Professional Documents

Culture Documents

6th Sem Teaching Scheme Detail

Uploaded by

habib AnsariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6th Sem Teaching Scheme Detail

Uploaded by

habib AnsariCopyright:

Available Formats

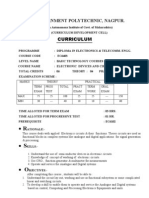

6TH SEM

TEACHING SCHEME

Teaching Scheme Examination Scheme

Subject

Subject THEORY PRACTICAL

code

MARKs

MARKS Total

T Tut Pra C (ESA) (PA) (ESA) (PA)

3360901 Switchgear & Protection 4 0 2 6 70 30 20 30 150

3360902 Installation, Commissioning & Maintenance 4 2 2 8 70 30 20 30 150

3360907 Maintenance of Transformer & Circuit breaker 3 0 2 5 70 30 20 30 150

3360908 Electrification of Building & Complex 3 0 2 5 70 30 20 30 150

3360909 Project II (Idp/Udp) 0 0 6 6 00 00 60 90 150

TOTAL 14 2 14 30 280 120 140 210 750

DE EE SEM-6 Detail Syllabus

(3360901) SWITCHGEAR AND PROTECTION

Teaching Scheme Total Examination Scheme

Credits Theory Mark Practical Total

(In Hours) (L+T+P)

L T P C ESE PA ESEMarksPA Marks

150

4 0 2 6 70 30 20 30

1. Elements of protection: Need of protective system, Functions of basic elements of a

protective system, Basic functional characteristics of protection system, Types, causes and

effects of various Faults, Protection zones, Backup protection & its types, Necessity of

Protective Transformers, Specifications and Connection diagram of Current Transformer

and Potential Transformer both single and 3 phase, Use of current limiting reactors and

their arrangements, Importance and methods of neutral Earthing.

2. Circuit Interrupting Devices: Necessity and types of interrupting devices, Sequence of

operation and interlocking, Fuse, types, terms related to fuse, characteristics, testing and

applications, Requirement and types of isolators, Arc phenomena and arc extinction in

circuit breaker, Important terms associated with circuit Breaker, Resistance switching,

Construction, working principle of Air break, Air Blast, Sulphur Hexa Fluoride (SF6 ) and

vacuum circuit breakers, Circuit breaker ratings, Auto-reclosure, Testing of circuit breaker,

Working principle of arc quenching in HVDC circuit breaker.

3. Protective Relays: Protective relay, classification and selection, Basic terms related to relay

- Pick up value, reset value and operating current etc., Principle of working ,construction

and operation of electromagnetic induction(shaded pole, watt-hour meter and induction

cup),Thermal relay, Settings of various types of relays, Directional relay, Distance

relay(impedance, reactance and mho), Negative phase sequence relay, Need of static relay,

Construction and types, Principle and working of Microprocessor based relay, Maintenance

and testing of relays.

4. Protection of transmission line and feeder: Need of transmission line protection scheme,

Selection of protection scheme -Overload protection, Over-current and earth fault

protection, Time graded and current graded protection, Current balance differential

protection, Need of Carrier aided protection, Carrier inter-tripping, acceleration and

blocking scheme, Distance /Impedance protection, Necessity and types of Auto reclosing,

Protection of parallel feeders and Ring Mains.

5. Protection of transformer, alternator, motor and bus bar: Over current, Percentage

differential and Restricted earth fault protection of Transformers, Inrush phenomenon and

over fluxing phenomenon in Transformer, Buchholz Relay, analysis of trapped gases,

Various faults and abnormal operating conditions in Alternator and its protection schemes,

Various faults and abnormal occurring in the Motor and its protection schemes, Differential

Protection of Bus bars.

6. Over voltage protection: Causes of over voltages, Methods of reducing over voltages,

Operating principles, construction and Applications of lightning arrester, Insulation co-

ordination, volt- time characteristic and basic impulse insulation level.

