Professional Documents

Culture Documents

Manually operated directional valve controls

Uploaded by

Riyaz SiddiqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manually operated directional valve controls

Uploaded by

Riyaz SiddiqueCopyright:

Available Formats

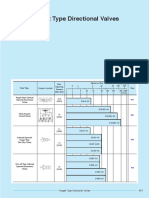

DIRECTIONAL CONTROLS

EIC-E-1005-0

■ Manually Operated Directional Valves

These valves may be used to manually shift the spool position and change the direction of oil flow.

■ Specifications

Maximum Flow L/min. Max. Operating Max. T-line Back

Mass

Model Numbers 70 140 210 315 Pressure Pressure

Kg

Kgf/cm2 Kgf/cm2 Kgf/cm2 Kgf/cm2 Kgf/cm2 Kgf/cm2

※

DMG-01-3C -10

DMG-01-3D※-10

35 35 35 -- 250 140 *2 1.8

DMG-01-2D※-10

DMG-01-2B※-10

DMG-03-3C※-50 100 *1 100 *1 100 *1 --

DMG-03-3D※-50 --

100 100 100 250 160 *3 4.0

DMG-03-2D※-50 --

DMG-03-2B※-50 100 *1 100 *1 100 *1 --

DMG-06-3C※-50

DMG-06-3D※-50 500 500 500 500 11.5

315 210 *3

DMG-06-2D※-50

DMG-06-2B※-50 420 300 250 200 12

Note: Max. flow means the limited flow which does not affect the normal function (changeover) of the valve.

1 Varies depending of the spool type. For the detail, see the “List of standard models and max. flow” for

DSG-03 Series Solenoid Operated Directional Valves (EIC-E-1002, Page 362 or 363 at 50 Hz

rated voltage.)

2 Lever operating torque varies depending on the T-Line back pressure. See the figure below.

3 If the T-Line back pressure exceeds 70 Kgf/cm2, directly connect the drain port to the reservoir.

DMG-01 Lever Operating Torque

Kgf-m

Operating Torque

0.15

0.1

0.05

0

0 50 100 140 Kgf/cm²

T-Line Back Pressure

Manually Operated Directional Valves

394

DIRECTIONAL CONTROLS

■ Model Number Designation

F- DM G -03 -2 B 2 A -50

Number Special

Spool

Special Series Type of Valve of Spool Two Design

Spring

seals Number Connections Size Valve Type Position Number

Arrangement

Positions Valve

C:

01 2, 3, 10

Spring

F: Centered 4,

Special 03 3 40, 50

seals D:

DM: 5, 6,

for G: No-Spring A*, B*

Manually 60,

Phosphate Sub- Detented (Omit if

Operated

Easter Type Plate 7, 8, not

Directional

Fluids Mounting 2 B: required)

Valve 06 9, 50

(Omit if Spring

not Offset 10,

required) 11,

See the table for combinations. 12

* Refer to column “valves with centre position and one offset position” (Special 2-position valves) on Page 396.

List of Spool Type

DMG-01 DMG-03 DMG-06

E

Spool Type 3C 3C 3C 2D Graphic Symbol

2D 2B 2D 2B

3D 3D 3D 2B

Spring Centred Models (3C )

Manually Operated

Directional Valves

OOOOOO O O

#1 #2 #3

A B

OOOO O O O

O O O O No-Spring Detented Models P T

3D 2D

40 O O O O #1 #2 #3 #1 (#2)* #3

A B A B

O

O P T P T

Spring Offset Models (2B )

O

#1 (#2) * #3

O O O A B

OO O O

P

OOO O * Position #2 is applied for model

DMG-01-2B※ and DMG-03-2B /2D ※ ※

O O O

O O O

11 O O

O O O

Position # 3

Position # 2

Position # 1 (#2, incase of DMG-01/03-2B※ , DMG-03-2D※ ) .

Note : The O Mark indicate the spool type available for each type.

