Professional Documents

Culture Documents

Introducing Two Most Common Types of Shear Walls and Their Construction Methods

Uploaded by

Melo PereiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introducing Two Most Common Types of Shear Walls and Their Construction Methods

Uploaded by

Melo PereiraCopyright:

Available Formats

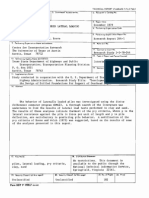

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/313530133

Introducing two most common types of shear walls and their construction

methods

Article · February 2017

CITATIONS READS

0 3,944

1 author:

Ali Fathalizadeh

Iran University of Science and Technology

4 PUBLICATIONS 0 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Integrating sustainable development into construction project management View project

Sustainable Development View project

All content following this page was uploaded by Ali Fathalizadeh on 10 February 2017.

The user has requested enhancement of the downloaded file.

8 Journal of Civil Engineering Researchers

JOURNAL OF

CIVIL

ENGINEERING

RESEARCHERS

Introducing two most common types of shear walls and their

construction methods

Ali Fathalizadeha *

a

Iran University of Science and Technology,Tehran, Iran

Abstract

In this article we have reviewed shear walls as an effective way for resisting lateral loads in tall buildings. Then two most

popular types of shear walls, steel and concrete walls, are reviewed and their construction methods are discussed. At the end

we have concluded that shear walls are one of the most effective and operational solutions for resisting earthquake and wind

forces.

© 2017 Journals-Researchers. All rights reserved

Keywords: Shear walls, Concrete shear wall, Steel shear wall, Construction, Lateral loads

kill human but structures, which are not constructed

with considering the earthquake forces do. Shear

1. Introduction walls are built to resist the lateral forces produced

during earthquake or wind. Shear walls behavior

In structural engineering, a shear wall is a depends upon the material used, wall thickness, wall

structural system composed of braced panels (also length, wall positioning in building frame also [2].

known as shear panels) to counter the effects of

lateral load acting on a structure [1]. Wind and

seismic loads are the most common loads that shear

walls are designed to carry. Vibrations, which are

caused under the earth’s surface, generate waves,

which disturb the earth’s surface, termed as

earthquakes.

——— It was said that earthquakes would not

*

Corresponding author. e-mail: ali.fath91@yahoo.com.

Journals-Researchers Publication 9

2. Structural Forms of Shear Walls

Monolithic shear walls are classified as short,

squat or cantilever according to their height to depth

ratio [Fig.1].

Fig.3 Positioning of shear walls

4. Concrete shear walls

Concrete shear walls are one of the most assured

types of shear walls. Buildings with cast-in-place

reinforced concrete shear walls are widespread in

Fig.1 Shear walls classifying according to their height to

depth ratio many earthquake-prone countries and regions [3].

This type of construction has been practiced since the

1960s in urban regions for medium to high-rise

Generally, shear walls are either plane or flanged in buildings (4 to 35 stories high).

section [Fig.2].

4.1. Structure of a concrete shear wall

A concrete shear wall consists of reinforcements

and concrete. Which can be built in two ways: 1. pre-

cast [Fig.4], 2. Cast in place [Fig.5]. But both of them

are almost similar in their reinforcements [Fig.6] [4].

Fig.2 Shear walls section types

3. Positioning of Shear Walls

Structurally, the best position for the shear walls is

in the center of each half of the building but this is

rarely practical [Fig.3].

Fig.4 Pre-cast shear wall

10 Journal of Civil Engineering Researchers

Fig.7 Shear wall’s starter bars placing

Fig.5 A cast in place shear wall

Fig.6 Reinforcement of shear walls

4.2. Construction of a concrete shear wall

After foundation reinforcement finished and

before pouring its concrete, shear wall starter bars

should be placed into foundation reinforcement

[Fig.7]. Then, after concrete pouring of foundation,

formworks should be installed [Fig.8]. Please note

Fig.8 formworks installation

that if there is not enough space through the wall to

install the reinforcements, form works should be

installed after reinforcement works [Fig.9]. The next

phase is pouring concrete into the forms. Forms can

be removed after a proper time when concrete has

reached a sufficient resistance (As mentioned in valid

codes).

Journals-Researchers Publication 11

Then column plates should be installed and

leveled by grout. Afterwards like all other steel frame

buildings, columns and beams can be installed

[Fig.11].

