Professional Documents

Culture Documents

1251 VHF-RM Horiz Treater

Uploaded by

luislanza_ve0 ratings0% found this document useful (0 votes)

52 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

52 views2 pages1251 VHF-RM Horiz Treater

Uploaded by

luislanza_veCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

VFH-RM® Vertical Flow Horizontal Treater

NATCO’s VFH-RM® Treaters are designed specifically for

cold weather applications

VFH-RM® units employ a process

originated by NATCO that combines the

advantages of vertical flow with the

benefits of horizontal vessels. They are

designed specifically for cold weather

applications, where fuel savings, simple

installation, and oil gravity conservation

are desired.

They are best suited for moderate to large

volumes of 28º to 42º API gravity crudes

and moderate amounts of free water. The

units are available with skids and a special

housing for the vessel and controls.

More economical separation

The vessel has two main compartments:

a heating section and coalescing section.

(figure 1)

The produced fluid enters the heating

section at the top of the vessel and flows VFH-RM® Treater

downward across a hood where initial

degassing and velocity reduction occur. Greater capacity Greater separation

Liberated gas passes into the secondary The VFH-RM® processor provides faster The large surface areas available in a

compartment. separation with less agitation. horizontal vessel improve separation

Preheating liberates most gas during efficiency.

The emulsion is distributed to the heating initial processing. Faster separation

compartment where it flows upward permits higher volumes.

around the firetube and settles to the

bottom of the vessel, where it is

discharged.

The emulsion is heated to coalescing

temperature and then skims over a weir

baffle to a surge section. Gas is withdrawn

through a back pressure valve. Oil rises

through the settling area where water

particles coalesce and fall to the bottom

of the vessel for removal.

Fuel conservation

VFH-RM® Treaters improve heat transfer,

which boosts unit efficiency and saves

fuel. Free water is removed before the

fluid contacts the firetube, so it is not

heated unnecessarily. Figure 1 VFH-RM® Vertical Flow Horizontal Treater

Issue 7 09.02 Page 1251-A1

VFH-RM® Vertical Flow Horizontal Treater

Simplifies design Fewer external components Automatic controls

The components, heat exchangers, The units can be shipped pre-assembled Optimum performance is maintained with

siphons, condensing heads, down- because nearly all components are a minimum of operator attention.

comers, etc. normally required in vertical internal. Skid-mounted assemblies can be Temperature, pressure and low fluid level

treaters are eliminated in the VFH-RM® put on line with minimum field safety controls are standard on all models.

design. The result is lower capital connections. Gauges enable operators to monitor all

investment for the same throughputs, as steps of the process easily.

well as lower operating costs.

For more information on the NATCO VFH-RM® Vertical Flow Horizontal Treater or other NATCO Group products contact:

NATCO Group Head Office NATCO Canada Axsia Group

Houston, USA Calgary, Canada Gloucester, England

Tel: +(1) 713 683 9292 Tel: +(1) 403 236 1850 Tel: +(44) 1452 833800

Email: sales@natco-us.com Email: sales@natco.ab.ca Email: asbl@axsia.com

NATCO Japan Axsia Howmar

Tokyo, Japan Camberley, England

Tel: +(81) 33288 1901 Tel: +(44) 1276 681101

Email: natco1@natcojapan.com Email: ahl@axsia.com

www.natcogroup.com

Issue 7 09.02 Page 1251-A2

You might also like

- White Oil Dehydration: Direct Current Electrostatic TreatersDocument2 pagesWhite Oil Dehydration: Direct Current Electrostatic Treatersluislanza_veNo ratings yet

- Catalog Chiller TraneDocument16 pagesCatalog Chiller TranePhạm ĐứcNo ratings yet

- 42Document8 pages42Syed Ali KhanNo ratings yet

- 7389m - Gearbox Service ManualDocument74 pages7389m - Gearbox Service ManualNyein KoNo ratings yet

- Midea DC Inverter VRF Products 2013 60Hz Part 1 PDFDocument25 pagesMidea DC Inverter VRF Products 2013 60Hz Part 1 PDFOnutu LohengrinNo ratings yet

