Professional Documents

Culture Documents

LCD Module Technical Specification: First Edition

Uploaded by

marco antonioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LCD Module Technical Specification: First Edition

Uploaded by

marco antonioCopyright:

Available Formats

First Edition

Oct 20, 2003

LCD Module Technical Specification Final Revision

******

Type No.

T-51638D084J-FW-A-AB

Approved by (Quality Assurance Division)

Checked by (ACI Engineering Division)

Prepared by (Module Coordination Group)

No. Item Page

-- CONTENTS 1

1 OVERVIEW 2

2 ABSOLUTE MAXIMUM RATINGS 3

3 ELECTRICAL CHARACTERISTICS 3

4 INTERFACE PIN CONNECTION 6

5 INTERFACE TIMING 7

6 BLOCK DIAGRAM 10

7 MECHANICAL SPECIFICATION 11

8 OPTICAL CHARACTERISTICS 13

9 RELIABILITY TEST CONDITION 15

10 INSPECTION STANDARDS 16

11 HANDLING PRECAUTIONS FOR TFT-LCD MODULE 17

-- PACKAGING SPECIFICATION 20

-- PRODUCT NUMBER LABELING FORMS 24

-- LAMP UNIT FOR 8.4” VGA 26

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 1/32

1. OVERVIEW

T-51638D084J-FW-A-AB is 8.4” color TFT-LCD (Thin Film Transistor Liquid Crystal Display) module

composed of LCD panel, driver ICs, control circuit, and backlight unit.

By applying 6 bit digital data, 640 × 480, 262,144-color images are displayed on the 8.4” diagonal

screen. Input power voltage is single 3.3V for LCD driving.

Inverter for backlight is not included in this module. General specifications are summarized in the

following table:

ITEM SPECIFICATION

170.9(H) × 128.2 (V)

Display Area (mm)

(8.4-inch diagonal)

Number of Dots 640 × 3 (H) × 480 (V)

Pixel Pitch (mm) 0.267 (H) × 0.267 (V)

Color Pixel Arrangement RGB vertical stripe

Display Mode normally white

Number of Colors 262,144

Contrast ratio 450

Optimum Viewing Angle(Contrast ratio) 6 o’clock

Brightness (cd/m2) 450

Module Size (mm) 199.5 (W) × 149.0 (H) × 11.5 (D)

Module Mass (g) 360(Typ)

Backlight Unit CCFL, 2-tubes, edge-light, replaceable

Surface Treatment Anti-glare and hard-coating 3H

Characteristic value without any note is typical value.

The LCD product described in this specification is designed and manufactured for the standard use

in OA equipment and consumer products, such as computers, communication equipment, industrial

robots, AV equipment and so on.

Do not use the LCD product for the equipment that require the extreme high level of reliability,

such as aerospace applications, submarine cables, nuclear power control systems and medical or

other equipment for life support.

OPTREX assumes no responsibility for any damage resulting from the use of the LCD product in

disregard of the conditions and handling precautions in this specification.

If customers intend to use the LCD product for the above items or other no standard items,

please contact our sales persons in advance.

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 2/32

2. ABSOLUTE MAXIMUM RATINGS

ITEM SYMBOL MIN. MAX. UNIT

Power Supply Voltage for LCD VCC 0 4.0 V

Logic Input Voltage VI 0 6.0 V

Lamp Voltage VL 0 1500 Vrms

Lamp Current IL 0 8.0 mArms

Lamp Frequency FL -- 80 kHz

Operation Temperature *1) Top 0 60 °C

Storage Temperature *1) Tstg -20 65 °C

[Note]

*1) Top,Tstg ≤ 40°C : 90%RH max. without condensation

Top,Tstg > 40°C : Absolute humidity shall be less than the value of 90%RH at 40°C without

condensation.

3. ELECTRICAL CHARACTERISTICS

(1) TFT- LCD Ambient Temperature: Ta = 25°C

ITEM SYMBOL MIN. TYP. MAX. UNIT Remarks

Note A)

Power Supply Voltages for LCD VCC 3.0 3.3 3.6 V

(See: Page 5,6)

Note B)

Power Supply Currents for LCD ICC -- 240 400 mA

(See: Page 6)

Permissive input ripple Voltage VRP -- -- 100 mVp-p VCC=+3.3V

High VIH 2.4 -- 5.5 V VCC=MAX

Logic Input Voltage

Low VIL 0 -- 0.8 V VCC=MIN

(2) Backlight Ta = 25°C

ITEM SYMBOL MIN. TYP. MAX. UNIT Remarks

Lamp Voltage VL -- 450 -- Vrms IL = 6.5 mArms

Lamp Current IL 3.0 6.5 7.0 mArms *1),*5)

Lamp Frequency FL 30 -- 60 kHz *2)

Starting Lamp Voltage VS 670 -- -- Vrms

*3),*4)

Lamp Life Time LT 50000 -- -- h

IL = 6.5 mArms

*1) Lamp Current measurement method (The current meter is inserted in low voltage line.)

CTL A

CTH

LCD Inverter

Power

Module CTL A Supply

CTH

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 3/32

*2) Lamp frequency of inverter may produce interference with horizontal synchronous frequency, and

this may cause horizontal beat on the display. Therefore, please adjust lamp frequency, and keep

inverter as far from module as possible or use electronic shielding between inverter and module to

avoid the interference.

*3) Lamp life time is defined as the time either when the brightness becomes 50% of the initial value, or

when the starting lamp voltage does not meet the value specified in this table.

*4) The life time of the backlight depends on the ambient temperature. The life time will decrease under

low/high temperature.

*5) Please use the inverter which has symmetrical current wave form as follows,

The degree of unbalance: less than 10%

The ratio of wave height: less than 2 ±10%

IPH IPH: High side peak

The degree of unbalance = |IPH - IPL| / Irms × 100(%)

The ratio of wave height = IPH (or I PL) / Irms

IPL IPL: Low side peak

CURRENT WAVE FORM

[Note]

A) Power and signals sequence:

t1 ≤ 10 ms 400 ms ≤ t5

0 < t2 ≤ 50 ms 200 ms ≤ t6

0 < t3 ≤ 50 ms 0 ≤ t7

0 ≤ t4 ≤ 50 ms

VCC

3.0 V 3.0 V

data

2.2 V

0.5 V 0.5 V

t1 t2 t3 t4 t5

VL

t6 t7

Data: RGB DATA, DCLK, HD, VD, DENA

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 4/32

VCC-dip conditions:

1) When 2.6 V ≤ VCC < 3.0 V, td ≤ 10 ms

2) When VCC < 2.6 V

VCC-dip conditions should also follow the power and signals sequence.

