Professional Documents

Culture Documents

IOT Based Automatic Water Container Filler Using Arduino

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IOT Based Automatic Water Container Filler Using Arduino

Copyright:

Available Formats

Volume 5, Issue 6, June – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

IOT Based Automatic Water

Container Filler Using Arduino

1

Ashish Mishra, 2Sarvgya Yadav, 3Shweta Singh, 4Vineet Pandey, 5Vishal Dwivedi, 6Deepti Ojha

1,2,3,4,5

Student, Department of ECE, ITM, GIDA, Gkp, UP, India

6

Head of Department, Department of ECE, ITM, GIDA, Gkp, UP, India

Abstract:- The objective of our project is to design, mechanical and digital machines, objects, animals or people

develop and monitor “Automatic Water Container that are provided with sole identifiers (UIDs) and the ability

Filler using Arduino”. This work provides with a lot of to transfer data over a network without requiring human-to-

benefits like low power feeding, low functioning cost, human or human-to-computer communication. With this

less care, accuracy and many more. This project is concept , few more concept is also required for our Project

based on automation and is a vast application IOT i.e,

concept. A prototype has been developed to illustrate The concept of I2C

the project. Feeding the container in hand to hand is the How to govern DC motor through Arduino?

main task that is carried out by a machine and this How to govern ultrasonic sensors through Arduino?

process is commonly used by many Robot. What is the function of LDR sensor and how it works?

What is the function of timer and how it works?

Keywords:- IOT, Automation, Sensors, Arduino, 555 Timer.

This Project is to feed the water filled container in

I. INTRODUCTION hand to hand or to the particular position with the help of

the above mention concept. This Project consists of –

In this paper, This Project is based on the concept of Electronic System

IOT (Internet of Things). The cyberspace of things, Software Controlled by Arduino UNO

or IOT, is a system of unified calculating devices,

II. BLOCK DIAGRAM M2 , M5 are connected to Master Arduino. Ultrasonic

Sensor US3 and Motor M1, M3, M4 are connected to Slave

There are two Arduino UNO board which are Arduino.

connected in series by using the concept of I2C and all the

control of the system id done through these two Arduino. After the measurement of water level and height of

Arduino 1 acts as Master Arduino and Arduino 2 acts as the container with the help of US1, US2, US5 message is

Slave. Ultrasonic Sensor US1, US2, US5, US4 and Motor send to Robot. If the container is empty of half filled, M1

IJISRT20JUN275 www.ijisrt.com 370

Volume 5, Issue 6, June – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

comes into function and moves towards the container.

When it comes near the door M2 starts working and door

opens automatically and the distance between robot and

door is measured by US3 ,which is attached in the front of

the robot. Then Robot moves towards the container and

Robotic Arm M3, M4 comes into function and pick the

container and put it under the tap. When it comes under the

tap US4 continuously measure the water level and M5

starts ,which moves downwards with the help of rack

pinion and comes in between the LDR and Led , this makes

the tap to open due to trigger in 555 timer. When container

is filled completely Again Robot pick and place it at its

position.

III. THEORY

LDR Sensor:

A. Arduino UNO An LDR or light dependent resistor is also known as

Arduino is an open-source microchip technology photo resistor, photocell, photoconductor. It is a one type of

platform based on easy-to-use hardware and software. The resistor whose resistance varies depending on the quantity

Arduino Uno is a microcontroller board based on the of light falling on its surface. When the light falls on the

ATmega328. It has 20 digital input/output pins (of which 6 resistor, then the resistance changes. These resistors are

can be used as PWM outputs and 6 can be used as analog often used in many circuits where it is required to sense the

inputs), a 16 MHz resonator, a USB connection, a power existence of light.

jack, an in-circuit system programming (ICSP) header, and

a reset button. It contains everything needed to support the

microcontroller; simply connect it to a computer with a

USB cable or power it with a AC-to-DC adapter or battery

to get started.

The Uno differs from all previous boards in that it

does not use the FTDI USB-to-serial driver chip. Instead, it

features an ATmega16U2 programmed as a USB-to-serial

converter. This auxiliary microcontroller has its own USB

bootloader, which allows forward-thinking users to

reprogram it.

