Professional Documents

Culture Documents

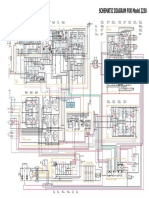

Armazones y Forma Contructiva Motores BALDOR Norrma IEC

Uploaded by

Cesareo Rafael Brochero MarenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Armazones y Forma Contructiva Motores BALDOR Norrma IEC

Uploaded by

Cesareo Rafael Brochero MarenCopyright:

Available Formats

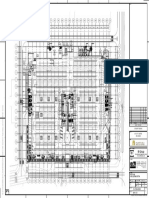

Key and Keyseat Dimensions NEMA Keyseat NEMA Keyseat

Shaft Dimensions Shaft Dimensions

Frame D G F GD Frame D G F GD

(U) (R) (S) (U) (R) (S)

63 11 8.5 4 4 180 48 42.5 14 9

3/8 21/64 FLAT 1-7/8 1-19/32 1/2

71 14 11 5 5 200 55 49 16 10 1/2 29/64 FLAT 2-1/8 1-27/32 1/2

Leader in Energy Efficient 80 19 15.5 6 6 225 60 53 18 11 Leader in Energy Efficient 5/8 33/64 3/16 2-3/8 2-1/64 5/8

7/8 49/64 3/16 2-1/2 2-3/16 5/8

Industrial Electric Motors and Drives 90 24 20 8 7 250 70 67.5 20 12 Industrial Electric Motors and Drives 1-1/8 63/64 1/4 2-7/8 2-29/64 3/4

100 28 24 8 7 280 80 71 22 14 1-3/8 1-13/64 5/16 3-3/8 2-7/8 7/8

112 28 24 8 7 315 85 76 22 14 1-5/8 1-13/32 3/8 3-7/8 3-5/16 1

L* 132 38 33 10 8 355 85 76 22 14

AC 160 42 37 12 8 C*

E XX P

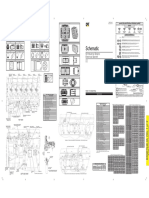

45˚ 45˚ AH (56-184)

T SINGLE PHASE BB AH (213-449) AB

6 LUG ONLY

TERM BLOCK V 45˚ 45˚

AD XO AJ

THERMAL

ETALPEMAN (WHEN

THERMAL

REQUIRED) Drawings represent standard TEFC NAMEPLATE

(WHEN REQ'D)

P

N general purpose motors. O

AK BD

D

TAP

U

*Dimensions are for reference only. D 4 HOLES

S M

4 TAPPED REMOVABLE

E E

S

HOLES DRIP COVER 2F BA

(OPTIONAL) H = Hole AA = CONDUIT SIZE

C* P

N AB

P AC

L*

GREASE

LA

E 45˚ 45˚ XX

GREASER

& RELIEF

(EACH END)

AD L* V

T

E

O

FITTING

(EACH END)

Drawings represent standard TEFC general purpose motors

AD

O

Refer Data Section 502 for various models, OPEN or TEFC

C

ETALPEMAN

P HC

N U

*Dimensions are for reference only. D

D

M

H D

H = Hole 2F BA AA E E K

A XX AUTO DRAIN C B

S (EACH END)

4 HOLES DIA. *Contact your local Baldor office for “C” Dimensions. Dimensions - N, O, P, AB and XO are specific to Baldor.

*Contact your local Baldor office for “L” Dimensions.