Fig.9 formworks installation and concrete pouring

Fig.11 column plates installation

Then steel plates are carried to the place by crane

and installed to columns and beams by bolts or

5. Steel Shear walls

welding [Figs.12-14] [7].

A steel plate shear wall (SPSW) consists of steel

infill plates bounded by boundary elements. They

constitute an SPSW. Its behavior is analogous to a

vertical plate girder cantilevered from its base [5].

Similar to plate girders, the SPSW system optimizes

component performance by taking advantage of the

post-buckling behavior of the steel infill panels. An

SPSW frame can be idealized as a vertical cantilever

plate girder, in which the steel plates act as the web,

the columns act as flanges and the cross beams

represent the transverse stiffeners [6].

5.1. Construction of a steel shear walls

After foundation reinforcement finished and

before pouring its concrete, shear wall Anker bolts

should be placed into foundation reinforcement

[Fig.10].

Fig.12 Carriage and installation of steel shear walls

Fig.10 shear wall’s Anker bolts

12 Journal of Civil Engineering Researchers

6. Conclusion

With buildings rising in stories, engineers are

trying to find new systems for designing and

constructing structures with better performance and

functionality. Shear walls are one of the best

solutions for resisting lateral loads, which can be

constructed by reinforced concrete or steel plates and

can be used in both concrete and steel framed

structures. Shear walls are either plane or flanged in

section and best position for them is in the center of

each half of the building. They are easy to construct

and make the structure more ductile and safe against

earthquake and wind forces.

Fig.13 Steel shear walls installed by bolts

References

[1] www.abag.ca.gov

[2] Venkata Sairam Kumar.N, Surendra Babu.R, Usha Kranti.J,

―Shear walls – A review‖ International Journal of Innovative

Research in Science, Engineering and Technology, Vol. 3,

Issue 2, February 2014

[3] M. Ofelia Moroni,‖ CONCRETE SHEAR WALL

CONSTRUCTION‖ Edificios Chilenos de Hormigón

Armado, 2002. Ed. ICH, Chile.

[4] Murty CVR, Rai DC, Bajpai KK, Jain SK. ―Effectiveness of

reinforcement details in exterior reinforced concrete beam

column joints for earthquake resistance, ACI Structural

journal, 100, Pp.49-155,2003.

[5] Max Guendel, Benno Hoffmeister, Markus Feldmann,

―Experimental and numerical investigations on steel shear

walls for seismic retrofitting‖. Proc of the 8th international

conference on structural dyncamics, Eurodyn, pp. 474-

481,2011.

Fig.14 Steel shear walls installed by welding [6] S.V.Venkatesh, H.Sharada Bai, ―Effect of internal & External

shear wall on performance of buildings frame subjected to

lateral load‖, International journal of earth science and

engineering, Vol.4, No.6, SPL, (Oct, 2011), pp 571-576,2011.

[7] S.W.Nunnally, ―Construction Methods and Management‖

,1980 by Prentice-Hall, Inc., Englewood Cliffs, N.J. 07632

View publication stats

You might also like

- Introducing Two Most Common Types of Shear Walls and Their Construction MethodsDocument6 pagesIntroducing Two Most Common Types of Shear Walls and Their Construction MethodsVictor OmotoriogunNo ratings yet

- ShearwallsfinalDocument6 pagesShearwallsfinalHarshitha ReddyNo ratings yet

- CONSTRUCTION JOINT EFFECTDocument17 pagesCONSTRUCTION JOINT EFFECThakim2020No ratings yet

- Joints ConcreteDocument17 pagesJoints ConcreteMuhammad IqbalNo ratings yet

- NOV151322 (1) For Geometric ND Limit StateDocument11 pagesNOV151322 (1) For Geometric ND Limit StateSrinivas TanigantiNo ratings yet

- Codes of Seismic BuildingDocument29 pagesCodes of Seismic Buildingutkarsh pandeyNo ratings yet

- Shear Wall MainDocument37 pagesShear Wall MainMr420• NeffexNo ratings yet

- AIJ Standard Reinforced Concrete Box-Shaped Wall StructuresDocument80 pagesAIJ Standard Reinforced Concrete Box-Shaped Wall StructuresdamindaNo ratings yet

- Confined MasonryDocument13 pagesConfined Masonryhemantks3No ratings yet

- كونكريت كورس اولDocument181 pagesكونكريت كورس اولمحمد حسن محمد حسنNo ratings yet

- AIJ Standard for Structured Design of RC Box WallsDocument80 pagesAIJ Standard for Structured Design of RC Box WallsAnnisaNo ratings yet

