Professional Documents

Culture Documents

Photo 2/10: - FPT Industrial's Cursor 13 Uses An Aluminum Flywheel Housing

Uploaded by

chunghae KIM0 ratings0% found this document useful (0 votes)

10 views2 pagesFiat Powertrain Technologies Industrial is an Italian manufacturer of engines, axles, and transmissions formed through the consolidation of the powertrain activities of Iveco, Case IH, and New Holland. The company offers a broad range of diesel engines from 2.0 to 20 liters for on-road, agriculture, construction, marine, and power generation applications. Its largest on-road engine is the 12.9L Cursor 13 that produces 571 hp and meets Euro VI emissions standards through an electronically controlled common-rail fuel injection system and variable-geometry turbocharger.

Original Description:

Original Title

IVE.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFiat Powertrain Technologies Industrial is an Italian manufacturer of engines, axles, and transmissions formed through the consolidation of the powertrain activities of Iveco, Case IH, and New Holland. The company offers a broad range of diesel engines from 2.0 to 20 liters for on-road, agriculture, construction, marine, and power generation applications. Its largest on-road engine is the 12.9L Cursor 13 that produces 571 hp and meets Euro VI emissions standards through an electronically controlled common-rail fuel injection system and variable-geometry turbocharger.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesPhoto 2/10: - FPT Industrial's Cursor 13 Uses An Aluminum Flywheel Housing

Uploaded by

chunghae KIMFiat Powertrain Technologies Industrial is an Italian manufacturer of engines, axles, and transmissions formed through the consolidation of the powertrain activities of Iveco, Case IH, and New Holland. The company offers a broad range of diesel engines from 2.0 to 20 liters for on-road, agriculture, construction, marine, and power generation applications. Its largest on-road engine is the 12.9L Cursor 13 that produces 571 hp and meets Euro VI emissions standards through an electronically controlled common-rail fuel injection system and variable-geometry turbocharger.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Fiat Powertrain Technologies Industrial is an Italian engine, axle, and transmission

manufacturer. The company is a conglomeration of all the engine, transmission, and

axle activities from Iveco, Case IH, and New Holland, bringing together 150 years of

experience, while expanding the technological knowledge and capacity each offered

individually.

FPT Industrial builds a broad range of diesel engines for such applications as on-road

trucks, agriculture, construction, marine, and power generation. The engines range

from 2.0 liters to as big as 20 liters. The company also offers several engines designed

to run on natural gas and bio-methane. There is a broad range of oil-burners offered in

the on-road segment, the largest powerplant being the Cursor 13, a 12.9L I-6 that

produces 571 hp and 1,844 lb-ft of torque and meets Euro VI emissions standards

thanks to its dynamic ECM.

Photo 2/10 | FPT Industrial’s Cursor 13 uses an aluminum flywheel housing.

The C13’s processor is engineered to ensure every internal engine part and supporting

system works at its peak efficiency. The ECM controls the electronic common-rail

fuel injection system for each cylinder independently for superior injection quality.

Injection control helps manage engine and fuel temperatures, as well as promote

balanced torque production. Further enhancing engine performance is an ECM-

controlled variable-geometry turbocharger, which, in addition to boost, also

pressurizes the cylinders during engine braking.

In order for any engine to perform at its peak potential for an entire lifespan, it needs a

robust architecture. FPT’s new engine is founded on a strong block and sub-block

made of stabilized cast-iron. Inside the casting are a micro-alloy steel crankshaft and

balancing mass that are supported by seven main bearings. The main- and rod-bearing

journals are induction-tempered for strength. At the end of the micro-alloy pressed-

steel connecting rods are hypereutectic aluminum-alloy pistons. These slugs are

designed with a cooling tunnel and a circular bowl that promotes swirl and improves

fuel distribution in the cylinder to provide the greatest efficiency.

