Professional Documents

Culture Documents

26 Process Safety Management: Quiz 1 (20 Points)

Uploaded by

Rishi TandonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

26 Process Safety Management: Quiz 1 (20 Points)

Uploaded by

Rishi TandonCopyright:

Available Formats

APM: Administration & Programs, 13th edition – Quizzes

26 PROCESS SAFETY MANAGEMENT

QUIZ 1 (20 POINTS)

True/False (5 points)

1. SARA Title III required companies to develop emergency preparedness plans; recognition, knowledge,

and inventories of hazardous chemicals; and to report toxic releases.

a. true

b. false

2. One of the factors in process safety management accountability is management and supervisory

accessibility and communications.

a. true

b. false

3. If original equipment design information is not available, the information need to establish a process

safety management program may be reconstructed from inspection records.

a. true

b. false

4. Management-of-Change programs do not need to consider temporary changes and variances in a

process.

a. true

b. false

5. Employers need verification that contractor employees have been trained even though they are only

temporary employees.

a. true

b. false

Multiple Choice (6 points)

6. Which of the following organizations was created by an amendment to the U.S. Clean Air Act?

a. the Center for Chemical Process Safety

b. the Chemical Safety and Hazard Investigation Board

c. the Organizations Resource Counselors

d. the Synthetic Organic Chemical Manufacturers Association

7. Which of the following are not exempt from OSHA’s PSM standard?

a. a company that stores 12,000 pounds of flammable liquid

b. hydrocarbons used only for fuel in the workplace

c. retail facilities

d. oil well drilling operations

© 2009 National Safety Council

APM: Administration & Programs, 13th edition – Quizzes

8. Among other factors, the short-term goals of a process risk management program should be based

on __________.

a. the regulatory requirements for program development

b. the timeliness and economic feasibility of instituting necessary changes

c. management’s desired level of compliance

d. the requirements for implementing a program

9. Which of the following methods of hazard analysis works by asking a series of questions to review

potential scenarios and possible consequences?

a. HAZOP Study

b. Checklist

c. “What If...?”

d. Failure Mode and Effect Analysis

10. Which of the following may be considered for a permit program?

a. hot work

b. confined-space entry

c. opening process equipment

d. all of the above

11. To comply with the OSHA PSM standard, employers must audit all process operations at least every

___________.

a. two years

b. three years

c. four years

d. five years

Short Answer (7 points)

12. According to the Chemical Manufacturers Association, what is process safety?

13. What does STEP stand for and what are its goals?

© 2009 National Safety Council

APM: Administration & Programs, 13th edition – Quizzes

14. Section 112 (r) of the Clean Air Act requires some facilities to develop risk management plans. Which

facilities are affected by this rule?

15. How should a facility determine the order of priority to be used for process hazard analyses?

16. Under what conditions should pre-start-up safety reviews be conducted?

17. At a minimum, what information should an incident investigation report cover?

18. Why might a company decide to stop routine process safety audits?

Short Essay (2 points)

19. Chemical information is vital to the creation of a process safety management program. What does

this information include and where can it found?

© 2009 National Safety Council

APM: Administration & Programs, 13th edition – Quizzes

20. Process facilities are subject to two different types of standards and regulations. What are they and

how are they different?

QUIZ 2 (20 POINTS TOTAL)

True/False (5 points)

1. According to OSHA, process safety management is the proactive identification, evaluation, mitiga-

tion, or prevention of chemical releases that could occur as a result of an equipment failure.

a. true

b. false

2. Risk management plans required by the Clean Air Act need not be registered with the EPA, although

they must be registered with state and local agencies.

a. true

b. false

3. The long-term goals of process risk management should be based on the degree of risk that manage-

ment is willing to accept.

a. true

b. false

4. An event tree analysis works backward from a defined incident to identify the combination of errors

or failures involved in an incident.