VCC

3.0 V

2.6 V

td

B) Typical current condition:

64- gray- bar-pattern

480 line mode

VCC = +3.3 V, fH =31.5 kHz, fV =60 Hz, fCLK= 25 MHz

Normal value, not peak value

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 5/32

4. INTERFACE PIN CONNECTION

CN 1(INTERFACE SIGNAL)

Used connector: DF9B-31P-1V(Hirose)

Corresponding connector: DF9B-31S-1V(Hirose)

Pin No. Symbol Function

1 GND

2 DCLK Clock signal for sampling catch data signal

3 HD Horizontal sync signal

4 VD Vertical sync signal

5 GND

6 R0 Red data signal(LSB)

7 R1 Red data signal

8 R2 Red data signal

9 R3 Red data signal

10 R4 Red data signal

11 R5 Red data signal(MSB)

12 GND

13 G0 Green data signal(LSB)

14 G1 Green data signal

15 G2 Green data signal

16 G3 Green data signal

17 G4 Green data signal

18 G5 Green data signal(MSB)

19 GND

20 B0 Blue data signal(LSB)

21 B1 Blue data signal

22 B2 Blue data signal

23 B3 Blue data signal

24 B4 Blue data signal

25 B5 Blue data signal(MSB)

26 GND

27 DENA Data enable signal(to settle the viewing area)

28 VCC 3.3 V Power Supply

29 VCC 3.3 V Power Supply

30 TEST This pin should be open. Test signal output for only internal test use.

31 REV Reverse scan control. L = Normal, H = Reverse

*) The shielding case is connected with GND

CN 2 , CN 3 (BACKLIGHT)

Backlight-side connector: BHR-02(8.0)VS-1N(JST)

Inverter-side connector: SM02(8.0)B-BHS(JST)

Pin No. Symbol Function

1 CTH VBLH(High Voltage)

3 CTL VBLL(Low Voltage)

[Note]VBLH-VBLL = VL

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 6/32

5. INTERFACE TIMING

(1) Timing Specifications

ITEM SYMBOL MIN. TYP. MAX. UNIT

Frequency fCLK 20 25 30 MHz

DCLK Period tCLK 33.3 40 50 ns

*1), *4) Low Width tWCL 10 -- -- ns

High Width tWCH 10 -- -- ns

DATA Set up time tDS 5 -- -- ns

(R,G,B,DENA,

HD, VD) *1) Hold time tDH 5 -- -- ns

Horizontal Active Time tHA 640 640 640 tCLK

Horizontal Front Porch tHFP 0 16 -- tCLK

DENA Horizontal Back Porch tHBP 19 144 -- tCLK

*3) Vertical Active Time tVA 480 480 480 tH

Vertical Front Porch tVFP 1 10 -- tH

Vertical Back Porch tVBP 8 35 -- tH

Frequency fH 27 31.5 38 kHz

HD

Period tH 26.3 31.7 37.0 µs

*2), *4)

Low Width tWHL 5 96 -- tCLK

Frequency fV 55 60 70 Hz

VD

Period tV 14.2 16.7 18.2 ms

*2)

Low Width tWVL 2 2 -- tH

[Note]

*1) DATA is latched at fall edge of DCLK in this timing specification.

*2) Polarities of HD and VD are negative in this specification.

*3) DENA (Data Enable) should always be positive polarity as shown in the timing specification.

*4) DCLK should appear during all invalid period, and HD should appear during invalid period of

frame cycle.

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 7/32

(2) Timing Chart

a. Pixel Timing Chart tCLK

tWCH tWCL

DCLK 2.0V

0.8V

tDS tDH

DATA(R,G,B),

2.0V

DENA, HD, VD

0.8V

b. Horizontal Timing Chart

DCLK

First Data

DATA

Invalid Data 1 2 3 639 640 Invalid Data

(R,G,B)

Last Data

tHFP t HBP t HA

DENA

tH=1/fH

tWHL

HD

c. Vertical Timing Chart

HD

LINE DATA Invalid Data 1 2 3 479 480 Invalid Data

t VFP tVBP tVA

DENA

t V=1/fV

tWVL

VD

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 8/32

(3) Color Data Assignment

R DATA G DATA B DATA

COLOR INPUT R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

DATA MSB LSB MSB LSB MSB LSB

BLACK 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED(63) 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

GREEN(63) 0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0

BASIC BLUE(63) 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1

COLOR CYAN 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1

MAGENTA 1 1 1 1 1 1 0 0 0 0 0 0 1 1 1 1 1 1

YELLOW 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0

WHITE 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

RED(0) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED (1) 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0

RED(2) 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0

RED

RED (62) 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0

RED(63) 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

GREEN(0) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GREEN (1) 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0

GREEN(2) 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0

GREEN

GREEN(62) 0 0 0 0 0 0 1 1 1 1 1 0 0 0 0 0 0 0

GREEN(63) 0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0

BLUE(0) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

BLUE(1) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

BLUE(2) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0

BLUE

BLUE(62) 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 0

BLUE(63) 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1

[Note]

1) Definition of gray scale

Color (n) --- n indicates gray scale level.

Higher n means brighter level.

2) Data

1:High, 0: Low

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 9/32

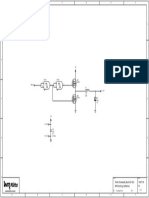

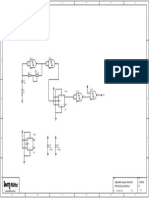

6. BLOCK DIAGRAM

BACKLIGHT CN2

Driver(source)

Timing signal

S1920

Display data

Timing

S1

S2

Converter

I/F Connector CN1

G1

Driver(gate)

G2

TFT-LCD

Power

G480

Power

Supply

Circuit BACKLIGHT CN3

BACKLIGHT

CCFL CN2,CN3

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 10/32

7. MECHANICAL SPECIFICATIONS

(1) Front Side

Unit: mm

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 11/32

(2) Rear Side

Unit: mm

[Note]

We recommend you referring to the detailed drawing for your design.

Please contact our company sales representative when you need the detailed drawing.

