Professional Documents

Culture Documents

350z Electric

Uploaded by

Adan Flores CorreaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

350z Electric

Uploaded by

Adan Flores CorreaCopyright:

Available Formats

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

K ELECTRICAL

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

SECTION PG B

E

CONTENTS

PRECAUTIONS .......................................................... 3 GROUND ................................................................... 30 F

Precautions for Battery Service ................................ 3 Ground Distribution ................................................. 30

POWER SUPPLY ROUTING CIRCUIT ...................... 4 MAIN HARNESS ................................................. 30

Schematic ................................................................ 4 ENGINE ROOM HARNESS ................................ 32 G

Wiring Diagram — POWER — ................................. 5 ENGINE CONTROL HARNESS .......................... 35

BATTERY POWER SUPPLY — IGNITION SW. BODY HARNESS ................................................ 37

IN ANY POSITION ................................................ 5 BODY NO. 2 HARNESS ..................................... 42

H

ACCESSORY POWER SUPPLY — IGNITION TAIL HARNESS ................................................... 43

SW. IN “ACC” OR “ON” ....................................... 10 BACK DOOR HARNESS .................................... 45

IGNITION POWER SUPPLY — IGNITION SW. HARNESS ................................................................. 46

IN “ON” AND/OR “START” ...................................11 Harness Layout ...................................................... 46 I

Fuse ....................................................................... 16 HOW TO READ HARNESS LAYOUT ................. 46

Fusible Link ............................................................ 16 OUTLINE ............................................................. 47

Circuit Breaker ....................................................... 16 MAIN HARNESS ................................................. 48 J

IPDM E/R (INTELLIGENT POWER DISTRIBUTION ENGINE ROOM HARNESS ................................ 50

MODULE ENGINE ROOM) ...................................... 17 ENGINE CONTROL HARNESS .......................... 54

System Description ................................................ 17 BODY HARNESS ................................................ 57

PG

SYSTEMS CONTROLLED BY IPDM E/R ........... 17 BODY NO. 2 HARNESS ..................................... 62

CAN COMMUNICATION LINE CONTROL ......... 17 TAIL HARNESS ................................................... 63

IPDM E/R STATUS CONTROL ........................... 18 TAIL NO. 2 HARNESS ........................................ 66

CAN Communication System Description .............. 18 ROOM LAMP HARNESS .................................... 67 L

CAN Communication Unit ...................................... 18 DOOR HARNESS ............................................... 69

Function of Detecting Ignition Relay Malfunction ... 18 Wiring Diagram Codes (Cell Codes) ...................... 71

CONSULT-II Function (IPDM E/R) ......................... 19 ELECTRICAL UNITS LOCATION ............................ 74 M

CONSULT-II BASIC OPERATION ....................... 19 Electrical Units Location ......................................... 74

SELF-DIAG RESULTS ........................................ 20 ENGINE COMPARTMENT .................................. 74

DATA MONITOR ................................................. 21 PASSENGER COMPARTMENT ......................... 75

ACTIVE TEST ..................................................... 22 LUGGAGE COMPARTMENT .............................. 78

Auto Active Test ..................................................... 23 HARNESS CONNECTOR ......................................... 80

DESCRIPTION .................................................... 23 Description .............................................................. 80

OPERATION PROCEDURE ............................... 23 HARNESS CONNECTOR (TAB-LOCKING

INSPECTION IN AUTO ACTIVE TEST MODE ... 23 TYPE) .................................................................. 80

Schematic .............................................................. 25 HARNESS CONNECTOR (SLIDE-LOCKING

IPDM E/R Terminal Arrangement ........................... 26 TYPE) .................................................................. 81

IPDM E/R Power/Ground Circuit Inspection .......... 27 ELECTRICAL UNITS ................................................ 82

Inspection With CONSULT-II (Self-Diagnosis) ....... 28 Terminal Arrangement ............................................ 82

Removal and Installation of IPDM E/R ................... 29 SMJ (SUPER MULTIPLE JUNCTION) ..................... 84

REMOVAL ........................................................... 29 Terminal Arrangement ............................................ 84

INSTALLATION ................................................... 29

Revision: 2004 December PG-1 2005 350Z

STANDARDIZED RELAY .......................................... 86 FUSE BLOCK - JUNCTION BOX (J/B) ....................88

Description .............................................................. 86 Terminal Arrangement .............................................88

NORMAL OPEN, NORMAL CLOSED AND FUSE, FUSIBLE LINK AND RELAY BOX ................89

MIXED TYPE RELAYS ........................................ 86 Terminal Arrangement .............................................89

TYPE OF STANDARDIZED RELAYS .................. 86

Revision: 2004 December PG-2 2005 350Z

PRECAUTIONS

PRECAUTIONS PFP:00001

A

Precautions for Battery Service AKS00AV9

Before disconnecting the battery, lower both the driver and passenger windows. This will prevent any interfer-

ence between the window edge and the vehicle when the door is opened/closed. During normal operation, the B

window slightly raises and lowers automatically to prevent any window to vehicle interference. The automatic

window function will not work with the battery disconnected.

C

PG

Revision: 2004 December PG-3 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

POWER SUPPLY ROUTING CIRCUIT PFP:24110

Schematic AKS0012B

TKWT3243E

Revision: 2004 December PG-4 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

Wiring Diagram — POWER — AKS0012C

BATTERY POWER SUPPLY — IGNITION SW. IN ANY POSITION A

PG

TKWT2521E

Revision: 2004 December PG-5 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

TKWT2348E

Revision: 2004 December PG-6 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

PG

TKWT1642E

Revision: 2004 December PG-7 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

TKWT1643E

Revision: 2004 December PG-8 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

PG

TKWT3244E

Revision: 2004 December PG-9 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

ACCESSORY POWER SUPPLY — IGNITION SW. IN “ACC” OR “ON”

TKWT2349E

Revision: 2004 December PG-10 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

IGNITION POWER SUPPLY — IGNITION SW. IN “ON” AND/OR “START”

A

PG

TKWT2350E

Revision: 2004 December PG-11 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

TKWM1379E

Revision: 2004 December PG-12 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

PG

TKWT2522E

Revision: 2004 December PG-13 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

TKWT1649E

Revision: 2004 December PG-14 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

PG

TKWB0268E

Revision: 2004 December PG-15 2005 350Z

POWER SUPPLY ROUTING CIRCUIT

Fuse AKS0012D

● If fuse is blown, be sure to eliminate cause of malfunction before

installing new fuse.

● Use fuse of specified rating. Never use fuse of more than speci-

fied rating.

● Do not partially install fuse; always insert it into fuse holder prop-

erly.

● Remove fuse for “ELECTRICAL PARTS (BAT)” if vehicle is not

used for a long period of time.