a. true

b. false

5. When implementing a training program for employees who work with hazardous chemicals, manage-

ment needs to consider the design of process maintenance procedures.

a. true

b. false

Multiple Choice (6 points)

6. When did the CMA initiate its Responsible Care Program?

a. 1983

b. 1985

c. 1988

d. 1990

© 2009 National Safety Council

APM: Administration & Programs, 13th edition – Quizzes

7. Which of the following focused on preventing releases of hazardous chemicals that could expose

employees and others to danger?

a. 29 CFR 1910.119, Process Safety Management of Highly Hazardous Chemicals

b. Petrochemical (PETROSEP) Industries Compliance Directive

c. Instruction CPL 2-2.45, Systems Safety Evaluation of Operations with Catastrophic Potential

d. 40 CFR 68 Section 112 (r), Risk Management Programs for Chemical Accidental Release

Prevention

8. Which of the follow methods of hazard analysis uses specific guide words, which are systematically

applied to parameters to identify the consequences of changes in the design of a process?

a. Fault Tree Analysis

b. Failure Mode and Effect Analysis

c. “What If...?”/Checklist

d. HAZOP Study

9. A good process safety management practice is to review process hazard analyses at least every _____,

even if the processes, equipment, or materials have not changed.

a. two years

b. three years

c. five years

d. seven years

10. Mechanical integrity requirements apply to ____________.

a. vent devices

b. pumps and piping systems

c. materials of construction

d. all of the above

11. To comply with OSHA regulations, how many compliance audit reports does an employer need to

keep on file?

a. the most recent report

b. the last two reports

c. the last three reports

d. none (OSHA does not require employers to keep reports.)

Short Answer (7 points)

12. What is the mission of the Center for Chemical Process Safety?

© 2009 National Safety Council

APM: Administration & Programs, 13th edition – Quizzes

13. What three points should management keep in mind when developing a safety management pro-

gram?

14. Why is it important for management to have information on the maximum inventory of hazardous

chemicals in a facility at any one time?

15. Block-flow diagrams and simple process-flow diagrams can help the safety professional gather and

provide __________.

16. Operating instructions should cover the processing unit’s operating limits, including which three

areas?

17. What are the four types of PSM inspections OSHA can carry out?

18. Name the five points that, at a minimum, a process safety audit must include.

© 2009 National Safety Council

APM: Administration & Programs, 13th edition – Quizzes

Short Essay (2 points)

19. Operating instructions should be clear, precise, and understandable. They should be accessible to

all employees and contractors involved in a process and should cover a minimum number of points.

What are these points?

20. The management of Steeling Corp. has decided to make a major change to a process and has set a

team to monitor the design of the new process and quality assurance. Before final design drawings

are issued, what areas will the team typically need to check?

© 2009 National Safety Council

You might also like

- CRSP Examination Preparation 1695464322Document14 pagesCRSP Examination Preparation 1695464322sidchetia786125No ratings yet

- Process Safety Performance Indicators PDFDocument15 pagesProcess Safety Performance Indicators PDFsgraureNo ratings yet

- XIV Paper 38Document11 pagesXIV Paper 38Zenon KociubaNo ratings yet

- 14 Elements PSMDocument4 pages14 Elements PSMLenaldy Nuari Garnoko100% (1)

- Cre Preliminary TestDocument8 pagesCre Preliminary TestN.r. SaravananNo ratings yet

- API 580 Mock ExamDocument5 pagesAPI 580 Mock ExamRandyCha100% (2)

- CIP Cycle Development ISPEDocument9 pagesCIP Cycle Development ISPEvijayns_250355172No ratings yet

- CMRP Practice Questions P3-OGSDocument3 pagesCMRP Practice Questions P3-OGSalnaggar.amroNo ratings yet

- Final - Print Adh Lam Slit - May 6 2010Document22 pagesFinal - Print Adh Lam Slit - May 6 2010cassilda_carvalho@hotmail.comNo ratings yet