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 12/32

8. OPTICAL CHARACTERISTICS

Ta = 25°C, VCC = 3.3 V, Input Signals: Typ. Values shown in Section 5

ITEM SYMBOL CONDITION MIN. TYP. MAX. UNIT Remarks

Contrast Ratio CR θ = φ = 0° -- 450 -- -- *1)*3)

IL=5.5mArms

Luminance Lw θ = φ = 0° 300 400 -- cd/m2

*2)*3)

IL=6.5mArms

350 450 -- cd/m2

*2)*3)

Response Time tr θ = φ = 0° -- 8 -- ms *3)*4)

tf θ = φ = 0° -- 27 -- ms *3)*4)

Viewing Horizontal φ CR ≥ 10 -- -65∼65 -- ° *3)

Angle Vertical θ -- -60∼50 -- ° *3)

Image Sticking tis 2h -- -- 2 s *5)

Red Rx 0.528 0.558 0.588

Ry 0.297 0.327 0.357

Color Green Gx 0.288 0.318 0.348

Coordinates Gy θ = φ = 0° 0.494 0.524 0.554 -- *3)

Blue Bx 0.125 0.155 0.185

By 0.108 0.138 0.168

White Wx 0.281 0.311 0.341

Wy 0.297 0.327 0.357

[Note]

These items are measured using CS1000(MINOLTA) for color coordinates, EZContrast(ELDIM) for

viewing angle, and CS1000 or BM-5A(TOPCON) for others under the dark room condition (no ambient

light) after more than 30 minutes from turning on the lamp unless noted.

Condition: FL = 60 kHz

*1) Definition of Contrast Ratio

CR=ON (White) Luminance / OFF(Black) Luminance: average of 5 points shown in a figure below

*2) Definition of Luminance

Lw= ON (White) Luminance: average of 5 points shown in a figure below

(1,1) 160 320 480

1 2

120

5

240

3 4

360

(640,480)

MEASUREMENT POINT

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 13/32

*3) Definition of Viewing Angle( θ , φ)

*4) Definition of Response Time

White

90% 90%

Luminance

10% Black 10%

tr tf

*5) Image Sticking

Continuously display the test pattern shown in the figure below for two-hours. Then display a

completely white screen. The previous image shall not persist more than two seconds at 25°C.

TEST PATTERN FOR IMAGE STICKING TEST

Cols 318-322

White

Area

Rows 238-242

Black

Lines

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 14/32

9. RELIABILITY TEST CONDITION

(1) Temperature and Humidity

TEST ITEM CONDITIONS

HIGH TEMPERATURE

40°C, 90%RH, 240 h

HIGH HUMIDITY OPERATION

HIGH TEMPERATURE STORAGE 65°C, 96 h

LOW TEMPERATURE STORAGE -20°C, 96 h

BETWEEN -20°C (1h) and 65°C(1h),

THERMAL SHOCK(NON-OPERATION)

5 CYCLES

(2) Shock & Vibration

ITEM CONDITIONS

Shock level: 1470m/s2 (150G)

SHOCK Waveform: half sinusoidal wave, 2ms

(NON-OPERATION) Number of shocks: one shock input in each direction of three mutually

perpendicular axis for a total of six shock inputs

Vibration level: 9.8m/s2 (1.0G)(Zero to Peak)

Waveform: sinusoidal

VIBRATION Frequency range: 5 to 500Hz

(NON-OPERATION) Frequency sweep rate: 0.5 octave /min

Duration: one sweep from 5 to 500 Hz in each of three mutually

perpendicular axis(each x,y,z axis: 1 hour, total 3 hours)

(3) Judgment standard

The judgment of the above tests should be made as follow:

Pass: Normal display image with no obvious non-uniformity and no line defect.

Partial transformation of the module parts should be ignored.

Fail: No display image, obvious non-uniformity, or line defects.

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 15/32

10. INSPECTION STANDARDS

Inspection condition is as follows:

Viewing distance is approximately 35 cm.

Viewing angle is normal to the LCD panel.

Ambient temperature is approximately 25°C.

Ambient light is from 300 to 500 lx.

Bright Dot is defined as follows:

Visible through 5% transmission ND filter under the condition that black image (color 0) is on the

display.

DEFECT TYPE LIMIT

0.01 mm < W ≤ 0.05 mm

N≤4

L ≤ 10 mm

SCRATCH 0.01 mm < W

N=0

10 mm < L

0.05 mm < W N=0

0.2 mm < φ ≤ 0.4 mm N≤4

DENT

0.4 mm < φ N=0

VISUAL

DEFECT BLACK SPOT 0.2 mm < φ ≤ 0.4 mm N≤5

BUBBLE 0.4 mm < φ N=0

L ≤ 3 mm

N≤4

W ≤ 0.1 mm

3 mm < L

LINT N=0

W ≤ 0.1 mm

ACCORDING TO

0.1 mm < W

BLACK SPOT

BRIGHT DOT N≤5

DARK DOT N≤5

TOTAL DOT N≤8

TWO ADJACENT DOT

BRIGHT DOT ≤ 2 PAIRS

DARK DOT ≤ 2 PAIRS

ELECTRICAL

DEFECT THREE OR MORE

NOT ALLOWED

ADJACENT DOT

DISTANCE BETWEEN

DEFECTS

BRIGHT DOT ≥ 15 mm

DARK DOT ≥ 15 mm

LINE DEFECT NOT ALLOWED

*1) W: width,L: length,φ : diameter,N: number

*2) DEFINITION OF ADJACENT

R G B R G B R G B

Defective Dot

R G B R G B R G B

Adjacent Dots

R G B R G B R G B

The defects that are not defined above and considered to be problem shall be reviewed and discussed by

both parties.

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 16/32

11. HANDLING PRECAUTIONS FOR TFT-LCD MODULE

Please pay attention to the followings in handling TFT-LCD products;

(1) ASSEMBLY PRECAUTION

a. Please use the mounting hole on the module in installing and do not bending or wrenching LCD in

assembling. And please do not drop, bend or twist LCD module in handling.

b. Please design display housing in accordance with the following guide lines.

(a) Housing case must be designed carefully so as not to put stresses on LCD all sides and not to

wrench module. The stresses may cause non-uniformity even if there is no non-uniformity

statically.

(b) Keep sufficient clearance between LCD module back surface and housing when the LCD

module is mounted. Approximately 1.0mm of the clearance in the design is recommended taking

into account the tolerance of LCD module thickness and mounting structure height on the

housing.

(c) When some parts, such as, FPC cable and ferrite plate, are installed underneath the LCD

module, still sufficient clearance is required, such as 0.5mm. This clearance is, especially, to be

reconsidered when the additional parts are implemented for EMI countermeasure.

(d) Design the inverter location and connector position carefully so as not to give stress to lamp

cable, or not to interface the LCD module by the lamp cable.

