Professional Documents

Culture Documents

Datasheet: Delastic Preformed Pavement Seals

Uploaded by

United Construction Est. TechnicalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet: Delastic Preformed Pavement Seals

Uploaded by

United Construction Est. TechnicalCopyright:

Available Formats

Datasheet

Pavements

REV 06/17

Characteristics and Properties

Delastic® Preformed Pavement Seals

Delastic ® Preformed Pavement Seal Characteristics

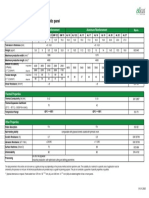

Delastic® Seal Characteristics Joint Design Criteria

Seal Nominal Nominal Max. Narrowest Widest Minimum Typical Installed

Catalog No. Width (W) Height (H) Movement 1 Opening 2 Opening 3 Depth (B) Width (A)**

E-437 0.437 (11.11) 0.937 (23.81) 0.153 (3.88) 0.219 (5.56) 0.372 (9.45) 1.000 (25.40) 0.250 (6.35)

E-562 0.562 (14.29) 0.625 (15.88) 0.188 (4.78) 0.290 (7.37) 0.478 (12.14) 1.063 (27.00) 0.3125 (7.94)

E-686 0.687 (17.46) 0.687 (17.46) 0.259 (6.59) 0.325 (8.26) 0.584 (14.84) 1.188 (30.18) 0.375 (9.53)

E-816 0.812 (20.64) 0.830 (21.08) 0.313 (7.95) 0.378 (9.59) 0.691 (17.54) 1.438 (36.53) 0.500 (12.70)

E-1006 1.000 (25.40) 1.000 (25.40) 0.450 (11.43) 0.400 (10.16) 0.850 (21.59) 1.625 (41.28) 0.500-0.5625 (12.70-14.29)

E-1256 1.250 (31.75) 1.000 (25.40) 0.563 (14.30) 0.500 (12.69) 1.063 (26.99) 1.875 (47.63) 0.750 (19.05)

V-1625 1.625 (41.28) 1.125 (28.58) 0.631 (16.03) 0.750 (19.05) 1.381 (35.08) 2.250 (57.15) 0.875 (22.23)

E-2000 2.000 (50.80) 1.500 (38.10) 0.950 (24.13) 0.750 (19.05) 1.700 (43.18) 2.500 (63.50) 1.125 (28.58)

E-2500 2.500 (63.50) 2.500 (63.50) 1.125 (28.58) 1.000 (25.40) 2.125 (53.98) 3.375 (85.73) 1.375 (34.93)

E-3000 3.000 (76.20) 2.500 (63.50) 1.550 (39.37) 1.000 (25.40) 2.550 (64.77) 4.000 (101.60) 1.750 (44.45)

Above: First number shown in bold represents inches, metric dimensions (mm) are shown in parentheses. Notes:*Thickness of the seal wall and internal web

are not drawn to scale. 1 Maximum movement which seal will accommodate in joint with correct design. 2 A narrower opening will place excessive stress on the

seal and may cause premature failure. 3 A wider opening may not provide sufficient compressive force to hold the seal in place.** To be used as reference only.

Installed width may vary by project.

A

3/16” ± 1/16”

ASTM D2628 Delastic ® Preformed Pavement Seals Physical Requirements W

Properties Requirements ASTM Test Method

Tensile Strength, min., psi (mPa) 2000 (13.8) D412 B

Elongation at Break, min. % 250 D412

1/8” H

Hardness, Type A durometer, points 55±5 D2240 (modified)A

Oven Aging, 70 h at 212oF (100oC) D573

Tensile Strength, loss, max., % 20 max

Elongation, loss, max., % 20 max

Hardness, Type A durometer, points change 0 to +10

Oil Swell, ASTM Oil No. 3, 70 h at 212oF (100oC) **Typical joint design

for the “E” and “V”

Weight change, max., % 45 max D471

series pavement seals

Ozone Resistance:

20% strain, 300 pphm in air, 70 hr at 104oF(40oC) no cracks D1149 (modified)B

**Thickness of the seal wall and internal web are not drawn to

Low-Temperature Stiffening, 7 days at 14oF (-10oC), scale.