- Certified Information Systems Auditor (CISA) - Mock Exam 1Document11 pagesCertified Information Systems Auditor (CISA) - Mock Exam 1Nishant KulshresthaNo ratings yet

- Evolution of Process Hazard Analysis in An Oil & Gas Pipeline Company: From Ad-Hoc To An Enterprise Standard PracticeDocument10 pagesEvolution of Process Hazard Analysis in An Oil & Gas Pipeline Company: From Ad-Hoc To An Enterprise Standard PracticeMarcelo Varejão CasarinNo ratings yet

- Reliability Centered Maintenance RCM Implementation and BenefitsDocument4 pagesReliability Centered Maintenance RCM Implementation and BenefitsNguyễn Duy KhangNo ratings yet

- Artigo - RBIDocument17 pagesArtigo - RBIIelson FreireNo ratings yet

- Certified Information Systems Auditor (CISA) - Mock Exam 7Document11 pagesCertified Information Systems Auditor (CISA) - Mock Exam 7Nishant KulshresthaNo ratings yet

- Sample Diploma Unit A Examination PaperDocument4 pagesSample Diploma Unit A Examination PaperKm MehboobNo ratings yet

- HSE Methodology For Sociatal RiskDocument27 pagesHSE Methodology For Sociatal RiskshaileshgadbailNo ratings yet

- Cs HM Sample TestDocument12 pagesCs HM Sample TestAbdul Hakam Mohamed YusofNo ratings yet

- 14 Elements of PSM - Industry ResourcesDocument5 pages14 Elements of PSM - Industry ResourcesSaad Ghouri100% (2)

- 3chemical and Process Safety Management 23111Document137 pages3chemical and Process Safety Management 23111DaNo ratings yet

- Exam Format Score Multiple Choice Questions (60 Score)Document14 pagesExam Format Score Multiple Choice Questions (60 Score)Muhammad Irfan100% (5)

- Certified Information Systems Auditor (CISA) - Mock Exam 2Document11 pagesCertified Information Systems Auditor (CISA) - Mock Exam 2Nishant KulshresthaNo ratings yet

- API 580 Mock ExamDocument5 pagesAPI 580 Mock ExamMansoor AliNo ratings yet

- Ch3 Industrial Hygiene CH3 Final (Condensed)Document82 pagesCh3 Industrial Hygiene CH3 Final (Condensed)Mohammed JanahiNo ratings yet

- Implementing A "Best Practices" Predictive Maintenance Program: Avoiding The 10 Most Common PitfallsDocument8 pagesImplementing A "Best Practices" Predictive Maintenance Program: Avoiding The 10 Most Common PitfallsErwin Olav Ecos TovarNo ratings yet

- HSE - Best Practice For RBI PDFDocument186 pagesHSE - Best Practice For RBI PDFDanie-Els100% (4)

- A Multi Objective Genetic Algorithm ForDocument43 pagesA Multi Objective Genetic Algorithm ForJoseNo ratings yet

- What is Reliability Centered Maintenance and its principlesDocument7 pagesWhat is Reliability Centered Maintenance and its principlesRoman AhmadNo ratings yet

- 10 - Hazard ProcedureDocument3 pages10 - Hazard ProcedureFrankNo ratings yet

- Contractor Safety Managment ProgramDocument19 pagesContractor Safety Managment Programsanjeev kumarNo ratings yet

- Certified Information Systems Auditor (CISA) - Mock Exam 3Document8 pagesCertified Information Systems Auditor (CISA) - Mock Exam 3Nishant KulshresthaNo ratings yet

- A Risk Based Inspection (Rbi) Preventive Maintanance Programme: A Case StudyDocument2 pagesA Risk Based Inspection (Rbi) Preventive Maintanance Programme: A Case StudyAchraf BouzianeNo ratings yet