Mounted on top of the block is a nickel-stabilized, cast-iron, one-piece cylinder head,

which features four valves per cylinder that are actuated by roller rocker arms and an

overhead camshaft. The case-hardened steel camshaft has three lobes per cylinder

(intake, exhaust, and injection) and is secured with seven journals. The cam’s

injection lobes actuate unit pump injectors (nozzle and pump in a single unit) that are

electronically controlled by the ECM. The camshaft’s timing comes from gears

mounted at the back of the engine. This configuration increases durability and reduces

any torsional effects.

You might also like

- CF Moto 250 NKDocument208 pagesCF Moto 250 NKalbeiro zuluaga100% (2)

- MERCEDES W123 Serv Manual Engine 617 - 95 - TDDocument532 pagesMERCEDES W123 Serv Manual Engine 617 - 95 - TDriomaior94% (32)

- Ford New Holland 8530 8630 8730 8830 TW5 TW15 TW25 TW35 Workshop ManualDocument1,445 pagesFord New Holland 8530 8630 8730 8830 TW5 TW15 TW25 TW35 Workshop ManualVESTEMAN100% (3)

- How to Build Max-Performance Chevy LT1/LT4 EnginesFrom EverandHow to Build Max-Performance Chevy LT1/LT4 EnginesRating: 3 out of 5 stars3/5 (1)

- Ducati Monster-821-Service-Manual PDFDocument1,164 pagesDucati Monster-821-Service-Manual PDFFabian Alejandro Ramos Sandoval100% (1)

- Suzuki VL1500 '98-'02 Service Manual (99500-39164-01E)Document444 pagesSuzuki VL1500 '98-'02 Service Manual (99500-39164-01E)Nikolas KarrerNo ratings yet

- Detroit Diesel S50 - 6SE050 - Service Guide (Printas Ej) PDFDocument1,683 pagesDetroit Diesel S50 - 6SE050 - Service Guide (Printas Ej) PDFfelipe macias100% (1)

- Alfa MiTo 1.4 16V Multiair - enDocument164 pagesAlfa MiTo 1.4 16V Multiair - enAJUSA Asistencia Técnica100% (1)

- The V8 Engine For McLaren's New MP4-12CDocument6 pagesThe V8 Engine For McLaren's New MP4-12Cddi11No ratings yet

- Workshop Manual: TAD1240GE, TAD1241GE/VE TAD1242GE/VE, TWD1240VEDocument114 pagesWorkshop Manual: TAD1240GE, TAD1241GE/VE TAD1242GE/VE, TWD1240VEAl Bima86% (7)

- 7fdl Brochure LocomotiveDocument2 pages7fdl Brochure LocomotiveFukyma Morgan100% (2)

- The New Mercedes-Benz Four-Cylinder Diesel Engine For Passenger CarsDocument8 pagesThe New Mercedes-Benz Four-Cylinder Diesel Engine For Passenger CarsqingcaoheNo ratings yet

- 12 - LE9 EcotecDocument4 pages12 - LE9 EcotecakirafactorNo ratings yet

- Manual Corolla Engine 4A-FE 3S-GTE 5S-FEDocument311 pagesManual Corolla Engine 4A-FE 3S-GTE 5S-FEanto_jo95% (39)

- LS Gen IV Engines 2005 - Present: How to Build Max PerformanceFrom EverandLS Gen IV Engines 2005 - Present: How to Build Max PerformanceRating: 5 out of 5 stars5/5 (2)

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972From EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (3)

- VM MotoriDocument228 pagesVM Motorimichaeltiboche100% (1)

- The 6.3L W12 FSI Engine: Self-Study Program 920113Document44 pagesThe 6.3L W12 FSI Engine: Self-Study Program 920113Zoran RadovicNo ratings yet

- 924 Porsche Technical Specifications 1 PDFDocument18 pages924 Porsche Technical Specifications 1 PDF9TECHNIK100% (1)

- Photo 2/10: - FPT Industrial's Cursor 13 Uses An Aluminum Flywheel HousingDocument2 pagesPhoto 2/10: - FPT Industrial's Cursor 13 Uses An Aluminum Flywheel Housingchunghae KIMNo ratings yet