CEL083

Fusible Link AKS0012E

A melted fusible link can be detected either by visual inspection or by

feeling with finger tip. If its condition is questionable, use circuit

tester or test lamp.

CAUTION:

● If fusible link should melt, it is possible that critical circuit

(power supply or large current carrying circuit) is shorted.

In such a case, carefully check and eliminate cause of mal-

function.

● Never wrap outside of fusible link with vinyl tape. Important:

Never let fusible link touch any other wiring harness, vinyl

or rubber parts. CKIT0163E

Circuit Breaker AKS0012F

The PTC thermistor generates heat in response to current flow. The

temperature (and resistance) of the thermistor element varies with

current flow. Excessive current flow will cause the element's temper-

ature to rise. When the temperature reaches a specified level, the

electrical resistance will rise sharply to control the circuit current.

Reduced current flow will cause the element to cool. Resistance falls

accordingly and normal circuit current flow is allowed to resume.

SEL109W

Revision: 2004 December PG-16 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PFP:284B7 A

System Description AKS00A2H

● IPDM E/R (Intelligent Power Distribution Module Engine Room) integrates the relay box and fuse block B

which were originally placed in engine room. It controls integrated relay via IPDM E/R control circuit.

● IPDM E/R-integrated control circuit performs ON-OFF operation of relay, CAN communication control,

hood switch signal reception, etc.

C

● It controls operation of each electrical part via ECM, BCM and CAN communication lines.

CAUTION:

None of the IPDM E/R-integrated relays can be removed.

D

SYSTEMS CONTROLLED BY IPDM E/R

1. Lamp control

Using CAN communication line, it receives signal from BCM and controls the following lamps: E

● Headlamps (Hi, Lo)

● Parking lamps

● Tail lamps F

● License plate lamps

2. Wiper control

Using CAN communication line, it receives signals from BCM and controls the front wipers. G

3. Rear window defogger relay control

Using CAN communication line, it receives signals from BCM and controls the rear window defogger

relay. H

4. A/C compressor control

Using CAN communication line, it receives signals from ECM and controls the A/C relay.

5. Cooling fan control I

Using CAN communication line, it receives signals from ECM and controls cooling fan relay.

CAN COMMUNICATION LINE CONTROL

With CAN communication, by connecting each control unit using two communication lines (CAN L line, CAN H J

line), it is possible to transmit maximum amount of information with minimum wiring. Each control unit can

transmit and receive data, and reads necessary information only.

1. Fail-safe control PG

● When CAN communication with other control units is impossible, IPDM E/R performs fail-safe control.

After CAN communication recovers normally, it also returns to normal control.

● Operation of control parts by IPDM E/R during fail-safe mode is as follows:

L

Controlled system Fail-safe mode

● With the ignition switch ON, the headlamp (low) is ON. M

Headlamp

● With the ignition switch OFF, the headlamp (low) is OFF.

● With the ignition switch ON, the tail and parking lamps is ON.

Tail and parking lamps

● With the ignition switch OFF, the tail and parking lamps is OFF.

● With the ignition switch ON, the cooling fan HI operates.

Cooling fan

● With the ignition switch OFF, the cooling fan stops.

Until the ignition switch is turned off, the front wiper LO and HI remains in the same status it

Front wiper

was in just before fail−safe control was initiated.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C compressor OFF

Revision: 2004 December PG-17 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R STATUS CONTROL

In order to save power, IPDM E/R switches status by itself based on each operating condition.

1. CAN communication status

● CAN communication is normally performed with other control units.

● Individual unit control by IPDM E/R is normally performed.

● When sleep request signal is received from BCM, mode is switched to sleep waiting status.

2. Sleep waiting status

● Process to stop CAN communication is activated.

● All systems controlled by IPDM E/R are stopped. When 3 seconds have elapsed after CAN communi-

cation with other control units is stopped, mode switches to sleep status.

3. Sleep status

● IPDM E/R operates in low power mode.

● CAN communication is stopped.

● When a change in CAN communication line is detected, mode switches to CAN communication status.

● When a change hood switch or ignition switch signal is detected, mode switches to CAN communica-

tion status.

CAN Communication System Description AKS00A2I

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Modern

vehicles are equipped with many electronic control units and each control unit shares information and links

with other control units during operation (not independent). In CAN communication, control units are con-

nected with 2 communication lines (CAN H line, CAN L line) allowing a high rate of information transmission

with less wiring. Each control unit transmits/receives data but selectively reads required data only.

CAN Communication Unit AKS00A2J

Refer to LAN-21, "CAN Communication Unit" .

Function of Detecting Ignition Relay Malfunction AKS00A2K

● When contact point of integrated ignition relay is stuck and cannot be turned OFF, IPDM E/R turns ON tail

and parking lamps for 10 minutes to indicate ignition relay malfunction.

● When a state of ignition relay having built-in does not agree with a state of Ignition switch signal input by a

CAN communication from BCM, IPDM E/R lets tail lamp relay operate.

Ignition switch signal Ignition relay status Tail lamp relay

ON ON —

OFF OFF —

ON OFF —

OFF ON ON (10 minutes)

NOTE:

When the ignition switch is turned ON, the tail lamp is OFF.

Revision: 2004 December PG-18 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

CONSULT-II Function (IPDM E/R) AKS00A2L

A

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

Inspection Item, Diagnosis Mode Description

SELF-DIAG RESULTS The IPDM E/R performs diagnosis of the CAN communication and self-diagnosis. B

DATA MONITOR The input/output data of the IPDM E/R is displayed in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

C

ACTIVE TEST The IPDM E/R sends a drive signal to electronic components to check their operation.

CONSULT-II BASIC OPERATION

D

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. With the ignition switch OFF, connect CONSULT-II and CON- E

SULT-II CONVERTER to the data link connector, then turn the

ignition switch ON.

F

H

PBIB1069E

2. Touch “START (NISSAN BASED VHCL)”.

I

PG

BCIA0029E

L

3. Touch “IPDM E/R” on “SELECT SYSTEM” screen.

If “IPDM E/R” is not displayed, refer to GI-39, "CONSULT-II Data

Link Connector (DLC) Circuit" . M

BCIA0030E

Revision: 2004 December PG-19 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

4. Select the desired part to be diagnosed on the “SELECT DIAG

MODE” screen.

BCIA0031E

SELF-DIAG RESULTS

Operation Procedure

1. Touch “SELF-DIAG RESULTS” on “SELECT DIAG MODE” screen.

2. Check display content in self-diagnostic results.

Display Item List

CONSULT-II TIME

Display Items Malfunction detecting condition Possible causes

display code CRNT PAST

NO DTC IS

DETECTED.FURTHER

- - - - -

TESTING MAY BE

REQUIRED.