Text Books: Switchgear and Protection-Rao S. S. -Khanna Publications, New Delhi (Latest

Edition)

Syllabus of (3360902) INSTALLATION, COMMISSIONING AND MAINTENANCE

Teaching Scheme Total Examination Scheme

Credits Theory Marks Practical Marks Total

(In Hours)

(L+T+P) Marks

L T P C ESE PA ESE PA

150

4 2 2 8 70 30 20 30

1. INSTALLATION OF ELECTRICAL EQUIPMENTS - Introduction, Unloading of electrical

equipment at site, Inspection, Storage, Foundation, Alignment of electrical machines,

Tools/Instruments necessary for installation, Inspection, storage and handling of

transformer, switchgear and induction motor, Preparation of technical report

2. COMMISSIONING AND TESTING – Tests before commissioning of electrical equipment

:Electrical and Mechanical test, Specific test son -transformer, induction motor,

alternator, synchronous power and electrical power installation, Need of gradually

loading of electrical equipment, Preparations before commissioning of power

transformer, Commissioning-power transformer, three phase induction motor,

Transformer insulation oil: Properties as per IS, sampling, testing and filtering/purifying,

standard tests as per IS, Measurement of insulation resistance of different

equipments/machines, Methods of Drying the winding of electrical equipments and its

record, Classification and measurement of insulation resistance, Polarization Index,

Appropriate insulation test for specific purpose, Factor affecting the insulation , Various

Tests to be performed after commissioning and before starting the machine , Various

instruments required for testing, Commissioning of switchgear, Test report on

commissioning and test certificate.

3. MAINTENANCE OF ELECTRICAL EQUIPMENTS - General aspectof maintenance,

Classification, Preventive maintenance-concept, classification, advantages,activities,

functionsof the Maintenance Department, Breakdown maintenance-concept,

advantages, activities, Reasons of failure of electrical equipment due to poor

maintenance, Factors for preparing maintenance schedule, Frequency of maintenance,

Maintenance schedule of transformer below and above 1000Kva, Maintenance schedule

-induction motor, circuit Breaker, overhead line, storage Battery, Probable faults due

to poor maintenance in transformer, induction motor, circuit breaker, overhead lines

and battery.

4. TROUBLE SHOOTING - Causesof fault in electrical equipments-Internal and external,

Instrumentsand tools fortrouble shooting, Common troubles in electrical equipment –

DC Machines, AC Machines, Transformers, Circuit-breaker, under-ground cable,

electrical Installation, Need of trouble shooting chart,advantages, Trouble shooting

chart –DC Motor, DC Generator, Transformer, Synchronous Motor, Induction Motor,

Circuit-breaker, Trouble shooting chart for Domestic appliances-electrical iron, ceiling

fan, Washing machine, Air cooler, Vacuumcleaner, Fluorescent tube light: Construction,

working and troubleshooting chart.

5. EARTHING - Necessity of earthing , System earthing : advantage of neutral earthing of

generator in power station, Equipment earthing: Objective, Types of earth electrodes,

Methods of earthing : plate earthing ,pipe earthing and coil earthing, Earthing in extra

high voltage and underground cable, Earthing resistance- factor affecting,

Determination of maximum permissible resistance of the earthing system ,

Measurement of earth resistance: voltmeter-ammeter method, earth tester method,

ohm meter method and earth loop tester method, Define: earthing , grounding and

bonding, Comparison between equipment earthing and system grounding, Earthing

procedure - Building installation, Domestic appliances, Industrial premises, Earthing in

substation, generating station and overhead line.