- Quantium 210Document4 pagesQuantium 210Alsheikh875No ratings yet

- Presentation Siemens ORCDocument12 pagesPresentation Siemens ORCCarlos Fernando Alfonso BallesterosNo ratings yet

- Thermo NESLAB Manual P/N 000258 Rev. 11/08/00Document18 pagesThermo NESLAB Manual P/N 000258 Rev. 11/08/00Edinson Vallejo VidalNo ratings yet

- The General Purpose DriveDocument8 pagesThe General Purpose DriveIvan MesarošNo ratings yet

- User's Guide: FMG-1000-SKDocument8 pagesUser's Guide: FMG-1000-SKeng_seng_lim3436No ratings yet

- Catalogue Daikin VRV IVDocument54 pagesCatalogue Daikin VRV IVHung Tran50% (2)

- Commercial Hot Water (Reference)Document2 pagesCommercial Hot Water (Reference)binhjukiNo ratings yet

- Modular Water Cooled Water Chiller: Shandong Vicot Air Conditioning Co., LTDDocument15 pagesModular Water Cooled Water Chiller: Shandong Vicot Air Conditioning Co., LTDrafaelkiNo ratings yet

- Product Data 42VQVDocument10 pagesProduct Data 42VQVdswintonNo ratings yet

- CWCS Fan Coil Cassette - 1 A 3 TR PDFDocument2 pagesCWCS Fan Coil Cassette - 1 A 3 TR PDFmarcio carvalhoNo ratings yet

- A121x DatasheetDocument15 pagesA121x DatasheetCelsoNo ratings yet

- Optimize Fuel Flow with Red Jacket STPsDocument6 pagesOptimize Fuel Flow with Red Jacket STPswarung1bensinNo ratings yet

- Tecnotion Ironless Vacuum BrochureDocument7 pagesTecnotion Ironless Vacuum BrochureElectromateNo ratings yet

- K GHH36Document20 pagesK GHH36Simon DrumsNo ratings yet

- Rexroth A2VK Series PDFDocument12 pagesRexroth A2VK Series PDFMomo-Princess Peanut-buttercupNo ratings yet

- Dynamini Series Adhesive Supply UnitDocument2 pagesDynamini Series Adhesive Supply UnitITWDynatecNo ratings yet

- 6LTAADocument7 pages6LTAAAbi Fatih100% (2)

- User's Guide: 4001A, 4002A, 4201A & 4202A Series Temperature ControllersDocument24 pagesUser's Guide: 4001A, 4002A, 4201A & 4202A Series Temperature ControllersFelipeMeloNo ratings yet

- Caldera RHEEM PrestigeDocument2 pagesCaldera RHEEM Prestigeiecorredor68No ratings yet

- Column PresentationDocument27 pagesColumn PresentationTaifurNo ratings yet

- Mi̇dea VRF ManualDocument316 pagesMi̇dea VRF ManualMurat Demirci100% (6)

- ColorQube 8570/8870 Service OrientationDocument18 pagesColorQube 8570/8870 Service OrientationJoão Ricardo Almeida Prado100% (1)

- K79746-747 Technical DescriptionDocument12 pagesK79746-747 Technical DescriptionJon Lopez100% (1)

- 3tech Telecom Power Brochure (201401231B)Document4 pages3tech Telecom Power Brochure (201401231B)Yahia Yohan KimNo ratings yet

- Conjet Brochure WebDocument3 pagesConjet Brochure WebkwstikosNo ratings yet

- 4MXCDocument8 pages4MXCAnonymous ApjtcZ6YT6No ratings yet

- Technical Offer From Thermax On 13.05.10Document32 pagesTechnical Offer From Thermax On 13.05.10venka07100% (1)

- HXE Water Cooled Magnetic Bearing Centrifugal ChillerDocument16 pagesHXE Water Cooled Magnetic Bearing Centrifugal ChillerĐặng Xuân ViệtNo ratings yet

- Alkitronic Nova enDocument2 pagesAlkitronic Nova encorsini999No ratings yet

- Alfa Laval Panx Palm Oil Decanter Centrifuge Product LeafletDocument4 pagesAlfa Laval Panx Palm Oil Decanter Centrifuge Product LeafletaniNo ratings yet