● If CAN communication reception/transmis- Any of or several items

sion data has a malfunction, or if any of the below have errors.

control units malfunction, data reception/

CAN COMM CIRC U1000 transmission cannot be confirmed. × × ● TRANSMIT DIAG

● ECM

● When the data in CAN communication is not

received before the specified time ● BCM/SEC

NOTE:

The details for display of the period are as follows:

● CRNT: Error currently detected with IPDM E/R.

● PAST: Error detected in the past and memorized with IPDM E/R.

Revision: 2004 December PG-20 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

DATA MONITOR

Operation Procedure A

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on the “SELECT MONITOR

ITEM” screen. B

ALL SIGNALS All items will be monitored.

MAIN SIGNALS Monitor the predetermined item. C

SELECTION FROM MENU Select any item for monitoring.

3. Touch the required monitoring item on “SELECTION FROM MENU”. In “ALL SIGNALS”, all items are

monitored. In “MAIN SIGNALS”, predetermined items are monitored. D

4. Touch “START”.

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”. E

All Items, Main Items, Selection From Menu

SELECT MONITOR ITEM F

CONSULT-II screen SELEC-

Item name Display or unit ALL MAIN Description

display TION

SIG- SIG-

FROM

NALS NALS G

MENU

Motor fan request MOTOR FAN REQ 1/2/3/4 × × × Signal status input from ECM

Compressor request AC COMP REQ ON/OFF × × × Signal status input from ECM H

Tail & clear request TAIL&CLR REQ ON/OFF × × × Signal status input from BCM

H/L LO request HL LO REQ ON/OFF × × × Signal status input from BCM

H/L HI request HL HI REQ ON/OFF × × × Signal status input from BCM I

Front fog request FR FOG REQ*1 ON/OFF × × × —

Head lamp washer J

HL WASHER REQ*1 ON/OFF × × —

request

STOP/1LOW/

Front wiper request FR WIP REQ × × × Signal status input from BCM

LOW/HI

PG

Wiper auto stop WIP AUTO STOP ACT P/STOP P × × × Output status of IPDM E/R

Wiper protection WIP PROT OFF/Block × × × Control status of IPDM E/R

Starter request ST RLY REQ*2 ON/OFF × × Status of input signal L

Ignition relay status monitored

Ignition relay status IGN RLY ON/OFF × × ×

with IPDM E/R

Rear window defogger

M

RR DEF REQ ON/OFF × × × Signal status input from BCM

request

Oil pressure switch OIL P SW *1 OPEN/CLOSE × × —

Day time light request DTRL REQ*1 ON/OFF × × —

Hood switch HOOD SW*1 ON/OFF × × —

Theft warning horn

THFT HRN REQ ON/OFF × × Signal status input from BCM

request

Horn chirp HORN CHIRP ON/OFF × × Output status of IPDM E/R

NOTE:

● Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the display may not be cor-

rect.

● *1: This items is displayed, but does not function.

● *2: The vehicle without intelligent key system displays only ON without change.

Revision: 2004 December PG-21 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

ACTIVE TEST

Operation Procedure

1. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Touch item to be tested.

3. Touch “START”, and confirm its operation.

4. Touch “STOP” while testing to stop the operation.

Test item CONSULT-II screen display Description

With a certain ON-OFF operation, the tail lamp relay can be oper-

Tail lamp operation TAIL LAMP

ated.

Rear window defogger opera- With a certain ON-OFF operation, the rear window defogger relay

REAR DEFOGGER

tion can be operated.

With a certain operation (OFF, HI ON, LO ON), the front wiper relay

Front wiper (HI, LO) operation FRONT WIPER

(Lo, Hi) can be operated.

Cooling fan operation MOTOR FAN With a certain operation (1,2,3,4), the cooling fan can be operated.

Headlamp washer NOTE 1 HEAD LAMP WASHER —

Lamp (HI, LO, FOG NOTE 2 ) With a certain operation (OFF, HI ON, LO ON, FOG ON NOTE ), the

LAMPS

operation lamp relay (Lo, Hi, Fog NOTE ) can be operated.

Horn operation HORN Push “ON” button, horn relay operates 20ms.

NOTE:

1. Headlamp washer item is displayed, but it cannot be tested.

2. Fog lamp item is displayed, but it cannot be tested.

Revision: 2004 December PG-22 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Auto Active Test AKS00A2M

DESCRIPTION A

In auto active test mode, operation inspection can be performed when IPDM E/R sends a drive signal to the

following systems:

● Rear window defogger B

● Front wipers

● Tail lamps and parking lamps

C

● Headlamps (Hi, Lo)

● A/C compressor (magnetic clutch)

● Cooling fan D

OPERATION PROCEDURE

1. Close hood and front door (passenger side), and then lift wiper arms away from windshield (to prevent

glass damage by wiper operation). E

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF. F

3. Turn ignition switch ON, and, within 20 seconds, press drivers front door switch 10 times (close other

door). Then turn ignition switch OFF.

4. Turn ignition switch ON within 10 seconds after ignition switch OFF. G

5. When auto active test mode is actuated.

6. After a series of operations is repeated three times, auto active test is completed.

NOTE: H

When auto active test mode has to be cancelled halfway, turn ignition switch OFF.

CAUTION:

Be sure to inspect BL-39, "Door Switch Check" when the auto active test cannot be performed. I

INSPECTION IN AUTO ACTIVE TEST MODE

When auto active test mode is actuated, the following eight steps are repeated three times. J

PG

PKIB6170E

NOTE:

It takes 10 seconds from 3 to 4.

Revision: 2004 December PG-23 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Concept of Auto Active Test

● IPDM E/R actuates auto active test mode when it receives door switch signal from BCM via CAN commu-

nication line. Therefore, when auto active test mode is activated successfully, CAN communication

between IPDM E/R and BCM is normal.

● If any of systems controlled by IPDM E/R cannot be operated, possible cause can be easily diagnosed

using auto active test.

Diagnosis chart in auto active test mode

Symptom Inspection contents Possible cause

YES ● BCM signal input circuit

Perform auto active

Rear window defogger test. Does rear win- ● Rear window defogger relay circuit

does not operate. dow defogger oper- NO ● Open circuit of rear window defogger

ate?

● IPDM E/R malfunction

YES ● BCM signal input system

Any of front wipers, tail

and parking lamps, Perform auto active ● Lamp/wiper motor malfunction

front fog lamps, and test. Does system in ● Lamp/wiper motor ground circuit malfunction

head lamps (Hi, Lo) do question operate? NO

● Harness/connector malfunction between IPDM E/R and system in question

not operate.

● IPDM E/R (integrated relay) malfunction

● BCM signal input circuit

YES ● CAN communication signal between BCM and ECM.

Perform auto active ● CAN communication signal between ECM and IPDM E/R

A/C compressor does

test. Does magnetic

not operate. ● Magnetic clutch malfunction

clutch operate?