Manually Operated Directional Valves

395

DIRECTIONAL CONTROLS

■ Valves with Centre position and One Offset Position (Special Two Position Valve)

※ ※

In addition to the standard two position valves (2D , 2B ), the following two types of two positions valves are

※ ※

available: Valves with centre position (#2) and position #1(2B A, 2D A), valves with centre position (#2) and

※

position #3 (2B B, 2D B). ※

The O mark in the table below indicates the spool type available for each models.

Spring Offset Models

Graphic Symbols Model Graphic Symbols Model

Valve A B

Valve A B

Type DMG-03DMG-06 Type DMG-01DMG-03 DMG-06

P T P T

2B2A O O 2B2B O O O

2B3A O O 2B3B O O O

2B4A O 2B4B O O O

2B40A O 2B40B O O

O

2B5B

2B5A O O

2B6A O 2B6B O

2B60A O 2B60B O O O

2B7A O 2B7B O O

2B8B O

2B9A O 2B9B O O

2B10A O 2B10B O O O

2B11A O 2B11B O O

2B12A O 2B12B O O O

* Position # 1 * Position # 1

* Position # 2 * Position # 2

No-spring Detented Models

Graphic Symbols Model Graphic Symbols Model

Valve A B

Valve A B

Type DMG-06 Type DMG-01DMG-06

P T P T

2D2A O 2D2B O O

2D3A O 2D3B O O

2D4A O 2D4B O O

2D40A O 2D40B O O

O

2D5B

2D5A O O

O O

2D6A 2D6B

O O O

2D60A 2D60B

2D7A O 2D7B O O

2D8A 2D8B O

2D9A O 2D9B O O

2D10A O 2D10B O O Note : Position number is determine with three

2D11A O 2D11B O O ※ ※

position type (3C and 3D ) as the standard.

2D12A O 2D12B O O

* Position # 1 * Position # 1

* Position # 2 * Position # 2

Manually Operated Directional Valves

396

DIRECTIONAL CONTROLS

■ Sub-plate

Valve Sub-plate Approx.

Thread

Model Model Mass

Size

Numbers Numbers Kg

DSGM-01-3080 1/8 BSP.F 0.8

DMG-01

DSGM-01X-3080 1/4 BSP.F 0.8

DSGM-03-3080 3/8 BSP.F 3.0

DMG-03 DSGM-03X-3080 1/2 BSP.F 3.0

DSGM-03Y-3080 3/4 BSP.F 4.7

DSGM-06-3080 3/4 BSP.F 7.4 Sub-plate dimension appearing page

DMG-06

DSGM-06X-3080 1 BSP.F 7.4 Sub-plate Model No. Page

Sub-plates are available. Specify sub-plate model from DSGM-01※ EIC-E-1001, Page-358

the table above. When sub-plates are not used, the

mounting surface should have a good machined finish. DSGM-03※ EIC-E-1002, Page-370

Sharable with solenoid operated Directional Valves and DSGM-06※ EIC-E-1003, Page-385

Solenoid Controlled Pilot Operated Directional Valves.

For dimensions, refer to the right table then see the

corresponding pages.

■ Mounting Bolts ■ Instructions E

Model Mounting Bolt Avoid connecting the tank Port “T”

Socket Head Cap Screw Qty.

Numbers Ordering Code to a line with possible surge pressure.

Manually Operated

Directional Valves

DMG-01 M5 x 45 Lg. 4 BKDMG-01-10

DMG-03 M6 x 35 Lg. 4 BKDMG-03-50

DMG-06 M12 x 60 Lg. 6 BKDMG-06-50

■ Pressure Drops

The pressure drop characteristics are based on the following conditions: viscosity of the fluid:35cSt

Specific Gravity: 0.850

For any other viscosity, multiple the factors in the table below.

Viscosity cSt 15 20 30 40 50 60 70 80 90 100

Factor 0.81 0.87 0.96 1.03 1.09 1.14 1.19 1.23 1.27 1.30

For any other specific gravity (G'), the pressure drop ( P') may be obtained

from the formula below.

P' = P G'/G where, P is a value on the following chart and G is 0.850.