(e) Keep sufficient clearance between LCD module and the others parts, such as inverter and

speaker so as not to interface the LCD module. Approximately 1.0mm of the clearance in the

design is recommended.

c. Please do not push or scratch LCD panel surface with anything hard. And do not soil LCD panel

surface by touching with bare hands. (Polarizer film, surface of LCD panel is easy to be flawed.)

d. Please do not press any parts on the rear side such as source TCP, gate TCP, control circuit board

and FPCs during handling LCD module. If pressing rear part is unavoidable, handle the LCD

module with care not to damage them.

e. Please wipe off LCD panel surface with absorbent cotton or soft cloth in case of it being soiled.

f. Please wipe off drops of adhesives like saliva and water on LCD panel surface immediately. They

might damage to cause panel surface variation and color change.

g. Please do not take a LCD module to pieces and reconstruct it. Resolving and reconstructing modules

may cause them not to work well.

h. Please do not touch metal frames with bare hands and soiled gloves. A color change of the metal

frames can happen during a long preservation of soiled LCD modules.

i. Please pay attention to handling lead wire of backlight so that it is not tugged in connecting with

inverter.

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 17/32

j. Be sure to connect the cables and the connectors correctly.

k. Please connect the metal frame of LCD module to GND in order to minimize the effect of external

noise and EMI.

(2) OPERATING PRECAUTIONS

a. Please be sure to turn off the power supply before connecting and disconnecting signal input cable.

b. Please do not change variable resistance settings in LCD module. They are adjusted to the most

suitable value. If they are changed, it might happen LCD does not satisfy the characteristics

specification.

c. LCD backlight takes longer time to become stable of radiation characteristics in low temperature

than in room temperature.

d. The interface signal speed is very high. Please pay attention to transmission line design and other

high speed signal precautions to satisfy signal specification.

e. A condensation might happen on the surface and inside of LCD module in case of sudden change of

ambient temperature.

f. Please pay attention not to display the same pattern for very long time. Image might stick on LCD.

Even if image sticking happens, it may disappear as the operation time proceeds.

g. Please obey the same safe instructions as ones being prepared for ordinary electronic products.

(3) PRECAUTIONS WITH ELECTROSTATICS

a. This LCD module use CMOS-IC on circuit board and TFT-LCD panel, and so it is easy to be affected

by electrostatics. Please be careful with electrostatics by the way of your body connecting to the

ground and so on.

b. Please remove protection film very slowly from the surface of LCD module to prevent from

electrostatics occurrence.

(4) STORAGE PRECAUTIONS

a. Please do not leave the LCDs in the environment of high humidity and high temperature such as

60°C90%RH.

b. Please do not leave the LCDs in the environment of low temperature; below -20°C.

(5) SAFETY PRECAUTIONS

a. When you waste damaged or unnecessary LCDs, it is recommended to crush LCDs into pieces and

wash them off with solvents such as acetone and ethanol, which should later be burned.

b. If any liquid leaks out of a damaged glass cell and comes in contact with the hands, wash off

thoroughly with soap and water.

c. Be sure to turn off the power supply when inserting or disconnecting the cable.

d. Inverter should be designed carefully so as not to keep working in case of detecting over current or

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 18/32

open circuit on the lamp.

(6) OTHERS

a. A strong incident light into LCD panel might cause display characteristics changing inferior

because of polarizer film, color filter, and other materials becoming inferior. Please do not expose

LCD module direct sunlight and strong UV rays.

b. Please pay attention to a panel side of LCD module not to contact with other materials in

preserving it alone.

c. For the packaging box, please pay attention to the followings;

(a) Packaging box and inner case for LCD are designed to protect the LCDs from the damage or

scratching during transportation. Please do not open except picking LCDs up from the box.

(b) Please do not pile them up more than 6 boxes. (They are not designed so.) And please do not

turn over.

(c) Please handle packaging box with care not to give them sudden shock and vibrations. And also

please do not throw them up.

(d) Packaging box and inner case for LCDs are made of cardboard. So please pay attention not to

get them wet. (Such like keeping them in high humidity or wet place can occur getting them

wet.)

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 19/32

Packaging specification

1. packaging box

material: cardboard, polyethylene form

construction: See Fig 1

max. packaging number: 10 pcs.

dimension: 593(W) × 255(D) × 325(H)

mass(including 10 modules): 5.8kg

label: Labels are put on the box.(See Fig 2,3,4)

Upper Protector

↓

Side Protector

Fig. 1. Illustration of packaging box structure

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 20/32

型名

Product name 収納数

Packaging number

バーコード

Bar-code バーコード

Bar-code

Box No.

Serial

シリアル番号 No. Serial

シリアル番号 No. Shipper

Mass

バーコード

Bar-code バーコード

Bar-code

Shipping No.

シリアル番号

Serial No. シリアル番号

Serial No.

Bar-code

Bar-code

バーコード Bar-code

バーコード

Products name

Serial

シリアル番号 No. Serial

シリアル番号 No. Bar-code

バーコード

Bar-code バーコード

Bar-code Packaging No.

Serial

シリアル番号 No. Serial

シリアル番号 No. Bar-code

Bar-code

バーコード Bar-code

バーコード Order No.

シリアル番号 シリアル番号 Bar-code

Serial No. Serial No.

バーコード

Bar-code バーコード

Bar-code Product name

Bar-code

Fig.2. Label1 Fig.3. Label 2

Consignee

OPTREX

Product name

TFT - LCD: AA084VC05

Product name of consignee

T-5638D084J-FW-A-AB

Order No.

P / O NO. 123456789

Box No.

C/S 001 OF 005

Place of production

MADE IN JAPAN

Bar-code

Shipping date 001 JA1BK4144

2001/11/15

Fig. 4. Label 3 Fig. 5 Sample of Label3

Label 3

Label 1

Label 2

Fig. 6. Location of Labels

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 21/32

2. Location of label on the packaging box

Labels are put on the box.(See. Fig 6)

3. Packaging form of product

(1) Each of LCD modules is packed in anti-electrostatic bag.(Fig 7)

(2) The packaging box contains 10 modules.(Fig 8,9)

(3) Upper protector is put on the products, and shut the box.(A→B→C→D) (Fig 10)

Tape(temporary)

Lamp lead

Product in

Anti-electrostatic bag

(Surface)

(Rear)

Fig. 7

Fig. 8

If the number of modules is smaller than 10pcs, modules are put in order ① , ② , ③ …

Fig9

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 22/32

Fig. 10

4. Cautions of shipping & storage

(1) Do not turn the packaging upside down while storage and transportation. The boxes should

not be piled up more than 6.

(2) Handle with care. Keep off from rain & dew.

(3) Keep off from direct sunlight exposure. Please store under room temperature & low humidity

in original packaging condition when they were shipped.

(4) Keep other cautions described in handling manual.