NO ● Harness/connector malfunction between IPDM E/R and magnetic clutch

● IPDM E/R (integrated relay) malfunction

● ECM signal input circuit

YES

● CAN communication signal between ECM and IPDM E/R

Perform auto active

Cooling fan does not

test. Does cooling ● Cooling fan motor malfunction

operate.

fan operate? NO ● Harness/connector malfunction between IPDM E/R and cooling fan motor

● IPDM E/R (integrated relay) malfunction

Revision: 2004 December PG-24 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Schematic AKS00A2N

PG

TKWT2351E

Revision: 2004 December PG-25 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R Terminal Arrangement AKS00A2O

CKIT0537E

Revision: 2004 December PG-26 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R Power/Ground Circuit Inspection AKS00A2P

1. CHECK FUSE AND FUSIBLE LINK A

Make sure the following fusible links or IPDM E/R fuses are not blown.

Terminal No. Signal name Fuse and fusible link No. B

C

E

1, 2 Battery power C

71

78

OK or NG D

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. E

2. CHECK POWER SUPPLY CIRCUIT

F

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector E3.

3. Check voltage between IPDM E/R harness connector E3 termi-

G

nals 1 (W), 2 (W/L) and ground.

1, 2 – Ground : Battery voltage

OK or NG H

OK >> GO TO 3.

NG >> Replace IPDM E/R power supply circuit harness.

I

PKIB6562E

3. CHECK GROUND CIRCUIT

J

1. Disconnect IPDM E/R harness connectors E8 and E9.

2. Check continuity between IPDM E/R harness connectors E8 ter-

minal 38 (B), E9 terminal 50 (B), 60 (B) and ground. PG

38, 50, 60 – Ground : Continuity should exist.

OK or NG L

OK >> INSPECTION END

NG >> Replace ground circuit harness of IPDM E/R.

M

SKIA6184E

Revision: 2004 December PG-27 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Inspection With CONSULT-II (Self-Diagnosis) AKS00A2Q

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. CHECK SELF DIAGNOSTIC RESULT

1. Connect CONSULT-II and select “IPDM E/R” on the Diagnosis System Selection screen.

2. Select “SELF-DIAG RESULTS” on the “SELECT DIAG MODE” screen.

3. Check display content in self diagnostic results.

CONSULT-II TIME

CONSULT-II display Details of diagnosis result

display code CRNT PAST

NO DTC IS DETECTED.

- - - No malfunction

FURTHER TESTING MAY BE REQUIRED.

Any of or several items below have errors.

● TRANSMIT DIAG

CAN COMM CIRC U1000 × ×

● ECM

● BCM/SEC

NOTE:

The details for display of the period are as follows:

● CRNT: Error currently detected with IPDM E/R.

● PAST: Error detected in the past and memorized with IPDM E/R.

Contents displayed

NO DTC IS DETECTED.FURTHER TESTING MAY BE REQUIRED.>>INSPECTION END

CAN COMM CIRC>>After print-out of the monitor items, refer to LAN-3, "Precautions When Using CON-

SULT-II" .

Revision: 2004 December PG-28 2005 350Z

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Removal and Installation of IPDM E/R AKS00A2R

REMOVAL A

1. Remove battery. Refer to SC-9, "Removal and Installation" in “Starting and Charging System (SC)” sec-

tion.

2. Remove IPDM E/R cover A. While pressing pawl on backside of B

IPDM E/R cover B toward vehicle front to unlock, lift up IPDM E/

R.

C

SKIA4968E

E

SKIA1902E

I

3. While pressing pawls on right and left side of IPDM E/R, remove

IPDM E/R cover B from IPDM E/R.

4. Remove harness connector from IPDM E/R. J

PG

L

SKIA4969E

INSTALLATION M

Installation is the reverse order of removal.

Revision: 2004 December PG-29 2005 350Z

GROUND

GROUND PFP:00011

Ground Distribution AKS0012P

MAIN HARNESS

CKIT0538E

Revision: 2004 December PG-30 2005 350Z

GROUND

PG

CKIT0539E

Revision: 2004 December PG-31 2005 350Z

GROUND

ENGINE ROOM HARNESS

CKIT0456E

Revision: 2004 December PG-32 2005 350Z

GROUND

PG

CKIB0202E

Revision: 2004 December PG-33 2005 350Z

GROUND

CKIT0170E

Revision: 2004 December PG-34 2005 350Z

GROUND

ENGINE CONTROL HARNESS

A

PG

CKIB0204E

Revision: 2004 December PG-35 2005 350Z

GROUND

CKIT0646E

Revision: 2004 December PG-36 2005 350Z

GROUND

BODY HARNESS

Coupe Models A

PG

CKIT0459E

Revision: 2004 December PG-37 2005 350Z

GROUND

CKIT0174E

Revision: 2004 December PG-38 2005 350Z

GROUND

Roadster Models

A

PG

CKIT0460E

Revision: 2004 December PG-39 2005 350Z

GROUND

CKIT0470E

Revision: 2004 December PG-40 2005 350Z

GROUND

PG

CKIT0174E

Revision: 2004 December PG-41 2005 350Z

GROUND

BODY NO. 2 HARNESS

CKIT0540E

Revision: 2004 December PG-42 2005 350Z

GROUND

TAIL HARNESS

Coupe Models A

PG

CKIT0462E

Revision: 2004 December PG-43 2005 350Z

GROUND

Roadster Models

CKIT0471E

Revision: 2004 December PG-44 2005 350Z

GROUND

BACK DOOR HARNESS

A

PG

CKIT0464E

Revision: 2004 December PG-45 2005 350Z

HARNESS

HARNESS PFP:00011

Harness Layout AKS0012Q

HOW TO READ HARNESS LAYOUT

The following Harness Layouts use a map style grid to help locate

connectors on the figures:

● Main Harness

● Engine Room Harness (Engine Compartment)

● Engine Control Harness (Engine Compartment)

● Body Harness

● Tail Harness

SEL252V

To Use the Grid Reference

1. Find the desired connector number on the connector list.

2. Find the grid reference.

3. On the figure, find the crossing of the grid reference letter column and number row.

4. Find the connector number in the crossing zone.

5. Follow the line (if used) to the connector.

CONNECTOR SYMBOL

Main symbols of connector (in Harness Layout) are indicated in the below.