Manually Operated Directional Valves

397

DIRECTIONAL CONTROLS

DMG-01

Kgf/cm² Valve Type Pressure Drop Curve Number

※ ※ ※ ※

1

14 3C 3D 2D 2B P→Α B→Τ P→Β A→Τ P→Τ

Pressure Drop ∆P

12 3C2 3D2 2D2 3 3 3 3

2

10 3C3 3D3 2D3 3 3 3 3 2

8 3 3C4 3D4 3 3 3 3

6 3C40 3D40 3 3 3 3

4 3C5 3D5 2 1 1 1 3

2 3C60 3D60 1 1 1 1 3

0 3C7 3D7 2D7 3 3 3 3

0 5 10 15 20 25 30 35 L/min 3C8 3D8 2D8 3 3

Flow Rate 3C9 3D9 3 3 3 3

3C10 3D10 3 3 3 3

3C11 3D11 3 3 3 3

3C12 3D12 3 3 3 3

2B2 2 2 3 3

2B3 2 2 3 3

2B8 3 3

For DMG-03, DMG-06, refer to the table below then see the related page.

Model Number Pressure Drop Characteristics Page Remarks

Same as DSG-03 Series Solenoid Operated Directional EIC-E-1002

DMG-03

3D※ is same as 3C※

Valves (standard Type) Page 367

Same as Solenoid Controlled Pilot Operated Directional EIC-E-1003

DMG-06

Valves (DSHG-06) Page 379

How to change Lever Position

30°

30°

Soc. Head Cap Screw

4 Hex. Soc.

30°

30°

30°

The lever position can be changed to any five positions as shown in the above sketch. For the lever position change, remove the

Soc. Head Cap Screw and lever once, set the lever at the required position and tighten it with Soc. Head Cap Screw firmly.

Manually Operated Directional Valves

398

DIRECTIONAL CONTROLS

DMG-01- -10 Mounting Surface : ISO 4401-AB-03-4-A

5.5 Dia. x Thru.

9.5 Dia. Spotface Cylinder Port "A"

4 Places Pressure

Port "P"

DIMENSIONS IN R 49 22: 3C

MILLIMETRES Position #3 71 17: 3D , 2D , 2B

0.75

40.5 11

15.5

27°

32.5

Centre Position #2

31

27°

Position #1 Tank Port "T"

Four positions are available Cylinder Port "B"

in 90° increment.

The operating lever position can be adjusted as required

5 on the circumference by loosening the set screw.

20 Dia. 26 Dia.

Lever Fixing Screw

2.5 Hex. Soc.

74

39

50.5

38

25

48

Mounting Surface

(O-rings Furnished)

65 E

Note : For the valve mounting surface dimensions, see the dimensional drawing of the sharable

sub-plate in page EIC-E-1001, Page-357

Manually Operated

Directional Valves

DMG-03- -50 Mounting Surface : ISO 4401-AC-05-4-A

Finishing Dimensions of Pressure Port "P" Cylinder Port "B"

Flow Restrictor 7 Dia. x Thru.

Cylinder Port "A" 11 Dia. Spotface

69.7 54

10.984 Dia. 4 Places

10.966

15°

12

(d Dia.) Max.

R 0.2

70

1

46

5~10

1.1

1.2

11.5 Dia.

11.3 48.7

Tank Port "T"

Orifice Dia. "d" should be 108.5

determined by customer application. 193.8

30° Notes 1. Each port (P, A, B and T) is machined for

Position #2

Position #1 flow restrictor. The flow restrictor should

20° be machined in accordance with the

74.5 Finishing Dimensions for Flow Retractor

27 ° R94.5 as shown in the left-hand drawing.

20 Although the tank port is shown on the left

Position #3

2. in our sub-plate, either may be used.