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 23/32

Products Number Labeling Forms

Products number label is constructed as below;

① Brand Name, Symbol

①Brand Name, Symbol

②T-51512D121-FW-A-AA

WARNING ②Products Name of Optrex

③Products Name

LAMP HIGH ④ Production Key Number(13Digits)

③AA121SK26

④ABC1234567890

VOLTAGE ⑤ Date Code

(Serial Number, Factory Sign)

⑤60100001L

⑦ ⑧ ⑥Bar-code of Date Code

⑥

Bar-code E158720 Made in Japan ⑦ UL File No.

⑧Production Country

① Brand Name, Symbol

OPTREX

② Products Name of Optrex

ex. T51512D121-FW-A-AA

③ Products Name

ex.1: AA121SK26 ex.2: AA150XA03 B

④ Production Key Number(13Digits)

(ID Number for Production Control)

⑤ Date Code(Serial Number, Factory Sign)

□ □ □ □ □ □ □ □ □

1 2 3 4 5 6 7 8 9

Factory Sign

Serial Number on Every Production Week

(00001 ∼ 99999)

Production Week Number(01 ∼53)

Production Year Number

(Last 1 Digit of AD Year Number)

・Date Code is constructed by 9 Digits as below;

1st Digit :Production Year Number(Last 1 Figure of AD Year)

2nd∼3rd Digit : Production Week Number in a Year

(A Year is divided to 53 weeks from Monday to Saturday)

4th∼8th Digit :Serial Number on Every Production Weeks.

( 00001 ∼ 99999 )

These are numbered in order according to Production Name.

9th Digit :Factory Sign ( on the Module Test Process)

( L: Shisui Factory Line, Y: YACHIYO SANYO Industries Line,

W: CPT Fab-1, R: CPT Fab-2 , U: CPT Wujiang-LCM)

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 24/32

⑥Bar-code(Date Code)

Bar-code Line for computer reading Date Code mentioned as above.

⑦UL File No.

ADI: E158720, CPT: E194548

⑧Production Country

ADI: Made in Japan, CPT: Made in Taiwan

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 25/32

LAMP UNIT for 8.4"VGA

APPLICATION

This technical literature applies to the replaceable lamp unit that is the maintenance parts for

8.4”VGA TFT-LCD module industrial use(model name:T-51638D084J-FW-A-AB).

(AA-L5903361(Top), AA-L5903362(Bottom))

MECHANICAL CHARACTERISTICS

Item Specification Remarks

Outline Dimension of Reflector 196+0.4

-0.6 × 3.9±0.1 × 6.23±0.1(mm) Except wire

Mass 8 (g) (MAX)

Lamp Diameter φ 2.4-1.8±0.1 (mm)

See DRAWING OF OUTLINE DIMENTIONS

ENVIRONMENTAL CONDITIONS

Operation Non Operation

Item Remarks

MIN MAX MIN MAX

Ambient Temperature -10°C 65°C -20°C 70°C No Condensation

Top,Tstg ≤ 40°C : 90%RH max. without condensation

Top,Tstg > 40°C : Absolute humidity shall be less than the value of 90%RH at 40°C without

condensation.

ELECTRICAL CHARACTERISTICS

Item Symbol Condition MIN TYP MAX Unit Remarks

Lamp Current IL Ta = 25°C 3.0 6.5 7.0 mArm

s

Lamp Voltage VL Ta = 25°C - 450 - Vrms

Starting Lamp Voltage VS Ta = 25°C 670 - - Vrms

Lamp Frequency FL Ta = 25℃ 30 - 60 kHz

*1) These values are shown by Elevam using S-12324A-00 inverter.

*2) Lamp Current measurement method (The current meter is inserted in low voltage line.)

CTL A

CTH

LCD

Power

Module Inverter

CTL A Supply

CTH

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 26/32

OPTICAL CHARACTERISTICS

Ta=25°C, 60±10%RH

Item Symbol MIN TYP MAX Unit Remarks

IL=5.5 mArms

300 400 -- cd/m2

Average of below 5 points

Luminance Lw

IL=6.5 mArms

350 450 -- cd/m2

Average of below 5 points

Color Coordinates Wx 0.281 0.311 0.341 - Value of center point(5)

(White) Wy 0.297 0.327 0.357 - Value of center point(5)

[Conditions]

Inverter frequency: 60kHz

[Measurement Point]

(1,1) 160 320 480

1 2

120

5

240

3 4

360

(640,480)

These items are measured when lamp units are assembled intot T-51638D084J-FW-A-AB, and

using CS1000(MINOLTA) for color coordinates, and CS1000 or BM-5A(TOPCON) for others

under the dark room condition (no ambient light) after more than 30 minutes from turning on

the lamp unless noted.

LIFE TIME OF THE LAMP UNIT

Environmental Conditions are as follows:

Ambient temperature is 25±5°C.

Lamp Current is 6.5 mArms.

Continuous Operation 50,000 h

Number of turning on and off 100,000 times (30 sec ON-OFF)

(1) Lamp life time is defined as the time either when the brightness becomes 50% of the initial

value, or when the starting lamp voltage does not meet the value specified in the table of

section 4.

(2) The life time of the backlight depends on the ambient temperature. The life time will decrease

under low/high temperature.

INTERFACE PIN CONNECTION

Backlight-side connector: BHR-02(8.0)VS-1N(JST)

Inverter-side connector: SM02(8.0)B-BHS(JST)

Pin No. Symbol Function

1 CTH VBLH(High voltage)

3 CTL VBLL(Low voltage)

[Note] VBLH-VBLL=VL

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 27/32

DRAWING OF OUTLINE DIMENTIONS

(1) AA-L5903361(Top)

112 ±5

(2) AA-L5903362(Bottom)

112 ±5

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 28/32

METHOD OF REPLACING THE LAMP UNIT

(1) Precautions

Please pay attention to the following items while replacing the Lamp Unit.

a. Please do not damage the LCD Panel Surface, and do not touch it with bare hands.

(Wearing gloves is recommended.)

b. Please be careful with electrostatics, and work in clean environment to prevent entering dust

and/or foreign matters that will cause bad display image.

(Using clean bench or similar environment is recommended.)

c. Please be careful of the edge of the frame metal.

(2) Method of replacing the Lamp Unit

1) Put the TFT-LCD Module on the table.(LCD Panel Surface is upside.)

Top

Please check the LCD Panel

Surface for scratch, dust, and

foreign matters.

Bottom

Picture 1

2) Turn the TFT-LCD Module upside down and unfasten the cable.

Please unfasten the wire

from the latch of plastic

frame.

Picture 2

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 29/32

3) Stand the TFT-LCD Module up and push down the latch with that the Lamp Unit fastens.

Latch

Push down the latch.

