Professional Documents

Culture Documents

Applications/Processing Guide: How To Use This Section The Resistive Element

Uploaded by

CarlosAgustoPinedaSanchezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Applications/Processing Guide: How To Use This Section The Resistive Element

Uploaded by

CarlosAgustoPinedaSanchezCopyright:

Available Formats

Applications/Processing Guide

HOW TO USE THIS SECTION The Resistive Element

This Applications/Processing Guide is intended to provide Trimmers for commercial applications typically have a

you with points to consider for designing circuits, selecting resistive element made of carbon or cermet (a combination of

trimmers and arranging board layouts, to achieve maximum CERamic and METal), or of resistance wire wound on an insulat-

performance and long life for your circuits and systems. We ed copper mandrel.

have also included information on steps your manufacturing The main advantages of wirewound trimmers are their low

engineers can take to preserve circuit reliability. temperature coefficient, higher power dissipation, lower noise,

For example, are you aware that the trimmers and other tighter resistance tolerance, and, when used as a variable resis-

mechanical components on your boards may face a more tor, the excellent current-carrying capacity through the wiper due

extreme environment during boardwashing on your own produc- to the lower contact resistance. Also, their long-term resistance

tion line, than they ever will in use? For those trimmers that may stability with time and temperature is slightly better than cermet.

need to be reset, are you remembering to select and mount the Cermet trimmers provide a wider resistance range (10 ohms

trimmers to provide easy accessibility? to 5 megohms, versus a maximum of 50K ohms for wirewound).

In this section, you'll find dozens of pointers, reminders Also, the wiper output can be set closer to the desired value

and useful facts that will help you be more knowledgeable and since the resistive element presents a continuous contact

successful in using trimmers. surface for the wiper, as opposed to the discrete turns (resolu-

tion) of the wirewound. Other advantages with cermet are the

lower reactance in high-frequency applications, the smaller sizes

TRIMMER BASICS available, and the generally lower price than wirewound types.

In its most common form, a trimmer is simply a device

containing a resistive element, and a wiper, or adjustable tap,

contacting the element. The wiper can be mechanically moved

to vary the amount of voltage or resistance in the circuit. The

resistive element is usually laid out in linear or a circular

configuration:

ADJUSTMENT SCREW

RESISTIVE ELEMENT

ADJUSTMENT ROTOR

WIPER

ADJUSTMENT SCREW

WIPER RESISTIVE

ELEMENT

WIPER

RESISTIVE ELEMENT

Specifications are subject to change without notice.

Customers should verify actual device performance in their specific applications.

Soldering And Cleaning Processes

This application note is designed to provide step-by-step 1. SOLDERING - Forced Hot Air, Convection, IR, Vapor Phase

processing recommendations. It covers the popular SMC (In-Line), Wave (Single and Dual)

soldering processes currently in use and provides recommenda-

tions and cautions for each step. Since many variations of 2. CLEANING - Solvent, Aqueous, Semi-Aqueous, No-Clean

temperature, time, processes, cleaning agents and board types On the facing page are the common methods, materials and

are found in the electronics industry, you’ll want to test and maximum temperature/time parameters for soldering and

verify your own system. cleaning processes.

The process steps, recommendations and cautions are

based on Bourns Trimpot surveys of SMC users, equipment

manufacturers and materials suppliers. Also, comments

reflect results of Bourns’ testing. Our findings suggest the

following soldering and cleaning processes:

1 Solder Paste

2

Adhesive

3

SMC

4

Adhesive

5

Flux

Printing Application Placement Cure Application

Reflow Flow (Wave) Flow (Wave) Flow (Wave)

GENERAL GENERAL GENERAL GENERAL GENERAL

Use the optimum The adhesive must hold Use pick-and-place Use heat/time cure Use the correct flux

solder paste for the the SM Component equipment with method with either to remove surface

pattern, printing (SMC) in correct vacuum nozzle ID size convection oven or oxides, prevent

process, solder paste orientation upon place- that allows adequate infrared radiation. reoxidation and

density and solder ment and maintain suction to pick the promote wetting.

joint quality. correct trimmer position SMC out of the RECOMMENDED

during physical embossed cavity. Cure using the RECOMMENDED

RECOMMENDED handling before final temperature and • RMA

Use 8 to 10 mil thickness solder processing. RECOMMENDED times recommended • No-clean SRB

for solder paste print. The nozzle inside by the adhesive (Synthetic resin

RECOMMENDED diameter (ID) should manufacturer. based)

CAUTION To assure positional not exceed .100 in. • OA (Organic Acid)

Since solder paste stability, place a single (2.54mm) to ensure CAUTION (See caution)

usually contains a high dot of epoxy under the adequate suction and Use enough cure

percentage of activators, SMC. part alignment. time to assure CAUTION

you must ensure complete adhesive Avoid highly

adequate cleaning to EPOXY

CAUTION transition from fluid activated fluxes.

remove all residues, Assure parts are to solid. Consult factory before

unless no-clean (low placed so that all using OA.

solids) paste is used. terminals are

equidistant (<4 mils)

from the solder pads.

CAUTION Align terminals with

Stability after placement solder belt direction of

is a direct function of travel to avoid body

the volume of adhesive shadowing effects

used. Use enough epoxy during flow soldering.

to assure stability

through the cure

process.

Avoid overflow of epoxy

to solder pad and

terminal areas.

Specifications are subject to change without notice.

Customers should verify actual device performance in their specific applications.

