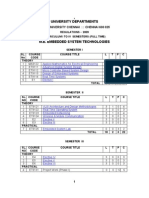

Professional Documents

Culture Documents

How Does A Generator Work?: © Clifford Power Systems, Inc

Uploaded by

Dileepkumar RudrarajuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How Does A Generator Work?: © Clifford Power Systems, Inc

Uploaded by

Dileepkumar RudrarajuCopyright:

Available Formats

How Does a Generator Work?

Clifford Power Systems is one of the largest full service generator providers in the United States. Our

generator experts specialize in equipment, service, parts and rental of power. To assure your continuous

power needs see: cliffordpower.com or contact us directly at 1-800-324-0066. This article was written by

Clifford Power Systems’ president, Tom Clifford.

Generators and the process of making electricity is a relatively simple process. Before we can understand how

a generator works perhaps we should first try to define what electricity is. At its simplest form electricity is a

positive or negative charge within the electrons of an atom. Because of the nature of atomic elements

electrons can be made to flow from one atom to another. This flow of the electrons between atoms generates

electrical current. Electrons flow readily in some materials but not in others.

So, based on the above essentially what a generator is doing is creating negative and positive charges within

an atom and moving electrons. How does it do this? The simple answer is that we rotate a magnet in a coil of

wires.

A bar magnet is created by exposing ferromagnetic metals and exposing them to a

magnetic field. Once heated to a certain temperature the ferromagnetic metals

become permanently magnetized.

If you place a piece of paper over the magnet and

sprinkle metal shaving on the paper you will notice that

the metal shavings line up in a pattern similar to that shown here:

The pattern shown is magnetic lines of flux. Most of the metal shavings will line

up close to the magnetized end of the magnet. This is the point where the magnetic flux is strongest. This is

also as follows:

If we rotate the magnet through a coil of insulated wires, the magnetism coming

from the magnet will affect the electrons within the coiled wire. The electrons will

receive a positive or negative charge. The strength of this charge is measured by

a term called voltage. So in essence, the stronger the magnet is the higher the

charge and thus the higher the voltage. Note that the voltage in the wire is

strongest the closer it gets to the positively or negatively charged end of the

magnet.

As the magnet rotates through the coil, the induced electrical charge at any

given portion of the wire coil goes up and down. This creates a sine wave of

voltage in the coil in which the voltage rises to a positive maximum and then

decreases to a negative maximum. One complete sine wave is one cycle. If

we attach a time frame to the cycle, we can create an event that occurs over

time. We call this a unit of frequency. In electricity, we refer to that cycle as a

1 © Clifford Power Systems, Inc.

hertz. If the magnet rotates completely around the coil 60 times in one second, we have 60 occurrences of the

complete sine wave. In the United States, we have a standard for electrical utilities that they

must operate at 60 Hz.

As long as nothing is connected between the ends of the two wires coming from the coil of

wire the electrons in the atoms of the wire material remain charged but are

not moving.

When a load, or resistance, is connected to the two end wires of the coil a

circuit is completed and atoms will begin to flow back and forth. The

movement of electrons in electrical wires is called current and is measured

in terms of amperage.

To control generator output voltage we need to have a means of

increasing or decreasing the magnetism of the rotating magnet. Another way

to make a magnet is to wrap a wire coil around a metal core and then

apply a direct current (DC) voltage to the wire coil. By increasing or

decreasing the DC voltage on the wire coils, we can make the magnetic field

of the magnet stronger or weaker.

AC Generators include a voltage regulator. The voltage regulator will

sense the voltage output and then raise or lower the DC voltage of the

rotating magnet.

2 © Clifford Power Systems, Inc.

In AC generators we refer to the different components as:

• Stator: AC Output Coil Windings

• Rotor: The rotating magnetic field

• Voltage Regulator: Controls the magnetism of the rotor to achieve desired output voltage.

Three Phase Stators

Most three phase stators, up to approximately 1000 KW, consist of 6 sets of windings, 10 or 12-Wire (2 per

set). 10 or 12 lead generators can be rewired for different voltage output configurations.