Hardness, Type A durometer, points change 0 to +15 D2240 A The term “modified” in the table relates to the specimen prepa-

ration. The use of joint seal as the specimen source requires that

Low-Temperature RecoveryC, 72 h at 14oF (-10oC), more plies than specified in either of the modified test procedures

50% Deflection, min., % 88 9.2D be used. Such specimen modification shall be agreed upon by the

purchaser and seller prior to testing. The hardness test shall be

Low-Temperature Recovery , 22 h at -20 F (-29 C),

C o o

made with the durometer in a durometer stand as recommended

50% Deflection, min., % 83 9.2D in Method D2240.

High-Temperature Recovery , 72 h at 212 F (100 C),

C o o B Test in accordance with Procedure A of D518.

50% Deflection, min., % 85 9.2D C Cracking, splitting or sticking of a specimen during a recovery

test shall mean that the specimen has failed the test.

Compression-Deflection, at 80% of Nominal Width,

min., lbf/in.(N/m) 3.5 (613) 9.3D D The reference sections are those of this specification.

Bridge the World with Leading Infrastructure Solutions

300 East Cherry Street • North Baltimore, OH 45872 | Telephone: 419.257.3561 • Fax: 419.257.2200 | www.dsbrown.com

You might also like

- Astm A319.370238-1Document2 pagesAstm A319.370238-1Fabio Augusto Hincapie Henao100% (1)

- Put An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamDocument8 pagesPut An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamjoseNo ratings yet

- VSL Tech Data PDFDocument29 pagesVSL Tech Data PDFhythamNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Calculation Sheet SubmittingDocument2 pagesCalculation Sheet SubmittingPloy Phoott NitthaNo ratings yet

- Datasheet: Delastic Preformed Compression SealsDocument2 pagesDatasheet: Delastic Preformed Compression SealsSaroj BhattaraiNo ratings yet

- B DPCS CharPropCVandCA DATA v024-WEBDocument2 pagesB DPCS CharPropCVandCA DATA v024-WEBguivc.ethernet.32No ratings yet

- FireStone EPDMDocument2 pagesFireStone EPDMAlaaGaballaNo ratings yet

- Grinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataDocument4 pagesGrinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataСергей КолесниковNo ratings yet

- Cold Shrink 8420Document3 pagesCold Shrink 8420PringetteNo ratings yet

- Doosan SD200 SpecDocument22 pagesDoosan SD200 SpecAndrea T FilottoNo ratings yet

- Material Datea 2.4602Document3 pagesMaterial Datea 2.4602Charwin XiaoNo ratings yet

- WaboFlex 1013 DataSheetDocument4 pagesWaboFlex 1013 DataSheetSean BrownNo ratings yet

- Pavement Seal DataDocument4 pagesPavement Seal Dataapi-3741340No ratings yet

- UPVC Pipe DIN 8062 TdsDocument3 pagesUPVC Pipe DIN 8062 TdsAdany AdenNo ratings yet

- 1118mm - Thickness Calculator For MS or DI PipesDocument8 pages1118mm - Thickness Calculator For MS or DI Pipesanirbanpwd76No ratings yet

- Datasheet PDFDocument1 pageDatasheet PDFFrizkaZaskiaNo ratings yet

- Stellite 12 Technical DataDocument2 pagesStellite 12 Technical DataJakeTheSnake69No ratings yet

- Joint 8Document1 pageJoint 8Muhammad RafiNo ratings yet

- LIT19142 PVRV 1220 1221 1222 1223 Data Sheet V3.2 WebDocument12 pagesLIT19142 PVRV 1220 1221 1222 1223 Data Sheet V3.2 Webcésar vásquez osorioNo ratings yet