C. 555 Timer

555 timer is used in almost every electronic circuit

today. For a 555 timer working as a flip flop or as a multi-

vibrator, it has a particular set of arrangements. It operates

from a wide range of power ranging from +5 Volts to +18

Volts supply voltage. Sinking or sourcing 200 mA of load

current. The external components should be selected

properly so that the timing breaks can be made into several

minutes along with the frequencies more than several

hundred kilohertz.

B. Sensors

Ultrasonic Sensor:

Ultrasonic sensors calculate distance by using

ultrasonic waves. The sensor head emits an ultrasonic wave

and receives the wave reflected back from the target.

Ultrasonic Sensors measure the distance to the target by

measuring the time between the emission and reception.

IJISRT20JUN275 www.ijisrt.com 371

Volume 5, Issue 6, June – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

D. DC Geared Motor

The motor we have used is Center shaft 100 rpm dc

geared motors specifically designed for robotic applications

.It is very easy to use. It has Nut and threads on shaft to

easily connect and internal threaded shaft for easily IV. COMPLETE PROJECT SYSTEM

connecting it to wheel. Easy to use and mount, long

durability and very affordable considering the features. A. Mechanism

These motors open a wide choice for us in terms of rolls Firstly, Level of the Water and height of the container

and chassis. is measured. If the water level is less than half, then robot

will move towards the container. When robot comes near

These motors are simple DC Motors containing gears the container door open automatically and robotic arm pick

for the shaft for obtaining the optimal performance the container ant put it under the tap. Vertical level

characteristics. They are known as Center Shaft DC Geared indicator comes into function and tap opens automatically.

Motors because their shaft covers through the center of When water filled into container Robot and robotic arm

their gear box assembly. again pick it up and place it at its position.

E. L293D Motor Driver

L293D is a typical Motor driver or Motor Driver IC

which allows DC motor to drive on either direction. L293D

is a 16-pin IC which can control a set of two DC motors at

once in any direction. It means that you can control two DC B. Software Implementation

motor with a single L293D IC. It works on the concept of The software part programming done through Arduino

H-bridge. Uno software (IDE). It is easy to write code and upload it to

the board. C and C++ language are used for programming.

In this project, programming is done in two phase. Firstly,

program for Master Arduino had been written. Then after

program for Slave Arduino had written. And the link

between these two Arduino is done by using the concept of

I2C.

IJISRT20JUN275 www.ijisrt.com 372

Volume 5, Issue 6, June – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

C. Connection

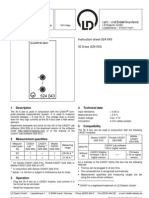

The connection of Ultrasonic Sensor with Arduino are

as follows:

Vcc to 5V Pin of the Arduino UNO board.

Gnd to Gnd Pin of the Arduino UNO board.

Trig to Digital Pin of the Arduino UNO board.

Echo to Digital Pin of the Arduino UNO board.

The connection of DC Geared Motor using interface

of L293D with Arduino are as follows:

Connect 5V and ground of the IC to 5V and ground of

Arduino.

Connect the motor to pins 2 and 3 of the IC.

Connect IN1 of the IC to pin 8 of Arduino.

Connect IN2 of the IC to pin 9 of Arduino.

Connect EN1 of IC to pin 2 of Arduino.

Connect SENS A pin of IC to the ground.

IJISRT20JUN275 www.ijisrt.com 373

Volume 5, Issue 6, June – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

B. Applications

The model can be used in schools, colleges, hotels etc to

avoid trafficking.

In stadiums where there is very large gatherings, this

will help a lot. The same thing is also possible in

marriage functions, ceremonies, events, parties etc..

It will be time saving, where we can save a lot of time.

We won’t have to rely on anyone to fill the water bottle.

It will also be revolution for the midgets. Midgets

always face difficulty in getting the water containers

from the two storey fridges but with this model they

will not face any difficulty in getting so.

