Professional Documents

Culture Documents

Specifications Features: Advanced Rolling Float Meter

Uploaded by

shadyghanemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specifications Features: Advanced Rolling Float Meter

Uploaded by

shadyghanemCopyright:

Available Formats

RFM-3600

FT-TECHINFO-232

FORERUNNER

TECHNOLOGIES

REV 1

Advanced Rolling Float Meter

Leveraging the success of FLE-10001, a velocity-sensor wheel feature has been incorporated

achieving Advanced Rolling Float Meter (RFM)2 capability. Capitalizing on the field-proven Sandia

Laboratory’s RFM, significant operational issues have been addressed including high-temperature

light plastic composite wheel (to detect extremely low flow velocities), tachometer redundancy and

modularity of components to achieve unprecedented levels of precision, ease in commissioning and

in maintenance.

The field-based DAQ box displays Volumetric Flow and can send out many more

information via Serial or Network. The intuitive calibration via keypad LCD interface is

made even easier by built in instructions and comments.

1- FLE-1000 is the revolutionary flow line sensor product of APS Enertek, the world’s first level

measurement utilizing encoder technology 2- The Rolling Float Meter has been extensively

field-tested by Sandia Laboratories of USA and with unclassified published design information

Specifications Features

I N F O R M A T I O N

Model Capable of accurately measuring volume flow in partially-filled

RFM-3600 pipes and open-troughs, the RFM-3600 is the ONLY suitable option

Application where minimum modification to the current rig design is required.

T E C H N I C A L

Measurement of volumetric liquid or slurry flow in

partially-filled fully closed pipes and open trough Digital detection of flow level makes repeatability unmatched by

channels any analog resistive sensor, including the original potentiometer-

Implementation

based design.

Two components – liquid pipe level is measured

indirectly by angular displacement of wheel arm Plastic composite material (at least 5 times lighter than the

and velocity by RPM of wheel

Volumetric Flow is calculated from the two

original all-metal wheel design) minimizes resistance to movement

components and channel or pipe shape information hence increasing reactivity and sensitivity.

Sensing Range and Limit Volume Flow calculation in the DAQ box considers effects of

RPM: 15,000

Volume Flow: Up to 33,000 gpm

1 surface velocity to wheel buoyancy, and handles rounded,

Precision rectangular, and U-shaped channel shapes.

Flow Level: 0.4%

RPM: 8 counts per revolution Comparable in

Volume Flow: 10 gpm accuracy and

Repeatability performance to

Flow Level: 99.2%

RPM: 100%

traditional full pipe

Volume Flow: > 94% flow meters.

Power Requirement

From field test data

18-28 VDC, < 3W consumption

Outputs and Connectivity (left), for 0 to 475

Volume Flow (gpm), Percent Flow, RPM gpm, volume flow

3x Analog Outputs 0-10 VDC (as above) average difference

WITS Level 0 by RS-232 or TCP/IP

is 12 gpm with

Operating Temperatures

Flow Level Sensor: -20 to 60°C (-4 to 140°F) variance <6%.

Composite Wheel: -40 to 135°C (-40 to 275°F)

Wheel Tachometer

Ambient: -20 to 80°C (-4 to 176°F) Wheel tachometer function is implemented with a NAMUR encoder

Splashing Fluid: -20 to 135°C (-4 to 275°F) for redundant RPM signals.

DAQ Box: -40 to 70°C (-40 to 158°F)

Dimensions

Flow Percent parameter is calculated with 100% equivalent to

Sensor System: 24”L x 11”W x 9”H horizontally positioned arm – allowing the RFM-3600 to completely

DAQ Box: 9 ¼”L x 10 ¼”W x 5 ½”H replace and supersede traditional flow paddles.