- CANAN Steel Deck Catalogue - 2023Document48 pagesCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- Strands Area and Their Specifications PDFDocument2 pagesStrands Area and Their Specifications PDFLamin AungNo ratings yet

- Cut-Out Fuse (92123R3-P-D)Document1 pageCut-Out Fuse (92123R3-P-D)Genius DacpanoNo ratings yet

- JJP BrochuresDocument8 pagesJJP BrochuresarunjacobnNo ratings yet

- Stellite Grade 12-DatasheetDocument2 pagesStellite Grade 12-DatasheetNinad PawarNo ratings yet

- NIC Components NRE-L SeriesDocument5 pagesNIC Components NRE-L SeriesNICCompNo ratings yet

- An924 Rev. 14Document8 pagesAn924 Rev. 14David WongNo ratings yet

- SUPA75 Slickline Rev 29 May 18Document1 pageSUPA75 Slickline Rev 29 May 18hoss mosafaNo ratings yet

- Output Summary: SI UnitsDocument14 pagesOutput Summary: SI UnitsEduardoNo ratings yet

- 6 4029 - Print - 04 09 2015Document3 pages6 4029 - Print - 04 09 2015Shahzad AhmadNo ratings yet

- Teslin: Quick OverviewDocument3 pagesTeslin: Quick OverviewDewiNo ratings yet

- Renk Tds Floating Labyrinth Seal enDocument2 pagesRenk Tds Floating Labyrinth Seal enJaime Vanegas IriarteNo ratings yet

- Summary of Fluoropolymer Properties - 1Document1 pageSummary of Fluoropolymer Properties - 1Amir KhanNo ratings yet

- 3019PE enUS ASTMDocument1 page3019PE enUS ASTMgawronNo ratings yet

- Tuyau en Fonte Ductile Ekoval ChoixDocument52 pagesTuyau en Fonte Ductile Ekoval ChoixmmfayistNo ratings yet

- Flexible Termination System (FT-CAP), X7R Dielectric, 6.3 - 250 VDC, VW 80808 SpecificationDocument19 pagesFlexible Termination System (FT-CAP), X7R Dielectric, 6.3 - 250 VDC, VW 80808 SpecificationNhan NguyenNo ratings yet

- XXAAXXDocument8 pagesXXAAXXMuhammad Emirzan FirdausNo ratings yet

- Ancla Tubing in Ficha Tecnica-WeatherfordDocument3 pagesAncla Tubing in Ficha Tecnica-WeatherfordDaniel Eduardo Ramos RicardezNo ratings yet

- 129WP 37150 - 50310Document1 page129WP 37150 - 50310dip461No ratings yet

- 12.7 7 Wire Strand Proprieties VSLDocument1 page12.7 7 Wire Strand Proprieties VSLAbu BiduNo ratings yet

- ACFrOgAypEHHHz8R2vfmG YuaPpgX73CsQiypZuLjEu Yr6vp EAmbiSa5 XPpvMo7ROwndFW2ds KQyPPUJMLpvbra3qj OANBv26rNSIjRuEcdh5 9TCoyogqKWI1dXG6eNnExqI0CT6tHwdmwDocument39 pagesACFrOgAypEHHHz8R2vfmG YuaPpgX73CsQiypZuLjEu Yr6vp EAmbiSa5 XPpvMo7ROwndFW2ds KQyPPUJMLpvbra3qj OANBv26rNSIjRuEcdh5 9TCoyogqKWI1dXG6eNnExqI0CT6tHwdmwPrashanth TNo ratings yet

- Teslin TableDocument1 pageTeslin TableEzequiel FernandezNo ratings yet

- NIC Components NRM SeriesDocument1 pageNIC Components NRM SeriesNICCompNo ratings yet

- LYE Book Fitting ms1919Document16 pagesLYE Book Fitting ms1919khai rule100% (1)