The use of cheap components makes this project very

cost effective. So if it comes in the market then it’s

availability will be high and affordable to all.

This model can be used in beverages and soft drinks

industries. And using Arduino against PLCs makes it’s

chances go higher.

C. Future Scopes

This model can be widely used in schools, colleges,

malls, hotels, restaurants etc. where gathering of people is

commonly more. At these places, serving of water is the

best scope that looks to be something that can be

implemented. We are still not having system which serves

the water filled glasses to us. So with few implementations

in the flexes this can be made possible .

At the same time the use of robotic arms can also be

implemented further for water saving process. The amount

of water left can be put back by the arm and we can refilter

it for further uses. When glass is controlled by the robotic

arm then also this possibility becomes more as the arm is

being controlled through the programs and with such

implementation using water level indicator, this task can be

done.

VI. RELATED WORKS

There are lots of project present in today’s market

related to this topic but looking onto the present scenario,

V. SIGNIFICANCE AND SCOPE this project is very much feasible in the market because it is

very cheap, not complex, and can be understood easily.

A. Necessity

The idea/necessity seen for this project comes from a Fully Automatic Water Tank Level Controller Magnetic

real incident. The project deals with a practical problem Sensors

which is very common in households i.e. water bottle re- Motor robotically switch off if no water in supply pipe

filing. or tank is full. Magnetic sensors for long life with No

corrosion, carbon and oxidation of sensors and no

Mother in houses are mostly worried for the same sanitation required for installation. Moisture resistant PTH

problem. The same incident took place on one of our group printed circuit board and water-resistant ABS plastic wall

member house too. Then the idea of automatic water bottle rising enclosure. Feather touch buttons and LED for water

re-filing strikes our mind. level indication and the sleek design gives your home

contemporary outlook Automatic and manual mode is

Another incident which motivated us was that a present.

relative of mine met an accident and the person was all

alone at the house. For drinking water the filing could not

be possible. With the help of our project we can tackle such

simple yet most common problems.

IJISRT20JUN275 www.ijisrt.com 374

Volume 5, Issue 6, June – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

The SGF2/100 rotary oral liquid filler & sealer is the

automatic liquid filling machine investigated as well as

produced by our company in the recent years for

flattering the source development using the electrical

and mechanical technique. Also this automatic liquid

filling machine is utilized to fill and seal the liquid

produced for health, products, machine, oral liquid

preparations and also chemical, food, & cosmetics.

VII. CONCLUSIONS

We here conclude that our project “Automatic water

Container Filler“ has been successfully completed under

our group and through mentor’s help.

Whatever we had mentioned in our abstract we have

done the same and used the procedure as mentioned earlier.

Also at the same time we are highly pleased our efforts and

the system is working very well.

Therefore with an automatic filling machine one can

ensure speed and easy filling processes to ensure efficient

filling of liquids or powders into bottles without wastage.

REFERENCES

[1]. "Getting Started: FOUNDATION >

Introduction". arduino.cc.

[2]. David Kushner (2011-10-26). "The Making of

Arduino". IEEE Spectrum.

[3]. Justin Lahart (27 November 2009). "Taking an Open-

Source Approach to Hardware". The Wall Street

Journal.

[4]. Hernando Barragán (2016-01-01). "The Untold

History of Arduino". arduinohistory.github.io.

[5]. "How many Arduinos are "in the wild?" About

300,000". Adafruit Industries.

[6]. "Arduino FAQ – With David Cuartielles". Malmö

University. April 5, 2013.

[7]. "The Foundation of Today's Digital World: The

Triumph of the MOS Transistor". Computer History

Museum.

[8]. Omura, Yasuhisa; Mallik, Abhijit; Matsuo, Naoto

(2017)”MOS Devices for Low-Voltage and Low-

Energy Applications”. John Wiley & Sons.

[9]. Vongsingthong, S.; Smanchat, S. (2014). "Internet of

Things: A review of applications &

technologies" (PDF). Suranaree Journal of Science

and Technology.

[10]. "The Enterprise Internet of Things Market". Business

Insider.