• Each pair of windings forms a phase

• Phases are named A, B, and C.

• Phases are 120° out of phase with one another.

• Phase rotation matters

• Power is derived from each phase and contributes to total power output.

On generators above 1000 KW, most are specifically wound for the generator voltage required for the specific

job requirements. These generators are sometimes referred to as 4 Bar. Primary voltage output on these units

cannot be changed.

12 Lead Generator Connections (Please note, these drawings are typical configurations, manufacturer

drawings must be followed prior to making any connection changes.)

Hi Wye Connection:

3 © Clifford Power Systems, Inc.

• For Nominal 277/480V,3f 4W, which means 277 volts phase to neutral, 480 volts phase to phase, 3 phase,

four wire

• Industrial and sub-distribution voltage

Low Wye Connection:

• For Nominal 120/208V,3f,4W, which means 120 volts phase to neutral, 208 volts phase to phase, 3 phase,

four wire

• User voltage, very common

Delta Connection

• For Nominal 120/240V,3f,3W, which means 120 volts phase to neutral, 240 volts phase to phase, 3 phase,

three wire

• Industrial heavy 3-phase loads usage such as large motors

• Caution: On a High Delta connection (as shown below), one of the lines to neutral connections will have a

higher voltage than the other two. This is sometimes referred to as “The Wild Leg.”. In the diagram below the

L0 connection (neutral) will typically be 120 volts between L0 and L1 and between L0 and L2. The voltage

across L0 and L3 will be approximately 190 volts. In generator systems that have an automatic transfer switch

4 © Clifford Power Systems, Inc.

it is very important to match the high leg with the high leg from the utility on the same pole on the automatic

transfer switch. Failure to do so could cause expensive damage to customer equipment.

Zig Zag Connection

• For Nominal 120/240V,1f,3W, which means 120 volts phase to

neutral, 240 volts phase to phase, single phase, three wire

• Light commercial, industrial, residential where 120V is heavily used.

• This configuration usually reduces generator efficiency by 30%

For 30 years, Clifford Power Systems® has been the one stop shop for business and residential

generator needs throughout the South Central United States. Our comprehensive services include: sale of

new and used equipment, emergency service and planned maintenance plans for all makes and models,

parts and accessories; rental, and installation and maintenance training. For more information see

cliffordpower.com.

5 © Clifford Power Systems, Inc.

You might also like

- iUSBDAQ UserManuDocument74 pagesiUSBDAQ UserManuNguyen Vu Do VanNo ratings yet

- Acquiring HW RAID ConfigurationDocument26 pagesAcquiring HW RAID ConfigurationShaani AliNo ratings yet

- PlankalkülDocument182 pagesPlankalkülmrpharmacistNo ratings yet

- 100% Training & Placement Program in Embedded & RoboticsDocument3 pages100% Training & Placement Program in Embedded & RoboticsAjinkya PatilNo ratings yet

- DC Generator CharacteristicsDocument30 pagesDC Generator CharacteristicssasirekhaNo ratings yet

- Nvidia Tegra Linux Driver Installation GuideDocument2 pagesNvidia Tegra Linux Driver Installation GuideMarc WooleyNo ratings yet

- SG DriverDocument18 pagesSG Driverhary123No ratings yet

- Wehrle UART Interface: StepsDocument4 pagesWehrle UART Interface: Stepsdarius100% (2)

- Writing Windows Device Drivers Yashavant P 33551368 PDFDocument2 pagesWriting Windows Device Drivers Yashavant P 33551368 PDFjhfjfjNo ratings yet

- (Ebook - PDF) A 5-Minute Introduction To Writing USB Device DriversDocument5 pages(Ebook - PDF) A 5-Minute Introduction To Writing USB Device Driversapi-26866651100% (1)

- Achievement - LearnEnglish - British CouncilDocument4 pagesAchievement - LearnEnglish - British CouncilLeonardo MotaNo ratings yet

- Interview QuestionDocument7 pagesInterview QuestionXuân Anh100% (1)