For the valve mounting surface

dimensions, see the dimensions, see the

25 Dia. 3. dimensional drawing of the sharable

sub-plate in page EIC-E-1002, page-369

139

2

76.3

59

46.3

27

39.7 19 Mounting Surface

92 (O-Rings Furnished)

Manually Operated Directional Valves

399

DIRECTIONAL CONTROLS

DMG-06- -50 Mounting Surface : ISO 4401-AE-08-4-A

Tank Port "T" Pressure Port "P"

13.5 Dia. x Thru.

300.5

20 Dia. Spotface

DIMENSIONS IN 95.8 130.2

6 Places

MILLIMETRES 53.2

Drain Port "V"

92.1

118

46.1

Cylinder

55.8 77

13

Port "B"

Cylinder Port "A"

Position # 2 260.5 52

30 57 57 34

40 Dia.

Position # 1 Indicates Spring Offset

Models (2B )

Indicates Spring Offset

Models (2B A).

Position # 3

47

116

41

40

6 Dia. Mounting Surface 12.5

6

Two Location Pins (O-rings Furnished.) 156

Note : for the valve mounting surface dimensions, see the dimensional drawing of the sharable sub-plate in

page EIC-E-1003, Page-384

■ Spare Parts List

Sl. List of Seals Part Numbers List of Seals Kits

Name of Part

No. DMG-01 DMG-03 DMG-06 Qty Model Numbers Seal Kit Numbers

1 O - Ring SO-NA-P6 - - 1 DMG-01-※※※-10 KS-DGM-01-10

DMG-03-※※※-50

2 O - Ring SO-NA-P8 - 2 KS-DGM-03-50

3 O - Ring SO-NB-P9 - - 4

DMG-06-※※※-50 KS-DGM-06-50

4 O - Ring - - SO-NB-P9 2

5 O - Ring - - SO-NB-P14 1

6 O - Ring SO-NB-P18 - - 3

7 O - Ring - - SO-NA-P20 2

8 O - Ring - SO-NB-P21 - 2

9 O - Ring - - SO-NB-P30 4

10 O - Ring - - SO-NB-P40 2

11 O - Ring - SO-NB-A023 - 1

12 O - Ring - AS568A-014 - 5

13 O – Ring - - SO-NB-P10 2

14 Backup Ring - - SO-BB-P10A 1

15 Backup Ring - SO-BB-P8 - 2

16 Backup Ring SO-BE-P12 - - 1

Note : When ordering the seals, please specify the seal kit number from the table right.

Manually Operated Directional Valves

400

You might also like

- Injection Pump DataDocument1 pageInjection Pump DataMuhammad rizki100% (3)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Part B: User ManualDocument13 pagesPart B: User ManualtecnicoopNo ratings yet

- Cylinder Head - Install: Shutdown SISDocument4 pagesCylinder Head - Install: Shutdown SISReymundo Enrique Dominguez HernandezNo ratings yet

- DCG CAM-operated-Directional-ValveDocument4 pagesDCG CAM-operated-Directional-ValveDANIEL LNo ratings yet

- Bk-3-Latest EIC-E-1003-0 (Solenoid Controlled Pilot Operated Directional Valves)Document15 pagesBk-3-Latest EIC-E-1003-0 (Solenoid Controlled Pilot Operated Directional Valves)Manoj PadhiNo ratings yet

- 2-Latest EIC-C-1002-0 (Pilot Operated Relief Valve)Document14 pages2-Latest EIC-C-1002-0 (Pilot Operated Relief Valve)Lin LeninNo ratings yet

- DSHG 06 3C4 YukenDocument16 pagesDSHG 06 3C4 YukenJindal HydraulicsNo ratings yet

- Directional Controls for Double Locking Check ValvesDocument2 pagesDirectional Controls for Double Locking Check ValvesPasu_08No ratings yet

- 2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Document12 pages2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Sujeet KumarNo ratings yet

- 2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Document12 pages2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)SivaNo ratings yet

- Remote Control Relief ValveDocument15 pagesRemote Control Relief ValveKantha RajNo ratings yet

- Electronic Relay Incorporated Solenoid Operated Directional ValvesDocument2 pagesElectronic Relay Incorporated Solenoid Operated Directional Valvesaries_fransischoNo ratings yet

- Directional Controls: Pilot Operated Directional ValvesDocument6 pagesDirectional Controls: Pilot Operated Directional ValvesPradeep ShekarNo ratings yet