NEMA QUICK REFERENCE CHART P

IEC QUICK REFERENCE CHART NEMA

IEC

Frame Type A

Foot Mounting

B C H D

Shaft

E LA M

B5 Flange

N P S T M N

B14 Face

P S T L AC

General

AD HC XX

FRAME

42

D

2-5/8

E

1-3/4

2F

1-11/16

SLOT

H

9/32

N

1-1/2

O

5

P

4-11/16 3/8

U

1-1/8

V AA

3/8

AB

4-1/32

AH

1-5/16

AJ

3-3/4

AK

3

BA

2-1/16

BB

1/8

BD

4-5/8

XO

1-9/16

TAP

1/4-20 R

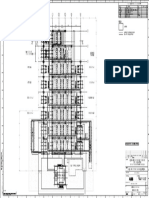

63 300 100

3.937

80

3.150

40

1.570

63

2.480

11

.433

23

.906

8

.313

115

4.528

95

3.740

140

5.512

9

.354

3

.118

75

2.953

60

2.362

90

3.540

M5 2.5

0.98

* 119

4.690

102

4

116d

121

4.760

136d

13

.500

22d

48

56

3

3-1/2

2-1/8

2-7/16

2-3/4

3

11/32

SLOT

11/32

1-7/8

2-7/16

5-7/8

6-7/8

5-11/16

6-5/8

1/2

5/8

1-1/2

1-7/8

1/2

1/2

4-3/8

5

1-11/16

2-1/16

3-3/4

5-7/8 4-1/2

3 2-1/2

2-3/4

1/8

1/8

5-5/8

6-1/2

2-1/4

2-1/4

1/4-20

3/8-16

O

D

4.567d 5.375d .880d 56H 5 SLOT 2-1/8

119 131 18 143T 3-1/2 2-3/4 4 11/32 2-1/2 6-7/8 6-5/8 7/8 2-1/4 3/4 5-1/4 2-1/8 5-7/8 4-1/2 2-1/4 1/8 6-1/2 2-1/4 3/8-16

71 300 112 90 45 71 14 30 8 130 110 160 10 3.5 85 70 105 M6 2.5 * 4.690 102 5.140 .690 145T 5

400 4.409 3.543 1.770 2.800 .551 1.181 .313 5.118 4.331 6.299 .393 .138 3.347 2.756 4.130 .098 145d 4 149d 21d

182 4-1/2 2-11/16 7/8 2-1/4 2-1/8 5-7/8 4-1/2 1/8 6-1/2 3/8-16

80 400

500

125

4.921

100

3.937

50

1.969

80

3.150

19

.748

40

1.575

13

.500

165

6.496

130

5.118

200

7.874

11

.430

3.5

.138

100

3.937

80

3.150

120

4.724

M6 3

.118

*

5.690d

145

5.690

168d

116

4.510

130

5.880d

152

6

162d

.844d

22

.880

21d

184

182T

184T

4-1/2 3-3/4 5-1/2

4-1/2

5-1/2

13/32 2-11/16

3-9/16

3-9/16

8-11/16 7-7/8 7/8

1-1/8

1-1/8

2-1/4

2-3/4

2-3/4

3/4 5-7/8 2-1/8

2-5/8

2-5/8

5-7/8

7-1/4

7-1/4

4-1/2

8-1/2

8-1/2

2-3/4 1/8

1/4

1/4

6-1/2

9

9

2-3/8 3/8-16

1/2-13

1/2-13

U

90 S 140

100

3.937 56 90 24 50 13 165 130 200 12 3.5 115 95 140 M8 3 *

6.614d

168

6.614

5.120

130

5.120

6.380d

173

6.810

.844d

22

.880

213

215

213T

5-1/4 4-1/4

5-1/2

7

5-1/2

13/32

3-1/2

3-1/2

3-7/8

10-1/4 9-9/16

1-1/8

1-1/8

1-3/8

3

3

3-3/8

3/4 7-3/8

2-3/4

2-3/4

3-1/8

7-1/4 8-1/2 3-1/2 1/4 9 2-3/4 1/2-13 C

T

L 5.511 125 2.205 3.543 .945 1.969 .500 6.496 5.118 7.874 .472 .138 4.530 3.740 5.512 .118 144d 107d 165d 21d 215T 7 3-7/8 1-3/8 3-3/8 3-1/8

4.921 5.687d 4.250d 6.531d .844d

254U 8-1/4 4-1/16 1-3/8 3-3/4 3-1/2

112 149 180

100 S 160 4.409 63 100 28 60 14 215 180 250 14 4 130 110 160 M8 3.5 * 200 5.875 7.906 27 256U 6-1/4 5 10 17/32 4-1/16 12-7/8 12-15/16 1-3/8 3-3/4 1 9-5/8 3-1/2 7-1/4 8-1/2 4-1/4 1/4 10 — 1/2-13

L 6.300 140 2.480 3.937 1.102 2.362 .562 8.465 7.087 9.840 .560 .160 5.108 4.331 6.299 .138 7.875 153d 239d 1.062 254T 8-1/4 4-5/16 1-5/8 4 3-3/4

5.512 6.060d 9.440d 256T 10 4-5/16 1-5/8 4 3-3/4

114 284U 9-1/2 5-1/8 1-5/8 4-7/8 4-5/8

112 S 190 4.488 70 112 28 60 14 215 180 250 14 4 130 110 160 M8 3.5 * 243 149 214 27 286U 11 5-1/8 1-5/8 4-7/8 4-5/8

M 7.480 140

5.512

140

2.760 4.409 1.102 2.362 .562 8.465 7.087 9.840 .560 .160 5.108 4.331 6.299 .138 7.875 5.875 8.437 1.062 284T

286T

284TS

7 5-1/2 9-1/2

11

9-1/2

17/32 4-7/8

4-7/8

3-3/8

14-5/8 14-5/8 1-7/8

1-7/8

1-5/8

4-5/8

4-5/8

3-1/4

1-1/2 13-1/8 4-3/8

4-3/8

3

9 10-1/2 4-3/4 1/4 11-1/4 — 1/2-13

C

A

132 S 216 5.512 89 132 38 80 14 265 230 300 14 4 165 130 200 M8 3.5 * 243 187 256 27

M 8.504 178 3.504 5.197 1.496 3.150 .562 10.433 9.055 11.811 .560 .160 6.496 5.118 7.874 .138 9.562 7.375 10.062 1.062 286TS 11 3-3/8 1-5/8 3-1/4 3