Soldering And Cleaning Processes

SOLDERING/CLEANING METHODS

REFLOW FLOW

Hot Air; Hot Air; Hot Air; Hot Air; Vapor Vapor Vapor Vapor

Infrared Infrared Infrared Infrared Phase Phase Phase Phase Wave Wave Wave Wave

Process Step (Solvent) (Semi-Aq) (Aqueous) (No-Clean) (Solvent) (Semi-Aq) (Aqueous) (No-Clean) (Solvent) (Semi-Aq) (Aqueous) (No-Clean) Material

1. Solder Paste Printing X X X X X X X X

2. Adhesive Application X X X X

3. Component Placement X X X X X X X X X X X X

4. Adhesive Cure X X X X

5. Flux Application X Rosin

5. Flux Application X Rosin

5. Flux Application X Organic Acid

5. Flux Application X Synthetic Resin Based

6. Solder (Reflow) X X X X X X X 63/37 Sn/Pb

7. Solder (Flow) X X X X 63/37 Sn/Pb

8. Wash (Solvent) X X X ODS Free

8. Wash (Semi-Aqueous) X X X Terpene, Hydrocarbon Based

8. Wash (Aqueous) X X X DI H20; Surfacant; Saponifier

High Pressure Fluids X X X (See Caution)

Max. Temp. (°C)/Time (Secs) 235/40 235/40 235/40 235/40 215/180 215/180 215/180 215/180 260/5 260/5 260/5

Min. Temp. (°C) 215 215 215 215 215 215 215 215 215 215 215

6

Solder

Reflow; Hot Air,

7

Solder

Flow (Wave)

8

Wash

Solvent

9

Wash

Semi-Aqueous

10Wash

Aqueous

11No-Wash

IR and Vapor

Phase

GENERAL GENERAL GENERAL GENERAL GENERAL GENERAL

Preheat sufficiently For maximum com- Use solvent clean- Use semi-aqueous Use aqueous cleaning No-wash is an

using both time ponent reliability ing primarily for for nonpolar primarily for polar option when

and temperature and performance, nonpolar contam- contaminants such contaminants such as no-clean (low

to vaporize all minimize the time inants such as as rosin based flux organic flux residues. solids) flux is

solder paste of temperature rosin based flux residues. used for solder

solvents and exposure above residues. RECOMMENDED operations.

moisture, leaving 200 °C. RECOMMENDED Use any of these

only solder and RECOMMENDED Use terpene or aqueous wash

flux as component RECOMMENDED Use any suitable hydrocarbon materials:

enters solder Solder zone profile washing solvents based for pre- • Deionized water

reflow phase. of 245 °C for 5 that meet ODC wash. Use water • Surfactants

seconds. requirements. for final wash. • Saponifiers

RECOMMENDED

Solder zone profile CAUTION CAUTION CAUTION CAUTION

of 230 °C for 20 Do not exceed Limit excessive Limit excessive Limit excessive

seconds. 260 °C peak temp- direct spray direct spray direct spray pressure

erature for dual pressure to 60 psi pressure to 60 psi to 60 psi or below for

CAUTION wave solder or below for opti- or below for opti- optimum reliability.

Do not exceed time process with a flow mum reliability. mum reliability. Ultrasonics may

and temperature zone totaling 5 cause component

reflow profile of seconds. damage or failure.

235 °C for 45 ± 5 sec-

onds for hot air/IR Minimize thermal

reflow. shock by limiting

temperature rise

Minimize thermal

shock by limiting

rate to 3 °C/sec

and by stabilizing

Board Rework Technique

temperature rise board and compo-

rate to 3 °C/sec nents temperature RECOMMENDED

and by stabilizing during preheating. Hot air reflow technique

board and compo- is preferred.

nents temperature

during preheating. GENERAL CAUTION

Excessive and/or repeated Avoid use of a soldering

Please click here high temperature heat iron or wave soldering as

to view our recom- exposure may affect a rework technique.

mended lead free component performance

soldering profile. and reliability.

Specifications are subject to change without notice.

Customers should verify actual device performance in their specific applications.

Applications/Processing Guide

TRIMMING POTENTIOMETERS AND DEFINITIONS INPUT AND OUTPUT TERMS

The following terms and definitions have been edited from the TOTAL APPLIED VOLTAGE: The total voltage applied between the

Industrial Standard published by the Variable Resistive Components designated input terminals.

Institute. It is intended to encourage standardization in communica- OUTPUT VOLTAGE: The voltage between the wiper terminal and the

tion and understanding between the manufacturer and user. The designated reference point. Unless otherwise specified, the

complete standard, including detailed test procedures, is available designated reference point is the CCW terminal.

upon request.

OUTPUT RATIO: The ratio of the output voltage to the designated

input reference voltage. Unless otherwise specified, the refer-

GENERAL TERMS ence voltage is the total applied voltage.

TRIMMING POTENTIOMETER: An electrical mechanical device with LOAD RESISTANCE: An external resistance as seen by the Output

three terminals. Two terminals are connected to the ends of a Voltage (connected between the wiper terminal and the desig-

resistive element and one terminal is connected to a movable nated reference point.)

conductive contact which slides over the element, thus allowing

the input voltage to be divided as a function of the mechanical

input. It can function as either a voltage divider or rheostat. ADJUSTMENT TERMS

WIREWOUND TRIMMING POTENTIOMETER: A trimming poten- DIRECTION OF TRAVEL: Clockwise (CW) or counterclockwise

tiometer characterized by a resistance element made up of (CCW) rotation when viewing the adjustment end of the poten-

turns of wire on which the wiper contacts only a small portion of tiometer.

each turn.

CCW CW

NON-WIREWOUND TRIMMING POTENTIOMETER: A trimming

potentiometer characterized by the continuous nature of the

YELLOW

➀ ➂ GREEN

surface area of the resistance element to be contacted. Contact ♦

is maintained over a continuous, unbroken path. The resistance

RED

➁ ♦ CW ROTATION

is achieved by using material compositions other than wire such

as carbon, conductive plastics, metal film and cermet.

MECHANICAL TRAVEL — SOLID STOPS: The total travel of the

RESISTANCE ELEMENT: A continuous, unbroken length of resistive adjustment shaft between integral stops. Continuity must be

material without joints, bonds or welds except at the junction of maintained throughout the travel.

the element and the electrical terminals connected to each end

of the element, or at an intermediate point such as a center tap. MECHANICAL TRAVEL — CLUTCHING ACTION: The total travel of

the adjustment shaft between the points where clutch actuation

ADJUSTMENT SHAFT: The mechanical input member of a trimming begins. Continuity must be maintained throughout the travel

potentiometer which when actuated causes the wiper to and during clutch actuation.

traverse the resistance element resulting in a change in output

voltage or resistance. MECHANICAL TRAVEL — CONTINUOUS ROTATION: The total

travel of the adjustment shaft when the wiper movement is

SINGLE-TURN ADJUSTMENT: Requires 360º or less mechanical unrestricted at either end of the resistive element as the adjust-

input to cause the wiper to traverse the total resistance element. ment shaft continues to be actuated.