- Aft-Catalog - s9 - Sec MOTION CONTROLSDocument14 pagesAft-Catalog - s9 - Sec MOTION CONTROLSAmcaNo ratings yet

- Section 9 Motion Control ValvesDocument14 pagesSection 9 Motion Control Valvesandres buguenoNo ratings yet

- DSG 03 Series Solenoid Operated Directional ValvesDocument12 pagesDSG 03 Series Solenoid Operated Directional ValvesSita Rama Raju PNo ratings yet

- Yuken Hydraulic CylinderDocument11 pagesYuken Hydraulic CylinderDk PanigrahiNo ratings yet

- Solenoid Controlled Relief ValvesDocument10 pagesSolenoid Controlled Relief ValvesRenjithSivaNo ratings yet

- Low Noise Solenoid Controlled Relief ValvesDocument7 pagesLow Noise Solenoid Controlled Relief ValveshectorNo ratings yet

- Atlantic ValvulaDocument8 pagesAtlantic ValvulaHector DiazNo ratings yet

- DT (G) - 02 Series PDFDocument3 pagesDT (G) - 02 Series PDFIwan SbNo ratings yet

- Poppet Type Solenoid Operated Directional ValvesDocument5 pagesPoppet Type Solenoid Operated Directional ValvesNEXON PIPENo ratings yet

- Fuel injection pump service data for Yanmar 3TNE82A-YB engineDocument1 pageFuel injection pump service data for Yanmar 3TNE82A-YB enginealeksandr.pozdnyakof100% (1)

- Pilot Operated Relief Valves: Pressure ControlsDocument7 pagesPilot Operated Relief Valves: Pressure Controlssymantec37No ratings yet

- EIC E 1001 0 DSG 01 Series Direction Control Valve PDFDocument12 pagesEIC E 1001 0 DSG 01 Series Direction Control Valve PDFmaherNo ratings yet

- Electrically Operated Pressure Reducing Cartridge, Size 16: Seated Pilot Stage, Spool Type Main Stage Series WDRVPA 5 ..Document5 pagesElectrically Operated Pressure Reducing Cartridge, Size 16: Seated Pilot Stage, Spool Type Main Stage Series WDRVPA 5 ..Roberto Blazquez SevillanoNo ratings yet

- Way Solenoid Valve of Forged Brass Body /sub-Base Mounting For General ApplicationDocument6 pagesWay Solenoid Valve of Forged Brass Body /sub-Base Mounting For General ApplicationLuis Erney Huertas ReyNo ratings yet

- Cargo Pump Curve - MT BourneDocument2 pagesCargo Pump Curve - MT Bournetimayaa1000100% (1)

- 01-08 Z011-GMX 04-2017 enDocument4 pages01-08 Z011-GMX 04-2017 enBryan QuirozNo ratings yet

- Proportional Electro-Hydraulic Relief Valves: SpecificationsDocument9 pagesProportional Electro-Hydraulic Relief Valves: SpecificationsMohammed SaeidNo ratings yet

- Bce 60 80 120 R en 2021Document1 pageBce 60 80 120 R en 2021tachetacheNo ratings yet

- WK 450 540 Check Valve Type S: DM /min Up To 260 Up To 31,5 Mpa Ns 6 To 30Document4 pagesWK 450 540 Check Valve Type S: DM /min Up To 260 Up To 31,5 Mpa Ns 6 To 30Gizem MuhendislikNo ratings yet

- BV Options DetailsDocument4 pagesBV Options DetailslorenzoNo ratings yet

- FlowCon SH 50 150 Data Sheet EngDocument8 pagesFlowCon SH 50 150 Data Sheet EngJerry FebriansyahNo ratings yet

- WRVD0M22Bpdf 1521Document3 pagesWRVD0M22Bpdf 1521yelmustafaaliNo ratings yet

- Egyptian Sponge Iron & Steel Company Direct Reduction Iron Facility On/Off Control Valve ListDocument4 pagesEgyptian Sponge Iron & Steel Company Direct Reduction Iron Facility On/Off Control Valve ListMohamed Elsaid El ShallNo ratings yet