- Error Detection TechniquesDocument87 pagesError Detection TechniquesmecarenNo ratings yet

- Embedded SystemsDocument4 pagesEmbedded Systemssubham duttaNo ratings yet

- Part XIDocument47 pagesPart XIDr. S.No ratings yet

- DNPR Driver For CitectSCADADocument11 pagesDNPR Driver For CitectSCADANguyễn Mạnh TiếnNo ratings yet

- WHQL PresentationDocument37 pagesWHQL PresentationBavisetti VenkatNo ratings yet

- IBM ServeRAID ManialDocument174 pagesIBM ServeRAID Manialbikash66No ratings yet

- Interview QuestionsDocument4 pagesInterview QuestionsDastagiri SahebNo ratings yet

- Learn English PDFDocument157 pagesLearn English PDFradicaNo ratings yet

- Robert Bosch Interview QuestionsDocument4 pagesRobert Bosch Interview QuestionsShashank JaiswalNo ratings yet

- In - RBEI - EPT4 Embedded Developer - Bengaluru - Bangalore - Robert Bosch Engineering and Business Solutions Private Limited - 2 To 7 Years of ExperienceDocument4 pagesIn - RBEI - EPT4 Embedded Developer - Bengaluru - Bangalore - Robert Bosch Engineering and Business Solutions Private Limited - 2 To 7 Years of ExperiencekrishaNo ratings yet

- Computer RAM CourseworkDocument3 pagesComputer RAM CourseworkEssays Are EasyNo ratings yet

- Writing a device driver for WindowsDocument6 pagesWriting a device driver for WindowsBraxton1981100% (1)

- D5 Motor User ManualDocument48 pagesD5 Motor User ManualZaheedAbrahams0% (2)

- EmbeddedC InterviewDocument7 pagesEmbeddedC InterviewaravindNo ratings yet

- DSE8680Document50 pagesDSE8680alexander900616No ratings yet

- Electro Static - ChargesDocument13 pagesElectro Static - Chargespraveen111102No ratings yet

- DC Generator, Basic Principle of Operation, Construction & Working PrincipleDocument3 pagesDC Generator, Basic Principle of Operation, Construction & Working PrincipleIzhar Jiskani62% (13)

- SmoothingDocument3 pagesSmoothingunaibmyfriend100% (1)

- Servicenow Sys Admin Exam SpecsDocument5 pagesServicenow Sys Admin Exam SpecsBabajan BaigNo ratings yet

- Embedded System TechnologiesDocument37 pagesEmbedded System TechnologiesjayaprahasNo ratings yet

- Electronic Governor Troubleshooting Guide - Low Profile Gasoline GensetsDocument9 pagesElectronic Governor Troubleshooting Guide - Low Profile Gasoline GensetshanifNo ratings yet

- Dcs Emulation SoftwareDocument17 pagesDcs Emulation SoftwareAhmed KhairiNo ratings yet

- Embedded Systems Interview QuestionsDocument13 pagesEmbedded Systems Interview QuestionsAnonymous JPbUTto8tqNo ratings yet

- Huawei Tecal RH2288 V2 Rack Server Brochure PDFDocument2 pagesHuawei Tecal RH2288 V2 Rack Server Brochure PDFMenganoFulanoNo ratings yet

- FTE Qualified Switch Firmware VersionsDocument15 pagesFTE Qualified Switch Firmware VersionsAnton SaitovNo ratings yet

- Chapter 6 - Developing Device DriversDocument70 pagesChapter 6 - Developing Device DriversSunil PaiNo ratings yet

- Samsung WMDocument7 pagesSamsung WMsarvessaiNo ratings yet

- C Interview QuestionsDocument17 pagesC Interview QuestionsNaresh KeNo ratings yet

- 1954 Advanced Embedded Systems Interview Questions Answers GuideDocument16 pages1954 Advanced Embedded Systems Interview Questions Answers GuideAhmed Essam WasfyNo ratings yet

- What Is A Soft StarterDocument2 pagesWhat Is A Soft StarterVFDS.comNo ratings yet