- Prefabricated Vertical Drain For Soft Ground Improvement: Verti-Drain Is DAEHAN's Registered TrademarkDocument6 pagesPrefabricated Vertical Drain For Soft Ground Improvement: Verti-Drain Is DAEHAN's Registered Trademark김경모No ratings yet

- Wabo Flex 0208Document4 pagesWabo Flex 0208walidNo ratings yet

- SM Series: Aluminium Electrolytic CapacitorDocument2 pagesSM Series: Aluminium Electrolytic CapacitorStuxnetNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- DS EN877 Epoxy Cast Iron Pipes&fittingsDocument16 pagesDS EN877 Epoxy Cast Iron Pipes&fittingsVicky Bi -Dinsen Impex CorpNo ratings yet

- NIC Components NNR SeriesDocument5 pagesNIC Components NNR SeriesNICCompNo ratings yet

- NEPRO Conduit Pvc1Document16 pagesNEPRO Conduit Pvc1chaouch.najehNo ratings yet

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungNo ratings yet

- NIC Components NRE-LW SeriesDocument5 pagesNIC Components NRE-LW SeriesNICCompNo ratings yet

- High Voltage C0G Dielectric, 500 - 10,000 VDC (Commercial Grade)Document24 pagesHigh Voltage C0G Dielectric, 500 - 10,000 VDC (Commercial Grade)ndfgdfs oishdfNo ratings yet

- Catálogo - Tipo 21Document6 pagesCatálogo - Tipo 21Marcos Marcandali de JesusNo ratings yet

- Quality Lab & Offices of DD Sapphire: Publich Health (Bill of Quantities)Document1 pageQuality Lab & Offices of DD Sapphire: Publich Health (Bill of Quantities)Imran AzizNo ratings yet

- SSAB Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 enDocument4 pagesSSAB Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 enchristos032No ratings yet

- Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 en PDFDocument4 pagesData Sheet 2136 Docol 420LA 2016-11-25 317 371857150 en PDFchristos032No ratings yet

- Axial Leads/Spinguard: General DescriptionDocument6 pagesAxial Leads/Spinguard: General DescriptionΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNo ratings yet

- 5 Langkah Strategi Caleg MilenialDocument3 pages5 Langkah Strategi Caleg MilenialUnited Construction Est. TechnicalNo ratings yet

- Strategi Calon Legislatif Baru Menghadapi PemiluDocument15 pagesStrategi Calon Legislatif Baru Menghadapi PemiluUnited Construction Est. TechnicalNo ratings yet

- Safety Materials JNPDocument2 pagesSafety Materials JNPUnited Construction Est. TechnicalNo ratings yet

- Kedudukan Arbitrase Adalah Di Jakarta, Indonesia.Document3 pagesKedudukan Arbitrase Adalah Di Jakarta, Indonesia.United Construction Est. TechnicalNo ratings yet

- JNP Trading Company: Your Local Partner Serving QatarDocument2 pagesJNP Trading Company: Your Local Partner Serving QatarUnited Construction Est. TechnicalNo ratings yet

- Saran Untuk Caleg Yang Asal NgomongDocument1 pageSaran Untuk Caleg Yang Asal NgomongUnited Construction Est. TechnicalNo ratings yet

- Strategi Caleg Yang Asal NgomongDocument3 pagesStrategi Caleg Yang Asal NgomongUnited Construction Est. TechnicalNo ratings yet

- National Paint Qatar Dealer AuthDocument3 pagesNational Paint Qatar Dealer AuthUnited Construction Est. TechnicalNo ratings yet

- TerramDocument5 pagesTerramAlle LunagNo ratings yet

- Nvironmental Ampaign LAN: N T E ISO 14001 YDocument10 pagesNvironmental Ampaign LAN: N T E ISO 14001 YUnited Construction Est. TechnicalNo ratings yet

- SRPC Khaleej PCDocument2 pagesSRPC Khaleej PCUnited Construction Est. TechnicalNo ratings yet