- PompeDocument4 pagesPompeAndreea DiaconuNo ratings yet

- RV - Relief Valves Catalog CP200-1Document1 pageRV - Relief Valves Catalog CP200-1Hamza ChenakerNo ratings yet

- Type VMPD/B: Pressure Relief ValvesDocument4 pagesType VMPD/B: Pressure Relief Valvestommy lapointeNo ratings yet

- DCNTLP 056 06Document2 pagesDCNTLP 056 06frankcengelNo ratings yet

- Olrl 602Document4 pagesOlrl 602alejandro perezNo ratings yet

- DSG-03 Series Solenoid Operated Directional ValvesDocument17 pagesDSG-03 Series Solenoid Operated Directional ValvesPitupyNo ratings yet

- DSG-03 Series Solenoid Operated Directional ValvesDocument17 pagesDSG-03 Series Solenoid Operated Directional ValveskammoNo ratings yet

- Pressure Reducing Valves for Industrial SystemsDocument2 pagesPressure Reducing Valves for Industrial SystemsEdwards YanezNo ratings yet

- Unloading Relief Valves: Pressure ControlsDocument6 pagesUnloading Relief Valves: Pressure ControlsmdkhandaveNo ratings yet

- DMBF Full en Metric LetterDocument4 pagesDMBF Full en Metric LetterRonaldNo ratings yet

- VR050 43010-0021Document2 pagesVR050 43010-0021Graham AldersonNo ratings yet

- DS3000 TPCDocument9 pagesDS3000 TPCHuy DangNo ratings yet

- Poppet Type Directional ValvesDocument46 pagesPoppet Type Directional ValvesdejanpecicNo ratings yet

- Compact Disc Check Valve for Industrial ApplicationsDocument2 pagesCompact Disc Check Valve for Industrial ApplicationsDinesh ChouguleNo ratings yet

- SRC - 130 KATALOGDocument3 pagesSRC - 130 KATALOGSomiar TradingNo ratings yet

- Double Check Valve DC: Technical DataDocument2 pagesDouble Check Valve DC: Technical DataAthanasoulis KostasNo ratings yet

- Electrovalvula Norgren V62Document5 pagesElectrovalvula Norgren V62Base SistemasNo ratings yet

- Electrovalvula Norgren V63Document5 pagesElectrovalvula Norgren V63Base SistemasNo ratings yet

- Electrovalvula Norgren V61Document5 pagesElectrovalvula Norgren V61Base SistemasNo ratings yet

- Aft-Catalog s3 SecDocument10 pagesAft-Catalog s3 SecwemersonsrNo ratings yet

- Castel Magn O8Document14 pagesCastel Magn O8Daniel Fancis Amabran BarrientosNo ratings yet

- Explosion-Proof Differential Pressure Switch: SERIES 1950Document2 pagesExplosion-Proof Differential Pressure Switch: SERIES 1950Alex RamirezNo ratings yet

- Butterfly Valve WaferDocument2 pagesButterfly Valve WaferAhlan kpNo ratings yet

- Forged check valves for flow controlDocument1 pageForged check valves for flow controlsitaNo ratings yet

- Part No. Description Qty. Part No. Description QtyDocument2 pagesPart No. Description Qty. Part No. Description QtyRiyaz SiddiqueNo ratings yet

- Conex: Shrinkage Compensating AdmixtureDocument2 pagesConex: Shrinkage Compensating AdmixtureRiyaz SiddiqueNo ratings yet

- Concrete Admixtures: High Performance & SpecialtyDocument6 pagesConcrete Admixtures: High Performance & SpecialtyRiyaz SiddiqueNo ratings yet

- Conex: Shrinkage Compensating AdmixtureDocument1 pageConex: Shrinkage Compensating AdmixtureRiyaz SiddiqueNo ratings yet

- PDH TRACKING FORM 2021Document2 pagesPDH TRACKING FORM 2021Riyaz SiddiqueNo ratings yet

- Lever Operated Dirctional Control Valve DL10Document4 pagesLever Operated Dirctional Control Valve DL10Riyaz SiddiqueNo ratings yet