Picture 3

4) Pull the cable slowly and remove the Lamp Unit.

Picture 4 Picture 5

5) Remove the other Lamp Unit at the opposite(bottom) side of LCD Module in the same way.

See.3) and 4)

6) Picture 6 shows the TFT-LCD Module after removing the Lamp Units.

Picture 6

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 30/32

7) Prepare to insert the new Lamp Units.

• Open the package and take the new Lamp Units out.

• Check the new Lamp Units for dust and foreign matters.

8) Stand the TFT-LCD module and insert the new Lamp Unit.

The light guide and reflector sheet should be inside of the Lamp Unit.

Please pay attention to insert direction.

Push down the latch of the plastic

frame (black) and insert the new

Lamp Unit.

The light guide and reflector sheet

should be inside of the Lamp Unit

keeping the white cable straight.

Picture 7

The white cable should be on

the side of LCD Panel Surface.

9) After inserting, please check the Lamp Unit is fastened with the latch.

Please check the Lamp Unit is

fastened with the latch.

Picture 8

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 31/32

10) Fasten the wires to the latch of the plastic frame.

Fasten the Pink and

white wires to the

latch of the plastic

frame.

Picture 9

11) Insert the other Lamp Unit to the opposite(bottom) side of the LCD module in the same way.

See. 8) to 10)

12) After replacing the Lamp Units, please check the following items.

• Appearance of TFT-LCD Module is not changed after replacing Lamp Units.

(See. Picture 1 and Picture 2)

• There is no damage, dust, or foreign matters on the LCD Panel Surface.

• Install the TFT-LCD Module then check turning on the lamps.

T-51638D084J-FW-A-AB (AB) No. 2003-0193 OPTREX CORPORATION Page 32/32

You might also like

- AA104VC08 MitsubishiDocument23 pagesAA104VC08 MitsubishiJosé AdelinoNo ratings yet

- AA121SL06Document25 pagesAA121SL06I’M FINE OkNo ratings yet

- Mitsubishi - AA101TA12 - DatasheetDocument25 pagesMitsubishi - AA101TA12 - DatasheetaylinaykanNo ratings yet

- TFT LCD Preliminary Specification HC315BH-D04: Model NoDocument23 pagesTFT LCD Preliminary Specification HC315BH-D04: Model NoBhadreshkumar SharmaNo ratings yet

- AC121SA01Document24 pagesAC121SA01I’M FINE OkNo ratings yet

- T315HW03 VBDocument30 pagesT315HW03 VBTecnico GenioNo ratings yet

- Claa154wb03 An ChunghwapicturetubesDocument27 pagesClaa154wb03 An ChunghwapicturetubesNoel Alejandro Cordova RangelNo ratings yet

- Claa080wq05 ChunghwapicturetubesDocument23 pagesClaa080wq05 ChunghwapicturetubestuxnskNo ratings yet

- Goldenmorning Electronic: Product Name: Rgs15128128Wr000 Product No.: Gme128128-01Document34 pagesGoldenmorning Electronic: Product Name: Rgs15128128Wr000 Product No.: Gme128128-01Scott WilsonNo ratings yet

- T400HW02-V5-AUO Samsung 40 Pol PDFDocument30 pagesT400HW02-V5-AUO Samsung 40 Pol PDFRubia De SouzaNo ratings yet

- CPT Claa080ua01 7.97'' PDFDocument23 pagesCPT Claa080ua01 7.97'' PDFxyc0nNo ratings yet

- GDM 24064 02Document31 pagesGDM 24064 02Fábio Vitor MartinsNo ratings yet

- Claa215fa04 Chunghwapicturetubes PDFDocument24 pagesClaa215fa04 Chunghwapicturetubes PDFSalvador MolvinniNo ratings yet

- Tcg057vglaaann-Gn20 PDFDocument20 pagesTcg057vglaaann-Gn20 PDFYouness Ben TibariNo ratings yet

- Panel AUO T260XW04 V3 0 PDFDocument29 pagesPanel AUO T260XW04 V3 0 PDFAnonymous St6bxHSYipNo ratings yet

- Data Image: Corporation CTP Module SpecificationDocument42 pagesData Image: Corporation CTP Module SpecificationImadMehdiNo ratings yet

- CLAA216WA01 PanalDocument25 pagesCLAA216WA01 PanalGursharan SinghNo ratings yet

- Model No.:: ApprovalDocument33 pagesModel No.:: ApprovalTomislav StudakNo ratings yet

- Claa320wf01d Chunghwapicturetubes PDFDocument28 pagesClaa320wf01d Chunghwapicturetubes PDFmhmd193No ratings yet

- CPT TFT-LCD Technical SpecificationDocument28 pagesCPT TFT-LCD Technical SpecificationabdessNo ratings yet

- V320BJ2-P03-CMIMEI Sony KDL 32 PanelDocument29 pagesV320BJ2-P03-CMIMEI Sony KDL 32 PanelIvan ZuñigaNo ratings yet

- Panel AMPIRE AM-1024768ETMCW-00 0 (DS)Document19 pagesPanel AMPIRE AM-1024768ETMCW-00 0 (DS)marcokersulrodriguesNo ratings yet

- T260XW02 V6 AuoDocument29 pagesT260XW02 V6 Auomhmd193No ratings yet

- LCD SpecDocument21 pagesLCD SpecKC KiewNo ratings yet

- CLAA102NA0ACWDocument16 pagesCLAA102NA0ACWIvan BenginNo ratings yet

- N156B6 L08Document31 pagesN156B6 L08JozefNo ratings yet

- Global LCD Panel Specification GuideDocument27 pagesGlobal LCD Panel Specification GuideLuis MezaNo ratings yet

- Evervision 7Document28 pagesEvervision 7Эдуард АлверцянNo ratings yet

- Rk055ahd091 CTGDocument17 pagesRk055ahd091 CTGEhab Anwar ElnagdyNo ratings yet

- LCD Module Technical Specification GuideDocument17 pagesLCD Module Technical Specification GuideAsad AhmedNo ratings yet

- Specifications For LCD Module: Customer Customer Part No. Ampire Part No. AM-800480R2TMQW-TU0H Approved by DateDocument59 pagesSpecifications For LCD Module: Customer Customer Part No. Ampire Part No. AM-800480R2TMQW-TU0H Approved by DateRathod GunvantrayNo ratings yet

- Au Optronics Corporation: Product SpecificationsDocument26 pagesAu Optronics Corporation: Product SpecificationsSertan YasanNo ratings yet

