Professional Documents

Culture Documents

Datasheet: Delastic Preformed Compression Seals

Uploaded by

Saroj BhattaraiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet: Delastic Preformed Compression Seals

Uploaded by

Saroj BhattaraiCopyright:

Available Formats

Datasheet

Bridges

Bridges

REV 01/13

Expansion Joint Systems

Delastic® Preformed

Compression Seals

CV & CA Characteristics

& Properties

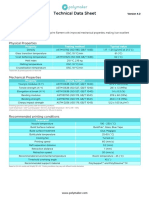

Delastic ® Delastic ® Seal Characteristics Joint Design Criteria

Seal Nominal Nominal Maximum Narrowest Widest Minimum

Catalog No. Width (W) Height (H) Movement Opening OpeningA DepthB

A

CV-1250 1.25 (32) 1.25 (32) 0.50 (13) 0.56 (14) 1.06 (27) 1.63 (41)

CV-1625 1.63 (41) 1.88 (40) 0.60 (15) 0.73 (19) 1.38 (35) 2.25 (57)

CV-1752 1.75 (44) 1.75 (44) 0.70 (18) 0.79 (20) 1.49 (38) 2.40 (61)

CV-2000 2.00 (51) 2.00 (51) 0.75 (19) 0.95 (24) 1.70 (43) 2.75 (70)

CV-2250 2.25 (57) 2.33 (59) 0.90 (23) 1.01 (26) 1.91 (49) 3.00 (76)

CV-2502 2.50 (64) 2.50 (64) 1.00 (25) 1.13 (29) 2.13 (54) 3.20 (81)

CV-3000 3.00 (76) 3.25 (83) 1.20 (31) 1.34 (34) 2.55 (65) 4.25 (108)

CV-3500 3.50 (89) 3.50 (89) 1.40 (36) 1.58 (40) 2.98 (76) 4.45 (113)

CV-4000 4.00 (102) 4.00 (102) 1.65 (42) 1.75 (44) 3.40 (86) 5.63 (143)

CA-4500 4.50 (114) 4.50 (114) 2.20 (56) 2.03 (52) 3.83 (97) 6.13 (156)

CA-5001 5.00 (127) 5.00 (127) 2.35 (60) 1.90 (48) 4.25 (108) 6.25 (159)

CA-6000 6.00 (152) 6.00 (152) 2.90 (74) 2.20 (56) 5.10 (129) 7.75 (197)

Bold numbers represent inches; metric (mm) shown in parentheses.

Joint opening dimensions (A) are based on minimum and maximum pressured allowed in ASTM D3542.

Minimum depth dimensions (B) include a 0.25 inch (6mm) recess below the roadway surface.

Bridge the World with Leading Infrastructure Solutions

300 East Cherry Street • North Baltimore, OH 45872 | Telephone: 419.257.3561 • Fax: 419.257.2200 | www.dsbrown.com

Datasheet Bridges

Delastic® Preformed Compression Seals

CV & CA Characteristics & Properties

| Expansion Joint Systems

2 of 2

ASTM D3542-08 - Physical Requirements for Preformed Elastomeric Joint Seals

Properties Requirements ASTM Test Method

Tensile Strength, min, psi (MPa) 2000 (13.8) D412

Elongation at Break, min, % 250 D412

Hardness, Type A durometer, points 55±5 D2240 (modified) A

Oven Aging, 70 h at 212oF (100oC) D573

Tensile Strength, loss, max, % 20

Elongation, loss, max, % 20

Hardness, Type A durometer, points change 0 to 10

Oil Swell, ASTM Oil No. 3, 70 h at 212oF (100oC)

Weight change, max, % 45 D471

Ozone ResistanceB:

20% strain, 303 mPa of ozone in air (the volume fraction

of ozone is 300 pphm in air at 1 atm), 70 h at 104oF (40oC), no cracks D1149C

wiped the toluene to remove surface contamination

Low-Temperature RecoveryC, 72 h at +14oF (-29 oC), 50%;

Deflection, min, % 88 Section 8.2D

Low-Temperature RecoveryC, 22 h at -20oF (-29 oC), 50%

Deflection, min, % 83 Section 8.2D

High-Temperature RecoveryC, 70 h at 212oF (100oC), 50%

Deflection, min, % 85 Section 8.2D

Compression-Deflection Properties: D575 Method A (modified) E

LC Min., in (mm) See 8.3.5

LC Max., in (mm) See 8.3.5

Movement Range, in (mm) See 8.3.5

A

The term “modified” in the table relates to the specimen preparation. The use of the joint seal as the specimen source requires that more plies

than specified in either of the modified test procedures be used. Such specimen modification shall be agreed upon between the purchaser and

the supplier prior to testing. The hardness test shall be made with the durometer in a durometer stand as recommended in Test Methods D2240.