6. ELECTRICAL ACCIDENTSAND SAFETY - Causes of electrical accident, Factors affecting the

severity of electrical shock, Actions to be taken when a person gets attached to live part,

Safety regulations and safety measures, Indian electricity supply act1948-1956, Factory

act 1948, Procedure of shut down for sub-station and power lines, Permit to work :

certificate of (i)requisition for shut down(ii) Permit to work and (iii)Line clear certificate,

Instruction for the safety of persons working on a job with a permit to work , Fire

extinguishers- For fixed installation and portable devices

Text Books: Testing Commissioning operation and maintenance of Electrical Equipments by Rao

S - Khanna Publication (Latest edition)

Syllabus of (3360907) Maintenance Of Transformer And Circuit Breaker

Teaching Scheme Total Examination Scheme1

Credits Theory Marks Practical Total

(In Hours)

(L+T+P) Marks Marks

L T P C ESE PA ESE PA 150

3 0 2 5 70 30 20 30

1. Preventive Maintenance - Maintenance and its types -Preventive and Breakdown,

Advantages of preventive maintenance, Scope of preventive maintenance, Economics of

preventive maintenance.

2. Maintenance of Transformers - Significance of transformer maintenance, Parts of

transformer- tank. Core, winding, conservator, radiators, bushings, terminals,

temperature measurement system, safety valves, tap changers and accessories/ fittings

etc., Factors affecting the life of transformer-moisture, water oxygen, solid impurities,

varnish, slackness of windings and dust, Inspection-sensory, records and electrical test,

General/Typical maintenance schedule of power transformers- up to 1000 kVA and

above 1000 Kva, Maintenance of transformer oil- characteristic, interpretation of tests,

procedure of testing BDV, filtering plant, Causes of failures of power transformers and

preventive actions, Detective devices-Buchholz relay, Pressure relief device, Differential

relay, Dial thermometer alarm contact, Overcurrent relay, ground fault relay, voltmeter,

ammeter, Human senses, Check list of maintenance of power transformers, Causes and

methods to reduce Audible Noise (AN) from transformer, Maintenance of distribution

transformer, i. Reasons for failure of Distribution Transformers and the remedial

measures thereof, ii. Inspection & Maintenance Schedule for Distribution Transformers:,

iii. Inspection & Maintenance of transformer and accessories within the sub-station and

its proximity, Procedure of measuring the insulation resistance of transformer windings.

3. Commissioning and Recharging of Transformers - Concept of commissioning and

recharging of transformer, General checks, Insulation resistance test, Measurement of

oil characteristics, Off circuit tap switch, Continuity test, Measurement of winding

resistance , Voltage ratio tests, Magnetizing current, Charging of the transformer, Do’s

and Don’ts for transformer, Various commissioning tests on a power transformers,

Procedure of loading the transformers, Transformer grounding.

4. Maintenance of Circuit Breaker - Steps in maintenance of CB, Maintenance of moulded

case circuit breakers -Frequency and routine maintenance tests, Maintenance of low-

voltage circuit breakers -Frequency and maintenance procedures, Maintenance of

medium-voltage circuit breakers – Air, Oil and Vaccum circuit breakers - Frequency of

maintenance, safety practices and maintenance procedures for each of the above,

Maintenance of high-voltage circuit breakers - frequency of inspections, External and

internal inspection guidelines, typical internal breaker problems, Influence of duty

imposed, Types of tests performed, OIL CB, Post fault maintenance, Steps in

maintenance of MOCB, Maintenance for AIR CB and Frequency of maintenance,

Maintenance of AIR BLAST CB, Maintenance of SF6 gas circuit breakers i. Properties of

SF6 (sulphur hexafluoride) gas ii. Handling non faulted SF6 iii. Handling faulted SF6 iv.