- CMU Hybrid Construction DetailsDocument8 pagesCMU Hybrid Construction DetailsB0B_PNo ratings yet

- Expansion and Construction JointsDocument46 pagesExpansion and Construction Jointscricket review100% (1)

- 29 Marylbone Road Report FinalDocument27 pages29 Marylbone Road Report FinaljimmychillsNo ratings yet

- Effect of Change in Shear Wall Location With Uniform and Varying Thickness in High Rise BuildingDocument5 pagesEffect of Change in Shear Wall Location With Uniform and Varying Thickness in High Rise BuildingBlond MecinajNo ratings yet

- Hybrid-Masonry-Design-2 13 01 - 12 29 09 PDFDocument6 pagesHybrid-Masonry-Design-2 13 01 - 12 29 09 PDFDennier CHÁVEZ GARRONo ratings yet

- Fema 308Document51 pagesFema 308ktiwari-1No ratings yet

- Study On Causes & Control of Cracks in A Structure: Mulla FayazDocument4 pagesStudy On Causes & Control of Cracks in A Structure: Mulla FayazShubham ThakurNo ratings yet

- AAAAAAAAADocument8 pagesAAAAAAAAAtedy yidegNo ratings yet

- Beam, Floor EtcDocument47 pagesBeam, Floor EtcakmaNo ratings yet

- National authority guide to concrete masonry hybrid structuresDocument8 pagesNational authority guide to concrete masonry hybrid structuresMega EstructurasNo ratings yet

- AIJ Standard for Structural Design of Reinforced Concrete Box-Shaped Wall StructuresDocument80 pagesAIJ Standard for Structural Design of Reinforced Concrete Box-Shaped Wall StructureshbookNo ratings yet

- Study on Earthquake Resistant Building Using Base IsolationDocument4 pagesStudy on Earthquake Resistant Building Using Base IsolationSidd PriyamNo ratings yet

- Hybrid Masonry Design 2.13.01 - 12.29.09Document6 pagesHybrid Masonry Design 2.13.01 - 12.29.09Sovich82No ratings yet

- BuildDocument11 pagesBuildTamirat TekaNo ratings yet

- 2016 06 IJTRD OptimumPositioningofShearWallsinMultistorey BuildingsDocument7 pages2016 06 IJTRD OptimumPositioningofShearWallsinMultistorey BuildingshemanthsridharaNo ratings yet

- Hybrid masonry construction detailsDocument8 pagesHybrid masonry construction detailsjerryNo ratings yet

- Horizontal Bands in Masonry BuildingsDocument6 pagesHorizontal Bands in Masonry BuildingsLaxmana PrasadNo ratings yet

- What Is ShoringDocument11 pagesWhat Is ShoringmenyiluNo ratings yet

- Specify The Methods For Strengthening of Masonry BuildingsDocument10 pagesSpecify The Methods For Strengthening of Masonry BuildingsInjun JoeNo ratings yet

- Bharat JournalDocument6 pagesBharat Journalersunilsingh1No ratings yet

- Cast-in-Place and Pre-Cast Concrete SystemDocument13 pagesCast-in-Place and Pre-Cast Concrete SystemJayson JavierNo ratings yet

- Building Materials and Technology-Vi 1Document9 pagesBuilding Materials and Technology-Vi 1visha patelNo ratings yet

- Hybrid Concrete Masonry Construction DetailsDocument12 pagesHybrid Concrete Masonry Construction DetailsENG MOHAMEDNo ratings yet

- ArchitectureDocument13 pagesArchitectureBona TekileNo ratings yet

- Hospital JoournalDocument22 pagesHospital Joournalvgujju5No ratings yet

- Shear WallDocument17 pagesShear WallIjaz100% (1)

- Seismic Analysis of Multi-Storied Building With Shear Walls Using EtabsDocument6 pagesSeismic Analysis of Multi-Storied Building With Shear Walls Using EtabsIsmailNo ratings yet

- Report Project Mom Section 10 Group 1Document24 pagesReport Project Mom Section 10 Group 1Muhammad Hazim Bin Abdul HishamNo ratings yet

- Hybrid Concrete Masonry Construction DetailsDocument12 pagesHybrid Concrete Masonry Construction DetailsCarlos Coral MoraNo ratings yet

- ITJEGAN'S OptionDocument14 pagesITJEGAN'S OptionMohan0% (1)