IJISRT20JUN275 www.ijisrt.com 375

You might also like

- MHAWK LHD Manual Electrico PDFDocument52 pagesMHAWK LHD Manual Electrico PDFAlex BravoNo ratings yet

- Spy Robot Wireless Video Surveillance Using ArduinoDocument5 pagesSpy Robot Wireless Video Surveillance Using ArduinoEyob SintNo ratings yet

- Tips For Upgrading Amps AV502Document8 pagesTips For Upgrading Amps AV502gmaldo7183100% (6)

- Exploring Arduino: Tools and Techniques for Engineering WizardryFrom EverandExploring Arduino: Tools and Techniques for Engineering WizardryRating: 4.5 out of 5 stars4.5/5 (5)

- Iec 60664 1 2007 en FR PDFDocument19 pagesIec 60664 1 2007 en FR PDFphong vi0% (1)

- Control Robot Remotely with Android PhoneDocument48 pagesControl Robot Remotely with Android PhoneMayur ZendeNo ratings yet

- Design and Implementation Mobile Control RobotDocument6 pagesDesign and Implementation Mobile Control RobotIJRASETPublicationsNo ratings yet

- Smart BuildingDocument56 pagesSmart BuildingparimalaNo ratings yet

- Water Trash CollectorDocument3 pagesWater Trash CollectorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Resume S.Karthikeyan B.E. Electrical & Electronic Engineering Email: Contact No: 9790894279 Career ObjectiveDocument4 pagesResume S.Karthikeyan B.E. Electrical & Electronic Engineering Email: Contact No: 9790894279 Career ObjectiveKarthiKeyanNo ratings yet

- Q-A's On Atpg & ScanDocument33 pagesQ-A's On Atpg & ScanShankhadeep Das100% (2)

- Hand Gesture Recognition and Cleaning RobotDocument8 pagesHand Gesture Recognition and Cleaning RobotIJRASETPublicationsNo ratings yet

- Smart Watch For Elderly PersonDocument5 pagesSmart Watch For Elderly PersonIJRASETPublicationsNo ratings yet

- Smart Car Parking System Using IR SensorDocument5 pagesSmart Car Parking System Using IR SensorIJRASETPublicationsNo ratings yet

- Home Automation ReportDocument52 pagesHome Automation ReportShashank PandeyNo ratings yet

- Women Safety Night Patrolling RobotDocument8 pagesWomen Safety Night Patrolling RobotIJRASETPublicationsNo ratings yet

- Robotic Arm: MimickingDocument5 pagesRobotic Arm: MimickingMaitriya DamaniNo ratings yet

- User Friendly Smart Energy System Using IOTDocument4 pagesUser Friendly Smart Energy System Using IOTInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- .Automatic Room Light Controller Using Arduino and PIR SensorDocument4 pages.Automatic Room Light Controller Using Arduino and PIR SensorLÂM PHẠM NHƯ100% (1)

- Fire Fighting RobotDocument60 pagesFire Fighting RobotkalaivaniNo ratings yet

- Home Security System Using Arduino UnoDocument7 pagesHome Security System Using Arduino UnoIJRASETPublicationsNo ratings yet

- Smart Waste Management System Using ARDUINO: November 2019Document7 pagesSmart Waste Management System Using ARDUINO: November 2019Rajesh KannanNo ratings yet

- AMC Project Paper PDFDocument9 pagesAMC Project Paper PDFRidhi JainNo ratings yet

- Digital Electronics - Arduino Robot ProjectDocument17 pagesDigital Electronics - Arduino Robot ProjectWri AnNo ratings yet

- Human Detection RobotDocument5 pagesHuman Detection RobotAnuj Raj0% (1)

- Street Light Automation Using IoTDocument43 pagesStreet Light Automation Using IoTAshwin100% (1)

- Iarjset 2021 8714Document4 pagesIarjset 2021 8714Amit KumarNo ratings yet

- Smart Home Automation and Security System Using Arduino and IOTDocument4 pagesSmart Home Automation and Security System Using Arduino and IOTRamaNo ratings yet