- IvecoDocument2 pagesIvecochunghae KIMNo ratings yet

- The Advanced Iveco Cursor 10 Heavy Duty Truck Diesel EngineDocument10 pagesThe Advanced Iveco Cursor 10 Heavy Duty Truck Diesel Enginemn16kumarNo ratings yet

- GM Racing EcotecDocument1 pageGM Racing EcotecbienhopleikuNo ratings yet

- V-ACT D16E Brochure 22 A 100 3523 - 2007-07Document2 pagesV-ACT D16E Brochure 22 A 100 3523 - 2007-07Rolando Mancilla FloresNo ratings yet

- Volvo 850 EngineDocument15 pagesVolvo 850 Enginevanapeer100% (3)

- Engine TypesDocument4 pagesEngine TypesRoss GrimmettNo ratings yet

- Himsen Cat h1728Document12 pagesHimsen Cat h1728Mohsen100% (1)

- The New BMW 2.0 L Four Cylinder Gasoline Engine With TurbochargerDocument9 pagesThe New BMW 2.0 L Four Cylinder Gasoline Engine With TurbochargerMarculescu Nicolae CatalinNo ratings yet

- Engine AssemblyDocument34 pagesEngine Assemblyvinu198500100% (3)

- Armstrong Siddeley - : FlightDocument1 pageArmstrong Siddeley - : Flightseafire47100% (1)

- KTM Engine Dev enDocument4 pagesKTM Engine Dev enstefan.vince536100% (1)

- New E85 Flex Fuel Engine (Rpo) For Chevrolet HHR Panel and Passenger VanDocument3 pagesNew E85 Flex Fuel Engine (Rpo) For Chevrolet HHR Panel and Passenger VanakirafactorNo ratings yet

- The Mini Cooper S PowertrainDocument4 pagesThe Mini Cooper S Powertrainrogerbkr100% (1)

- R8Document15 pagesR8Dieguis Bruno100% (1)

- SWMDocument24 pagesSWMRaj DhuriNo ratings yet

- Hdi (Diesel) Engines: Cylinder BlockDocument6 pagesHdi (Diesel) Engines: Cylinder BlockfotonengineNo ratings yet

- Evo IxDocument9 pagesEvo IxHannu JaaskelainenNo ratings yet

- Marine Diesel EngineDocument5 pagesMarine Diesel Enginemy generalNo ratings yet

- TractorDocument20 pagesTractorPepe AlfredNo ratings yet

- DJA20013Document23 pagesDJA20013وان محمد هاتيمىNo ratings yet

- IC EngineDocument32 pagesIC EngineTaslim AminNo ratings yet

- Himsen Cat h2533Document12 pagesHimsen Cat h2533Mohsen50% (2)

- EngineDocument41 pagesEngineGurmeet Mehma100% (5)

- Off-Highway TruckDocument32 pagesOff-Highway TruckTeeyas PutreeNo ratings yet

- Tugas DeckyDocument2 pagesTugas Deckyselviana safitriNo ratings yet

- TUGASDocument2 pagesTUGASselviana safitriNo ratings yet

- 1.1 Definition: Fuel Is Released Inside The Engine and Used Directly For Mechanical Work'. TheDocument5 pages1.1 Definition: Fuel Is Released Inside The Engine and Used Directly For Mechanical Work'. TherocksNo ratings yet

- Ox2 EngineDocument9 pagesOx2 EngineManojkumar ManoNo ratings yet

- Vortec 4300 MarineBase 2009Document3 pagesVortec 4300 MarineBase 2009Romulo Davila JimenoNo ratings yet

- ASSIGNMENT 2 by b3Document16 pagesASSIGNMENT 2 by b3devmarineacademyNo ratings yet

- FMP - 617 Farm Mechanization Practical 1Document9 pagesFMP - 617 Farm Mechanization Practical 1رانا ریحان انور خاںNo ratings yet

- Piston of Large Marine EngineDocument3 pagesPiston of Large Marine EngineRuwan SusanthaNo ratings yet

- Performance of IC's EngineDocument45 pagesPerformance of IC's EngineNandhakumarNo ratings yet