Procedure of filling SF6 gas in single pressure puffer type SF6 CB v. Gas monitoring

system and gas handling system for SF6 filled equipment vi. Types and function of SF6

gas handling units vii. Maintenance of SF6 CB, Maintenance of VACCUM CB, Life of

arcing contacts in various CB in case of normal current switching and short circuit

operation, Causes of failure of CB, trouble shooting and procedure of failure analysis,

Typical Record card for maintenance work of CB, Commissioning tests on HV a.c. CB ,

Operating mechanism used in HV a.c. CB, Safety precautions to be taken in maintenance

of CB

Text Books: Testing Commissioning operation and maintenance of Electrical Equipments - Rao S

- Khanna Publication (latest edition)

Syllabus of (3360908) ELECTRIFICATION OF BUILDING AND COMPLEXES

Teaching Scheme Total Credits Examination Scheme

Theory Marks Practical Total Marks

(In Hours) (L+T+P)

Marks

L T P C ESE PA ESE PA

150

3 0 2 5 70 30 20 30

1. Elements of electrification: Classification of Electrical Installation, General requirement of

Electrical installation, Reading and Interpretation of Electrical Engineering Drawings,

diagrams, plans and layout, Testing of wiring Installation for verification of current;

earthing, insulation resistance and continuity as per IS, Preparation of testing/supervisory

report, Selection of main cable, main switches, circuit breakers, etc., Illumination

requirements in high rise, Commercial and public Building, Economical consideration in the

illumination design.

2. Electrification of multistory buildings: Wiring layout of an electrical installation,

Electrification of wiring supply-location from nearby substation, Type of wiring- Concealed,

conduit or Surface conduit, Decision on number of sub circuits from the total circuit

requirement, Calculation of total load on electrical distribution work, Estimation of material

requirements floor wise, Specification of wiring material and accessories, Estimation of total

cost of electrification using Schedule Of Rates, Case studies, Requirements of approval from

electrical inspection for high rise building, Load calculation for lifts, escalators, air

conditioners and their simplified wiring diagram, Problems, Case studies.

3. Electrification of complexes and public buildings: Concept of commercial Installation,

Comparison of Residential and commercial Installation, Fundamental considerations for

planning of an electrical installation system for commercial building, Special requirements

of hotels, theaters, library and cultural halls etc. from electrification points of view,

Estimation of material requirement, unit cost and total cost of electrification of complexes,

Case studies.

4. Distribution system for multistoried buildings: Methods and Estimation of underground

service connection, Incoming supply to substation for multistoried high rise buildings

(building height more than 15m.), Distribution panels and bus bar system, Meter

connection- bifurcation of metering-meters as per consumers demand, use of digital –

meters for prevention of theft of power, Cable laying in building, special precautions

5. Electrical safety and IE rules: Importance of safety rules, Safety precaution in electrical

installation of multistoried buildings, Fire alarm system, Smoke detection system, Safety for

lifts and escalators, Earthing system (IE rules regarding safety), Lightening arrestors

arrangements, Use of ELEB and MCB in an installation, Electronic safety locks at the

entrance, Use of national building code (electrical service ) for safety, Use of D.G. set as a

standby power supply in case of emergency, IE rules related to Electrical Installation and

Testing

Text Books: Electrical Design Estimation & Costing - Raina K.B., Bhattacharya S.K., Willet Estern

Ltd., Latest edition

You might also like

- Electric System - 1: Master Switch Battery RelayDocument18 pagesElectric System - 1: Master Switch Battery RelayLeopoldo Del Campo100% (4)

- Electrical Wiring Estimation 170529115347Document45 pagesElectrical Wiring Estimation 170529115347habib AnsariNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Prot. & Metering NoteDocument84 pagesProt. & Metering NoteSLDC DDNo ratings yet

- Keiilf: Training ManualDocument53 pagesKeiilf: Training ManualGary GouveiaNo ratings yet

- Machine Condition Monitoring Technical Library - N - Apr.2014 - NIDocument4 pagesMachine Condition Monitoring Technical Library - N - Apr.2014 - NIHmidaNo ratings yet

- On Site Installation Check List 5.0Document125 pagesOn Site Installation Check List 5.0gustavo_adolfo_25100% (2)

- How To Build High-Q Coils PDFDocument2 pagesHow To Build High-Q Coils PDFmiguellm5071No ratings yet

- Parts List QPNC 75 To QPNC 250Document12 pagesParts List QPNC 75 To QPNC 250Javier CevallosNo ratings yet