- Mark One XDocument4 pagesMark One XTiu TonNo ratings yet

- Lite-Puter DX-610/DX-626 User ManualDocument12 pagesLite-Puter DX-610/DX-626 User Manualescuela_danza_2No ratings yet

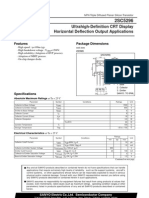

- High-Speed Transistor for CRT DisplaysDocument2 pagesHigh-Speed Transistor for CRT DisplaysdomisoftNo ratings yet

- Single Package: Engineering Product DataDocument53 pagesSingle Package: Engineering Product DataOmair FarooqNo ratings yet

- Corona & Plasma: For ExtrusionDocument8 pagesCorona & Plasma: For ExtrusionHuy Tuan QuachNo ratings yet

- Hot Refueling Nozzle HelicoptersDocument2 pagesHot Refueling Nozzle HelicoptersMauricio Pinaya DalenceNo ratings yet

- And8196 DDocument4 pagesAnd8196 Dlxz5101No ratings yet

- ABB VFD CatalogesDocument25 pagesABB VFD CatalogesadehriyaNo ratings yet

- ASU 600 150 - DatasheetDocument2 pagesASU 600 150 - DatasheetloadrpkNo ratings yet

- EOR Water InjectionDocument35 pagesEOR Water Injectionganeshan0% (1)

- MC050 010Document4 pagesMC050 010Jhecko BalbinotNo ratings yet

- T 600 R PDFDocument8 pagesT 600 R PDFAndres ChoezNo ratings yet

- Ifms Intelligent Fluid Management System: Solution OutlineDocument8 pagesIfms Intelligent Fluid Management System: Solution OutlineArmstrong Fluid TechnologyNo ratings yet

- ThermaPhase BrochureDocument2 pagesThermaPhase BrochureFernando Vazques PerezNo ratings yet

- Hydac Accessories - CatalogDocument68 pagesHydac Accessories - CatalogQualidade1 viaNo ratings yet

- Axial Piston Compact Unit A10CODocument8 pagesAxial Piston Compact Unit A10COJohn SimmondsNo ratings yet

- Panasonic Th-32c200dx Chassis Km14Document40 pagesPanasonic Th-32c200dx Chassis Km14VinylJogjaNo ratings yet

- A1205 Datasheet PDFDocument14 pagesA1205 Datasheet PDFAlekso GjakovskiNo ratings yet

- A1205 DatasheetDocument14 pagesA1205 DatasheetAlekso GjakovskiNo ratings yet

- Weathermaker Single Package Rooftop Gas Heat/Electric Cooling Vertical Air Flow UnitDocument76 pagesWeathermaker Single Package Rooftop Gas Heat/Electric Cooling Vertical Air Flow UnitMohamed AmrNo ratings yet

- Energia Eolica Nordex N90 2500 enDocument20 pagesEnergia Eolica Nordex N90 2500 enNardo Antonio Llanos MatusNo ratings yet

- JVC lt-37x688 42x688 SMDocument108 pagesJVC lt-37x688 42x688 SMAnonymous 2HtY2RbpLVNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Field or Refinery: A Higher Level of Desalting PerformanceDocument2 pagesField or Refinery: A Higher Level of Desalting Performanceluislanza_veNo ratings yet

- 1245 Electromax TreaterDocument2 pages1245 Electromax Treaterluislanza_veNo ratings yet

- 1211 Vertical EmulsionDocument2 pages1211 Vertical Emulsionluislanza_veNo ratings yet

- Electrostatic Handbook 2003Document228 pagesElectrostatic Handbook 2003luislanza_ve100% (5)

- NEMA Enclosure Types 11-05-2Document9 pagesNEMA Enclosure Types 11-05-2Duron SaavedraNo ratings yet

- HistorianDocument409 pagesHistorianluislanza_veNo ratings yet

- Verb Tense Grade 9Document2 pagesVerb Tense Grade 9tba.shraddhaNo ratings yet

- Corrosion MonitoringDocument80 pagesCorrosion Monitoring이선엽86% (7)