- OSHA's Expectations for Mechanical Integrity ProgramsDocument6 pagesOSHA's Expectations for Mechanical Integrity ProgramsYounes OULMANENo ratings yet

- Applied Industrial Plant MaintenanceDocument11 pagesApplied Industrial Plant MaintenanceJason Stuart100% (2)

- Industrial Hygiene Chapter OverviewDocument68 pagesIndustrial Hygiene Chapter OverviewAshokNo ratings yet

- Process Safety Management (PSM) Is A Regulation Issued by The U.SDocument5 pagesProcess Safety Management (PSM) Is A Regulation Issued by The U.Sbahaa mostafaNo ratings yet

- 2012 01 IDIP Unit A Past PaperDocument4 pages2012 01 IDIP Unit A Past Paperfh71100% (1)

- Process Safety ManagementDocument28 pagesProcess Safety ManagementIndranil Hatua100% (13)

- Final - CSTE - June 17 2006Document3 pagesFinal - CSTE - June 17 2006api-19916530No ratings yet

- OSHA (PSM) Standard, 29 CFR 1910.119 - PSM of Highly Hazardous ChemicalsDocument7 pagesOSHA (PSM) Standard, 29 CFR 1910.119 - PSM of Highly Hazardous ChemicalsKG Shim50% (2)

- CRE Preliminary Test (30) : ASQ CRE (Certified Reliability Engineer)Document8 pagesCRE Preliminary Test (30) : ASQ CRE (Certified Reliability Engineer)Idris AbiolaNo ratings yet

- Asset Mgt 101: 4 Maintenance StrategiesDocument6 pagesAsset Mgt 101: 4 Maintenance StrategiestristanmaharajNo ratings yet

- NIST - Practice For OBE - Mock Assessment - 4Document5 pagesNIST - Practice For OBE - Mock Assessment - 4VISHNURAJ GNo ratings yet

- FMEA ExampleDocument16 pagesFMEA ExampleganeshrudraNo ratings yet

- Form Risk AssessementDocument16 pagesForm Risk AssessementbaluchakpNo ratings yet

- CSTE - June 17 2006Document3 pagesCSTE - June 17 2006api-3828205No ratings yet

- Cis 10Document1 pageCis 10batistillenieNo ratings yet

- EMC-3003 Industrial Plants Maintenance LO # 1Document21 pagesEMC-3003 Industrial Plants Maintenance LO # 1sushil.vgiNo ratings yet

- Industrial Plant Maintenance FundamentalsDocument135 pagesIndustrial Plant Maintenance Fundamentalssushil.vgiNo ratings yet

- Application Controls and General ControlsDocument65 pagesApplication Controls and General ControlsCillian ReevesNo ratings yet

- CISA Sample ExamDocument15 pagesCISA Sample ExamAmor Dulce100% (2)

- Process Safety Management (PSM) : General Awareness TrainingDocument18 pagesProcess Safety Management (PSM) : General Awareness Trainingrpercy01No ratings yet

- Controlling The Cost of Poor Quality in The Maintenance Process of The Narrow Body Base Maintenance Department Using The DMAIC Method at PT. GMF AeroAsiaDocument21 pagesControlling The Cost of Poor Quality in The Maintenance Process of The Narrow Body Base Maintenance Department Using The DMAIC Method at PT. GMF AeroAsiaSidik purnomoNo ratings yet

- Performance Management for the Oil, Gas, and Process Industries: A Systems ApproachFrom EverandPerformance Management for the Oil, Gas, and Process Industries: A Systems ApproachRating: 5 out of 5 stars5/5 (3)

- Industrial Agents: Emerging Applications of Software Agents in IndustryFrom EverandIndustrial Agents: Emerging Applications of Software Agents in IndustryPaulo LeitãoNo ratings yet

- Process Safety Management and Human Factors: A Practitioner’s Experiential ApproachFrom EverandProcess Safety Management and Human Factors: A Practitioner’s Experiential ApproachWaddah S. Ghanem Al HashmiRating: 5 out of 5 stars5/5 (1)