- Krautkrämer Ultrasonic Transducers: For Flaw Detection and SizingDocument48 pagesKrautkrämer Ultrasonic Transducers: For Flaw Detection and SizingBahadır Tekin100% (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Power Transformer Online Monitoring Using Electromagnetic WavesFrom EverandPower Transformer Online Monitoring Using Electromagnetic WavesNo ratings yet

- Age Declaration Form PDFDocument1 pageAge Declaration Form PDFdhokalerajNo ratings yet

- SCHEME - E Fourth Semester - ED, EI, EJ, EN, ET, EXDocument40 pagesSCHEME - E Fourth Semester - ED, EI, EJ, EN, ET, EXMrunal Tambe0% (1)

- SF Gas Insulated Ring Main Unit RMUDocument24 pagesSF Gas Insulated Ring Main Unit RMUr_mukuyuNo ratings yet

- GTU Course on Testing and Commissioning of Electrical EquipmentDocument4 pagesGTU Course on Testing and Commissioning of Electrical EquipmentMitesh Gandhi100% (2)

- Study and Evaluation Scheme: Uttarakhand Technical University SESSION 2009-10Document11 pagesStudy and Evaluation Scheme: Uttarakhand Technical University SESSION 2009-10Surendar SinghNo ratings yet

- InstallationCommissioning MaintenanceDocument5 pagesInstallationCommissioning MaintenanceER Mukesh ThakurNo ratings yet

- 2EE701 Commissioning Testing & Maintaining Electrical EquipmantDocument2 pages2EE701 Commissioning Testing & Maintaining Electrical EquipmantDwij patelNo ratings yet

- BT Sem VI ElecDocument15 pagesBT Sem VI ElecsamirsamoNo ratings yet

- 1ET1020704 - Testing and Commissioning of Electrical EquipmentsDocument3 pages1ET1020704 - Testing and Commissioning of Electrical Equipmentsabdullamalek339No ratings yet

- SCHEME - E Fifth Semester (EE)Document54 pagesSCHEME - E Fifth Semester (EE)Yaser Shaikh0% (3)

- 4.6 Final Aeronautics Avionics - 2Document12 pages4.6 Final Aeronautics Avionics - 2Manish Mishra100% (1)

- Fault and Abnormal 1Document71 pagesFault and Abnormal 1Mahesh PushpakumaraNo ratings yet

- Grid maintenance and P&I trainingDocument18 pagesGrid maintenance and P&I trainingArslan AhmadNo ratings yet

- Gujarat Technological University: Page 1 of 5Document5 pagesGujarat Technological University: Page 1 of 5Darshit KotadiyaNo ratings yet

- Bhivarabai Sawant Institute of Technology and Research, (Women), Wagholi, PuneDocument3 pagesBhivarabai Sawant Institute of Technology and Research, (Women), Wagholi, PuneSandeep ChawdaNo ratings yet

- Lesson Plan: S.No. Topic Hrs. Theory Hrs. Practical Compln. Date Sign Lecturer Sign Course Co-Ordinator 1Document2 pagesLesson Plan: S.No. Topic Hrs. Theory Hrs. Practical Compln. Date Sign Lecturer Sign Course Co-Ordinator 1Harishbhusan PanigrahiNo ratings yet

- Study & Evaluation Scheme Three Year Diploma Course in Instrumentation and Control Engineering (2014 Scheme) Semester - VDocument15 pagesStudy & Evaluation Scheme Three Year Diploma Course in Instrumentation and Control Engineering (2014 Scheme) Semester - VVarun RanaNo ratings yet

- A Course in Electrical and Electronic Measurements and Instrumentation - A.K.sawhneyDocument14 pagesA Course in Electrical and Electronic Measurements and Instrumentation - A.K.sawhneyHarshal SonawaneNo ratings yet

- 4th Sem 4 Electrical EngineeringDocument31 pages4th Sem 4 Electrical EngineeringSajan MahatoNo ratings yet