- 32_Power_NCDocument10 pages32_Power_NCArnold RosenbergNo ratings yet

- Design and Implementation of Line Follower Robot Using Arduino MicrocontrollerDocument4 pagesDesign and Implementation of Line Follower Robot Using Arduino MicrocontrollerFahru ZainiNo ratings yet

- Smart Home Automation and Security System Using Arduino and IOT 1Document3 pagesSmart Home Automation and Security System Using Arduino and IOT 1PriyaNo ratings yet

- REPORTDocument22 pagesREPORThohi4808No ratings yet

- Coin Based Mobile ChargerDocument13 pagesCoin Based Mobile ChargerIJRASETPublicationsNo ratings yet

- Parking System 3Document5 pagesParking System 3Shahi JiNo ratings yet

- Live Human Detecting Robot For Earthquake Rescue OperationDocument5 pagesLive Human Detecting Robot For Earthquake Rescue OperationIntegrated Intelligent Research100% (1)

- IoT Based Industrial Information GatheringDocument7 pagesIoT Based Industrial Information GatheringEditor IJTSRDNo ratings yet

- Design of Internet of Things (IoT) Based Hydroponic Controlling Device in Pyramid Greenhouse - Arif UmamiDocument8 pagesDesign of Internet of Things (IoT) Based Hydroponic Controlling Device in Pyramid Greenhouse - Arif UmamiDedi FatchurohmanNo ratings yet

- IJCRT2207414 Mini Project Reasearch PaperDocument10 pagesIJCRT2207414 Mini Project Reasearch PaperHimanshu KumarNo ratings yet

- Research Proposal (Plaza)Document10 pagesResearch Proposal (Plaza)Edmarjan ConcepcionNo ratings yet

- 5 e 9 DDocument4 pages5 e 9 DSCORSAM1No ratings yet

- Supervisory Control and Data Acquisition For Motor Operation Using ArduinoDocument6 pagesSupervisory Control and Data Acquisition For Motor Operation Using ArduinoIJRASETPublicationsNo ratings yet

- Review On Different Microcontroller Boards Used in IoTDocument11 pagesReview On Different Microcontroller Boards Used in IoTIJRASETPublicationsNo ratings yet

- IOT Based Electrical Energy Monitoring in A Domestic AppliancesDocument6 pagesIOT Based Electrical Energy Monitoring in A Domestic AppliancesIJRASETPublicationsNo ratings yet

- Iot Based Surveillance Robot IJERTV7IS030061Document5 pagesIot Based Surveillance Robot IJERTV7IS030061rgkusumbaNo ratings yet

- IJRTI2206020Document4 pagesIJRTI2206020clashofclanwithth9No ratings yet

- Design of Robotic Arm Controller Using Android AppDocument9 pagesDesign of Robotic Arm Controller Using Android AppIJRASETPublicationsNo ratings yet

- Survillance Rover Final ReportDocument57 pagesSurvillance Rover Final ReportAdhiraj SaxenaNo ratings yet

- IoT Based Water Distribution and Fertilizer Sprinkling System in An Agricultural FieldDocument7 pagesIoT Based Water Distribution and Fertilizer Sprinkling System in An Agricultural FieldIJRASETPublicationsNo ratings yet

- Irjet V7i61194Document4 pagesIrjet V7i61194Aryan ShrivaNo ratings yet

- Obstacle Avoidance Robot Using ArduinoDocument5 pagesObstacle Avoidance Robot Using ArduinoRichard Kaven SerquinaNo ratings yet

- Smart Blinds System Using LDRDocument7 pagesSmart Blinds System Using LDRSyed Waqas HussainNo ratings yet

- Four-Legged Walking Robot: A Comprehensive Report On The QuadrupedDocument10 pagesFour-Legged Walking Robot: A Comprehensive Report On The QuadrupedArnav SharmaNo ratings yet

- IJRPR3895Document6 pagesIJRPR3895Sagar ChaulagaiNo ratings yet

- Gesture Control Robot Using ArduinoDocument3 pagesGesture Control Robot Using ArduinoEditor IJTSRDNo ratings yet