- Personal Alarm Using IC 74HC04Document22 pagesPersonal Alarm Using IC 74HC04satyasampathNo ratings yet

- The Interlock DeviceDocument17 pagesThe Interlock Devicescm61No ratings yet

- Feedback Amplifiers: Electronic Circuit IIDocument55 pagesFeedback Amplifiers: Electronic Circuit IIDeepa RangasamyNo ratings yet

- Embedded Systems - Overview - TutorialspointDocument1 pageEmbedded Systems - Overview - TutorialspointJustice SamusodzaNo ratings yet

- Microsoft Excel 2010 NotesDocument18 pagesMicrosoft Excel 2010 Notesgladys faithNo ratings yet

- EMBEDDED C BASICSDocument18 pagesEMBEDDED C BASICSBarbie VeniNo ratings yet

- Basic Electrical Mostly Asked 125 Questions and AnswersDocument13 pagesBasic Electrical Mostly Asked 125 Questions and AnswersMaliha MouNo ratings yet

- WDF Drivers OverviewDocument611 pagesWDF Drivers OverviewMyScribdNo ratings yet

- Schneider MODBUS TCP/IP: HMI SettingDocument2 pagesSchneider MODBUS TCP/IP: HMI SettingdaocongdablNo ratings yet

- How MSPs Can Leverage Domain SeparationDocument18 pagesHow MSPs Can Leverage Domain SeparationKittu KittuNo ratings yet

- CAPASITORDocument3 pagesCAPASITORFery YelyantoNo ratings yet

- Monitor Health with ArduinoDocument16 pagesMonitor Health with ArduinoAnikesh SharmaNo ratings yet

- MotorDocument19 pagesMotoreshet chafNo ratings yet

- Ac TransformerDocument6 pagesAc Transformervishal_kalraNo ratings yet

- Group 1 AC GeneratorDocument26 pagesGroup 1 AC GeneratorKhen Joshua VillegasNo ratings yet

- Electricity and MagnetismDocument12 pagesElectricity and MagnetismVanita Shetty BhoolaNo ratings yet

- Electromagnetism: GCSE PhysicsDocument43 pagesElectromagnetism: GCSE PhysicsNorazlin UjangNo ratings yet

- Analysis and Design of Framed and Block Machine FoundationDocument10 pagesAnalysis and Design of Framed and Block Machine FoundationJCarlos ValadezNo ratings yet

- 202005131124250101gaurav-Machine FoundationDocument14 pages202005131124250101gaurav-Machine FoundationSOURAV OJHA goalNo ratings yet

- Dynamic Analysis of Machine FoundationDocument15 pagesDynamic Analysis of Machine FoundationSMT VIETNAMNo ratings yet

- Lateral Earth Pressures: DurationDocument63 pagesLateral Earth Pressures: DurationDileepkumar RudrarajuNo ratings yet

- Indian Standard Is 875 - 3 2015Document69 pagesIndian Standard Is 875 - 3 2015pvrk_78No ratings yet

- Earth Is Our MotherlandDocument1 pageEarth Is Our MotherlandDileepkumar RudrarajuNo ratings yet

- Kindle User Guide en-GBDocument54 pagesKindle User Guide en-GBDileepkumar RudrarajuNo ratings yet

- What Is Vedic AstrologyDocument3 pagesWhat Is Vedic Astrologynimi2364010No ratings yet

- LLR Test General Driving Principles EnglishDocument23 pagesLLR Test General Driving Principles Englishu2mailrahulNo ratings yet

- Moisture Detectors Buehler KosteusvahtiDocument2 pagesMoisture Detectors Buehler KosteusvahtiKHANNNNo ratings yet

- ELX303+ +Power+Electronic+Equipment+ +AC DC+Converter+Design+ +part+11+ +october+2020Document51 pagesELX303+ +Power+Electronic+Equipment+ +AC DC+Converter+Design+ +part+11+ +october+2020Sohaib JavaidNo ratings yet