B

Sample prepared in accordance with Method A of Test Method D518.

C

Cracking, splitting or sticking of a specimen during a recovery test shall mean that the specimen has failed the test.

D

The reference section and subsections are those of specification D 3542 – 08 Preformed Polychloroprene Elastomeric Joint Seals for Bridges.

E

Speed of testing shall be 0.5 ± 0.05 in. (13 ± 1.3 mm), minimum at room temperature of 73°F ± 4°F (23 ± 2.2°C). The sheets of sandpaper are not

used.

Bridge the World with Leading Infrastructure Solutions

300 East Cherry Street • North Baltimore, OH 45872 | Telephone: 419.257.3561 • Fax: 419.257.2200 | www.dsbrown.com

You might also like

- Calculation Sheet SubmittingDocument2 pagesCalculation Sheet SubmittingPloy Phoott NitthaNo ratings yet

- B DPCS CharPropCVandCA DATA v024-WEBDocument2 pagesB DPCS CharPropCVandCA DATA v024-WEBguivc.ethernet.32No ratings yet

- Datasheet: Delastic Preformed Pavement SealsDocument1 pageDatasheet: Delastic Preformed Pavement SealsUnited Construction Est. TechnicalNo ratings yet

- Poron 4701-30 Very SoftDocument2 pagesPoron 4701-30 Very SoftItzelMalagonVeraNo ratings yet

- Sumitube Sa2fDocument2 pagesSumitube Sa2fNicacio LucenaNo ratings yet

- A PDFDocument4 pagesA PDFVerenice CentenoNo ratings yet

- DOWLEX™ 2038.68G: Polyethylene ResinDocument3 pagesDOWLEX™ 2038.68G: Polyethylene ResinJosé PalmaNo ratings yet

- Technical Data Sheet Nonwoven Polyester (Pet) : Pt. Hilon IndonesiaDocument2 pagesTechnical Data Sheet Nonwoven Polyester (Pet) : Pt. Hilon IndonesiaG Nurhidayat ANo ratings yet

- XIAMETER™ RBB-2030-40 Base: Features & Benefits ApplicationsDocument3 pagesXIAMETER™ RBB-2030-40 Base: Features & Benefits ApplicationsDaniela Alejandra Daza LancherosNo ratings yet

- Hdi0653u1 Enus AstmDocument1 pageHdi0653u1 Enus AstmJonathan GuadarramaNo ratings yet

- Dow ELITE 5220G Enhanced Polyethylene ResinDocument2 pagesDow ELITE 5220G Enhanced Polyethylene Resinusman3549606No ratings yet

- PORON 4701-50 Firm - Supported MaterialsDocument2 pagesPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedNo ratings yet

- ELITE 5400G: Blown Film ResinDocument2 pagesELITE 5400G: Blown Film ResinEndayenew MollaNo ratings yet

- Tds - Macgrid BiaxialDocument1 pageTds - Macgrid BiaxialLiliana Ribeiro100% (2)

- Tech Data - PF Alidrain AD230 - 250Document1 pageTech Data - PF Alidrain AD230 - 250BinSayeed100% (1)

- Exelene Hdpe 20000 2021Document1 pageExelene Hdpe 20000 2021diana sarmientoNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDocument2 pagesTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanNo ratings yet

- Output Summary: SI UnitsDocument14 pagesOutput Summary: SI UnitsEduardoNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- B EJS NewConstrucEJS BRO00-5723 v074-WEBDocument16 pagesB EJS NewConstrucEJS BRO00-5723 v074-WEBGUILLERMO OTERO PRECIADONo ratings yet

- Hoja Tecnica PEAD PE-100 Tipo P600Document1 pageHoja Tecnica PEAD PE-100 Tipo P600Manuel Agustin TeneNo ratings yet