- Arduino Based Wireless Robotic Hand Using ZigbeeDocument8 pagesArduino Based Wireless Robotic Hand Using Zigbeeshaik nayeemNo ratings yet

- Smart Blind StickDocument5 pagesSmart Blind StickLalitNo ratings yet

- IOT Garbage Monitoring with ArduinoDocument8 pagesIOT Garbage Monitoring with ArduinoLeo UltraNo ratings yet

- Wireless Data Acquisition System For Single Phase Induction MotorDocument3 pagesWireless Data Acquisition System For Single Phase Induction MotorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Irjet V6i454Document4 pagesIrjet V6i454Ngoc AnhNo ratings yet

- Ete Ece491Document21 pagesEte Ece491sushantsaurav18No ratings yet

- Smart Paltnt''''d''d' F'D'F'D''''''''Document5 pagesSmart Paltnt''''d''d' F'D'F'D''''''''dabangraja178No ratings yet

- Paper 1415Document9 pagesPaper 141524-ECE-MATHIMALA-PNo ratings yet

- 13 GarbageDocument61 pages13 Garbagegangarapusrihari46No ratings yet

- IOT Based Smart Electric Energy Meter Using ES8266Document6 pagesIOT Based Smart Electric Energy Meter Using ES8266IJRASETPublicationsNo ratings yet

- Comparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightDocument4 pagesComparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diabetic Retinopathy Stage Detection Using CNN and Inception V3Document9 pagesDiabetic Retinopathy Stage Detection Using CNN and Inception V3International Journal of Innovative Science and Research TechnologyNo ratings yet

- The Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterDocument11 pagesThe Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Advancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisDocument8 pagesAdvancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)Document2 pagesDense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Electro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyDocument7 pagesElectro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Terracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonDocument14 pagesTerracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Digital Marketing Dimensions on Customer SatisfactionDocument6 pagesThe Impact of Digital Marketing Dimensions on Customer SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review: Pink Eye Outbreak in IndiaDocument3 pagesA Review: Pink Eye Outbreak in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETDocument6 pagesAuto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Development and Evaluation of Methi-Shikakai Herbal ShampooDocument8 pagesDesign, Development and Evaluation of Methi-Shikakai Herbal ShampooInternational Journal of Innovative Science and Research Technology100% (3)

- A Survey of the Plastic Waste used in Paving BlocksDocument4 pagesA Survey of the Plastic Waste used in Paving BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentDocument7 pagesCyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hepatic Portovenous Gas in a Young MaleDocument2 pagesHepatic Portovenous Gas in a Young MaleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Explorning the Role of Machine Learning in Enhancing Cloud SecurityDocument5 pagesExplorning the Role of Machine Learning in Enhancing Cloud SecurityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Navigating Digitalization: AHP Insights for SMEs' Strategic TransformationDocument11 pagesNavigating Digitalization: AHP Insights for SMEs' Strategic TransformationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Perceived Impact of Active Pedagogy in Medical Students' Learning at the Faculty of Medicine and Pharmacy of CasablancaDocument5 pagesPerceived Impact of Active Pedagogy in Medical Students' Learning at the Faculty of Medicine and Pharmacy of CasablancaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Automatic Power Factor ControllerDocument4 pagesAutomatic Power Factor ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaDocument2 pagesMobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsDocument5 pagesReview of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Studying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaDocument5 pagesStudying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicDocument7 pagesThe Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Drug Dosage Control System Using Reinforcement LearningDocument8 pagesDrug Dosage Control System Using Reinforcement LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Securing Document Exchange with Blockchain Technology: A New Paradigm for Information SharingDocument4 pagesSecuring Document Exchange with Blockchain Technology: A New Paradigm for Information SharingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Enhancing the Strength of Concrete by Using Human Hairs as a FiberDocument3 pagesEnhancing the Strength of Concrete by Using Human Hairs as a FiberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formation of New Technology in Automated Highway System in Peripheral HighwayDocument6 pagesFormation of New Technology in Automated Highway System in Peripheral HighwayInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Supply Chain 5.0: A Comprehensive Literature Review on Implications, Applications and ChallengesDocument11 pagesSupply Chain 5.0: A Comprehensive Literature Review on Implications, Applications and ChallengesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intelligent Engines: Revolutionizing Manufacturing and Supply Chains with AIDocument14 pagesIntelligent Engines: Revolutionizing Manufacturing and Supply Chains with AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Self-Disposing Contactless Motion-Activated Trash Bin Using Ultrasonic SensorsDocument7 pagesThe Making of Self-Disposing Contactless Motion-Activated Trash Bin Using Ultrasonic SensorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- DTC 97 EDU Circuit MalfunctionDocument5 pagesDTC 97 EDU Circuit Malfunctionkavidush123No ratings yet