Weights

Sensor System All encoders and tachometers are certified intrinsically safe2

No cover (open trough): 18.8 kg (41.5 lbs) System remains functional without the bulky stainless steel cover3

With cover (closed pipe): 25 kg (55 lbs)

DAQ Box: 2.5 kg (5.5 lbs) thus removing the safety hazard associated with handling

Permissible Humidity traditional RFM sensors weighing upwards of 45 kg (99 lbs).

Up to 98% Installation and maintenance are easily handled by one person,

Vibration Absorption

and the cover becomes necessary only for closed pipe application.

Sensing Equipment: 5 g (500 Hz)

Approvals / Certification Streamlined and lightweight design make the RFM-3600 at least

Sensors: ATEX II 1G EEx ia IIB T4 2x lighter than a conventional RFM

DAQ Box: UL/ULC, CE IP 66

NOTES: 1 – maximum volume flow changes depending on dimensions and shape of trough or pipe, the value 33,000 gpm is based from

a 12-inch rectangular base open trough channel. 2 – DAQ box our outfitted with I.S. barriers. 3 – in the original Sandia Labs design,

the cover and frame are inseparable, making the system difficult and hazardous for human handling during installation and maintenance.

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Split Valuation SAPDocument7 pagesSplit Valuation SAPPramod ShettyNo ratings yet

- A Summary of The Theories or Concepts About Child Development From Piaget, Vygotsky, Brunner, and Gardner-Zahra Warda Mufidah 183221217Document16 pagesA Summary of The Theories or Concepts About Child Development From Piaget, Vygotsky, Brunner, and Gardner-Zahra Warda Mufidah 183221217Fida100% (1)

- CulvertsDocument14 pagesCulvertsMatsobane LekalaksNo ratings yet

- JLN-205 Servic EmanualDocument43 pagesJLN-205 Servic EmanualPrasad Dharmarathna100% (2)

- Problem Set Math Day 1-4Document15 pagesProblem Set Math Day 1-4vince rian legaspi100% (3)

- WWW - Smccnasipit.edu - PH: Saint Michael College of CaragaDocument5 pagesWWW - Smccnasipit.edu - PH: Saint Michael College of CaragaDivine CompendioNo ratings yet

- Density (Unit Weight), Yield, and Air Content (Gravimetric) of ConcreteDocument4 pagesDensity (Unit Weight), Yield, and Air Content (Gravimetric) of ConcretemickyfelixNo ratings yet

- Computed Radiography 1Document38 pagesComputed Radiography 1Charisa Antonette HuelvaNo ratings yet

- Elster SM Ri X L g250Document12 pagesElster SM Ri X L g250JM Carrasco HottmanNo ratings yet

- Classroom of The Elite Vol. 8Document244 pagesClassroom of The Elite Vol. 8Rahul Lakra85% (13)

- Illness Narratives - Positioned IdentitiesDocument35 pagesIllness Narratives - Positioned IdentitiesAnaNo ratings yet

- Specification MPU1200-Series-B ssks002Document6 pagesSpecification MPU1200-Series-B ssks002montanovillarroelfabiolalourdeNo ratings yet

- Gas Filter Correlation CO Analyzer: Model 300EDocument2 pagesGas Filter Correlation CO Analyzer: Model 300EGrupo EcologicaNo ratings yet

- Project Report Rohini RadarDocument33 pagesProject Report Rohini RadarAzmath CorpNo ratings yet

- High Performance Vector Control SE2 Series InverterDocument9 pagesHigh Performance Vector Control SE2 Series InverterhanazahrNo ratings yet

- Specification MPU600-Series-B ssks003Document6 pagesSpecification MPU600-Series-B ssks003montanovillarroelfabiolalourdeNo ratings yet

- Model R82 Pulse Burst Radar Level Transmitter: DescriptionDocument12 pagesModel R82 Pulse Burst Radar Level Transmitter: DescriptionAbdul Shaharlal ENo ratings yet