- 6th Sem - 28 - Electrical Engg Industrial ControlDocument27 pages6th Sem - 28 - Electrical Engg Industrial Controlbumbamalakar745No ratings yet

- Power System ProtectionDocument2 pagesPower System ProtectionShivansh BhardwajNo ratings yet

- Syllabus SG&PDocument2 pagesSyllabus SG&PDeepakPorwalNo ratings yet

- Electro-Hydraulic Systems. Development of Circuits For Industrial,-/automationDocument3 pagesElectro-Hydraulic Systems. Development of Circuits For Industrial,-/automationAmeya GanpatyeNo ratings yet

- Wave Shaping and Swiching CircuitsDocument3 pagesWave Shaping and Swiching Circuitskaran007_mNo ratings yet

- 4th Sem - 4 - Electrical EngineeringDocument36 pages4th Sem - 4 - Electrical Engineeringdgangopadhyay3064No ratings yet

- Ec302: Power Electronics CREDITS 5 (L 3, T 0, P 2) : Course ObjectiveDocument3 pagesEc302: Power Electronics CREDITS 5 (L 3, T 0, P 2) : Course ObjectiveYash SinghNo ratings yet

- Electrical Machines & DrivesDocument2 pagesElectrical Machines & DrivesDhiraj PrakashNo ratings yet

- Digital Control: Laboratorios LA-FM-007 Versión: 4 Fecha: 15/03/2019 Página 1 de 9Document9 pagesDigital Control: Laboratorios LA-FM-007 Versión: 4 Fecha: 15/03/2019 Página 1 de 9Valentina BeltranNo ratings yet

- Laboratory Manual Power Systems Laboratory (R18A0287) Iv B.Tech I - Sem (Eee)Document54 pagesLaboratory Manual Power Systems Laboratory (R18A0287) Iv B.Tech I - Sem (Eee)anuj singhNo ratings yet

- R18 B.Tech Eee Iii YearDocument42 pagesR18 B.Tech Eee Iii YearNIMMANAGANTI RAMAKRISHNANo ratings yet

- Theory: Total 18 - 80 320 - 400Document20 pagesTheory: Total 18 - 80 320 - 400Itz AjiTNo ratings yet

- END SEM Exam Term Work Practi CAL Exam Total MarksDocument20 pagesEND SEM Exam Term Work Practi CAL Exam Total MarksnavneetNo ratings yet

- Study Scheme: B Tech. Electrical & Electronics Engineering: Semester III EEEDocument9 pagesStudy Scheme: B Tech. Electrical & Electronics Engineering: Semester III EEERaviSainiNo ratings yet

- Scheme of Teaching and Examination B.E.: Electronics & Communication EngineeringDocument8 pagesScheme of Teaching and Examination B.E.: Electronics & Communication EngineeringmabhatNo ratings yet

- Course Btech EceDocument61 pagesCourse Btech EcepraveenNo ratings yet

- Modern Power Generation PlantDocument3 pagesModern Power Generation PlantNirbhayNo ratings yet

- Eemi 2130903Document3 pagesEemi 2130903Dhaval PatelNo ratings yet

- Ilovepdf Merged PDFDocument108 pagesIlovepdf Merged PDFAmrit SainiNo ratings yet

- Visvesvaraya Technological University, Belagavi Choice Based Credit System (CBCS) Scheme of Teaching and Examination 2015-2016Document33 pagesVisvesvaraya Technological University, Belagavi Choice Based Credit System (CBCS) Scheme of Teaching and Examination 2015-2016A VNo ratings yet

- Electrical Circuit Analysis and Network TheoremsDocument38 pagesElectrical Circuit Analysis and Network TheoremsRIVA COMPUTERSNo ratings yet

- Lab Manual: Shree Ramchandra College of Engineering, Lonikand, Pune - 412 216Document43 pagesLab Manual: Shree Ramchandra College of Engineering, Lonikand, Pune - 412 216jatindraNo ratings yet