- Shear Wall Constructionin BuildingsDocument7 pagesShear Wall Constructionin BuildingsVictor OmotoriogunNo ratings yet

- Analysis and Design of Shear WallDocument30 pagesAnalysis and Design of Shear Wallmohammedzeeshan100% (3)

- Analysis and Design of Shear WallDocument30 pagesAnalysis and Design of Shear WallAnonymous 5VwQ0KC378% (9)

- Earthquake Resistant BuildingsDocument10 pagesEarthquake Resistant BuildingssolairajaNo ratings yet

- Design Loadbearing Masonry StructuresDocument9 pagesDesign Loadbearing Masonry StructuresthushtikaNo ratings yet

- Paper 1Document8 pagesPaper 1BUSH RCNo ratings yet

- Introduction To Reinforced Concrete Design Part 1Document6 pagesIntroduction To Reinforced Concrete Design Part 1jhess QuevadaNo ratings yet

- Seismic Design Principles & EffectsDocument10 pagesSeismic Design Principles & Effectsfaheem momdNo ratings yet

- Effect of Shear Wall Configuration On Seismic Performance of Building PDFDocument5 pagesEffect of Shear Wall Configuration On Seismic Performance of Building PDFumair baigNo ratings yet

- Universiti Tun Hussein Onn Malaysia Faculty of Civil Engineering and Built EnvironmentDocument14 pagesUniversiti Tun Hussein Onn Malaysia Faculty of Civil Engineering and Built EnvironmentEzanie IzyanNo ratings yet

- Assaignement Plastic Design Infill Wall StructuresDocument42 pagesAssaignement Plastic Design Infill Wall Structuresmerlin otemakumiNo ratings yet

- Seismic Analysis of Multi-Storied Building With Shear Walls Using ETABS-2013Document11 pagesSeismic Analysis of Multi-Storied Building With Shear Walls Using ETABS-20138790922772No ratings yet

- Construction TechnologyDocument78 pagesConstruction TechnologyAldina MuthoniNo ratings yet

- Paper 060 Project Application of Structural Analysis, Design and Laboratory Testing of A Complex Masonry FascadeDocument9 pagesPaper 060 Project Application of Structural Analysis, Design and Laboratory Testing of A Complex Masonry FascadeFarzan BabaeiNo ratings yet

- Catapang, John Walter C 3 CE-4 Assignment #1Document6 pagesCatapang, John Walter C 3 CE-4 Assignment #1Walter CatapangNo ratings yet

- Analysis and Design of Shear WallDocument30 pagesAnalysis and Design of Shear Wallteguh widayat100% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Introduction to Design of Building StructuresFrom EverandIntroduction to Design of Building StructuresRating: 4 out of 5 stars4/5 (22)

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Dashti - Out Plane Response - 2Document33 pagesDashti - Out Plane Response - 2Melo PereiraNo ratings yet

- Fracture Energy MC1990vs2010 - 2Document2 pagesFracture Energy MC1990vs2010 - 2Melo PereiraNo ratings yet

- Confined Concrete - Fracture Energy - 1Document11 pagesConfined Concrete - Fracture Energy - 1Melo PereiraNo ratings yet

- Markeset - Hillerborg - Softening in CompressionDocument7 pagesMarkeset - Hillerborg - Softening in CompressionMelo PereiraNo ratings yet

- Concrete Damage Plasticity Model FRPDocument40 pagesConcrete Damage Plasticity Model FRPMelo PereiraNo ratings yet

- Dashti Out Plane Response 3Document44 pagesDashti Out Plane Response 3Melo PereiraNo ratings yet

- Grammatikou+Fardis - Flexural Rotation Capacity Models Fitted To Test Results Using DifferentDocument17 pagesGrammatikou+Fardis - Flexural Rotation Capacity Models Fitted To Test Results Using DifferentMelo PereiraNo ratings yet

- Fardis - Seismic Retrofitting Techniques For Concrete BuildingsDocument12 pagesFardis - Seismic Retrofitting Techniques For Concrete BuildingsMelo PereiraNo ratings yet

- Grammatikou - Models of Flexural Controlled StrengthDocument35 pagesGrammatikou - Models of Flexural Controlled StrengthMelo PereiraNo ratings yet

- Reconnaissance Observations by CIGIDEN After The 2015 Illapel, Chile Earthquake and TsunamiDocument13 pagesReconnaissance Observations by CIGIDEN After The 2015 Illapel, Chile Earthquake and TsunamiMelo PereiraNo ratings yet