- Hoja de DatosDocument9 pagesHoja de DatosJhon AlfonsoNo ratings yet

- MiniDocument4 pagesMinicitramuaraNo ratings yet

- Portable Shaker TableDocument2 pagesPortable Shaker TablesohailNo ratings yet

- FMR Series Datasheet 2019Document6 pagesFMR Series Datasheet 2019Ahmed Hassan Abd ElhafezNo ratings yet

- Gas Turbin Meter CatalogDocument16 pagesGas Turbin Meter CatalogAlvaro Joel Quinteros RochaNo ratings yet

- Series 6623 - Fuel Consumption Monitor With Display PanelDocument1 pageSeries 6623 - Fuel Consumption Monitor With Display PanelShubhankar MenonNo ratings yet

- Catalogo de Medidor FMG, Rotary Meter Series FMR PDFDocument9 pagesCatalogo de Medidor FMG, Rotary Meter Series FMR PDFMARLON MARIO MELGAREJO ACOSTANo ratings yet

- 515 BF03 ApDocument4 pages515 BF03 Appcxhu1No ratings yet

- SCFT Measurement Turbine: Device FeaturesDocument4 pagesSCFT Measurement Turbine: Device FeaturesBHAART PANCHALNo ratings yet

- ProductSheet MEK2500 PS2028 3 en 20201201Document3 pagesProductSheet MEK2500 PS2028 3 en 20201201Papcel InstrumentNo ratings yet

- HP-PNE5100A-2 - Crystal Resonator Measuring Functions of HP E5100A-B Network AnalyzerDocument12 pagesHP-PNE5100A-2 - Crystal Resonator Measuring Functions of HP E5100A-B Network Analyzersirjole7584100% (1)

- Cat12 eDocument21 pagesCat12 eFrancisco Mones RuizNo ratings yet

- Datasheet 9000Document2 pagesDatasheet 9000LucasNo ratings yet

- Sha IDocument5 pagesSha IEshwar KarthiNo ratings yet

- Centrifugal Pump RotaflowDocument6 pagesCentrifugal Pump RotaflowNildo ZepedaNo ratings yet

- 100 DatasheetDocument8 pages100 DatasheetAmirul ShamNo ratings yet

- Linear Rod Pump: A RevolutionaryDocument4 pagesLinear Rod Pump: A Revolutionaryshy_boyNo ratings yet

- X-Ray Activity Reporting SystemDocument2 pagesX-Ray Activity Reporting SystemPeter Yli0% (1)

- Order Tracking Program CAT-SAA1-ORDTRK Datasheet 1603-1Document2 pagesOrder Tracking Program CAT-SAA1-ORDTRK Datasheet 1603-1SamirNo ratings yet

- Direct Torque Control - Wikipedia PDFDocument6 pagesDirect Torque Control - Wikipedia PDFMohammad HaroonNo ratings yet

- C.I. XTR106Document16 pagesC.I. XTR106ajb_scribdNo ratings yet

- P1000 Industrial Fan and Pump Drive: 240V Class: To 175 HP 480V Class: 1 To 1000 HP 600V Class: 1 To 250 HPDocument2 pagesP1000 Industrial Fan and Pump Drive: 240V Class: To 175 HP 480V Class: 1 To 1000 HP 600V Class: 1 To 250 HPlordsethdarknessNo ratings yet

- ON Icon: Inline Ultrasonic Flow MeterDocument4 pagesON Icon: Inline Ultrasonic Flow MeterJayaminNo ratings yet

- 2300 Vibration Datasheet 105m0340pDocument16 pages2300 Vibration Datasheet 105m0340pNaseer HydenNo ratings yet

- PWM DacDocument19 pagesPWM DacgacalaNo ratings yet

- Ultrasonic Gas FlowmeterDocument6 pagesUltrasonic Gas Flowmeterhk168100% (1)