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingFrom EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo ratings yet

- Food Control System Assessment Tool: Dimension D – Science/Knowledge Base and Continuous ImprovementFrom EverandFood Control System Assessment Tool: Dimension D – Science/Knowledge Base and Continuous ImprovementNo ratings yet

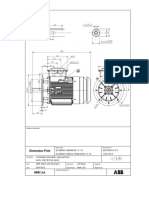

- ABB Motors and Technical Data Sheet Generators: No. Data Unit RemarksDocument5 pagesABB Motors and Technical Data Sheet Generators: No. Data Unit RemarksRishi TandonNo ratings yet

- Fotoelektrik PDFDocument7 pagesFotoelektrik PDFSISI GELAPNo ratings yet

- Data Sheet: SpecificationsDocument3 pagesData Sheet: SpecificationsRishi TandonNo ratings yet

- Construction Type / Fire ClassificationDocument1 pageConstruction Type / Fire ClassificationMysara MohsenNo ratings yet

- Dim - Print M2BAX 160ML IM B5, V1, V3, Protective Roof PDFDocument1 pageDim - Print M2BAX 160ML IM B5, V1, V3, Protective Roof PDFRishi TandonNo ratings yet

- Ukraine Cyber-Induced Power Outage: Analysis and Practical Mitigation StrategiesDocument10 pagesUkraine Cyber-Induced Power Outage: Analysis and Practical Mitigation StrategiesRishi Tandon100% (1)

- Interview Result - Sr. Manager (Electrical) PDFDocument1 pageInterview Result - Sr. Manager (Electrical) PDFRishi TandonNo ratings yet

- List of Candidates For Interview - Chief Manager (Electrical) PDFDocument3 pagesList of Candidates For Interview - Chief Manager (Electrical) PDFRishi TandonNo ratings yet

- Postponement of Interview PDFDocument1 pagePostponement of Interview PDFRishi TandonNo ratings yet

- Result Am (Lab)Document1 pageResult Am (Lab)Rishi TandonNo ratings yet

- Notification - Result SR Chemist PDFDocument1 pageNotification - Result SR Chemist PDFRishi TandonNo ratings yet

- Government of India Prospectus for Advanced Diploma in Industrial SafetyDocument16 pagesGovernment of India Prospectus for Advanced Diploma in Industrial SafetyEHS Plant6No ratings yet

- Hyundai HHT Manual Menu GuideDocument40 pagesHyundai HHT Manual Menu GuideReynold Suarez75% (12)

- HISAC ULTIMA - Test ReportDocument2 pagesHISAC ULTIMA - Test ReportRishi TandonNo ratings yet

- Advertisement JenDocument10 pagesAdvertisement JenhimnishsiyagNo ratings yet

- Indian Standard: Methods For Sampling of Clay Building BricksDocument9 pagesIndian Standard: Methods For Sampling of Clay Building BricksAnonymous i6zgzUvNo ratings yet

- F404-15 Standard Consumer Safety Specification For High ChairsDocument19 pagesF404-15 Standard Consumer Safety Specification For High ChairsAhmed AlzubaidiNo ratings yet

- Rsa Netwitness Endpoint: Detect Unknown Threats. Reduce Dwell Time. Accelerate ResponseDocument8 pagesRsa Netwitness Endpoint: Detect Unknown Threats. Reduce Dwell Time. Accelerate ResponseRaghavNo ratings yet

- 2015 Idmp Employee Intentions Final PDFDocument19 pages2015 Idmp Employee Intentions Final PDFAstridNo ratings yet

- Business Plan For Mobile Food CourtDocument13 pagesBusiness Plan For Mobile Food CourtMd. Al- AminNo ratings yet

- 2021 Subsector OutlooksDocument24 pages2021 Subsector OutlooksHungNo ratings yet