- GP100ORXP enUS ASTMDocument1 pageGP100ORXP enUS ASTMRaul ArmendarizNo ratings yet

- GP - TS - US - MacGrid WG - 75 Year Jan12Document1 pageGP - TS - US - MacGrid WG - 75 Year Jan12mojmaxNo ratings yet

- PC 8B35 Ge Lexan PCDocument3 pagesPC 8B35 Ge Lexan PCbalu gunaNo ratings yet

- ELITE 5401G: Blown Film ResinDocument2 pagesELITE 5401G: Blown Film ResinEndayenew MollaNo ratings yet

- Creepage Extension Sheds: Product Dimensions - Ces SeriesDocument1 pageCreepage Extension Sheds: Product Dimensions - Ces SeriesHKC EQUIPEMENTSNo ratings yet

- Teslin: Quick OverviewDocument3 pagesTeslin: Quick OverviewDewiNo ratings yet

- MIRATAKDocument1 pageMIRATAKmiroslava mondragonNo ratings yet

- Masterseries Sample Output: Moment CapacityDocument1 pageMasterseries Sample Output: Moment CapacitysillywildfoxNo ratings yet

- Melinex® SDocument2 pagesMelinex® Smhamam29No ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- Assignment 3Document34 pagesAssignment 3YAHAMPATH ARACHCHIGE PASAN MADURA YahampathNo ratings yet

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungNo ratings yet

- Kpic Yuhwa p600Document1 pageKpic Yuhwa p600quanghoang10986No ratings yet

- HD Smooth Geomembrane MetricDocument1 pageHD Smooth Geomembrane MetricAndreas Erdian WijayaNo ratings yet

- PolyMax PLA TDS V4Document2 pagesPolyMax PLA TDS V4fNo ratings yet

- 01.03.03.101 Spesifikasi-BPM HDPE SmoothDocument1 page01.03.03.101 Spesifikasi-BPM HDPE SmoothRezky BaskoroNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- HDPE Blow Ineos-G50-100Document2 pagesHDPE Blow Ineos-G50-100luisalbertolvNo ratings yet

- Mejora Continua en Molinos SAGDocument24 pagesMejora Continua en Molinos SAGRelining MineralsNo ratings yet

- Datasheet LTM-2125 PDFDocument1 pageDatasheet LTM-2125 PDFjavadmohammadiNo ratings yet

- ELITE™ AT 6111: Enhanced Polyethylene ResinDocument3 pagesELITE™ AT 6111: Enhanced Polyethylene ResinRoberto De Mesa PNo ratings yet

- AASHTODocument1 pageAASHTOZax SantanaNo ratings yet

- UPVC Pipe DIN 8062 TdsDocument3 pagesUPVC Pipe DIN 8062 TdsAdany AdenNo ratings yet

- EPDM SpecsDocument1 pageEPDM SpecsRosendo GarcíaNo ratings yet

- Polyester: Data SheetDocument1 pagePolyester: Data SheetñeNo ratings yet

- HDI2061 enUS ASTMDocument1 pageHDI2061 enUS ASTMWendy WilchesNo ratings yet

- DOW™ Butene 1221P: Linear Low Density Polyethylene ResinDocument3 pagesDOW™ Butene 1221P: Linear Low Density Polyethylene ResinMinh TranNo ratings yet

- Chapter 3 Miscellaneous Items: Quality Control Manual On Concrete and Steel Bridge StructuresDocument33 pagesChapter 3 Miscellaneous Items: Quality Control Manual On Concrete and Steel Bridge StructuresMae Ann GonzalesNo ratings yet

- ELITE™ 5110G: Enhanced Polyethylene ResinDocument3 pagesELITE™ 5110G: Enhanced Polyethylene ResinHabiba JamilNo ratings yet

- PolyCast TDS V3Document2 pagesPolyCast TDS V3jerome.luganNo ratings yet

- Datasheet - r680s - Randompp - e 3Document2 pagesDatasheet - r680s - Randompp - e 3Gulzar HossainNo ratings yet

- DOWLEX™ 2047G: Polyethylene ResinDocument3 pagesDOWLEX™ 2047G: Polyethylene Resinujang sukartaNo ratings yet

- Virgin PTFE G400 Extruded - Rev.06Document1 pageVirgin PTFE G400 Extruded - Rev.06Alessio Di BellaNo ratings yet