- Monitor Transformer Temperatures with PC-414R IndicatorDocument4 pagesMonitor Transformer Temperatures with PC-414R IndicatorMKNo ratings yet

- Project Review: Arun III Hydroelectric Project: Background Location and AccessibilityDocument2 pagesProject Review: Arun III Hydroelectric Project: Background Location and AccessibilitySachin ChakradharNo ratings yet

- Management Science Chapter 11Document42 pagesManagement Science Chapter 11Myuran SivarajahNo ratings yet

- Quick Start GuideDocument3 pagesQuick Start Guideswornavidhya.mahadevanNo ratings yet

- TD Tip Tinner PDFDocument2 pagesTD Tip Tinner PDFbehzadNo ratings yet

- Women EmpowermentDocument14 pagesWomen EmpowermentProfessor HappyNo ratings yet

- Untitled PresentationDocument14 pagesUntitled PresentationThe BeatableNo ratings yet

- ERAB Licence Limit DescriptionDocument2 pagesERAB Licence Limit DescriptionsrimantaNo ratings yet

- Acknowledgement Master Thesis SampleDocument7 pagesAcknowledgement Master Thesis Samplebk3q07k5100% (2)

- PTTI Presentation Prepared at STEVTADocument35 pagesPTTI Presentation Prepared at STEVTAkhalidhussainrazaNo ratings yet

- Ut350 ConfigDocument21 pagesUt350 ConfigrenzomcuevaNo ratings yet

- Tribological Performance Characterization of Brake Friction Materials: What Test? What Coefficient of Friction?Document13 pagesTribological Performance Characterization of Brake Friction Materials: What Test? What Coefficient of Friction?palash roy choudhuryNo ratings yet

- Coordinates Activity SheetDocument2 pagesCoordinates Activity SheetBernadette L. Macadangdang100% (2)

- NJM3771D2Document9 pagesNJM3771D2mahdi elmayNo ratings yet

- Introductory2014 Lesson1 2DDocument32 pagesIntroductory2014 Lesson1 2DMu HardiNo ratings yet

- Manual E7370Document12 pagesManual E7370Carlos Rodríguez MartínNo ratings yet

- 09 - Designing and Managing Integrated Marketing CommunicationDocument29 pages09 - Designing and Managing Integrated Marketing CommunicationIbrahim Ahmed FurrukhNo ratings yet

- AGN 017 - Unbalanced Loads: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesDocument9 pagesAGN 017 - Unbalanced Loads: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesJhay Phee LlorenteNo ratings yet

- DISC-Test Test PDFDocument22 pagesDISC-Test Test PDFKazekamiXNo ratings yet

- Professional Guide To Water Seepage: Investigation, Diagnosis, Testing & Reporting in Residential BuildingsDocument58 pagesProfessional Guide To Water Seepage: Investigation, Diagnosis, Testing & Reporting in Residential BuildingsRam Gopal PathakNo ratings yet

- Math in The Modern WorldDocument8 pagesMath in The Modern WorldMichael JoavanniNo ratings yet

- Archaeoastronomy in IndiaDocument19 pagesArchaeoastronomy in IndiaParag MahajaniNo ratings yet

- Power BI Performance Tips and TechniquesDocument27 pagesPower BI Performance Tips and TechniquesClaudio Santander HernándezNo ratings yet

- Jack Welch's Leadership Transforms GEDocument2 pagesJack Welch's Leadership Transforms GEkimNo ratings yet

- ROSS FRL LubricatorsDocument16 pagesROSS FRL LubricatorsDavid Antonio Vargas CastilloNo ratings yet

- Process TechnologyDocument31 pagesProcess TechnologyEugene MicarandayoNo ratings yet

- Mass and Energy Balancing Calculations For Plant ChapterDocument50 pagesMass and Energy Balancing Calculations For Plant ChapterRamesh SoniNo ratings yet

- Modeling For Simulation and Control of Acid-Base Neutralization SystemsDocument12 pagesModeling For Simulation and Control of Acid-Base Neutralization SystemscacacocoNo ratings yet