- The Path Forward An Implementation Plan: Prepared by The American Forest & Paper Association 1999Document32 pagesThe Path Forward An Implementation Plan: Prepared by The American Forest & Paper Association 1999United Construction Est. TechnicalNo ratings yet

- Safety Data Sheet SRPC Khaleej PCDocument10 pagesSafety Data Sheet SRPC Khaleej PCUnited Construction Est. TechnicalNo ratings yet

- City of Gastonia Wastewater Treatment DivisionDocument14 pagesCity of Gastonia Wastewater Treatment DivisionLee OngNo ratings yet

- fAMOUS Culligan 7Document10 pagesfAMOUS Culligan 7United Construction Est. TechnicalNo ratings yet

- The Study of Minority Communities and The Waste Stream: October 2002Document100 pagesThe Study of Minority Communities and The Waste Stream: October 2002United Construction Est. TechnicalNo ratings yet

- Mining-Contract-Negotiations-For-Developing-Countries-Volume-1 - Iisd-HandbookDocument69 pagesMining-Contract-Negotiations-For-Developing-Countries-Volume-1 - Iisd-HandbookUnited Construction Est. TechnicalNo ratings yet

- Me AND kID 8Document2 pagesMe AND kID 8United Construction Est. TechnicalNo ratings yet

- Kids Culligan 3Document4 pagesKids Culligan 3United Construction Est. TechnicalNo ratings yet

- Contractual Arrangement - Uranium Te - 0468Document142 pagesContractual Arrangement - Uranium Te - 0468United Construction Est. TechnicalNo ratings yet

- You Can Give Your Customers Culligan WaterDocument2 pagesYou Can Give Your Customers Culligan WaterUnited Construction Est. TechnicalNo ratings yet

- Fruit Culligan 4Document4 pagesFruit Culligan 4United Construction Est. TechnicalNo ratings yet

- Area Culligan 2Document6 pagesArea Culligan 2United Construction Est. TechnicalNo ratings yet

- M Aterial Submittal For Domestic Water System DisinfectionDocument4 pagesM Aterial Submittal For Domestic Water System DisinfectionUnited Construction Est. TechnicalNo ratings yet

- Sopra: Product Data SheetDocument2 pagesSopra: Product Data SheetUnited Construction Est. TechnicalNo ratings yet

- Jotafloor Industrial Brochure - tcm132-91542Document16 pagesJotafloor Industrial Brochure - tcm132-91542United Construction Est. TechnicalNo ratings yet

- General Specification of Mainlaying Materials - 2005Document77 pagesGeneral Specification of Mainlaying Materials - 2005babmech6007No ratings yet

- Area Culligan 2Document6 pagesArea Culligan 2United Construction Est. TechnicalNo ratings yet

- Jotafloor Easy Painting Guide For Concrete Floors - tcm40 5703 PDFDocument8 pagesJotafloor Easy Painting Guide For Concrete Floors - tcm40 5703 PDFaljarrah84No ratings yet

- IN50660B Merino Panel Product ISO 14001Document1 pageIN50660B Merino Panel Product ISO 14001United Construction Est. TechnicalNo ratings yet

- ScanningElectronMicros PDFDocument13 pagesScanningElectronMicros PDFAbhishek GaurNo ratings yet

- US6040283 Concentrated Alkaline Glutaraldehyde Phenolic DisinfectantDocument5 pagesUS6040283 Concentrated Alkaline Glutaraldehyde Phenolic DisinfectantAyu WinarniNo ratings yet

- CHAPTER I-WPS OfficeDocument25 pagesCHAPTER I-WPS OfficeLynlyn BagacinaNo ratings yet

- Compressive Strength of Geopolymer Bricks From Mine TailingsDocument29 pagesCompressive Strength of Geopolymer Bricks From Mine TailingsJerrick Wayne VertudazoNo ratings yet