- AutomotiveDocument23 pagesAutomotivelaylayden kaNo ratings yet

- Pimsat Colleges Engineering Materials 1Document8 pagesPimsat Colleges Engineering Materials 1Sev Anne T. GonzalesNo ratings yet

- 4.2L V8 FSI EngineDocument40 pages4.2L V8 FSI EngineVASEKNo ratings yet

- 3.0 V6 TdiDocument44 pages3.0 V6 TdiAnonymous UnVea6Tn100% (3)

- Reciprocating Engine Parts Design: G.T.U. B.E. (Mech) Sem-Viii 2011-12Document61 pagesReciprocating Engine Parts Design: G.T.U. B.E. (Mech) Sem-Viii 2011-12Divyraj JadejaNo ratings yet

- Lotus Omnivore Initial ResultsDocument6 pagesLotus Omnivore Initial ResultsPaulNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- The Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignFrom EverandThe Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignRating: 3.5 out of 5 stars3.5/5 (3)

- Scope: This Specification Shall Not Be Used For New Product Fuel System Components, Use CES 16602Document6 pagesScope: This Specification Shall Not Be Used For New Product Fuel System Components, Use CES 16602pathinathanNo ratings yet

- Parts Catalog Cummins, QSK60G4 - ESN 33178675 - CPL 2888Document140 pagesParts Catalog Cummins, QSK60G4 - ESN 33178675 - CPL 2888ivan sulistian100% (3)

- H-2 Controlair Valve: Service InformationDocument18 pagesH-2 Controlair Valve: Service InformationRonald LlerenaNo ratings yet

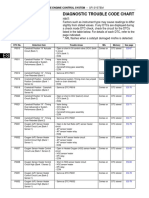

- Es 62 Es Diagnostic Trouble Code Chart PDFDocument10 pagesEs 62 Es Diagnostic Trouble Code Chart PDFSR BangashNo ratings yet

- Gsr600k7e19 PDFDocument96 pagesGsr600k7e19 PDFAdolfoNo ratings yet

- Northen LightDocument67 pagesNorthen Lightmohd tawfikNo ratings yet

- Aprilia Etv Mille, Caponord, Frame ManualDocument346 pagesAprilia Etv Mille, Caponord, Frame ManualPapas MamasNo ratings yet

- Car Craft 03 Mar 2011Document92 pagesCar Craft 03 Mar 2011tom jonesNo ratings yet

- SFM125 Roadster 2013 K157FMI Big Bore 150cc L230 Camshaft 115mm JetDocument1 pageSFM125 Roadster 2013 K157FMI Big Bore 150cc L230 Camshaft 115mm Jetstefan.vince536No ratings yet

- C20-32CL (Lot No 9974,8301)Document156 pagesC20-32CL (Lot No 9974,8301)Christian BedoyaNo ratings yet

- Volvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi SEZ5Document51 pagesVolvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi SEZ5Luciano LiuzziNo ratings yet

- Jeep Engine and Cam SpecsDocument6 pagesJeep Engine and Cam Specsmnlwood25580% (1)

- Service Bulletin Trucks: MID 128 Engine Control Unit, Fault CodesDocument20 pagesService Bulletin Trucks: MID 128 Engine Control Unit, Fault CodesСергей СергейNo ratings yet

- Fuses Passat 2018Document38 pagesFuses Passat 2018monoblock911No ratings yet

- LR4 2010 5.0LDocument832 pagesLR4 2010 5.0LLuis Ramon Arguello RealNo ratings yet

- Bravo Service Manual Part 1Document544 pagesBravo Service Manual Part 1carlsdigaround100% (2)

- GM 3 L Service ManualDocument82 pagesGM 3 L Service ManualHans KramerNo ratings yet

- Yamaha Mio Service ManualDocument305 pagesYamaha Mio Service ManualMyFullNo ratings yet

- Introduction To Automotive Components and Vehicle SystemDocument57 pagesIntroduction To Automotive Components and Vehicle SystemnahomNo ratings yet