- Is 516 1959 PDFDocument30 pagesIs 516 1959 PDFannie3456789No ratings yet

- Yuken Valves Valvulas Direccionales PDFDocument184 pagesYuken Valves Valvulas Direccionales PDFSimon NgigiNo ratings yet

- Conex: Shrinkage Compensating AdmixtureDocument1 pageConex: Shrinkage Compensating AdmixtureRiyaz SiddiqueNo ratings yet

- EIC F 1003 0 04 Series Modular ValveDocument11 pagesEIC F 1003 0 04 Series Modular ValveRiyaz SiddiqueNo ratings yet

- Wind Analysis Over Multistorey Building Having Flat Slab-Shear Wall Interaction: A ReviewDocument5 pagesWind Analysis Over Multistorey Building Having Flat Slab-Shear Wall Interaction: A ReviewIJAERS JOURNALNo ratings yet

- EIC N 1001 0 Hydraulic FluidsDocument13 pagesEIC N 1001 0 Hydraulic FluidsCharitha LiyanagamaNo ratings yet

- 3403 Application of Post Tension Technology On Tall BuildingsDocument13 pages3403 Application of Post Tension Technology On Tall BuildingsyhumaaawNo ratings yet

- Is 516 1959 PDFDocument30 pagesIs 516 1959 PDFannie3456789No ratings yet

- Tension Capacity of PileDocument8 pagesTension Capacity of Pilenimal179100% (1)

- A Study of Factors Affecting The Flexura - 2016 - Journal of King Saud UniversitDocument10 pagesA Study of Factors Affecting The Flexura - 2016 - Journal of King Saud UniversitRiyaz SiddiqueNo ratings yet

- Full Thesis PDFDocument210 pagesFull Thesis PDFRiyaz SiddiqueNo ratings yet

- FEM Design Verification Checklist For ADAPT-Builder 2016 (Summary)Document26 pagesFEM Design Verification Checklist For ADAPT-Builder 2016 (Summary)Riyaz SiddiqueNo ratings yet

- 1498 Soil ClasificationDocument28 pages1498 Soil ClasificationRamesh100% (4)

- Indian Steel TableDocument97 pagesIndian Steel Tableshreekant2785% (13)

- Akimoelu Et Al 2017 Evaluation of Splitting Tensile and Compressive Stregth Relationship SCCDocument7 pagesAkimoelu Et Al 2017 Evaluation of Splitting Tensile and Compressive Stregth Relationship SCCDemarcus WerdineNo ratings yet

- PW Drilling and Sampling of Soil and Rock - 1Document12 pagesPW Drilling and Sampling of Soil and Rock - 1itng2527No ratings yet

- Piles DesignDocument15 pagesPiles Designvenkatesh19701No ratings yet

- Full Thesis PDFDocument210 pagesFull Thesis PDFRiyaz SiddiqueNo ratings yet

- Indian Steel TableDocument97 pagesIndian Steel Tableshreekant2785% (13)

- EM 1110-1-2908 - Rock FoundationsDocument120 pagesEM 1110-1-2908 - Rock FoundationsPDHLibraryNo ratings yet

- Is 516 1959 PDFDocument30 pagesIs 516 1959 PDFannie3456789No ratings yet

- Geotechnical Investigation ReportDocument66 pagesGeotechnical Investigation ReportRiyaz SiddiqueNo ratings yet

- Shrinkage CrackDocument9 pagesShrinkage CrackRiyaz SiddiqueNo ratings yet

- FIC VY240D - REV 0.1 (ComunidadeTecnica - Com.br)Document49 pagesFIC VY240D - REV 0.1 (ComunidadeTecnica - Com.br)Selmar CavalcantiNo ratings yet

- Ukpsc Ae 2023 Admit CardDocument2 pagesUkpsc Ae 2023 Admit CardChetan ChauhanNo ratings yet

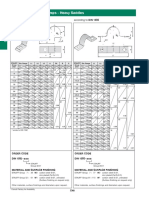

- Heavy Saddle ClampsDocument1 pageHeavy Saddle ClampsSudarshan KaragudariNo ratings yet