- ElectricalDocument40 pagesElectricalAkash SNo ratings yet

- Voltage Drop Calculation ReportDocument3 pagesVoltage Drop Calculation ReportbrumanciaNo ratings yet

- EED203 Mid Exam Paper SolutionsDocument8 pagesEED203 Mid Exam Paper SolutionsAvinash SinghNo ratings yet

- EM ATS Catalogue 2018 enDocument23 pagesEM ATS Catalogue 2018 enMaritza LópezNo ratings yet

- Mitsubishi FR A220E 2 2K UL Manual 202053121826Document198 pagesMitsubishi FR A220E 2 2K UL Manual 202053121826abidin ulusoyNo ratings yet

- SP0407 Commissioning Tests For HV UG CablesDocument13 pagesSP0407 Commissioning Tests For HV UG Cablesyavuz772100% (4)

- Shindengen mtd2003fDocument3 pagesShindengen mtd2003fcsesadminNo ratings yet

- Webasto Combination Timer 1531Document6 pagesWebasto Combination Timer 1531carmanagerzone100% (1)

- PSIM User ManualDocument224 pagesPSIM User ManualFendi BmkNo ratings yet

- Altec 128bDocument4 pagesAltec 128bonetwondlNo ratings yet

- Low-Voltage Power Circuit Breakers and AC Power Circuit Protectors-Preferred Ratings, Related Requirements, and Application RecommendationsDocument29 pagesLow-Voltage Power Circuit Breakers and AC Power Circuit Protectors-Preferred Ratings, Related Requirements, and Application RecommendationsukritNo ratings yet

- Sony Led Blinking CodesDocument2 pagesSony Led Blinking CodesalkalinemanNo ratings yet

- P-i-n Diode Working and TypesDocument9 pagesP-i-n Diode Working and TypesAshwin JoshiNo ratings yet

- kc7783r PDFDocument1 pagekc7783r PDFHaris WidiyantoNo ratings yet

- RF 60 61 64Document1 pageRF 60 61 64Олег ЛеонтьевNo ratings yet

- Pulse Transformer and Its ApplicationsDocument22 pagesPulse Transformer and Its ApplicationsHuỳnh Lê Duy50% (2)

- Experiment No.2: Objective: Study of Characteristics of Silicon DiodeDocument5 pagesExperiment No.2: Objective: Study of Characteristics of Silicon DiodeUday BhartiyaNo ratings yet

- lm324 NsreDocument42 pageslm324 Nsrewilman rengelNo ratings yet

- Physics Investigatory ProjectDocument25 pagesPhysics Investigatory ProjectSudarshan Thakur33% (6)

- GES-6121C: Multiples of Current RatingDocument1 pageGES-6121C: Multiples of Current RatingAdolfo Sotomayor BurgosNo ratings yet

- Automatic Shut-Off Circuits for Audio EquipmentDocument3 pagesAutomatic Shut-Off Circuits for Audio Equipmentsushant sharmaNo ratings yet

- Ee6002 Power System Transients: Part-A Important Questions For May/June-2016Document1 pageEe6002 Power System Transients: Part-A Important Questions For May/June-2016Karthikeyan GovindarajNo ratings yet

- 8437SBTET (C09) DEEE 4th Sem - Ac Machines-I PDFDocument3 pages8437SBTET (C09) DEEE 4th Sem - Ac Machines-I PDFRAJ NAYAAK0% (1)

- Capacitor Circuits MC Questions PDFDocument5 pagesCapacitor Circuits MC Questions PDFLynn Hollenbeck Breindel100% (1)

- DM 0138 DM 0138: Drum Motor Drum MotorDocument5 pagesDM 0138 DM 0138: Drum Motor Drum MotorRintheGreatNo ratings yet

- Capsule Modification and MountingDocument2 pagesCapsule Modification and MountingFernando CostaNo ratings yet

- Camion 789DDocument14 pagesCamion 789Ddinny blanco rojasNo ratings yet

- Error Codes PATDocument9 pagesError Codes PATRajan Mullappilly88% (16)