- (GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-DevelopersDocument3 pages(GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-Developersdadme010% (2)

- Combined SGMA 591Document46 pagesCombined SGMA 591Steve BallerNo ratings yet

- Maputo Port Approach Passage PlanDocument1 pageMaputo Port Approach Passage PlanRitesh ChandraNo ratings yet

- Aproximaciones Al Concepto de Grupos y Tipos de GruposDocument16 pagesAproximaciones Al Concepto de Grupos y Tipos de GruposM. CNo ratings yet

- Pantangco DigestDocument2 pagesPantangco DigestChristine ZaldivarNo ratings yet

- L4 Examples - Exact Differential Equations PDFDocument16 pagesL4 Examples - Exact Differential Equations PDFCarlo EdolmoNo ratings yet

- The Effect of Multicollinearity in Nonlinear Regression ModelsDocument4 pagesThe Effect of Multicollinearity in Nonlinear Regression ModelsKeshav PoolaNo ratings yet

- GCSE History Revision Guide and Workbook Examines Henry VIII's Reign 1509-1540Document23 pagesGCSE History Revision Guide and Workbook Examines Henry VIII's Reign 1509-1540Haris KhokharNo ratings yet

- L4. LO2. Safekeep Dispose Tools, Materials and OutfitDocument77 pagesL4. LO2. Safekeep Dispose Tools, Materials and OutfitGiedon Quiros73% (15)

- Capital Harness XC LaunchDocument36 pagesCapital Harness XC LaunchnizarfebNo ratings yet

- Adb Doc Easa Reliance 8 Centerline Stopbar Declaracao de Conformidade EasaDocument2 pagesAdb Doc Easa Reliance 8 Centerline Stopbar Declaracao de Conformidade Easagiant360No ratings yet

- PMDC Renewal FormDocument3 pagesPMDC Renewal FormAmjad Ali100% (1)

- EN - Ultrasonic Sensor Spec SheetDocument1 pageEN - Ultrasonic Sensor Spec Sheettito_matrixNo ratings yet

- Elizabeth Line When Fully Open PDFDocument1 pageElizabeth Line When Fully Open PDFArmandoNo ratings yet

- Vargas V YapticoDocument4 pagesVargas V YapticoWilfredo Guerrero IIINo ratings yet

- Moisture Control Guidance For Building Design, Construction and Maintenance (2013)Document144 pagesMoisture Control Guidance For Building Design, Construction and Maintenance (2013)Schreiber_Dieses100% (1)

- Week 2 - Assignment SolutionsDocument2 pagesWeek 2 - Assignment SolutionsSanyamNo ratings yet

- Kirkpatricks ModelDocument2 pagesKirkpatricks Modelnazia_ahmed_10No ratings yet

- Excerpt: "Railroaded" by Richard WhiteDocument38 pagesExcerpt: "Railroaded" by Richard Whitewamu885No ratings yet

- Plant Property and Equipment - Part 1 - PW - CWRDocument51 pagesPlant Property and Equipment - Part 1 - PW - CWRBENEDICT ANDREI SANTIAGONo ratings yet

- Handling Precautions: Butterfly Valves (Common To All Models)Document9 pagesHandling Precautions: Butterfly Valves (Common To All Models)xaaabbb_550464353No ratings yet

- Bomani Barton vs. Kyu An and City of Austin For Alleged Excessive Use of ForceDocument16 pagesBomani Barton vs. Kyu An and City of Austin For Alleged Excessive Use of ForceAnonymous Pb39klJNo ratings yet

- Tinas Resturant AnalysisDocument19 pagesTinas Resturant Analysisapi-388014325100% (2)

- Group Assignment For Quantitative: Analysis For Decisions MakingDocument45 pagesGroup Assignment For Quantitative: Analysis For Decisions Makingsemetegna she zemen 8ተኛው ሺ zemen ዘመንNo ratings yet