MULTITURN ADJUSTMENT: Requires more than 360º mechanical ADJUSTMENT TRAVEL (ELECTRICAL): The total travel of the adjust-

adjustment to cause the wiper to traverse the total resistance ment shaft between minimum and maximum output voltages.

element.

CONTINUITY TRAVEL: The total travel of the shaft over which elec-

TERMINAL: An external member that provides electrical access to trical continuity is maintained between the wiper and the resis-

the resistance element and wiper. tance element.

LEADWIRE TYPE TERMINAL: Flexible insulated conductor.

PRINTED CIRCUIT TERMINAL: Rigid uninsulated electrical conduc- ELECTRICAL AND OPERATIONAL CHARACTERISTICS

tor, suitable for printed circuit board plug-in.

TOTAL RESISTANCE: The DC resistance between the input termi-

SOLDER LUG TERMINAL: Rigid uninsulated electrical conductor, nals with the wiper positioned to either end stop, or in dead

suitable for external lead attachment. band for continuous rotation potentiometers.

WIPER: The wiper is the member in contact with the resistive ele- TEST VOLTAGE

ment that allows the output to be varied when the adjustment

shaft is rotated. Maximum

STOP-CLUTCH: A device which allows the wiper to idle at the ends Total Resistance, Nominal Test Voltage

of the resistive element without damage as the adjustment shaft Non-Wirewound Wirewound

continues to be actuated in the same direction. Ohms Volts DC Volts DC

STOP – SOLID: A positive limit to mechanical and/or electrical .1 TO 1.0 0.1 0.1

adjustment. 1.0 to 50 0.3 0.3

STACKING: The mounting of one trimming potentiometer adjacent to 50 to 100 2.0 2.0

or on top of another utilizing the same mounting hardware. 100 to 1000 3.0 3.0

1K to 100K 10 10

THEORETICAL RESOLUTION: (Wirewound only) The theoretical Over 0.1 megohm 50 —

measurement of sensitivity to which the output ratio may be

adjusted; the reciprocal of the number of turns of wire in resis- NOTE: The test voltages should never exceed the equivalent of 10% rated power.

tance winding expressed as a percentage. The minimum voltage to be used is 10 MV.

N = Total number of resistance wire turns.

1

N X 100 = Theoretical resolution percent.

Specifications are subject to change without notice.

Customers should verify actual device performance in their specific applications.

Applications/Processing Guide

ABSOLUTE MINIMUM RESISTANCE: The resistance measured TABLE II

between the wiper terminal and each end terminal with the

wiper positioned to give a minimum value. Test Current (±20%) Total Resistance Range

END RESISTANCE: The resistance measured between the wiper ter- 30 ma 2 = Rt = 200

minal and an end terminal when the wiper is positioned at the 5 ma 200 ‹ Rt = 3K

corresponding end of mechanical travel. Absolute minimum 1 ma 3K ‹ Rt = 200K

resistance and end resistance are synonymous for continuous 200 ua 200K ‹ Rt = 1 megohm

rotation trimmers. 50 ua 1 megohm ‹ Rt = 5 megohm

TEMPERATURE COEFFICIENT OF RESISTANCE: The unit change in

resistance per degree Celsius change from a reference temper-

ature, expressed in parts per million per degree Celsius as EQUIVALENT NOISE RESISTANCE: Wirewound only. Any spurious

follows: variation in the electrical output not present in the input, defined

quantitatively in terms of an equivalent parasitic, transient resis-

R2 – R1 tance in ohms, appearing between the contact and the resistant

element when the shaft is rotated. The equivalent Noise

TC = ——————— X 106 Resistance is defined independently of the resolution, function-

R1 (T2 – T1) al characteristics and the total travel. The magnitude of the

Where: Equivalent Noise Resistance is the maximum departure from a

R1 = Resistance at reference temperature in ohms. specific reference line. The wiper of the potentiometer is

R2 = Resistance at test temperature in ohms. required to be excited by a specific current and moved at a

T1 = Reference temperature in degrees Celsius. specific speed.

T2 = Test temperature in degrees Celsius.

RESISTANCE-TEMPERATURE CHARACTERISTIC: The difference TEST TRIMMER

between the total resistance values measured at a reference

1 3

temperature of 25ºC and the specified test temperature

expressed as a percent of the Total Resistance.

2

R2 – R1 1 ma

RTC = ——————— X 100 SCOPE

OR EQUIVALENT

R1 DETECTOR

Where:

CALIBRATION INPUT Z

R1 = Resistance at reference temperature (25ºC) in ohms. RESISTOR 10 X Rt

R2 = Resistance at the test temperature in ohms.

CONTACT RESISTANCE VARIATION: The apparent resistance seen

between the wiper and the resistance element when the wiper Max. deviation (volts)

is energized with a specified current and moved over the ENR (ohms) =

adjustment travel in either direction at a constant speed. The

.001 amps

output variations are measured over a specified frequency

bandwidth, exclusive of the effects due to roll-on or roll-off of CONTINUITY: Continuity is the maintenance of continuous electrical

the terminations and is expressed in ohms or % of total resis- contact between the wiper and both end terminals of the resis-

tance. tive element.

SETTING STABILITY: The amount of change in the output voltage,

CONSTANT without readjustment, expressed as a percentage of the total

CURRENT applied voltage.

SOURCE

NOT TO EXCEED DIELECTRIC STRENGTH: The ability to withstand the application of

RATING OF Rt a specified potential of a given characteristic, between the ter-

BEING TESTED minals and all other external conducting members such as

shaft, housing and mounting hardware without exceeding a

1 Rt 3 specified leakage current value.

▲ AC INSULATION RESISTANCE: The resistance to a specified DC voltage

2 AMPLIFIER impressed between the terminals and all other external

OR FILTER

CALIBRATION conducting members such as shaft, housing and mounting

DECADES

OSCILLOSCOPE

hardware.

SEE NOTE

POWER RATING: The maximum power that a trimming potentiometer

can dissipate across the total resistive element under specified

OUTPUT DETECTOR conditions while meeting specified performance requirements.

ROTATIONAL LIFE: The number of cycles obtainable under specified

operating conditions while remaining within specified allowable

Figure 1. Contact-resistance-variation measuring circuit

degradation. A cycle is defined as one complete traversal of the

Rt = Test specimen wiper over the resistive element in both directions.