- Fsmbrzmodl enDocument4 pagesFsmbrzmodl enAuilias DiasNo ratings yet

- MODELS WT1010/WT1030/WT1030M Digital Power Meters: IWASE Hisashi TSUJI Hirotaka TACHIBANA Katsuya HIRAI KazuoDocument4 pagesMODELS WT1010/WT1030/WT1030M Digital Power Meters: IWASE Hisashi TSUJI Hirotaka TACHIBANA Katsuya HIRAI KazuoNikolayNo ratings yet

- SENSUS 420 420pc MID ENDocument4 pagesSENSUS 420 420pc MID ENLejla BuljetovicNo ratings yet

- FESTO FRC Filter/Regulator-Lubricatorsor LubricatorsDocument17 pagesFESTO FRC Filter/Regulator-Lubricatorsor LubricatorsNickNo ratings yet

- 84F Product SpecificationsDocument40 pages84F Product SpecificationsAntonio CodoceoNo ratings yet

- 515-AC01-AP-2 Controlador InjectorDocument4 pages515-AC01-AP-2 Controlador InjectorJose HuescaNo ratings yet

- High Performance Digital Gas Mass Flow Meters & Controllers: N N N N NDocument8 pagesHigh Performance Digital Gas Mass Flow Meters & Controllers: N N N N NJose GoNo ratings yet

- HiFi Stereo Review 1979 05 OCR Page 0056Document1 pageHiFi Stereo Review 1979 05 OCR Page 0056Juan Carlos FloresNo ratings yet

- (Paper) A Low Dropout, CMOS Regulator With High PSR Over Wideband FrequenciesDocument4 pages(Paper) A Low Dropout, CMOS Regulator With High PSR Over Wideband FrequenciesahmedNo ratings yet

- TOPAS PS 120 Data SheetDocument2 pagesTOPAS PS 120 Data SheetmasmoohNo ratings yet

- Turbine FL Ow Meter SCFT AnalogueDocument5 pagesTurbine FL Ow Meter SCFT AnalogueCésar PérezNo ratings yet

- MP-25TA Sensor MagneticoDocument4 pagesMP-25TA Sensor MagneticoomarvicoNo ratings yet

- R8000 Duplexer Tuning With The R8000Document6 pagesR8000 Duplexer Tuning With The R8000BDNo ratings yet

- Sensorless Techniques For AC Machines Drives: AuthorDocument20 pagesSensorless Techniques For AC Machines Drives: AuthorUmer FarooqNo ratings yet

- Only Paramtr Frenic MultiDocument38 pagesOnly Paramtr Frenic MultiVinesh BaraiyaNo ratings yet

- 3 Loop Gain Crossover FrequencyDocument8 pages3 Loop Gain Crossover Frequency양영주No ratings yet

- The Exact Odorization Ratio For Every Cubic Meter of Gas Data SheetDocument6 pagesThe Exact Odorization Ratio For Every Cubic Meter of Gas Data Sheetphoenix_lwpNo ratings yet

- Hoja de Datos - 2538Document19 pagesHoja de Datos - 2538Luis AsmatNo ratings yet

- ACOEM Tunnel Sensors AIRFLOW MkII V1.2Document4 pagesACOEM Tunnel Sensors AIRFLOW MkII V1.2Ambuj SaxenaNo ratings yet

- GB Vapour RecoveryDocument17 pagesGB Vapour RecoveryrobertwinwoodNo ratings yet

- World-Class Accuracy & Measurement Range: Ac/Dc Current Sensor Ct6904Document8 pagesWorld-Class Accuracy & Measurement Range: Ac/Dc Current Sensor Ct6904Arun JosephNo ratings yet

- Data Sheet: Sca2100-D02 2-Axis High Performance Accelerometer With Digital Spi InterfaceDocument5 pagesData Sheet: Sca2100-D02 2-Axis High Performance Accelerometer With Digital Spi InterfaceshadyghanemNo ratings yet

- Sensar Temperatura Con LM34 y ArduinoDocument1 pageSensar Temperatura Con LM34 y ArduinosalokaNo ratings yet