- Visvesvaraya Technological University, Belagavi Choice Based Credit System (CBCS) Scheme of Teaching and Examination 2015-2016Document33 pagesVisvesvaraya Technological University, Belagavi Choice Based Credit System (CBCS) Scheme of Teaching and Examination 2015-2016sushilNo ratings yet

- MSBTE Academic Year 2009-10 Teaching and Examination Scheme for Electronics Engineering GroupDocument40 pagesMSBTE Academic Year 2009-10 Teaching and Examination Scheme for Electronics Engineering Grouponkarsdatar0% (1)

- State Council For Technical Education and Vocational Training, OdishaDocument28 pagesState Council For Technical Education and Vocational Training, OdishaSUDHIR KUMAR DASNo ratings yet

- Describe Circuit Breakers and Various Protection CircuitsDocument2 pagesDescribe Circuit Breakers and Various Protection CircuitsPrEmNo ratings yet

- M.tech SyllabusDocument36 pagesM.tech SyllabusprateekiitkNo ratings yet

- ES101Document3 pagesES101Sualé SualéNo ratings yet

- TE Electronics Syllabus Wef 14 15 - 27 4 15Document36 pagesTE Electronics Syllabus Wef 14 15 - 27 4 15saurabhm6No ratings yet

- 4el01: Power Electronics CREDITS - 3 (LTP: 3,0,0)Document2 pages4el01: Power Electronics CREDITS - 3 (LTP: 3,0,0)Keval ShahNo ratings yet

- Substation Engineering CourseDocument2 pagesSubstation Engineering Courseasad khanNo ratings yet

- Guru Nanak Institutions Technical Campus: Mr. S. Rajander ReddyDocument18 pagesGuru Nanak Institutions Technical Campus: Mr. S. Rajander ReddyPatil PurnachandraNo ratings yet

- Course Code Course Name Teaching Scheme (Contact Hours) Credits Assigned Theory Pract. Tut. Theory Tut. Pract. TotalDocument4 pagesCourse Code Course Name Teaching Scheme (Contact Hours) Credits Assigned Theory Pract. Tut. Theory Tut. Pract. TotalPabocNo ratings yet

- Model Curriculum: Field Engineer - RACWDocument20 pagesModel Curriculum: Field Engineer - RACWpatel gauravNo ratings yet

- Power system protection & switchgear: An overviewDocument2 pagesPower system protection & switchgear: An overviewbhatkanti groupNo ratings yet

- Course Specification and Course PlanDocument4 pagesCourse Specification and Course PlanSafnas KariapperNo ratings yet

- Me Iii Sem HVPSDocument8 pagesMe Iii Sem HVPSharry potterNo ratings yet

- Embedded Mechatronic Systems 2: Analysis of Failures, Modeling, Simulation and OptimizationFrom EverandEmbedded Mechatronic Systems 2: Analysis of Failures, Modeling, Simulation and OptimizationNo ratings yet

- Reliability Investigation of LED Devices for Public Light ApplicationsFrom EverandReliability Investigation of LED Devices for Public Light ApplicationsNo ratings yet

- SIMULATING DYNAMICSDocument24 pagesSIMULATING DYNAMICShabib AnsariNo ratings yet

- 07 Chapter 02 PDFDocument38 pages07 Chapter 02 PDFhabib AnsariNo ratings yet

- Lec 14Document22 pagesLec 14habib AnsariNo ratings yet

- Refer Slide Time: 00:18Document34 pagesRefer Slide Time: 00:18habib AnsariNo ratings yet

- PDF Advertisement For WS 73Document18 pagesPDF Advertisement For WS 73Rojan MathewNo ratings yet

- Electric Vehicles - Part 1 AssignmentDocument4 pagesElectric Vehicles - Part 1 Assignmenthabib AnsariNo ratings yet