CKIT0108E

Revision: 2004 December PG-46 2005 350Z

HARNESS

OUTLINE

Coupe Models A

I

TKIT0198E

Roadster Models

J

PG

TKIT0101E

Revision: 2004 December PG-47 2005 350Z

HARNESS

MAIN HARNESS

TKIT0287E

Revision: 2004 December PG-48 2005 350Z

HARNESS

PG

TKIT0288E

Revision: 2004 December PG-49 2005 350Z

HARNESS

ENGINE ROOM HARNESS

Engine Compartment

TKIT0289E

Revision: 2004 December PG-50 2005 350Z

HARNESS

PG

TKIT0290E

Revision: 2004 December PG-51 2005 350Z

HARNESS

Passenger Compartment

TKIT0291E

Revision: 2004 December PG-52 2005 350Z

HARNESS

Battery Cable

A

PG

CKIT0202E

Revision: 2004 December PG-53 2005 350Z

HARNESS

ENGINE CONTROL HARNESS

Engine Compartment

TKIT0423E

Revision: 2004 December PG-54 2005 350Z

HARNESS

PG

TKIT0424E

Revision: 2004 December PG-55 2005 350Z

HARNESS

Passenger Compartment

TKIT0425E

Revision: 2004 December PG-56 2005 350Z

HARNESS

BODY HARNESS

Coupe Models A

PG

TKIT0294E

Revision: 2004 December PG-57 2005 350Z

HARNESS

TKIT0295E

Revision: 2004 December PG-58 2005 350Z

HARNESS

Roadster Models

A

PG

TKIT0296E

Revision: 2004 December PG-59 2005 350Z

HARNESS

TKIT0297E

Revision: 2004 December PG-60 2005 350Z

HARNESS

PG

TKIT0117E

Revision: 2004 December PG-61 2005 350Z

HARNESS

BODY NO. 2 HARNESS

TKIT0226E

Revision: 2004 December PG-62 2005 350Z

HARNESS

TAIL HARNESS

Coupe Models A

PG

TKIT0298E

Revision: 2004 December PG-63 2005 350Z

HARNESS

Roadster Models

TKIT0299E

Revision: 2004 December PG-64 2005 350Z

HARNESS

PG

TKIT0300E

Revision: 2004 December PG-65 2005 350Z

HARNESS

TAIL NO. 2 HARNESS

Roadster Models

TKIT0113E

Revision: 2004 December PG-66 2005 350Z

HARNESS

ROOM LAMP HARNESS

Coupe Models A

PG

TKIT0301E

Revision: 2004 December PG-67 2005 350Z

HARNESS

Roadster Models

TKIT0302E

Revision: 2004 December PG-68 2005 350Z

HARNESS

DOOR HARNESS

Driver Side Door A

I

TKIM0204E

Passenger Side Door

J

PG

TKIM0205E

Revision: 2004 December PG-69 2005 350Z

HARNESS

Back Door

TKIT0068E

Revision: 2004 December PG-70 2005 350Z

HARNESS

Wiring Diagram Codes (Cell Codes) AKS00A3P

A

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

B

Code Section Wiring Diagram Name

3METER DI Triple Meter

ABS BRC Anti-Lock Brake System C

A/C ATC Air Conditioner

AF1B1 EC Air Fuel Ratio Sensor 1 Bank 1

AF1B2 EC Air Fuel Ratio Sensor 1 Bank 2

D

AF1HB1 EC Air Fuel Ratio Sensor 1 Heater Bank 1

AF1HB2 EC Air Fuel Ratio Sensor 1 Heater Bank 2 E

APPS1 EC Accelerator Pedal Position Sensor

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor F

ASC/BS EC Automatic Speed Control Device (ASCD) Brake Switch

ASC/SW EC Automatic Speed Control Device (ASCD) Steering Switch

G

ASCBOF EC Automatic Speed Control Device (ASCD) Brake Switch

ASCIND EC Automatic Speed Control Device (ASCD) Indicator

AT/IND DI A/T Indicator Lamp H

AUDIO AV Audio

BACK/L LT Back-Up Lamp

I

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN EC CAN Communication Line J

CAN LAN CAN System

CHARGE SC Charging System

PG

CHIME DI Warning Chime

CLOCK DI Clock

COMBSW LT Combination Switch L

COMM AV Audio Visual Communication Line

COOL/F EC Cooling Fan Control

DEF GW Rear Window Defogger M

D/LOCK BL Power Door Lock

DTRL LT Headlamp - With Daytime Light System

ECM/PW EC ECM Power Supply for Back-Up

ECTS EC Engine Coolant Temperature Sensor

ETC1 EC Electric Throttle Control Function

ETC2 EC Electric Throttle Control Motor Relay

ETC3 EC Electric Throttle Control Motor

EVCB1 EC Exhaust Valve Timing Control Magnet Retarder (Bank 1)

EVCB2 EC Exhaust Valve Timing Control Magnet Retarder (Bank 2)

EVCSB1 EC Exhaust Valve Timing Control Position Sensor (Bank 1)

EVCSB2 EC Exhaust Valve Timing Control Position Sensor (Bank 2)

F/LID BL Fuel Lid Opener

F/PUMP EC Fuel Pump

Revision: 2004 December PG-71 2005 350Z

HARNESS

Code Section Wiring Diagram Name

F/ROOF RF Soft Top

FTS AT A/T Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUELB1 EC Fuel Injection System Function (Bank 1)

FUELB2 EC Fuel Injection System Function (Bank 2)

H/LAMP LT Headlamp

HORN WW Horn

HSEAT SE Heated Seat

IATS EC Intake Air Temperature Sensor

IGNSYS EC Ignition System

ILL LT Illumination

I/MIRR GW Inside Mirror (Auto Anti-Dazzling Mirror)

INJECT EC Injector

IVCB1 EC Intake Valve Timing Control Solenoid Valve Bank 1

IVCB2 EC Intake Valve Timing Control Solenoid Valve Bank 2

KEYLES BL Remote Keyless Entry System

KS EC Knock Sensor

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Circuit

MAIN EC Main Power Supply and Ground Circuit

M/ANT AV Manual Antenna

METER DI Speedometer, Tachometer, Temp. and Fuel Gauges

MIL/DL EC MIL & Data Link Connectors

MIRROR GW Power Door Mirror

MMSW AT Manual Mode Switch

NATS BL Nissan Anti-Theft System

NAVI AV Navigation System

NONDTC AT Non-Detective Items

O2H2B1 EC Heated Oxygen Sensor 2 Heater Bank 1

O2H2B2 EC Heated Oxygen Sensor 2 Heater Bank 2

O2S2B1 EC Heated Oxygen Sensor 2 Bank 1

O2S2B2 EC Heated Oxygen Sensor 2 Bank 2

PGC/V EC EVAP Canister Purge Volume Control Solenoid Valve

PHSB1 EC Camshaft Position Sensor (PHASE) (Bank 1)

PHSB2 EC Camshaft Position Sensor (PHASE) (Bank 2)

PNP/SW AT Park/Neutral Position Switch

PNP/SW EC Park/Neutral Position Switch

POS EC Crankshaft Position Sensor (CKPS) (POS)