Output detector bandwidth: 100 cycles to 50 kilocycles LOAD LIFE: The number of hours at which a device may dissipate

Minimum input impedance to output detector: rated power under specified operating conditions while remain-

At least 10 times the nominal resistance being tested ing within specified allowable degradations.

NOTE: At the calibration of the decade, terminals 1 and 2 must be ADJUSTABILITY (OUTPUT RESISTANCE): The precision with which

coincident. Calibration decade is to be set for the contact-resistance the output resistance of a device can be set to the desired

variation (CRV) level of the specified nominal resistance being tested. value.

Specifications are subject to change without notice.

Customers should verify actual device performance in their specific applications.

Applications/Processing Guide

ADJUSTABILITY (OUTPUT VOLTAGE RATIO): The precision with Forced Hot Air Convection System — Uses a multizone forced

which the output voltage ratio of a device can be set to the air convection system with heat source panels using IR or other

desired value. type heating elements. Approximately 85% of the heating is

provided by free convection to reflow solder on exposed PC

boards.

MECHANICAL TERMS Dual Wave System — Utilizes two parallel solder waves. The

STARTING TORQUE: The maximum moment in the clockwise and first is a turbulent wave followed by a laminar wave. The turbu-

counterclockwise directions required to initiate shaft adjust- lent wave is for small, constricted areas, while the laminar wave

ment anywhere in the mechanical travel. removes solder projections.

STOP TORQUE: The maximum static moment that can be applied Vapor Phase System — Provides a single-zone condensation

to adjustment shaft at each mechanical stop for a specified heat source achieved with liquid fluorinated hydrocarbons that

period of time without loss of continuity or mechanical damage have been brought to the boiling point to create a saturated

affecting operational characteristics. vapor zone. Heat is then released by the fluid’s heat of vapor-

SOLDERABILITY: The ability of the terminals to accept a uniform ization as the vapor condenses on the product.

coating of solder under specified conditions. Soldering (Through-hole)

WELDABILITY: The ability of materials to be welded together under Two types of equipment are usually associated with through-

specified conditions. hole soldering:

TERMINAL STRENGTH: The ability of the terminals to withstand Single Wave System — Provides an inclined portion of the

specified mechanical stresses without sustaining damage that solder wave for the PC board to pass over. The PC board is

would affect utility of the terminals or operation of the trimming positioned to bring many potential solder joints in contact with

potentiometer. the wave simultaneously for a short time for soldering.

IMMERSION SEALED: The ability of the unit to withstand submer- Drag System — Provides for PC boards to be dragged across

sion in acceptable cleaning solutions used in normal soldering the surface of the solder pot. Soldered connections are made

processes without performance degradation under specified during this operation.

environmental conditions. PC Board Washing

Two types of equipment are usually associated with both SMT

and through-hole products.

TRIMMER "ABILITIES"

Pressure System — Accomplishes cleaning by directing sprays

When you are selecting components for a new design, you

of water under high pressure from multiple nozzles.

typically take into account the environmental conditions that the

components will need to endure during the lifetime of the instrument Flooding System — Utilizes a combination of flooding (at

or device. Designers in the past have often overlooked the environ- normal water pressure) and surfactant action for cleaning).

mental extremes of their own production lines, where the conditions Soldering and Wash Processes

may be much more severe than anything encountered in actual end Figure 1 shows typical profiles any component may see during

use. a soldering and board washing operation. For details of materi-

al and process variables recommendations, see “Soldering and

PROCESSABILITY Cleaning Processes”, page 76.

"Processability" refers to the ability of the unit to withstand the

Solder

production-line processes associated with the finishing steps on the

PC boards. Typically, both SMT and through-hole products are sub-

jected to similar PC board processing operations after preparation

for assembly. These operations can generally be summarized as

follows:

2

Wash

2nd Stage Dryer

Flux

➤ Pre-Heat ➤ Solder 1 3

Top Mounted

Thermocouple

Air Knife

4

Air Knife

2nd Pre-Heat

Air Knife

1st Pre-Heat

Rinse

Rinse

Rinse

°C

1st Stage Dryer

5

Rinse

Wash Rinse Dry

Flux

➤ ➤ Bottom

Mounted

Thermocouple

Soldering (SMT) 6

Four types of equipment are usually associated with SMT

Minutes

soldering:

IR System — Uses a multi-zone infrared furnace with IR

elements heated to a temperature substantially above chamber

or product temperature. Energy is supplied to the product

primarily by IR radiation to reflow solder.

Specifications are subject to change without notice.

Customers should verify actual device performance in their specific applications.

Applications/Processing Guide

To minimize exposure to high-pressure water during board

Rate of Change of Profile wash

(Indicator of Level of Stability)

• Select trimmer models with pin styles that orient the

rotor seal area away from exposure to the high-pressure

7 Unstable Temp water stream

(# of Cycles)

SETTABILITY

°C/Min.

Settability refers to the ease with which a trimmer can be set

accurately to the position that produces the desired circuit condition.

Where the requirement is for obtaining a highly accurate set-

ting the preference is for cermet — because a small incremental

adjustment in a wirewound unit does not always produce the

expected change in output as the wiper moves off one turn of wire

and onto another.

Setting accuracy is better with a multiturn unit than with a

single-turn. This is especially true when the speed of setting is also

Minutes a requirement as on a production line (Figure 2).

SINGLE-TURN SETTABILITY (3386) MULTITURN SETTABILITY (3299)

Figure 1.

400

Typical temperature profile for board washing

400

and soldering. M.V.

300

EXPERIENCED EXPERIENCED

Critical profile parameters TECHNICIAN TECHNICIAN

200

1 Temperature Shock (°C)

2 Maximum Temperature (°C) MV.

3 Temperature Exposure (Minimum) 400

M.V.

4 Temperature Gradient (°C) 500

5 Temperature Shock Decrease in Water (°C)

400

6 Temperature Shock Decrease in Water & Air Pressure (°C)

LESS EXPERIENCED LESS EXPERIENCED

7 Unstable Temperature (see next page) MV. TECHNICIAN TECHNICIAN

0 1.7 3.4 5.1 6.8 8.5 10.2 0 1.7 3.4 5.1 6.8 8.5 10.2

SEC. SEC.

General Guidelines for Guarding Against Component Damage

To minimize temperature shock

• Pre-heat boards to maximum acceptable level Figure 2.

• Reduce time in solder When accurate setting is required, a multiturn trimmer

can generally be set faster than a single-turn.