- Lecture1 180520043158Document57 pagesLecture1 180520043158habib AnsariNo ratings yet

- Electric Vehicles - Part 1 AssignmentDocument4 pagesElectric Vehicles - Part 1 Assignmenthabib AnsariNo ratings yet

- L 03 (SS) (Ia&c) ( (Ee) Nptel)Document10 pagesL 03 (SS) (Ia&c) ( (Ee) Nptel)Abdelraheem S. AlkuorNo ratings yet

- Workshop On Industrial ControlDocument2 pagesWorkshop On Industrial Controlhabib AnsariNo ratings yet

- VX150 VX2 FMB T: 3: Troubleshooting ManualDocument105 pagesVX150 VX2 FMB T: 3: Troubleshooting ManualragiNo ratings yet

- 1.5KE Series: 1500W Transient Voltage SuppressorDocument6 pages1.5KE Series: 1500W Transient Voltage SuppressorjefriNo ratings yet

- Training Report Doordarshan KendraDocument55 pagesTraining Report Doordarshan KendrameetprakharNo ratings yet

- Schem e For Tie, Trafo, MotorDocument52 pagesSchem e For Tie, Trafo, Motormukesh_kht1No ratings yet

- Lot (1) - Rfq-Drawing - Abu Dhar Alghafari SchoolDocument15 pagesLot (1) - Rfq-Drawing - Abu Dhar Alghafari SchoolMOHAMMED. HAKAMINo ratings yet

- JCLP SpliTech2019 FinalDocument19 pagesJCLP SpliTech2019 FinalRemigild PeterNo ratings yet

- Thesis Power Factor CorrectionDocument5 pagesThesis Power Factor CorrectionYolanda Ivey100% (2)

- A4 PDFDocument12 pagesA4 PDFΜάκης ΠιστόλαςNo ratings yet

- 64-Kbit (8K × 8) Serial (SPI) F-RAM: Features Functional DescriptionDocument21 pages64-Kbit (8K × 8) Serial (SPI) F-RAM: Features Functional DescriptionsupNo ratings yet

- SRMU Training at META Co. RiyadhDocument46 pagesSRMU Training at META Co. RiyadhTanveer Ahmad100% (1)

- Talking Board: 80 December 1981 U.K. 65 PDocument76 pagesTalking Board: 80 December 1981 U.K. 65 PWagner SilvaNo ratings yet

- GE Energy Mark Ve Control: I/O Communication (PMVE) Module DescriptionDocument142 pagesGE Energy Mark Ve Control: I/O Communication (PMVE) Module DescriptionJorge Contreras100% (1)

- Fpga Motor Control Reference Design: Spartan™-3 Microblaze™Document15 pagesFpga Motor Control Reference Design: Spartan™-3 Microblaze™ASOCIACION ATECUBONo ratings yet

- NLC #4Document2 pagesNLC #4aeilorv infanteNo ratings yet

- BEEE - LAB Manual-Intro - Part 2Document6 pagesBEEE - LAB Manual-Intro - Part 2Anant UpadhiyayNo ratings yet

- (0999)Document2 pages(0999)Maria Jose VelazquezNo ratings yet

- RBH Integra32 Install SheetDocument2 pagesRBH Integra32 Install SheetJairo DiazNo ratings yet

- AMANAT KUMAR-21220521 (Experiments)Document55 pagesAMANAT KUMAR-21220521 (Experiments)Amanat kumarNo ratings yet

- Digital DimmerDocument13 pagesDigital DimmerZezo MarchettiNo ratings yet

- Electrostatics Formulas and ConceptsDocument2 pagesElectrostatics Formulas and ConceptsAbdul AhadNo ratings yet

- ECE551 - Homework 1 - Spring 2019 SolutionDocument4 pagesECE551 - Homework 1 - Spring 2019 SolutionJAY CHHEDANo ratings yet

- Transitor 2SB647Document4 pagesTransitor 2SB647Louis CaraballoNo ratings yet