- Mikroe 3904Document17 pagesMikroe 3904kushliakNo ratings yet

- Powertip Tech. Corp.: Specification For ApprovalDocument24 pagesPowertip Tech. Corp.: Specification For ApprovalRaul Alexandru CuldaNo ratings yet

- B8 NT156WHM-N42-8D31 V8.0 Product Specification Rev.O - 20160105 (N42-8D31 LBG)Document33 pagesB8 NT156WHM-N42-8D31 V8.0 Product Specification Rev.O - 20160105 (N42-8D31 LBG)vasul.denusNo ratings yet

- 30 Pin Laptop Led Screen PDFDocument33 pages30 Pin Laptop Led Screen PDFCarlos GomesNo ratings yet

- Data Image: Corporation TFT Module SpecificationDocument20 pagesData Image: Corporation TFT Module SpecificationImadMehdiNo ratings yet

- T420HW06 V2 AuoDocument29 pagesT420HW06 V2 AuoMaria MartinezNo ratings yet

- Panel AUO T315XW04 V3 CELL 0Document24 pagesPanel AUO T315XW04 V3 CELL 0MauricioNo ratings yet

- T315HW07 V8 PDFDocument31 pagesT315HW07 V8 PDFJose GargaglioneNo ratings yet

- Chimei N173O6 L02Document29 pagesChimei N173O6 L02alelujaNo ratings yet

- Formike Electronic Co.,Ltd: Prduct SpecificatonDocument33 pagesFormike Electronic Co.,Ltd: Prduct SpecificatonlulilanNo ratings yet

- Datasheet (ltm200wd1)Document34 pagesDatasheet (ltm200wd1)walter andiasNo ratings yet

- Panel T315HDocument31 pagesPanel T315HJan Carlos RodriguezNo ratings yet

- T260XW02SpecVer1 2Document26 pagesT260XW02SpecVer1 2Oscar Andres Ramirez AmayaNo ratings yet

- Dmf5001ny Ly Aie PDFDocument17 pagesDmf5001ny Ly Aie PDFPTCNo ratings yet

- Displaytech-240320dl 03a440753dDocument17 pagesDisplaytech-240320dl 03a440753dBrad FrancNo ratings yet

- Acer S190WL S196WL 2chip 20120602 A00 Service ManualDocument66 pagesAcer S190WL S196WL 2chip 20120602 A00 Service ManualDoru RazvanNo ratings yet

- Chunghwa Picture Tubes, Ltd. Technical Specification: Model: CLAA170EA07PDocument27 pagesChunghwa Picture Tubes, Ltd. Technical Specification: Model: CLAA170EA07PandymustopaNo ratings yet

- T260XW02V5Document26 pagesT260XW02V5Oscar Andres Ramirez AmayaNo ratings yet

- B156XW02 V.2 PDFDocument31 pagesB156XW02 V.2 PDFMihael PolakNo ratings yet

- Lta320w2 L03Document33 pagesLta320w2 L03antoNo ratings yet

- LTM200KT07 V SamsungDocument33 pagesLTM200KT07 V SamsungYoutube For EducationNo ratings yet

- Specification: 46" HDTV-Panel T460HW01Document27 pagesSpecification: 46" HDTV-Panel T460HW01Matt KuoNo ratings yet

- LTM200KT10 DatasheetDocument33 pagesLTM200KT10 DatasheetID100% (1)

- Product Specification: Part Name: Customer Part ID: Topovision ID: Ver: A 3.5 Inch TFT Display Module TVT0350K3-IDocument18 pagesProduct Specification: Part Name: Customer Part ID: Topovision ID: Ver: A 3.5 Inch TFT Display Module TVT0350K3-IMackie Kannard-SmithNo ratings yet

- Data SheetDocument33 pagesData SheetimanteaNo ratings yet

- Specification: LQ035NC111Document35 pagesSpecification: LQ035NC111ImadMehdiNo ratings yet

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- Microprocessor Architectures and Systems: RISC, CISC and DSPFrom EverandMicroprocessor Architectures and Systems: RISC, CISC and DSPRating: 4 out of 5 stars4/5 (1)

- The Ahhhh Meme Compilation (2017) - Youtube: VídeosDocument2 pagesThe Ahhhh Meme Compilation (2017) - Youtube: Vídeosmarco antonioNo ratings yet

- AVCM8340 141111Document2 pagesAVCM8340 141111marco antonioNo ratings yet

- Lg+cm8340-Ab - DCHLLLK Afn76592102 EvDocument79 pagesLg+cm8340-Ab - DCHLLLK Afn76592102 Evlibre2009No ratings yet

- Vaula 230 WR CircuitryDocument1 pageVaula 230 WR Circuitrymarco antonioNo ratings yet

- Injectomat Agilia Technical Manual EngDocument19 pagesInjectomat Agilia Technical Manual Engediciba89% (9)

- LCD Module Technical Specification: First EditionDocument32 pagesLCD Module Technical Specification: First Editionmarco antonioNo ratings yet

- Vaula 231 WR CircuitryDocument1 pageVaula 231 WR Circuitrymarco antonioNo ratings yet

- Injectomat Agilia Technical Manual EngDocument19 pagesInjectomat Agilia Technical Manual Engediciba89% (9)

- Motherboard Quanta r13 Da0r13mb6e, Da0r13mb6e0, Da0r13mb6e1Document40 pagesMotherboard Quanta r13 Da0r13mb6e, Da0r13mb6e0, Da0r13mb6e1alessok100% (1)

- Vaula 328 WR CircuitryDocument1 pageVaula 328 WR Circuitrymarco antonioNo ratings yet

- Descriptio Features: LT1513/LT1513-2 SEPIC Constant-Or Programmable-Current/ Constant-Voltage Battery ChargerDocument16 pagesDescriptio Features: LT1513/LT1513-2 SEPIC Constant-Or Programmable-Current/ Constant-Voltage Battery Chargermike milgrauNo ratings yet

- Viewstation ManualDocument62 pagesViewstation ManualbismarckllNo ratings yet

- R4 Bat1 Q4 R10: Pedal de Trêmolo para Guitarra WR Kits Eng. Eletrônica 21/11/19Document1 pageR4 Bat1 Q4 R10: Pedal de Trêmolo para Guitarra WR Kits Eng. Eletrônica 21/11/19marco antonioNo ratings yet

- D D D D D D D D: Description/ordering InformationDocument17 pagesD D D D D D D D: Description/ordering Informationmarco antonioNo ratings yet

- BC548 Hoja de Datos PDFDocument5 pagesBC548 Hoja de Datos PDFJuan FiNo ratings yet