To avoid heating components above their maximum rated

temperature

• Use lowest acceptable solder temperature STABILITY

• Use maximum allowable conveyor speed

• Limit pre-heat temperature to maximum necessary Stability refers to the ability of the trimmer to remain at the

desired setting. Environmental factors play an important role here:

To limit time of exposure above rated temperature stability may be affected by temperature exposure, thermal shock/

• Limit time in solder cycling, humidity, and mechanical shock or vibration.

• After solder operation, cool board to wash temperature This is not a matter of concern in most applications, since

before it enters wash Bourns trimmers exhibit excellent stability under all specified condi-

tions. Stability is most often a concern when cermet trimmers are

To minimize temperature difference between top and bottom of used in low current "dry" circuits (50uA amps and below). Under

board these conditions the contact resistance may vary, making the wiper

• Apply pre-heat to both top and bottom appear unstable. This is most noticeable in some rheostat applica-

tions. This can be avoided by using a wirewound unit, or choosing a

To reduce temperature shock on entering the moist environ- cermet trimmer that has been designed for dry-circuit applications.

ment of the wash Bourns applications engineers can assist you on this and other

• Use wash/rinse temperature as near component questions.

temperature as possible

• Extend time between solder process and wash ACCESSIBILITY

• Cool board after solder operation, prior to entering wash

When selecting a trimmer and determining its placement on the

To minimize temperature variations as component travels board, keep in mind the people who will have to use it. Bourns trim-

through moisture mers are available in a wide variety of sizes, shapes, configurations,

• Minimize number of wash/rinse and rinse/dry cycles and placement of adjustment screws. You will usually find a unit on

• Use heated air for air knives (to counter evaporative which the access for adjustment will be convenient for the user.

cooling effect)

• Minimize difference between wash and rinse temperature

Specifications are subject to change without notice.

Customers should verify actual device performance in their specific applications.

Applications/Processing Guide

Keep in mind the different requirements for accessibility • Smaller Finished Product Size

depending on whether adjustment will be done on the assembly line (addresses demand for miniaturization).

or in the field; with the board uncovered, in a housing or cabinet, or Cost, performance, quality/reliability and size — how are these

on an extender. Also consider whether production-line adjustment factors interrelated and how are they achieved through surface

will be done manually or by robotics. A Bourns applications engineer mounting?

can advise on special high-speed automatic adjustment features. A by-product of SMD technology is the downsizing of compo-

nents. Size reductions range from 25% to 60%, depending upon the

USABILITY device in question. High PC board densities can be achieved (more

components per square inch of real estate; surface mounted units

In selecting a trimmer for a specific application, it's important to can also be assembled on both sides). PC board material savings

be aware that the catalog contains a myriad of facts about each alone are substantial. When circuits diminish, external hardware and

model that can assist you in finding the most suitable choice. For other materials follow — further savings. Even freight charges are

example: decreased by lighter equipment weight and less packaging.

Contact Resistance Variation (CRV) — Under MIL-R 22097 and Surface mounted component prices are forecasted to decline,

MIL-R-39035, the maximum CRV is 3%. All Bourns trimmers meet the result of automated volume production. Volume is directly related

this standard (3% or 3 ohms, whichever is greater). For applications to component standardization. By having a few sizes to cover a large

that demand a more rigorous standard, some Bourns trimmers are range of electrical values and/or parameters, large quantities of a

rated at 2% or 2 ohms, and many others at 1% or 1 ohm. given device can be produced at a much lower per unit cost. Selling

Power Rating — The ambient temperature at which the trimmer prices fall as volume increases. Component quality is also enhanced

will operate has an important bearing on power rating. Power ratings by eliminating many of the variables associated with short produc-

are usually specified at 70º or 85ºC; at a temperature of 150ºC, the tion runs.

power rating of many trimmers is reduced to zero. Automatic SMD handling equipment, although capital intensive,

Temperature Coefficient of Resistance (T.C.) — This specifica- is the single-most effective way to reduce labor costs and increase

tion is a measure of how much the resistance changes with a yields. Typical "pick and place" machines can assemble compo-

change in temperature. In many applications a T.C. of ±250PPM/ºC nents 8 to 10 times faster than human assemblers, with virtually no

is acceptable. Typical T.C. specifications for cermet models are mistakes. Major direct labor reductions are obvious. The combina-

±100PPM/ºC and ±50PPM/ºC for wirewound models. tion of improved component quality and "mistake-free" component

placement further decreases costs by eliminating the normal rework

of auto-inserted boards.

RELIABILITY The many advantages of SMD technology will force change

One of the greatest challenges facing American manufactur- upon both electronic equipment manufacturers and component

ers in the early '90s lies in the area of reliability — a challenge for suppliers alike. Worldwide competitive prices and performance

component manufacturers and equipment manufacturers alike. pressures will make it happen. Few electronic components will

Bourns has been on the leading edge of this effort, both in the area escape its influence, trimming potentiometers being no exception.

of instituting new methods and technologies for achieving higher Bourns is committed to SMD conversion, and we intend to be a

reliability, and bringing an awareness of the need to other manufac- leader in surface mounted trimmer devices. Bourns surface mount

turers. trimmers begin on page 12.

SURFACE MOUNTED DEVICES (SMD) GENERAL NOTES:

Plated-Through Holes: (Ref. MIL-STD-275D).

AN EMERGING TECHNOLOGY 5.5 Plated-through holes. The difference between the inside diame-

Surface mounting of electronic components represents another ter of the plated-through hole and the nominal outside diameter

significant advance in PC board processing. Many U.S. companies of the inserted lead shall be not greater than 0.028 inch

have expressed an interest in SMD assembly methods to replace the (0.71mm) or less than 0.010 inch (0.25 mm). Unless otherwise

often troublesome and costly techniques now used with leaded specified, the hole size shall be the finished plated size after

components. Unfortunately, for a number of reasons, this interest solder coating or fusing. When flat ribbon leads are mounted

has not resulted to date in a major commitment to SMD handling through plated-through holes, the difference between the nomi-

equipment. nal thickness of the lead and the inside diameter of the plated-

There are direct and indirect benefits associated with surface through hole shall not exceed 0.028 inch (0.71 mm).

mounting. Since the direct benefits are outgrowths of the indirect

ones, some explanation of these interrelated factors is required in

order to understand this complex, highly technical and investment

intensive subject. Further, a listing of the primary advantages will

make additional comments on Japan's SMD usage and growth

unnecessary.