- Technical Specification - MCS LiteDocument6 pagesTechnical Specification - MCS LiteKrunoslavNo ratings yet

- Unisonic Technologies Co., LTD: NPN Epitaxial Silicon TransistorDocument5 pagesUnisonic Technologies Co., LTD: NPN Epitaxial Silicon TransistorDuvan AriasNo ratings yet

- CI 1580A ENG User ManualDocument50 pagesCI 1580A ENG User ManualArdy KristianNo ratings yet

- 01 - PVC Conduits InstallationDocument11 pages01 - PVC Conduits InstallationRaju ManojNo ratings yet

- VTU Exam Question Paper With Solution of 18CS63 Web Technology and Its Applications Aug-2022-Dr. Sudhakar K N & Dr. Ganesh D RDocument36 pagesVTU Exam Question Paper With Solution of 18CS63 Web Technology and Its Applications Aug-2022-Dr. Sudhakar K N & Dr. Ganesh D RSatwik NmNo ratings yet

- Gartner Reprint 2022Document33 pagesGartner Reprint 2022Sajan Rajagopal100% (1)

- Club Planner Victor CruzDocument2 pagesClub Planner Victor CruzVictor CruzNo ratings yet

- Presentation Mathematical EconomicsDocument15 pagesPresentation Mathematical Economicsambarmalik 226No ratings yet

- Registration Slip 2300805632Document2 pagesRegistration Slip 2300805632Avinash KumarNo ratings yet

- Monitoring and Evaluation FinalDocument20 pagesMonitoring and Evaluation FinalNational Child Health Resource Centre (NCHRC)No ratings yet

- Info Iec60038 (Ed6.2) en DDocument4 pagesInfo Iec60038 (Ed6.2) en DArief Muhammad LubisNo ratings yet

- Instructions: Hmems80 2020 Semester 1 Assignment 01 (Unique Number: 873964) Due Date: 9 March 2020Document8 pagesInstructions: Hmems80 2020 Semester 1 Assignment 01 (Unique Number: 873964) Due Date: 9 March 2020Matshele SerageNo ratings yet

- CLE-C4ED SMDocument69 pagesCLE-C4ED SMAndrei TraintaNo ratings yet

- 15 ++103-+115+QH+8 (1) +2022+An++AditiaDocument13 pages15 ++103-+115+QH+8 (1) +2022+An++AditiaSuzan HakyNo ratings yet

- Contractors Electrical WebpageDocument4 pagesContractors Electrical WebpageJAGUAR GAMINGNo ratings yet

- Google Drive Resume Template FreeDocument4 pagesGoogle Drive Resume Template Freec2k2x8ds100% (1)

- Tidal Energy: Mayank GoyalDocument31 pagesTidal Energy: Mayank GoyalMayank GoyalNo ratings yet

- Entry 5: Chapter 5, Lesson 5 - Staff and Support AgenciesDocument2 pagesEntry 5: Chapter 5, Lesson 5 - Staff and Support AgenciesMr ExMachineNo ratings yet

- Page 44Document1 pagePage 44Abhishek ShatagopachariNo ratings yet

- Arghya Kundu (Profile)Document4 pagesArghya Kundu (Profile)akundu2000No ratings yet

- Directions: Analyze The Case Studies Given Below and Answer Briefly and Concisely The Case Questions Semester, AY 2020-2021Document4 pagesDirections: Analyze The Case Studies Given Below and Answer Briefly and Concisely The Case Questions Semester, AY 2020-2021Abigail Turot60% (5)

- Mobile Phones and Autonomy 2Document30 pagesMobile Phones and Autonomy 2Adliana ColinNo ratings yet

- Fabric filters efficiently remove fine particlesDocument4 pagesFabric filters efficiently remove fine particlesPraphulJainNo ratings yet

- BFF/ BHM 2003 Computer ProgrammingDocument44 pagesBFF/ BHM 2003 Computer ProgrammingRandy ClarckNo ratings yet