POWER PG Power Supply Routing

PRE/SE EC EVAP Control System Pressure Sensor

P/SCKT WW Power Socket

PS/SEN EC Power Steering Pressure Sensor

ROOM/L LT Interior Room Lamp

RP/SEN EC Refrigerant Pressure Sensor

Revision: 2004 December PG-72 2005 350Z

HARNESS

Code Section Wiring Diagram Name

A

SEAT SE Power Seat

SEN/PW EC Sensor Power Supply

SHIFT AT A/T Shift Lock System B

SRS SRS Supplemental Restraint System

START SC Starting System

STOP/L LT Stop Lamp C

STSIG AT Start Signal Circuit

TAIL/L LT Parking, License and Tail Lamps

D

TCS BRC Traction Control System

TLID BL Trunk Lid Opener

TPS1 EC Throttle Position Sensor (Sensor 1) E

TPS2 EC Throttle Position Sensor (Sensor 2)

TPS3 EC Throttle Position Sensor

F

TRNSCV BL Homelink Universal Transceiver

TURN LT Turn Signal and Hazard Warning Lamp

T/WARN WT Low Tire Pressure Warning System G

VDC BRC Vehicle Dynamics Control System

VEHSEC BL Vehicle Security System

H

VENT/V EC EVAP Canister Vent Control Valve

VSSA/T AT Vehicle Speed Sensor A/T (Revolution Sensor)

WARN DI Warning Lamps I

WINDOW GW Power Window

WIPER WW Front Wiper and Washer

WIP/R WW Rear Wiper and Washer

J

PG

Revision: 2004 December PG-73 2005 350Z

ELECTRICAL UNITS LOCATION

ELECTRICAL UNITS LOCATION PFP:25230

Electrical Units Location AKS0012S

ENGINE COMPARTMENT

CKIT0212E

Revision: 2004 December PG-74 2005 350Z

ELECTRICAL UNITS LOCATION

PASSENGER COMPARTMENT

A

PG

CKIT0541E

Revision: 2004 December PG-75 2005 350Z

ELECTRICAL UNITS LOCATION

CKIT0542E

Revision: 2004 December PG-76 2005 350Z

ELECTRICAL UNITS LOCATION

PG

CKIT0349E

Revision: 2004 December PG-77 2005 350Z

ELECTRICAL UNITS LOCATION

LUGGAGE COMPARTMENT

Coupe Models

CKIT0216E

Revision: 2004 December PG-78 2005 350Z

ELECTRICAL UNITS LOCATION

Roadster Models

A

PG

CKIT0350E

Revision: 2004 December PG-79 2005 350Z

HARNESS CONNECTOR

HARNESS CONNECTOR PFP:00011

Description AKS0012T

HARNESS CONNECTOR (TAB-LOCKING TYPE)

● The tab-locking type connectors help prevent accidental looseness or disconnection.

● The tab-locking type connectors are disconnected by pushing or lifting the locking tab(s). Refer to the fig-

ure below.

Refer to the next page for description of the slide-locking type connector.

CAUTION:

Do not pull the harness or wires when disconnecting the connector.

[Example]

SEL769DA

Revision: 2004 December PG-80 2005 350Z

HARNESS CONNECTOR

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)

● A new style slide-locking type connector is used on certain systems and components, especially those A

related to OBD.

● The slide-locking type connectors help prevent incomplete locking and accidental looseness or discon-

nection. B

● The slide-locking type connectors are disconnected by pushing or pulling the slider. Refer to the figure

below.

CAUTION: C

● Do not pull the harness or wires when disconnecting the connector.

● Be careful not to damage the connector support bracket when disconnecting the connector.

D

[Example]

PG

SEL769V

Revision: 2004 December PG-81 2005 350Z

ELECTRICAL UNITS

ELECTRICAL UNITS PFP:00011

Terminal Arrangement AKS0012V

CKIT0294E

Revision: 2004 December PG-82 2005 350Z

ELECTRICAL UNITS

PG

CKIT0647E

Revision: 2004 December PG-83 2005 350Z

SMJ (SUPER MULTIPLE JUNCTION)

SMJ (SUPER MULTIPLE JUNCTION) PFP:B4341

Terminal Arrangement AKS0012W

CKIT0543E

Revision: 2004 December PG-84 2005 350Z

SMJ (SUPER MULTIPLE JUNCTION)

PG

CKIT0158E

Revision: 2004 December PG-85 2005 350Z

STANDARDIZED RELAY

STANDARDIZED RELAY PFP:00011

Description AKS0012X

NORMAL OPEN, NORMAL CLOSED AND MIXED TYPE RELAYS

Relays can mainly be divided into three types: normal open, normal closed and mixed type relays.

SEL881H

TYPE OF STANDARDIZED RELAYS

1M ···················· 1 Make 2M ···················· 2 Make

1T ···················· 1 Transfer 1M·1B ···················· 1 Make 1 Break

SEL882H

Revision: 2004 December PG-86 2005 350Z

STANDARDIZED RELAY

PG

SEL188W

Revision: 2004 December PG-87 2005 350Z

FUSE BLOCK - JUNCTION BOX (J/B)

FUSE BLOCK - JUNCTION BOX (J/B) PFP:24350

Terminal Arrangement AKS0012Y

CKIT0363E

Revision: 2004 December PG-88 2005 350Z

FUSE, FUSIBLE LINK AND RELAY BOX

FUSE, FUSIBLE LINK AND RELAY BOX PFP:24382

A

Terminal Arrangement AKS0012Z

PG

CKIT0186E

Revision: 2004 December PG-89 2005 350Z

FUSE, FUSIBLE LINK AND RELAY BOX

Revision: 2004 December PG-90 2005 350Z

You might also like

- Yaris Electrical Wiring DiagramDocument264 pagesYaris Electrical Wiring Diagrammuie11219569100% (14)

- 350z Procharger Install ManualDocument52 pages350z Procharger Install Manualr3belzNo ratings yet

- 2004 Service Manual For Nissan 350zDocument7 pages2004 Service Manual For Nissan 350zHoward Ostfeld0% (1)

- MOPAR REMANUFACTURED SINGLE BOARD ENGINE CONTROLLER REMOVAL GUIDEDocument7 pagesMOPAR REMANUFACTURED SINGLE BOARD ENGINE CONTROLLER REMOVAL GUIDEgatito1971No ratings yet

- Navigator Suspension Light Off!!! - ForM01161Document3 pagesNavigator Suspension Light Off!!! - ForM01161J WatsonNo ratings yet

- 4706 - Pro48-705 Pinout For 2003-2006 Nissan 350Z/ Infiniti G35 VQ35DEDocument1 page4706 - Pro48-705 Pinout For 2003-2006 Nissan 350Z/ Infiniti G35 VQ35DEAdan Flores CorreaNo ratings yet

- Mini r53 HeadDocument10 pagesMini r53 Headisrael negreteNo ratings yet

- VY BCM ABS SRS Wiring Diagrams pcmhacking.netDocument5 pagesVY BCM ABS SRS Wiring Diagrams pcmhacking.netJet64u86No ratings yet