- Polymax PC Tds v4Document2 pagesPolymax PC Tds v4Hector GarciaNo ratings yet

- List Material Dead Stock PKSDocument12 pagesList Material Dead Stock PKSbintang_arifNo ratings yet

- Mole McqsDocument8 pagesMole McqsShoaib Aslam DhakkuNo ratings yet

- Chem Soc Rev: Review ArticleDocument28 pagesChem Soc Rev: Review ArticleCB Dong SuwonNo ratings yet

- Chemistry Lab ReportDocument16 pagesChemistry Lab Reportapi-327702881No ratings yet

- Denture Base PolymersDocument20 pagesDenture Base Polymersفیضان حنیفNo ratings yet

- Refrigerant Piping: By: Cecil R. Visger, Past International PipingDocument18 pagesRefrigerant Piping: By: Cecil R. Visger, Past International PipingBehnam AshouriNo ratings yet

- RCD Formulas DomingoDocument3 pagesRCD Formulas DomingoSteve Baria100% (1)

- Foe Sample QuistionSDocument21 pagesFoe Sample QuistionSYuGenNo ratings yet

- NAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsDocument8 pagesNAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsRobovenNo ratings yet

- Grundfosliterature 5235678Document104 pagesGrundfosliterature 5235678Adriana SandruNo ratings yet

- BOMBASDocument4 pagesBOMBASjcrrautocadNo ratings yet

- Mock QuestionDocument23 pagesMock QuestionVincent RoblonNo ratings yet

- Midterm Exam Form 5 INTESCIENCE COMPLETEDocument9 pagesMidterm Exam Form 5 INTESCIENCE COMPLETECHRISTOPHER SCALENo ratings yet

- ActionTypes LookupDocument2 pagesActionTypes LookupRohitKumarNo ratings yet

- Piping Spool Fabrication ProcedureDocument14 pagesPiping Spool Fabrication ProcedureMiky Andrean100% (6)

- Study of Natural Fibers As An Admixture For Concrete Mix DesignDocument9 pagesStudy of Natural Fibers As An Admixture For Concrete Mix DesignJOHN FHILIP ORIT67% (3)

- Flexonyl Blue WF 153Document2 pagesFlexonyl Blue WF 153Leandro EsvizaNo ratings yet

- Comparative Study of LiBF4, LiAsF6, LiPF6, and LiClO4 As Electrolytes inDocument10 pagesComparative Study of LiBF4, LiAsF6, LiPF6, and LiClO4 As Electrolytes inJose Luis FloresNo ratings yet

- l5 Spring BalanceDocument11 pagesl5 Spring BalanceNur Syamiza ZamriNo ratings yet

- U6OHREPORT2008Document89 pagesU6OHREPORT2008Anonymous pKsr5vNo ratings yet

- Mildew (Fungus) Resistance of Paper and Paperboard: Standard Test Methods ForDocument4 pagesMildew (Fungus) Resistance of Paper and Paperboard: Standard Test Methods ForShaker QaidiNo ratings yet

- 7.0 Solubility and Solubility EquilibriaDocument19 pages7.0 Solubility and Solubility EquilibriashepherdmburuguNo ratings yet

- Lecture On Transcription and TranslationDocument47 pagesLecture On Transcription and TranslationAnna Beatrice BautistaNo ratings yet

- 3m C2a1 Filter MsdsDocument7 pages3m C2a1 Filter MsdsGLOCK35No ratings yet

- Module Mol Chapter 7Document78 pagesModule Mol Chapter 7eyoelNo ratings yet

- Tt-p-1757b Type II Class N - TdsDocument2 pagesTt-p-1757b Type II Class N - TdspokleNo ratings yet

- Tilapia Production Using Biofloc TechnologyDocument3 pagesTilapia Production Using Biofloc TechnologyYousaf JamalNo ratings yet

- MWM TCG2020Document8 pagesMWM TCG2020Md Iqbal HossainNo ratings yet

- Experiment 4Document6 pagesExperiment 4kuekNo ratings yet

- Methylene Blue (Cationic Dye) Adsorption Into PDFDocument8 pagesMethylene Blue (Cationic Dye) Adsorption Into PDFLyndzey AlondeNo ratings yet