- FCM6812 - Pre-Calibrated Module For Combustible Gas: FigaroDocument2 pagesFCM6812 - Pre-Calibrated Module For Combustible Gas: FigaroshadyghanemNo ratings yet

- SCA121T Series: Stand Alone InclinometerDocument2 pagesSCA121T Series: Stand Alone InclinometershadyghanemNo ratings yet

- SCA61T Inclinometer Datasheet 8261900ADocument18 pagesSCA61T Inclinometer Datasheet 8261900AAdriana BarreroNo ratings yet

- Arduino Xbee Shield Wireless ModuleDocument3 pagesArduino Xbee Shield Wireless ModuleMC. Rene Solis R.No ratings yet

- Arduino Lab 1 - The Voltage DividerDocument8 pagesArduino Lab 1 - The Voltage DividerRahmat PrihartonoNo ratings yet

- Onisc GMBH: Data and FactsDocument2 pagesOnisc GMBH: Data and FactsshadyghanemNo ratings yet

- Device and Method For Photovoltaic Generation of HydrogenDocument9 pagesDevice and Method For Photovoltaic Generation of HydrogenshadyghanemNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2008/0067061 A1Document6 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2008/0067061 A1shadyghanemNo ratings yet

- Platestahl Umformtechnik GMBH: Data and FactsDocument3 pagesPlatestahl Umformtechnik GMBH: Data and FactsshadyghanemNo ratings yet

- Schumacher Titan GMBH & Co KG: Data and FactsDocument3 pagesSchumacher Titan GMBH & Co KG: Data and FactsshadyghanemNo ratings yet

- Qs Weitwinkel Handels GMBH: Data and FactsDocument2 pagesQs Weitwinkel Handels GMBH: Data and FactsshadyghanemNo ratings yet

- Zapp Materials Engineering GMBH: Data and FactsDocument2 pagesZapp Materials Engineering GMBH: Data and FactsshadyghanemNo ratings yet

- Titanbau Schäfer & Preker GMBH: Data and FactsDocument3 pagesTitanbau Schäfer & Preker GMBH: Data and FactsshadyghanemNo ratings yet

- Winter Metalle GMBH: Data and FactsDocument2 pagesWinter Metalle GMBH: Data and FactsshadyghanemNo ratings yet

- Timet Germany GMBH: Data and FactsDocument2 pagesTimet Germany GMBH: Data and FactsshadyghanemNo ratings yet

- Barufe GMBHDocument1 pageBarufe GMBHshadyghanemNo ratings yet

- Titanium Solutions GMBH: Data and FactsDocument1 pageTitanium Solutions GMBH: Data and FactsshadyghanemNo ratings yet

- Allegheny Technologies GMBH: Data and FactsDocument2 pagesAllegheny Technologies GMBH: Data and FactsshadyghanemNo ratings yet

- Ametek GMBH Geschaeftsbereich Specialty Metal ProductsDocument5 pagesAmetek GMBH Geschaeftsbereich Specialty Metal ProductsshadyghanemNo ratings yet

- Masterflex Brennstoffzellentechnik GMBH: Data and FactsDocument1 pageMasterflex Brennstoffzellentechnik GMBH: Data and FactsshadyghanemNo ratings yet

- Fuel Cells Components Applications PDFDocument67 pagesFuel Cells Components Applications PDFshadyghanemNo ratings yet

- Udo Plante GMBH: Data and FactsDocument2 pagesUdo Plante GMBH: Data and FactsshadyghanemNo ratings yet

- Bibus Metals GMBHDocument1 pageBibus Metals GMBHshadyghanemNo ratings yet

- Gräbener Maschinentechnik - Fuel Cells PDFDocument2 pagesGräbener Maschinentechnik - Fuel Cells PDFshadyghanemNo ratings yet

- CERAPEM MembranesDocument27 pagesCERAPEM MembranesshadyghanemNo ratings yet

- DOM003 - EN Hydrogen Gas GeneratorsDocument31 pagesDOM003 - EN Hydrogen Gas GeneratorsshadyghanemNo ratings yet