- Dashti - Out Plane Response - 1Document49 pagesDashti - Out Plane Response - 1Melo PereiraNo ratings yet

- Art:10.1007/s40069 012 0001 4 PDFDocument16 pagesArt:10.1007/s40069 012 0001 4 PDFcdestudosNo ratings yet

- Dashti - Out of Plane Response RC WallsDocument23 pagesDashti - Out of Plane Response RC WallsMelo PereiraNo ratings yet

- 16WCEE-Illapel Chile 2015 HospitalsDocument13 pages16WCEE-Illapel Chile 2015 HospitalsMelo PereiraNo ratings yet

- Compression Failure Concrete Walls Chile EarthquakeDocument12 pagesCompression Failure Concrete Walls Chile EarthquakeMelo PereiraNo ratings yet

- Dashti - Cantebury EarthquakeDocument16 pagesDashti - Cantebury EarthquakeMelo PereiraNo ratings yet

- Comportamiento Aislados Sismo Item 3 OooooooooooooooooDocument59 pagesComportamiento Aislados Sismo Item 3 OooooooooooooooooCarlos RodriguezNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationLakshmi NarayananNo ratings yet

- Beyer - Cantebury EarthquakeDocument36 pagesBeyer - Cantebury EarthquakeMelo PereiraNo ratings yet

- The Seismic Shear Demand in Ductile Cantilever Wall Systems and The EC8 ProvisionsDocument21 pagesThe Seismic Shear Demand in Ductile Cantilever Wall Systems and The EC8 ProvisionsMelo PereiraNo ratings yet

- Seismic Shear Forces On RC Walls: Review and Bibliography: Bulletin of Earthquake Engineering October 2013Document28 pagesSeismic Shear Forces On RC Walls: Review and Bibliography: Bulletin of Earthquake Engineering October 2013Melo PereiraNo ratings yet

- RC Structures - Flexure+shear+bondDocument90 pagesRC Structures - Flexure+shear+bondMelo PereiraNo ratings yet

- Structural Timber - Determination of Characteristic Values of Mechanical Properties and DensityDocument18 pagesStructural Timber - Determination of Characteristic Values of Mechanical Properties and DensityMelo PereiraNo ratings yet

- Robinson GS 1964 PHD Thesis PDFDocument456 pagesRobinson GS 1964 PHD Thesis PDFMelo PereiraNo ratings yet

- Cap7 AtritoDocument8 pagesCap7 AtritoMelo PereiraNo ratings yet

- Is 813Document33 pagesIs 813gurubasavarajakm0% (1)

- SEO-Optimized Title for Sample DocumentDocument11 pagesSEO-Optimized Title for Sample DocumentMelo PereiraNo ratings yet

- Beyer Et Al Reinforced Concrete Wall Response Under Uni and Bidir Loading WCEE 2017 2373Document9 pagesBeyer Et Al Reinforced Concrete Wall Response Under Uni and Bidir Loading WCEE 2017 2373Melo PereiraNo ratings yet

- Dhakal ArtigoDocument28 pagesDhakal ArtigoMelo PereiraNo ratings yet

- Seismic Applications of Nonlinear Response Spectra Based On The Theory of Modal AnalysisDocument8 pagesSeismic Applications of Nonlinear Response Spectra Based On The Theory of Modal AnalysisMelo PereiraNo ratings yet

- Casagrande - Characteristics of Cohesionless Soils Affecting The Stability of Slopes and Earth FillsDocument10 pagesCasagrande - Characteristics of Cohesionless Soils Affecting The Stability of Slopes and Earth FillsAshishBastola100% (1)

- 02 - STRUCTURE - 01 - European Fitness For Service Network (FITNET) Fatigue Module DevelopmentDocument10 pages02 - STRUCTURE - 01 - European Fitness For Service Network (FITNET) Fatigue Module DevelopmentnotsofarNo ratings yet

- A Presentation On Final Year Project: Birla Institute of Technology Mesra (Ranchi)Document18 pagesA Presentation On Final Year Project: Birla Institute of Technology Mesra (Ranchi)Dhruv VashisthaNo ratings yet

- Effect of Fiber Length and Placement Method On Flexural BehaviorDocument15 pagesEffect of Fiber Length and Placement Method On Flexural BehaviorHanumaNo ratings yet