- M272M273 Manual Engine PDFDocument38 pagesM272M273 Manual Engine PDFАлексейNo ratings yet

- 2006 E320cdi E350 E500 E3505004matic E55amgDocument521 pages2006 E320cdi E350 E500 E3505004matic E55amgacer012006No ratings yet

- Engine Timing Belt Replacement Guide for 1.6L EcoBoost C-MAX 2011-2012Document11 pagesEngine Timing Belt Replacement Guide for 1.6L EcoBoost C-MAX 2011-2012SenaMecánicaElectrónica100% (1)

- Blitz SBC I-D ManualDocument14 pagesBlitz SBC I-D ManualReem MinnisNo ratings yet

- 18263446-Jaguar XJR 1997-2003 Workshop Service Repair Manual PDFDocument2,490 pages18263446-Jaguar XJR 1997-2003 Workshop Service Repair Manual PDFAdan Flores CorreaNo ratings yet

- 2004 Nissan 350z 41Document88 pages2004 Nissan 350z 41Roger jose arezo de paiva100% (1)

- 2007 Nissan VersaDocument304 pages2007 Nissan Versafrank1220uNo ratings yet

- 1991 ServiceManual Mitsubishi 3000GT Vol 2Document316 pages1991 ServiceManual Mitsubishi 3000GT Vol 2NoAccount888100% (1)

- Table of Contents for Diesel Engine Diagnostic ManualDocument300 pagesTable of Contents for Diesel Engine Diagnostic ManualNasos Maratsolas0% (1)

- Maintenance and Care: Form No.8CC7-EA-11HDocument52 pagesMaintenance and Care: Form No.8CC7-EA-11HChaiyakorn Aaron100% (1)

- Territory SZ MKII OM Print4OctoberDocument199 pagesTerritory SZ MKII OM Print4OctoberErwin HernandezNo ratings yet

- Jetta 2000 PDFDocument225 pagesJetta 2000 PDFMatt BurnsNo ratings yet

- 2010 Nissan VersaDocument338 pages2010 Nissan VersaChristian HammNo ratings yet

- MDX Suspension NoisesDocument2 pagesMDX Suspension NoisesScotty MacNo ratings yet

- PATS Anti-Theft System Diagnosis GuideDocument19 pagesPATS Anti-Theft System Diagnosis Guidemiguel plazaNo ratings yet

- Obd 2 CodesDocument34 pagesObd 2 CodesKatu2010100% (1)

- Honda Prelude IV (92-96) - Engine VIN IDDocument3 pagesHonda Prelude IV (92-96) - Engine VIN IDTor Warut100% (1)

- Ecm Reprogramm With Consult 2Document17 pagesEcm Reprogramm With Consult 2Arturo Lomelí100% (2)

- Parts ManualDocument142 pagesParts ManualAlexandru AlistarhNo ratings yet

- 2009 Nissan AltimaDocument3 pages2009 Nissan AltimavalclerNo ratings yet

- Sony XAV-63 - ManualDocument64 pagesSony XAV-63 - ManualVinay Patel100% (1)

- 2009 Chevrolet Silverado BrochureDocument23 pages2009 Chevrolet Silverado BrochureGateway Chevrolet Cadillac100% (4)

- Expedition & Navigator 97 - 02 4wheel Without Ride Light InstructionsDocument12 pagesExpedition & Navigator 97 - 02 4wheel Without Ride Light InstructionsstrutmastersNo ratings yet

- Volvo Auto DtcsDocument4 pagesVolvo Auto Dtcscorie132100% (1)

- ZD Racing 1 - 10 ZMT-10 User-Manual-3576507Document19 pagesZD Racing 1 - 10 ZMT-10 User-Manual-3576507ruup2010 AlexNo ratings yet

- Remote Audio Controls Fix for Honda VehiclesDocument9 pagesRemote Audio Controls Fix for Honda VehiclesdewwNo ratings yet

- Valve Body Assembly On Vehicle RepairDocument7 pagesValve Body Assembly On Vehicle RepairWillian Jane100% (1)

- 960 - 1996 Owner's ManualDocument254 pages960 - 1996 Owner's ManualhucnNo ratings yet

- Ninja 250 Start & Ignition SchematicDocument1 pageNinja 250 Start & Ignition Schematicperc vicentNo ratings yet

- BMW E53 X5 (2000-2006) Interior LED LightDocument14 pagesBMW E53 X5 (2000-2006) Interior LED LightJanneLaukkanenNo ratings yet

- Jaguar X-Type Wiring DiagDocument25 pagesJaguar X-Type Wiring Diagadimaio_3d0% (5)

- Steering System Chrysler Sebring 2008Document178 pagesSteering System Chrysler Sebring 2008Juan MederosNo ratings yet

- Jeep KK DTC LISTDocument6 pagesJeep KK DTC LISTHenry SilvaNo ratings yet

- Ee Prom Work Beginners AdvancedDocument11 pagesEe Prom Work Beginners AdvancedJustin Leo100% (2)

- Subaru Impreza 2009 Wiring DiagramsDocument198 pagesSubaru Impreza 2009 Wiring DiagramsPiotr KuchnioNo ratings yet

- Useful Info For Acura Legend 1993Document3 pagesUseful Info For Acura Legend 1993jcalaqNo ratings yet

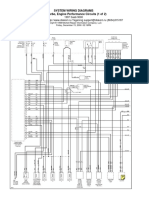

- System Wiring Diagrams 2.3L Turbo, Engine Performance Circuits (1 of 2)Document29 pagesSystem Wiring Diagrams 2.3L Turbo, Engine Performance Circuits (1 of 2)Karlis VilcinsNo ratings yet

- Service Bulletin Mazda 6 2002-2007Document12 pagesService Bulletin Mazda 6 2002-2007KreAch3RNo ratings yet

- Datsun - 510 - 1969-1973 Service - ManualDocument144 pagesDatsun - 510 - 1969-1973 Service - ManualAlex MoparNo ratings yet

- 2004 Legacy Service Manual Quick Reference Index Transmission SectionDocument33 pages2004 Legacy Service Manual Quick Reference Index Transmission SectionСергей ЕсиповNo ratings yet

- Jeep Wrangler 2002 Parts ListDocument341 pagesJeep Wrangler 2002 Parts Listno1mike100% (1)

- In This Issue: Brake System Service Toyota's Hybrid Vehicle Continuously Variable Transmission Power Steering ServiceDocument40 pagesIn This Issue: Brake System Service Toyota's Hybrid Vehicle Continuously Variable Transmission Power Steering ServiceDilan SenarathneNo ratings yet

- WD Subaru 1501480Document30 pagesWD Subaru 1501480Anton RepkaNo ratings yet

- All R56 IconsDocument3 pagesAll R56 IconsJesus Eddy Peña MelissaratosNo ratings yet