- Descriptio Features: LT1513/LT1513-2 SEPIC Constant-Or Programmable-Current/ Constant-Voltage Battery ChargerDocument16 pagesDescriptio Features: LT1513/LT1513-2 SEPIC Constant-Or Programmable-Current/ Constant-Voltage Battery Chargermike milgrauNo ratings yet

- Motherboard Quanta r13 Da0r13mb6e, Da0r13mb6e0, Da0r13mb6e1Document40 pagesMotherboard Quanta r13 Da0r13mb6e, Da0r13mb6e0, Da0r13mb6e1alessok100% (1)

- Trio Service ManualDocument82 pagesTrio Service Manualeduardoquijada100% (1)

- Passport 2 Service Manual - 001 PDFDocument158 pagesPassport 2 Service Manual - 001 PDFSergio Iván CasillasNo ratings yet

- Passport XG Service ManualDocument544 pagesPassport XG Service ManualThatch50% (2)

- 0691revc - Contents Acctplusbrite SVC Man PDFDocument95 pages0691revc - Contents Acctplusbrite SVC Man PDFmarco antonioNo ratings yet

- Passport XG Service ManualDocument544 pagesPassport XG Service ManualThatch50% (2)

- Spectrum or Service Manual PDFDocument134 pagesSpectrum or Service Manual PDFelis abdiel sanchezNo ratings yet

- Spectrum or Service Manual PDFDocument134 pagesSpectrum or Service Manual PDFelis abdiel sanchezNo ratings yet

- Passport 2 Service Manual - 001 PDFDocument158 pagesPassport 2 Service Manual - 001 PDFSergio Iván CasillasNo ratings yet

- Modulo de GasesDocument127 pagesModulo de GasesCatalina FajardoNo ratings yet

- Accutorr Plus SVC Man ContentsDocument101 pagesAccutorr Plus SVC Man ContentsSergio Iván CasillasNo ratings yet

- 0070 10 0604 01 - Duo Service Manual PDFDocument39 pages0070 10 0604 01 - Duo Service Manual PDFmarco antonioNo ratings yet

- Mindray M5 VetDocument214 pagesMindray M5 VethabibNo ratings yet

- 3.97inch 16BIT Module MRB3973 User Manual: Lcdwiki CR2019-MI4055Document27 pages3.97inch 16BIT Module MRB3973 User Manual: Lcdwiki CR2019-MI4055Rafael LucasionistNo ratings yet

- Exploded View Parts ListDocument9 pagesExploded View Parts ListHoàng NguyễnNo ratings yet

- Display 30 Pinos B140XTN02.4-AUODocument33 pagesDisplay 30 Pinos B140XTN02.4-AUOBobNo ratings yet

- Laptop Level-1 Service Training - Course Syllabus: Tools and Testing EquipmentsDocument12 pagesLaptop Level-1 Service Training - Course Syllabus: Tools and Testing EquipmentsHari HargovindNo ratings yet

- MT8150XE Datasheet ENGDocument2 pagesMT8150XE Datasheet ENGCarlos Eberhard Diaz TorresNo ratings yet

- LTN156AT01Document23 pagesLTN156AT01Salvador Canedo RomeroNo ratings yet

- 2011 BossAudio LoDocument132 pages2011 BossAudio LoRuben CabreraNo ratings yet

- White Paper A Comparison of Video Wall TechnologiesDocument28 pagesWhite Paper A Comparison of Video Wall TechnologiesKaren SimsNo ratings yet

- CP500 Series Control Panels Catalogue SummaryDocument8 pagesCP500 Series Control Panels Catalogue SummaryMitul ShahNo ratings yet

- Specification FOR Approval: 18.5" HD TFT LCD TitleDocument31 pagesSpecification FOR Approval: 18.5" HD TFT LCD TitleyoyneerNo ratings yet

- Nec LCD PanelDocument28 pagesNec LCD PanelEdwin OndoyNo ratings yet

- GR 10 Olev Exam Notes & Questions by Harshvardhan Sir Computer Science Cie IgcseDocument39 pagesGR 10 Olev Exam Notes & Questions by Harshvardhan Sir Computer Science Cie IgcseAala SolihNo ratings yet

- Display 1Document2 pagesDisplay 1great dayNo ratings yet

- Coolmay CatalogDocument16 pagesCoolmay CatalogDavidBezerraNo ratings yet

- LTA400HM07 SamsungDocument25 pagesLTA400HM07 SamsungOrangelin SantaellaNo ratings yet

- Tianjin APT 500C TFT Display SpecsDocument9 pagesTianjin APT 500C TFT Display SpecsMartin huntNo ratings yet

- LTA260W2 L13 SamsungDocument28 pagesLTA260W2 L13 SamsungkarkeraNo ratings yet

- Automation Technology eDocument160 pagesAutomation Technology ekukuh_subiartoNo ratings yet

- L1732TQ SpecsDocument2 pagesL1732TQ SpecsCarlos Junior PereiraNo ratings yet

- T315 XW01 V0Document23 pagesT315 XW01 V0gondifNo ratings yet

- MODEL NO.: N156B6-L0B: TFT LCD Approval SpecificationDocument33 pagesMODEL NO.: N156B6-L0B: TFT LCD Approval SpecificationazmNNo ratings yet

- V570 57 T20B T40B - Tech SpecDocument6 pagesV570 57 T20B T40B - Tech Specberemis9No ratings yet

- Siemens Simatic HMI 2009 PDFDocument178 pagesSiemens Simatic HMI 2009 PDFnilton.flavioNo ratings yet

- Specification FOR Approval: 27" Full HD TFT LCD TitleDocument31 pagesSpecification FOR Approval: 27" Full HD TFT LCD TitleСергій НестеровичNo ratings yet

- Physiologic Monitoring Systems, Acute Care Neonatal ECG Monitors Monitors, Central Station - 060421011312Document12 pagesPhysiologic Monitoring Systems, Acute Care Neonatal ECG Monitors Monitors, Central Station - 060421011312Katlheen KrautzNo ratings yet

- LG Display LC420EUH-SCA1 OverviewDocument1 pageLG Display LC420EUH-SCA1 Overviewfantom2303 brazhnikovNo ratings yet

- 32" Game Touch Product OverviewDocument3 pages32" Game Touch Product OverviewAshley NambaNo ratings yet

- 2 Product SpecificationsDocument10 pages2 Product Specificationsxor_45No ratings yet

- N101l6-L01-Cmi MeiDocument28 pagesN101l6-L01-Cmi MeimassipoedNo ratings yet

- Fujitsu Esprimo E7935 E-Star 5.0 Desktop PC: DatasheetDocument7 pagesFujitsu Esprimo E7935 E-Star 5.0 Desktop PC: DatasheetrobNo ratings yet