In capsule format, the primary advantages (with comments on

secondary benefits) are:

• Lower End-Equipment Cost

(positions OEM's for aggressive pricing to achieve market

penetration).

• Superior Product Performance

(satisfies user requirements for improved operational

performance).

• Improved Product Quality and Reliability

(creates confidence factor which easily translates to

increased demand or sales).

Specifications are subject to change without notice.

Customers should verify actual device performance in their specific applications.

You might also like

- Quality Crimp HandbookDocument24 pagesQuality Crimp HandbookFlavia DogojieNo ratings yet

- Effective Use of Gauges and Measuring InstrumentsDocument31 pagesEffective Use of Gauges and Measuring Instrumentsaizaz65No ratings yet

- Swivel Joints - Sour Gas - Operating & MaintenanceDocument6 pagesSwivel Joints - Sour Gas - Operating & MaintenanceGenard Sabenacio GarciaNo ratings yet

- Main Plant Kamimine Plant: DistributorDocument5 pagesMain Plant Kamimine Plant: DistributorsmendozaNo ratings yet

- Swivel Joints - Operating & MaintenanceDocument4 pagesSwivel Joints - Operating & MaintenanceGenard Sabenacio GarciaNo ratings yet

- Hydraulic and Pressure Test ToolsDocument1 pageHydraulic and Pressure Test ToolsBob ForeverNo ratings yet

- Finat Test Methods 8th EditionDocument101 pagesFinat Test Methods 8th EditionAdrián González100% (2)

- The Art of Coffee Roasting. ThesisDocument168 pagesThe Art of Coffee Roasting. ThesisOscar DíazNo ratings yet

- Service Guide For Maintenance of Hoerbiger Valves: Compression Technology GroupDocument8 pagesService Guide For Maintenance of Hoerbiger Valves: Compression Technology Groupmahmod alrousan100% (1)

- REPUBLIC OF THE PHILIPPINES PROFESSIONAL REGULATION COMMISSION PREBOARD EXAM 1 – Math 1Document10 pagesREPUBLIC OF THE PHILIPPINES PROFESSIONAL REGULATION COMMISSION PREBOARD EXAM 1 – Math 1Joshua Casuga100% (1)

- Primerless Crosslinked Protective TapeDocument2 pagesPrimerless Crosslinked Protective Taperesp-ectNo ratings yet

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- Lighting SystemsDocument67 pagesLighting SystemsSuzette BinongcalNo ratings yet

- Properties of Metals StructureDocument10 pagesProperties of Metals StructureCyril Cauilan50% (2)

- Maximizing Trimmer PerformanceDocument8 pagesMaximizing Trimmer PerformanceNiyamathullahNo ratings yet

- TA - 031 - en General Information For Diaphragm SealsDocument5 pagesTA - 031 - en General Information For Diaphragm Sealstudonghoa tmpNo ratings yet

- tds_armo_grid_sr_eu_en_ver202301Document2 pagestds_armo_grid_sr_eu_en_ver202301abdo abjNo ratings yet

- FORD WX200 Rev2014Document4 pagesFORD WX200 Rev2014Amandeep SinghNo ratings yet

- NETZSCH TORNADO® Rotary Lobe Pumps ENDocument20 pagesNETZSCH TORNADO® Rotary Lobe Pumps ENtroycorser9No ratings yet

- Installation Acoplamiento Omega Rexnord Tipo E & ES Size 2M-140M - Eng.Document4 pagesInstallation Acoplamiento Omega Rexnord Tipo E & ES Size 2M-140M - Eng.oscarNo ratings yet

- Abrasive Flow Machining AFM An OverviewDocument10 pagesAbrasive Flow Machining AFM An OverviewAntin Aquil RajNo ratings yet

- Sealing High-Speed Shafts in TurbomachineryDocument4 pagesSealing High-Speed Shafts in TurbomachineryimtiazNo ratings yet

- Rammer Hammers LargeDocument9 pagesRammer Hammers LargePiyumi HasanthikaNo ratings yet

- Magneto-Rheological Damper TechnologyDocument25 pagesMagneto-Rheological Damper TechnologyShikhar GuptaNo ratings yet

- EN350490 - 1810 2810 BrochureDocument8 pagesEN350490 - 1810 2810 Brochuresf wNo ratings yet

- Roto PeenDocument12 pagesRoto Peenronbytom ronbytomNo ratings yet

- WACKER 460 NATURAL STONE en 2019.11.05Document4 pagesWACKER 460 NATURAL STONE en 2019.11.05klp_kedarpNo ratings yet

- Tensiometer Measurement SolutionsDocument8 pagesTensiometer Measurement SolutionsImad achlihNo ratings yet

- 1910 - Handy Adhesion PDFDocument3 pages1910 - Handy Adhesion PDFMohamed NouzerNo ratings yet

- Chemask Solder Masking Agent: Product# CM8, CM1Document2 pagesChemask Solder Masking Agent: Product# CM8, CM1Alexsander CamargoNo ratings yet

- Coating Joint - Canusa Wrapid TapDocument2 pagesCoating Joint - Canusa Wrapid TapDani HartantoNo ratings yet

- Wrapid Tape™: Product DescriptionDocument2 pagesWrapid Tape™: Product DescriptionCristobal Leal Aranda100% (1)

- Plasticising: Screws - Cylinders - Non-Return Valves: Suitable For Every Application!Document12 pagesPlasticising: Screws - Cylinders - Non-Return Valves: Suitable For Every Application!Becheru IonutNo ratings yet

- Elcometer - SAGMETER 4270-ManualDocument9 pagesElcometer - SAGMETER 4270-ManualRıdvan SürmeliNo ratings yet

- 6 Expert Tips On How To Choose Your Industrial Fitting!: White PaperDocument10 pages6 Expert Tips On How To Choose Your Industrial Fitting!: White PaperEfar EfarNo ratings yet

- Tbo Quality CrimpingDocument27 pagesTbo Quality Crimpingyavuz772No ratings yet

- Protective & Marine Coatings: Zinc Clad Iv EuDocument2 pagesProtective & Marine Coatings: Zinc Clad Iv Eusrinath vNo ratings yet