- Biology Unit 2 For Cape ExaminationsDocument11 pagesBiology Unit 2 For Cape ExaminationsTrishannNo ratings yet

- RHIZOSPHERE Project WorkDocument22 pagesRHIZOSPHERE Project WorkAniekeme GabrielNo ratings yet

- MilkDocument54 pagesMilkmonangNo ratings yet

- Fusetex Rubber Bonding ProcessDocument23 pagesFusetex Rubber Bonding ProcessA31fordNo ratings yet

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument3 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company IdentificationTOPS SYNERGIST CO.,LTDNo ratings yet

- Class 10 Chapter 2 Science Notes Acids, Bases, and SaltsDocument18 pagesClass 10 Chapter 2 Science Notes Acids, Bases, and SaltsJapani TutorNo ratings yet

- c1 Revision Notes - Set 1 OnlyDocument10 pagesc1 Revision Notes - Set 1 Onlyapi-320022467No ratings yet

- Mohdyunus,+Journal+Manager,+JEMAT+VOL+6+NO+1 PAPER+4 PROBIT+Pp+21-23Document3 pagesMohdyunus,+Journal+Manager,+JEMAT+VOL+6+NO+1 PAPER+4 PROBIT+Pp+21-23Adelia RahmaNo ratings yet

- Pharmaceutical PowdersDocument72 pagesPharmaceutical Powdersvidyasreedm151No ratings yet

- Flotation of AntimonyDocument13 pagesFlotation of AntimonyAbdul Rafeh AijazNo ratings yet

- Metabolism Poster AssignmentDocument6 pagesMetabolism Poster AssignmentMuhammad Najam AbbasNo ratings yet

- Emmission and Peformance Analysis of The Ternary DDocument21 pagesEmmission and Peformance Analysis of The Ternary DSHYAM SUNDARNo ratings yet

- Aci Design PDFDocument91 pagesAci Design PDFSufyan SafiNo ratings yet

- A Study On Mechanical Behaviour of Hair Fiber Reinforced Epoxy CompositesDocument26 pagesA Study On Mechanical Behaviour of Hair Fiber Reinforced Epoxy CompositesSarabjot AzrotNo ratings yet

- 1798-305-RC-0-B Packing ProcedureDocument28 pages1798-305-RC-0-B Packing ProcedureBrain AliveNo ratings yet

- Trichomes: What Is A TrichomeDocument7 pagesTrichomes: What Is A Trichomejose gomezNo ratings yet

- Methamphetamine From Ephedrine Tablets - Breaking BadDocument10 pagesMethamphetamine From Ephedrine Tablets - Breaking BadIgnacio BeltránNo ratings yet

- Department of Education: Republic of The PhilippinesDocument5 pagesDepartment of Education: Republic of The Philippinesjohn carlo rollonNo ratings yet

- Radioactive Minerals of IndiaDocument24 pagesRadioactive Minerals of IndiaNaveenNo ratings yet

- Design of A Plant For The Production of 16,000 Metric Tonnes of Bio-Methanol Per Annum From WoodDocument13 pagesDesign of A Plant For The Production of 16,000 Metric Tonnes of Bio-Methanol Per Annum From WoodInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Applied Clay Science: Peng Yuan, Daoyong Tan, Faïza Annabi-BergayaDocument19 pagesApplied Clay Science: Peng Yuan, Daoyong Tan, Faïza Annabi-BergayaAzri RahmadiNo ratings yet

- Biology Grade 11 Mock Exam Paper 1Document7 pagesBiology Grade 11 Mock Exam Paper 1Nicketa AndersonNo ratings yet

- Resina EpoxicaDocument5 pagesResina Epoxicaluis3286No ratings yet

- MSDS FG-460Document10 pagesMSDS FG-460CARLOS LEONNo ratings yet

- Foodpro Epdm Materials enDocument8 pagesFoodpro Epdm Materials enJesus D. Gutierrez G.No ratings yet