- LM741 ModDocument2 pagesLM741 ModMuhammad Umer Farooq50% (2)

- Murata Products For Automotive K35eDocument13 pagesMurata Products For Automotive K35ealltheloveintheworldNo ratings yet

- 30 AboxDocument1 page30 AboxHoàng YếnNo ratings yet

- Extremewireless Wing 7532 802.11ac Access Point: Maximum Speed. Minimum CostDocument7 pagesExtremewireless Wing 7532 802.11ac Access Point: Maximum Speed. Minimum Costjarko tarrilloNo ratings yet

- Ultrasonic Fuel Sensor Data Sheet UF202Document7 pagesUltrasonic Fuel Sensor Data Sheet UF202Rahul AroraNo ratings yet

- E1330c Usen PDFDocument88 pagesE1330c Usen PDFingesco6No ratings yet

- Order DMX3 breakers componentsDocument3 pagesOrder DMX3 breakers componentsShan TanuNo ratings yet

- Frenic 5000 G11SDocument24 pagesFrenic 5000 G11Scoyed83246No ratings yet

- Introduction To AVRDocument14 pagesIntroduction To AVRkrishna mohan pandeyNo ratings yet

- History of ICTDocument20 pagesHistory of ICTZakwan HamdanNo ratings yet

- Sumitomo HF-430 Guìa RápidaDocument31 pagesSumitomo HF-430 Guìa RápidaJohancito Valencia100% (2)

- d43256 Memorie de 256kDocument25 pagesd43256 Memorie de 256kapi-252724932No ratings yet

- Coimbatore Energy Meter Manufacturer ProfileDocument8 pagesCoimbatore Energy Meter Manufacturer ProfileKumar ChandanNo ratings yet

- L330 LowPowerOpAmps 2UPDocument7 pagesL330 LowPowerOpAmps 2UPVan Nguyen Huu VanNo ratings yet

- Mechatronics Unit 1Document21 pagesMechatronics Unit 1rajkiran_raj100% (1)

- ELEKTROTOM HiTT 106 GBDocument8 pagesELEKTROTOM HiTT 106 GBBo ScoobmanNo ratings yet

- Existing Equipment DetailsDocument77 pagesExisting Equipment DetailsRamawatarNo ratings yet

- Test Request Form: Requested Test (Put "X" To Check)Document2 pagesTest Request Form: Requested Test (Put "X" To Check)Claudia Lizeth Chacon PedrazaNo ratings yet

- PSCAD EMTD Model Of3phase Grid Connected Photovoltaic Solar System PDFDocument7 pagesPSCAD EMTD Model Of3phase Grid Connected Photovoltaic Solar System PDFcarlos cervantesNo ratings yet

- Circuit Recloser With Bistable Electromagnetic ActuatorDocument16 pagesCircuit Recloser With Bistable Electromagnetic ActuatorRicardo DoldanNo ratings yet

- Daily NotesDocument111 pagesDaily NotesRana AhmedNo ratings yet

- Simple Breathalyzer Construction and Use GuideDocument3 pagesSimple Breathalyzer Construction and Use GuideFrank Cruz100% (1)

- 4a.price Schedule - 20 MLD - KR Puram STPDocument51 pages4a.price Schedule - 20 MLD - KR Puram STPsharan kommiNo ratings yet

- ARTA User ManualDocument5 pagesARTA User ManualestenioNo ratings yet