- No-Skive: Tough Cover Compact HoseDocument2 pagesNo-Skive: Tough Cover Compact HoseleonardoNo ratings yet

- Viledon MVPGTE10-LDocument2 pagesViledon MVPGTE10-LmsafwanizzudinNo ratings yet

- Hyperplas Standard Membrane - TDS PDFDocument4 pagesHyperplas Standard Membrane - TDS PDFSenthilkumar NarayananNo ratings yet

- 407 Mapefoam GBDocument4 pages407 Mapefoam GBAndrius KulvietisNo ratings yet

- Rod wiper with shoulder seal propertiesDocument2 pagesRod wiper with shoulder seal propertiespatricioNo ratings yet

- Technical Data SheetDocument4 pagesTechnical Data SheetHardikNo ratings yet

- Productdatasheet Airzet PKDocument1 pageProductdatasheet Airzet PKloloNo ratings yet

- Macropoxy C88Document2 pagesMacropoxy C88nellyNo ratings yet

- Corona & Plasma: For ExtrusionDocument5 pagesCorona & Plasma: For ExtrusionHuy Tuan QuachNo ratings yet

- Fasson 0828 DatasheetDocument1 pageFasson 0828 DatasheetGregory Alan Francisco IINo ratings yet

- TM-02 Spring Rail Clamp 04-2014Document23 pagesTM-02 Spring Rail Clamp 04-2014akın ersözNo ratings yet

- CPC Aseptic ConnectionsDocument7 pagesCPC Aseptic ConnectionsMochammad RezaNo ratings yet

- Accessories: Elbow / Grs-Guide Rail Systems: Submersible Sewage Effluent PumpsDocument2 pagesAccessories: Elbow / Grs-Guide Rail Systems: Submersible Sewage Effluent PumpsMOHD SHAIFUL AMRI BIN SAIFUDDINNo ratings yet

- New Oil Meter 2018Document4 pagesNew Oil Meter 2018Abass BilaNo ratings yet

- FRP Cumigrate PDFDocument3 pagesFRP Cumigrate PDFഒരു യാത്രക്കാരൻNo ratings yet

- Bourns Trimmer PrimerDocument72 pagesBourns Trimmer PrimerAnonymous AwyjZGV0VONo ratings yet

- RACE File System OptimizationDocument3 pagesRACE File System OptimizationVimi GeorgeNo ratings yet

- WUJING Brochure (Parts)Document16 pagesWUJING Brochure (Parts)Nicole WuNo ratings yet

- PW SeriesDocument8 pagesPW SeriesMt GrNo ratings yet

- Pump installation options: elbows or guide rail systemsDocument2 pagesPump installation options: elbows or guide rail systemssagbvnNo ratings yet

- HydroMax Weld NippleDocument12 pagesHydroMax Weld NippleAyman AlhalfawyNo ratings yet

- Raychem MWTM Medium Wall PDFDocument4 pagesRaychem MWTM Medium Wall PDFLeo TopacioNo ratings yet

- Rema-Tip-Top-Remasleeve RemagripDocument16 pagesRema-Tip-Top-Remasleeve Remagripdedison_rNo ratings yet

- Instruments Valve ManifoldDocument7 pagesInstruments Valve ManifoldkicsnerNo ratings yet

- Ebno Santa RosaDocument6 pagesEbno Santa RosaCarlosAgustoPinedaSanchezNo ratings yet

- Check List Template: # Descriptions 1 Topic 1 Check Items StatusDocument1 pageCheck List Template: # Descriptions 1 Topic 1 Check Items StatusHector DespachosNo ratings yet

- Tower Lease Agreement v3Document6 pagesTower Lease Agreement v3CarlosAgustoPinedaSanchezNo ratings yet

- Log Saija 3 SepDocument4 pagesLog Saija 3 SepCarlosAgustoPinedaSanchezNo ratings yet

- Feed Sse MFS 1cku C38 C50 - Rev003Document1 pageFeed Sse MFS 1cku C38 C50 - Rev003CarlosAgustoPinedaSanchezNo ratings yet

- Antena Bibanda, OSJ146440Document3 pagesAntena Bibanda, OSJ146440CarlosAgustoPinedaSanchezNo ratings yet

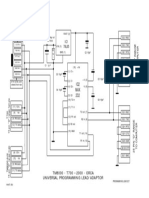

- ProgrammingDocument1 pageProgrammingCarlosAgustoPinedaSanchezNo ratings yet

- Satellite Orbits, Coverage, and Antenna AlignmentDocument59 pagesSatellite Orbits, Coverage, and Antenna AlignmentCarlosAgustoPinedaSanchezNo ratings yet

- 26 B Mount Blocks 04222020Document15 pages26 B Mount Blocks 04222020CarlosAgustoPinedaSanchezNo ratings yet

- Critical Factors Installing A DH Antenna: YOUR STARTING POINT! Pilot Hole Is Located On The 2Document15 pagesCritical Factors Installing A DH Antenna: YOUR STARTING POINT! Pilot Hole Is Located On The 2CarlosAgustoPinedaSanchezNo ratings yet

- DH 39Document2 pagesDH 39CarlosAgustoPinedaSanchezNo ratings yet

- 48 Inch Az El Instructions 01242020 New RibsDocument20 pages48 Inch Az El Instructions 01242020 New RibsCarlosAgustoPinedaSanchezNo ratings yet

- ThebbarcDocument23 pagesThebbarcCarlosAgustoPinedaSanchezNo ratings yet

- DMFC Rigel Stepper Motor Pinout PDFDocument1 pageDMFC Rigel Stepper Motor Pinout PDFCarlosAgustoPinedaSanchezNo ratings yet

- RC2K Upload / Download Utility: Design & Development EngineersDocument10 pagesRC2K Upload / Download Utility: Design & Development EngineersCarlosAgustoPinedaSanchezNo ratings yet

- RC3000 Integrated Beacon Receiver GuideDocument11 pagesRC3000 Integrated Beacon Receiver GuideCarlosAgustoPinedaSanchezNo ratings yet

- RC2KA Man v232 080812HMDocument129 pagesRC2KA Man v232 080812HMCarlosAgustoPinedaSanchezNo ratings yet

- Rc2kx v240 Addendum Selex VersionDocument12 pagesRc2kx v240 Addendum Selex VersionCarlosAgustoPinedaSanchezNo ratings yet

