS�SAUDTARAMCO OIL COMPANY

secon Ea ABDUL MOHSEN Att AL-TAMIME

[Link] gSou) PARTNERS COMPANY

OC. NO-AMT-FQPSEWI vot

PROJECT QUALITY PLAN

Ta meas

Instruments and equipment’s used for testing and inspection shall be checked

Periodically to prove its worthiness for use, Survey instruments shall be calibrated every

Al least 6 mus or as per smunulucturer's recommendation, An independent calibration

so testing Company sal ei calbraionwith certificates issued for

irument and equipment, The inspection and testing instrument and equipment

tel bythe independent nd Tint Party Engineering Office sal ices be checked

and calibrated. Al-Tamimi QC Engineer shall file the calibration ceriicates for

‘monitoring and Verification by Saudi Aramco Inspectors/Representtive.

16, PROCUREMENT CYCLE,

Procurement Plan shall be submit separately from this PQP and shall emphasize the below

procurement activity eyele:

PROCUREMENT HANDLING PROCESS FLOWCHART,�‘SAUDI ARAMCO OIL COMPANY

SpgaustgSoy

ABDUL MOHSEN AH AL-TAMIM

PARTNERS COMPANY

PROJECT QUALITY PLAN

OC. No-AMT-FoP SGEW-caL evan

17, ATTACHMENTS

14.1 Site Organization Chart

142 Inspection & Test Pan

14.3 Requests for Inspection

144 Survey Report

145 Non- Conformance Report

146 Non- Conformance Report

14.7 Request for Material Inspection

148 NCRs Log Sheet Summary

149 Coneetive Action Request

14.10 Conerste Pour Card

14.11 Request for Inspection Logsheet

1412 Bauipment Serial Number

1413 Quality Audit and Management

14.14 Technical Query

14,15 Document Transmittal

1416 Outgoing Log Transmital

14.17 Monthly Summary

14.18 Summary Saudi Arab Personnel

14.19 Mobilization Demobilization Plan

‘Attachment = 1

Attachment -2

‘Attachment -3

‘Attachment =4

Attachment -5

‘Attachment 5 -A,

Attachment -6

Attachment -7

Attachment =

Attachment -9

Attachment -10

‘Attachment -11

Attachment-12

Attachment-13,

Attachment-14

Attachment-15

Attachment-16

Attachment-17

Attachment -18�[|

he

ah

io) ao O00�‘want on »|

: ” a cin

___ Bon ANEINIOWLIY) a

amas (2 | eel ®

a 2. corer | emma emo bemnaues ”

| NOLWTNASM

siiesemamersened Bh |e mean

Se was] ) $e ferro] panmgna nme, teh

St

pe Be ‘mansunannoce | o+

aot A

sree ge I fn [seared fea

| = saa

= py er

“ ay Nog TST BOMPEVTONTS�wzsteg

“ino seudiver | sortnrauye | -wovonasuog Buna mse pie Yogenea wopmiedead wHS~ omg

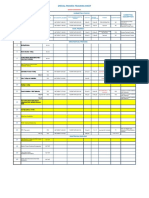

= Nid NOUN WoIdAL COVEN ONS}�‘TamimiREQUEST FOR INSPECTION

TO CRAIN Pe ‘The: South Ghavar UK aly Works @ TF

To: Pts nspecton Ui.

Cid Mech, Comme ether

nspowinontrigis ei on si on

(Gere owing loalosequprest —

ork Yee Pret Oly ns Mol Pest Whines Pit

‘wok fren] [CONTRACTOR has vera tat he work to elapsed s

[SAPHIT repreotive ba

mete aad in complnce with the allowing

for nsotion and eantrms th projet ern

epitome:

SAPNErName__sigarwe

ae ene ____ |] sassansvoent ___contnetaCompany AN

| ee ONGC Wane

‘OAC Signi

Dae

“This frm ese the deine pan Depron empliye:

ane site Da Tine

"NOTE specs iat orien ieee ony nde apponal or dapovl of he work lity tse

Dist: A Origal= Poet Mammen 1 acy open (2nd copy Commer

NCE Wo.%�rok stg ey Par Pn

eters BH Coste © avaten apa rag Ws

Nena

cara

mana�INON-CONFORMANCE REPORT (NCR) | wee a

PROJECT TITLE SOUTH GHAWAR UR EARLY WORKS & TCE Nee STATUS

Contract ¥6600005093 61-10 10331 om tT a

LOCATION: South Ghawar, KSA

Coesign Cl Procwement Cleonstruction CJpre-commisioning

DISCIPLINE it Mechanical Cetectcal’ E]communication others

‘Title of Non-Contormance:

L.

Tor Soniomancebaciniontaamen Ls CIvo

iad roar Date RTs

acc nate cnyacrianen

oot ca formanae OD Ow

[caneaivedtion eroamen LT ves LT Noy Coron

Name:

‘ACD: Agreed Completion Date

‘Glesingcommants Name

Designation:

Signature:

Fine! Verifestion: C]Accepted Cl Rejected

Bena

“Tob Completion/Accopiance Conformation

TE taspecior (QAIGE Manager ‘SAPID Qualiy Representative

Sin Sion

ite _ ate

Page tof

aP/00c/03Issueo:�ace un amar es For manus

Gpgnu gSout ON

NON ~ CONFORMANCE REPORT

Soham =

rain lan om. | — Wa Basin 0 Tome

= ma

Tin ani Di

a aa SS RTT

i in

Sr

sore sens owe

TUNCHMENT ‘WO. Ba

Proven Aton:

Teape aed PO

a = =

aa

aa

pai

Soren

—_ seo =

fara

Toenwmcmm | oy . .

= oe��Mereed ari

eraray | oR

san | tee, | cov | 289 | oxponen | ke pone aes “ON

posta | “ata

18

aT HRS TETAS

40 se powepdn uoneubis2q_

"2 se HRC WHY WORM HPA a

Sowvue (anv =

BOL ® SHOM Alea UN JemeYD WNOS ‘SAIL efOg

Asewiuing ays 607 SHON

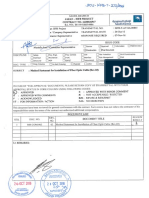

«eee Bg fossmeter�ANDUL MOHSEN 4.14, AL-TAMIINL

hgSobt my

Ararnco

PARTNERS COMPANY

South Ghawar UR Baily Works & TOF

Bl: 10-1431 Contzact” 6600045003

CORRECTIVE ACTION REQUEST

"Hajece ou waar on many Worse Tor Ppa aT

Tacation: South hava, SA cof balan

oar ia Bais of Von

Vera ‘Signature peesowaged yt ignatre te

Pre oft�Pour Card Number:

CONCRETE POUR CARD

RFINO.

‘CONTRACTOR Al Tamimi Co, Contract Number and Title

Location of Pour

Description of Pour

Type and Source oF

Concrete

Amount of Concrete

Contractor Inspection Approvals

Inspected and Approved

Date

ne and Grade

Formwork and Waterstop

Reinforcement

Embedded Metal

Embedded Pipe

Embedded Condi

Preparation of Construction Joint

Water Procfing

Cleanliness and Access

Verification of Rate of Placement: M/HR

Provision for Hot Weather Concreting

Form nace

Told Point Released

‘Contractor ignature/ate/Time Tame PntedSignature/Date

ARANCO J CONSULTANT Engineer