- EKOLYSER Project Single View - Research Energy StorageDocument2 pagesEKOLYSER Project Single View - Research Energy StorageshadyghanemNo ratings yet

- Ccms / Gdes: Catalyst Coated Membranes Gas Diffusion ElectrodesDocument1 pageCcms / Gdes: Catalyst Coated Membranes Gas Diffusion ElectrodesshadyghanemNo ratings yet

- Ministry of Health and Family Welfare Pregnancy GuidelinesDocument173 pagesMinistry of Health and Family Welfare Pregnancy GuidelinesKhushi GuptaNo ratings yet

- HG - Grade 12 - Module 3 - October 14Document19 pagesHG - Grade 12 - Module 3 - October 14RhasmineKyle BeltranNo ratings yet

- Spouse Visa AttorneyDocument2 pagesSpouse Visa AttorneyShaheen SadiqueNo ratings yet

- Astm D 420Document7 pagesAstm D 420Veronica MongeNo ratings yet

- Saidin PSC - SHO UTMSPACE - 13.01.22 Module Slide 6s - LDocument43 pagesSaidin PSC - SHO UTMSPACE - 13.01.22 Module Slide 6s - LAmer IkhwanNo ratings yet

- Strategic Plan Executive SummaryDocument1 pageStrategic Plan Executive Summaryapi-532125110No ratings yet

- Chapter 2 PDFDocument21 pagesChapter 2 PDFMahdi BanjakNo ratings yet

- GE 4 MMW in A NutshellDocument7 pagesGE 4 MMW in A NutshellPEACH CATHERINE MANOTANo ratings yet

- Appendix A: Sample Plan A Vacation TableDocument3 pagesAppendix A: Sample Plan A Vacation TableChristian Xander LaureteNo ratings yet

- Review Iftekher 2013Document11 pagesReview Iftekher 2013RezaNo ratings yet

- Design of Deep Supported Excavations: Comparison Between Numerical and Empirical MethodsDocument7 pagesDesign of Deep Supported Excavations: Comparison Between Numerical and Empirical MethodsNajihaNo ratings yet

- ConferenceProceedings finalBalHNS2009Document332 pagesConferenceProceedings finalBalHNS2009kayron limaNo ratings yet

- CRE Chapter 5 (Solutions)Document8 pagesCRE Chapter 5 (Solutions)Bella HannaNo ratings yet

- ECC Strategic Plan BookletDocument20 pagesECC Strategic Plan BookletAida MohammedNo ratings yet

- 6480 49 35800 2 10 20230801Document12 pages6480 49 35800 2 10 20230801samsidar nidarNo ratings yet

- R.M. M, J. C, S.L. I S.M. H R C. M P J. M G : Aier Horover Verson AND Ayes Odney Aier and Eter C OldrickDocument1 pageR.M. M, J. C, S.L. I S.M. H R C. M P J. M G : Aier Horover Verson AND Ayes Odney Aier and Eter C OldrickPeter McGoldrickNo ratings yet

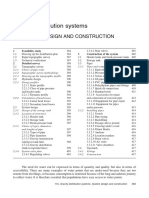

- Gravity Distribution Systems: A System Design and ConstructionDocument40 pagesGravity Distribution Systems: A System Design and ConstructionTooma DavidNo ratings yet

- SP Q4 Week 2 HandoutDocument10 pagesSP Q4 Week 2 HandoutLenard BelanoNo ratings yet

- The Hornbook Method and The Conflict of LawsDocument16 pagesThe Hornbook Method and The Conflict of LawslanglangNo ratings yet

- October 2016 2Document16 pagesOctober 2016 2Tanvika AroraNo ratings yet

- Genomic and CDNA LibrariesDocument15 pagesGenomic and CDNA LibrariesPrabhleen KaurNo ratings yet