- Hasil Acceptance Test USSD Mobile Banking IndosatDocument23 pagesHasil Acceptance Test USSD Mobile Banking IndosatCarlosAgustoPinedaSanchezNo ratings yet

- DH 1.2m, 1.5m & 1.8m Antenna Series SpecsDocument1 pageDH 1.2m, 1.5m & 1.8m Antenna Series SpecsCarlosAgustoPinedaSanchezNo ratings yet

- ReleaseNotes CRFC v113 PDFDocument3 pagesReleaseNotes CRFC v113 PDFMemoPalacioNo ratings yet

- CM Site Survey and AcceptanceDocument1 pageCM Site Survey and AcceptanceCarlosAgustoPinedaSanchezNo ratings yet

- New and Used Inc.: Notes: Efdata C-Band To 70 MHZ Down ConverterDocument1 pageNew and Used Inc.: Notes: Efdata C-Band To 70 MHZ Down ConverterCarlosAgustoPinedaSanchezNo ratings yet

- Hughesnet ht2000w Satellite Modem User Guide 1041264-0001 ADocument53 pagesHughesnet ht2000w Satellite Modem User Guide 1041264-0001 AArizal CotoNo ratings yet

- Cambium MIB Release 4.6.0.1 Defines Hardware GroupsDocument258 pagesCambium MIB Release 4.6.0.1 Defines Hardware GroupsCarlosAgustoPinedaSanchezNo ratings yet

- Factura PDFDocument1 pageFactura PDFCarlosAgustoPinedaSanchezNo ratings yet

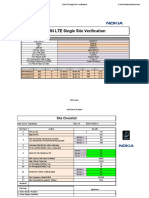

- ZAIN LTE Single Site VerificationDocument21 pagesZAIN LTE Single Site VerificationCarlosAgustoPinedaSanchezNo ratings yet

- E110100Prodelin 1385Document2 pagesE110100Prodelin 1385CarlosAgustoPinedaSanchezNo ratings yet

- CSAT Ethernet Version 1.2.1 ReleaseDocument3 pagesCSAT Ethernet Version 1.2.1 ReleaseCarlosAgustoPinedaSanchezNo ratings yet

- Wave Calculation Study of an Air Cushion Surge ChamberDocument27 pagesWave Calculation Study of an Air Cushion Surge ChamberEng Bagaragaza RomualdNo ratings yet

- CALENG3 - Lecture 7 - Spring-Mass ProblemDocument24 pagesCALENG3 - Lecture 7 - Spring-Mass ProblemGromwell GalimbaNo ratings yet

- CE 2121 LECTURE Module 3 PDFDocument21 pagesCE 2121 LECTURE Module 3 PDFRowena EdradaNo ratings yet

- What Is Reactance VoltageDocument2 pagesWhat Is Reactance VoltageMuhd HaffizyNo ratings yet

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDocument20 pagesFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraNo ratings yet

- Lecture 1 - Unit 1 - DSP (BEC-42) NewDocument21 pagesLecture 1 - Unit 1 - DSP (BEC-42) NewDr. Satish ChandraNo ratings yet

- Power Plant: Better Life Created by SteelDocument4 pagesPower Plant: Better Life Created by SteelAlejandro Jose Garcia FernandezNo ratings yet

- Distinguish TestDocument1 pageDistinguish TestAnsia MeenazNo ratings yet

- Parameters of DC High-Speed Circuit-Breakers: Artur RojekDocument5 pagesParameters of DC High-Speed Circuit-Breakers: Artur RojekagarwaalaaaaNo ratings yet

- 24kW PowerCore ETP48400-C9A4 User Manual (Claro, Peru)Document82 pages24kW PowerCore ETP48400-C9A4 User Manual (Claro, Peru)Ray PillacaNo ratings yet

- Phase Difference & Phase RelationshipsDocument24 pagesPhase Difference & Phase RelationshipsGabriel Carl AlpuertoNo ratings yet

- NDE Requirements (ASME Sec - VIII)Document2 pagesNDE Requirements (ASME Sec - VIII)Senol LimanNo ratings yet

- COPLANAR EQUILIBRIUM ANALYSIS Single and Composite BodiesDocument49 pagesCOPLANAR EQUILIBRIUM ANALYSIS Single and Composite Bodiesjoemer cabayaoNo ratings yet

- Recibidor de LiquidoDocument4 pagesRecibidor de LiquidoIsrael YepezNo ratings yet

- High Conductance Fast Diode: Absolute Maximum Ratings Sym Parameter Value UnitsDocument2 pagesHigh Conductance Fast Diode: Absolute Maximum Ratings Sym Parameter Value UnitsZoltán ÁgostonNo ratings yet

- Physics of Explosions Lab: Trolley Momentum ExperimentDocument6 pagesPhysics of Explosions Lab: Trolley Momentum ExperimentAkili ArmaniNo ratings yet

- MARIEL PULBOSA - WS-7 Mole MathtersDocument3 pagesMARIEL PULBOSA - WS-7 Mole MathtersMARIEL PULBOSANo ratings yet

- Gruppe Spot II LED FloodlightDocument2 pagesGruppe Spot II LED FloodlightManju BargaveeNo ratings yet

- CH 3. Continuity Differentiability - Differentiation (Math +2)Document68 pagesCH 3. Continuity Differentiability - Differentiation (Math +2)Sajag GargNo ratings yet

- Heat TransferDocument1 pageHeat TransferRisa M. LimNo ratings yet

- Refrigeration System ComponentsDocument4 pagesRefrigeration System ComponentsBensoyNo ratings yet

- RRZZVV-65B-R6H4: Electrical SpecificationsDocument5 pagesRRZZVV-65B-R6H4: Electrical SpecificationsСтанислав НиколовNo ratings yet

- Merawi 24Document12 pagesMerawi 24ወልደ መስቀል ፍቅሩNo ratings yet

- Bearing Capacity of Mat FoundationsDocument7 pagesBearing Capacity of Mat FoundationsConstructora Ingenieria AlemanNo ratings yet

- Theory of Solutions DPP-2 (Questions) PDFDocument4 pagesTheory of Solutions DPP-2 (Questions) PDFHarshjeetNo ratings yet

- Assignment (Alpha, Beta and Gamma Decay)Document5 pagesAssignment (Alpha, Beta and Gamma Decay)Az RahmanNo ratings yet