- Design of Deep Beam by Strut and Tie Method and Fluxural Theory - Civil Engineering Ryerson Assignment 3-bDocument14 pagesDesign of Deep Beam by Strut and Tie Method and Fluxural Theory - Civil Engineering Ryerson Assignment 3-bAfzal Waseem100% (1)

- Chapter 1 - Design of Special BeamsDocument15 pagesChapter 1 - Design of Special BeamsSine EntertaimentNo ratings yet

- Plate Girder PDFDocument16 pagesPlate Girder PDFArjun GuptaNo ratings yet

- Gete 201100024Document11 pagesGete 201100024superwxrNo ratings yet

- Mathcad - C06-C10 PDFDocument7 pagesMathcad - C06-C10 PDFKrish ChandNo ratings yet

- NSCP 2010 Seismic ProvisionsDocument67 pagesNSCP 2010 Seismic ProvisionsJule LobresNo ratings yet

- Design of Pile Cap and Abutment WallDocument20 pagesDesign of Pile Cap and Abutment Wallshashibhushan singh100% (1)

- Structural Design Short FormulaDocument5 pagesStructural Design Short FormulaMIslamMonirNo ratings yet

- MIT Physics Mechanics Notes Chapter26 Elastic Properties of Materials v10Document11 pagesMIT Physics Mechanics Notes Chapter26 Elastic Properties of Materials v10Andrew ZhighalovNo ratings yet

- Introduction To Prestressing CE 572: Purdue University School of Civil EngineeringDocument21 pagesIntroduction To Prestressing CE 572: Purdue University School of Civil EngineeringNatarajan SaravananNo ratings yet

- Appendix - F - 147645033 012 R Rev0Document58 pagesAppendix - F - 147645033 012 R Rev0bufaloteNo ratings yet

- A New Codified Design Theory of Second-Order Direct Analysis For Steel A...Document7 pagesA New Codified Design Theory of Second-Order Direct Analysis For Steel A...Luis MartinsNo ratings yet

- The Influence of Reinforcement Geometry and Soil Types On The Interface Behaviour in Pullout ConditionsDocument7 pagesThe Influence of Reinforcement Geometry and Soil Types On The Interface Behaviour in Pullout Conditionskunalji_jainNo ratings yet

- Efficient 3D and 2D Modelling of Pile Foundations in FEMDocument21 pagesEfficient 3D and 2D Modelling of Pile Foundations in FEMOmar Elio67% (3)

- MERU UNIVERSITY EXAM ON SOLID & STRUCTURAL MECHANICS IDocument4 pagesMERU UNIVERSITY EXAM ON SOLID & STRUCTURAL MECHANICS IezraNo ratings yet

- Mechanical Report Square SectionDocument22 pagesMechanical Report Square SectiondrajkumarceNo ratings yet

- Simplified Macro Modelling Strategies For The Seismic As - 2019 - Journal of Bui PDFDocument18 pagesSimplified Macro Modelling Strategies For The Seismic As - 2019 - Journal of Bui PDFAliNo ratings yet

- CyclicFoundationDesign_Prague_Masin_2023Document32 pagesCyclicFoundationDesign_Prague_Masin_2023Peteris SkelsNo ratings yet

- Analysis of Single Piles Under Lateral LoadingDocument181 pagesAnalysis of Single Piles Under Lateral LoadingAmanda CervantesNo ratings yet

- Pier DesignDocument54 pagesPier DesignMd Ghani HaiderNo ratings yet

- Investigation of Rousselier Model and Gurson-Tvergaard-Needleman Model in Ductile Fracture of API X65 Gas Pipeline SteelDocument23 pagesInvestigation of Rousselier Model and Gurson-Tvergaard-Needleman Model in Ductile Fracture of API X65 Gas Pipeline SteelTerem TebautaNo ratings yet

- GATE Civil Engineering Topic Wise Practice Tests - 166Document1 pageGATE Civil Engineering Topic Wise Practice Tests - 166chinmay naikNo ratings yet

- Beam Deflection MethodsDocument14 pagesBeam Deflection MethodskishorechakravarthyNo ratings yet

- 2001 Restrepo Floor Horizontal AccelerationsDocument26 pages2001 Restrepo Floor Horizontal AccelerationsJamesFarrugiaNo ratings yet

- Beam Design and Vibration AnalysisDocument9 pagesBeam Design and Vibration AnalysisjatinNo ratings yet

- Study Guide 001 (Both) For TST271ZDocument332 pagesStudy Guide 001 (Both) For TST271Zstevens50% (2)