- OBD2 Protocols List Suggested by ManufacturersDocument224 pagesOBD2 Protocols List Suggested by ManufacturersAli HamzaNo ratings yet

- 2000 Jeep Grand Cherokee Service Manual (Battery)Document26 pages2000 Jeep Grand Cherokee Service Manual (Battery)Rob CirincioneNo ratings yet

- E Prog Sin FotoDocument16 pagesE Prog Sin FotoGasper CeballosNo ratings yet

- M11 Circuit Diagram (Manual)Document130 pagesM11 Circuit Diagram (Manual)Vasiliy PupkinNo ratings yet

- Mazda 3 L3Document50 pagesMazda 3 L3David MendezNo ratings yet

- E36 - Sedan - Coupe After 1Document577 pagesE36 - Sedan - Coupe After 1Bahjat MerhyNo ratings yet

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesFrom EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesNo ratings yet

- Nissan Pathfider 2005 ManualDocument84 pagesNissan Pathfider 2005 ManualDragos StefanNo ratings yet

- Circuit Elements GuideDocument100 pagesCircuit Elements GuideKevin MulvihillNo ratings yet

- PG PDFDocument72 pagesPG PDFRony CentenoNo ratings yet

- Downloaded From Manuals Search EngineDocument171 pagesDownloaded From Manuals Search EngineAdan Flores CorreaNo ratings yet

- Super Airflow Converter: Super Air Flow Converter Wiring Diagram by ModelDocument64 pagesSuper Airflow Converter: Super Air Flow Converter Wiring Diagram by ModelChristopher RusliNo ratings yet

- Automatic Transmission PDFDocument898 pagesAutomatic Transmission PDFAdan Flores CorreaNo ratings yet

- ENGINEDocument2,790 pagesENGINEAdan Flores CorreaNo ratings yet

- Troubleshooting: Problem Symptoms TableDocument24 pagesTroubleshooting: Problem Symptoms Tableapi-3833108No ratings yet

- Body ElectricalDocument102 pagesBody Electricalapi-3833108No ratings yet

- Toyota Turbo Applications ListDocument33 pagesToyota Turbo Applications ListAdan Flores Correa100% (5)

- Literature Review of Ohms LawDocument8 pagesLiterature Review of Ohms Lawafmznqfsclmgbe100% (1)

- Samsung Un43tu7000fDocument98 pagesSamsung Un43tu7000fMiguel ZambranoNo ratings yet

- Flexible Grid Connection and Islanding of SPC-based PV Power ConvertersDocument12 pagesFlexible Grid Connection and Islanding of SPC-based PV Power ConvertersGeorge MatosNo ratings yet

- Operating Manual For Series NRX Trip Units - Digitrip™ 520/520MDocument42 pagesOperating Manual For Series NRX Trip Units - Digitrip™ 520/520Mfredys jose Morales quinteroNo ratings yet

- Pengenalan Praktis Timbangan ChronosDocument21 pagesPengenalan Praktis Timbangan ChronosNanang Roni WibowoNo ratings yet

- AC Generators or Alternators ExplainedDocument43 pagesAC Generators or Alternators ExplainedPauline SilvaNo ratings yet

- SCEPresentation 2022 2023TransmissionPlanningProcess Sep28 2022Document22 pagesSCEPresentation 2022 2023TransmissionPlanningProcess Sep28 2022arjeegeeNo ratings yet

- Overview ZF Systems Procent Rev. 2.2Document1 pageOverview ZF Systems Procent Rev. 2.2Muhittin KNo ratings yet

- Solution Manual For Optoelectronics and Photonics Principles and Practices 2Nd Edition Kasap 0132151499 9780132151498 Full Chapter PDFDocument32 pagesSolution Manual For Optoelectronics and Photonics Principles and Practices 2Nd Edition Kasap 0132151499 9780132151498 Full Chapter PDFrichard.parga191100% (15)

- Describing and Specifying The Excitation Source in Emission Spectrochemical AnalysisDocument4 pagesDescribing and Specifying The Excitation Source in Emission Spectrochemical AnalysisPYDNo ratings yet

- (Install) Aerisa 1250D IpureairDocument2 pages(Install) Aerisa 1250D IpureairChad100% (1)

- Exp 3 Oscilloscope and Voltage MeasurementDocument7 pagesExp 3 Oscilloscope and Voltage MeasurementusmpowerlabNo ratings yet

- EasyRET Low-Band 2-Port Antenna with 1 Integrated RCU - 1.4m SpecsDocument1 pageEasyRET Low-Band 2-Port Antenna with 1 Integrated RCU - 1.4m SpecsWaleed HasNo ratings yet

- Numerical modelling and design of electrical devicesDocument69 pagesNumerical modelling and design of electrical devicesfabrice mellantNo ratings yet

- R2A20121SP: Synchronous Phase Shift Full-Bridge Control ICDocument28 pagesR2A20121SP: Synchronous Phase Shift Full-Bridge Control ICdragon-red0816No ratings yet

- DTS WN 04-2017 EngDocument4 pagesDTS WN 04-2017 Engvipul patelNo ratings yet

- 5.UV Sterilizer Cabinet & Wax HeaterDocument2 pages5.UV Sterilizer Cabinet & Wax HeaterJoveth YanesNo ratings yet

- Television 1928Document58 pagesTelevision 1928Rick MendelezNo ratings yet

- PRT RDM2Document42 pagesPRT RDM2jstclmethan100% (1)

- Fairchild Semiconductors Design Solutions 0701 PDFDocument8 pagesFairchild Semiconductors Design Solutions 0701 PDFFernando Vidal100% (1)

- 590J-V2 DatasheetDocument7 pages590J-V2 DatasheetGamblerNo ratings yet

- Transformer ProtectionDocument7 pagesTransformer ProtectionJeyson BarreraNo ratings yet

- HFDSR Technical DatasheetDocument1 pageHFDSR Technical DatasheetSulistyono SulistyonoNo ratings yet

- Syllabus of 2nd Semester All 2 PDFDocument43 pagesSyllabus of 2nd Semester All 2 PDFDeepak Kumar gautamNo ratings yet

- Electrostatic Forces and FieldsDocument16 pagesElectrostatic Forces and FieldsShahbaz KhanNo ratings yet

- Emtl Question Bank Imp QsDocument9 pagesEmtl Question Bank Imp QsSri MurthyNo ratings yet

- MV and Synch Gear As Built-7Document37 pagesMV and Synch Gear As Built-7Sayed Younis SadaatNo ratings yet

- SCCL SyllabusDocument1 pageSCCL SyllabusSainathNo ratings yet

- Lighting Fundamentals ExplainedDocument23 pagesLighting Fundamentals ExplainedBetinol RachelNo ratings yet