7.008 324U 10-1/2 5-7/8 1-7/8 5-5/8 5-3/8

210 326U 12 5-7/8 1-7/8 5-5/8 5-3/8

160 M

L

254

10

8.268

254

10

241

108

4.252

160

6.299

42

1.654

110

4.331

20

.787

300

11.811

250

9.842

350

13.780

19

.748

5

.200

215

8.465

180

7.087

250

9.840

M12 4

.160

* 329

12.940

242

9.510

329

12.940

35

1.375

324T

326T

324TS

8 6-1/4 10-1/2

12

10-1/2

21/32 5-1/2

5-1/2

3-15/16

16-1/2 16-1/2 2-1/8

2-1/8

1-7/8

5-1/4

5-1/4

3-3/4

2 14-1/8 5

5

3-1/2

11 12-1/2 5-1/4 1/4 13-3/8 — 5/8-11

T

A

326TS 12 3-15/16 1-7/8 3-3/4 3-1/2

180 M 279 9.488 121 180 48 110 20 300 250 350 19 5 * 395 333 372 51

L 10.984 279 4.764 7.087 1.890 4.331 .787 11.811 9.842 13.780 .748 .200 15.560 13.120 14.640 2.008 364U 11-1/4 6-3/4 2-1/8 6-3/8 6-1/8

10.984 365U 12-1/4 6-3/4 2-1/8 6-3/8 6-1/8

364T 9 7 11-1/4 21/32 6-1/4 18-1/2 18-1/4 2-3/8 5-7/8 2-1/2 15-1/16 5-5/8 11 12-1/2 5-7/8 1/4 13-3/8 — 5/8-11

L

267

200 L 318 10.512 133 200 55 110 27 350 300 400 19 5 * 441 359 416 63 365T 12-1/4 6-1/4 2-3/8 5-7/8 5-5/8

M 12.520 305 5.236 7.874 2.165 4.331 1.062 13.780 11.811 15.748 .748 .200 17.375 14.125 16.375 2.500 364TS 11-1/4 4 1-7/8 3-3/4 3-1/2

12.008 365TS 12-1/4 4 1-7/8 3-3/4 3-1/2

225 S

M

356

14.016

286

11.260

311

12.244

149

5.866

225

8.858

60

2.362

140

5.512

19

.748

400

15.748

350

13.780

450

17.716

19

.748

6

.236

* 495

19.488

383

15.079

483

19.016

63

2.500

404U

405U

404T 10 8

12-1/4

13-3/4

12-1/4 13/16

7-3/16

7-3/16

7-5/16 20-5/16 20-1/8

2-3/8

2-3/8

2-7/8

7-1/8

7-1/8

7-1/4 3 18

6-7/8

6-7/8

7 11 12-1/2 6-5/8 1/4 13-7/8 — 5/8-11

O

250 S

M

406

15.984

311

12.244

349

13.740

168

6.614

250

9.843

70

2.756

140

5.512

* 520

20.472

457

17.992

513

20.197

63

2.500

405T

404TS

405TS

13-3/4

12-1/4

13-3/4

7-5/16

4-1/2

4-1/2

2-7/8

2-1/8

2-1/8

7-1/4

4-1/4

4-1/4

7

4

4

G

444U 14-1/2 8-5/8 22-7/8 22-3/8 2-7/8 8-5/8 19-9/16 8-3/8

280 S 457

368

14.488 190 280 80 170 LEGEND * 616 497 581 63

445U

444T

16-1/2

14-1/2

8-5/8

8-1/2

22-7/8

22-7/8

22-3/8

22-3/8

2-7/8

3-3/8

8-5/8

8-1/2

19-9/16

19-9/16

8-3/8

8-1/4

M 17.992 419 7.485 11.025 3.150 6.693 24.252 19.567 22.874 2.500

16.496 Metric (MM) Dimensions in Black 445T 16-1/2 8-1/2 22-7/8 22-3/8 3-3/8 8-1/2 19-9/16 8-1/4

Inch Dimensions in Red 447T 11 9 20 13/16 8-15/16 22-15/16 23-3/4 3-3/8 8-1/2 3 21-11/16 8-1/4 14 16 7-1/2 1/4 16-3/4 — 5/8-11

406

315 S 508 16 216 315 85 170 * 759 683 682 102 449T 25 8-15/16 22-15/16 23-3/4 3-3/8 8-1/2 21-11/16 8-1/4

M 20 457 8.500 12.400 3.346 6.693

d = DC Motors 29.900 26.880 26.840 4 444TS 14-1/2 5-3/16 22-7/8 22-3/8 2-3/8 4-3/4 19-9/16 4-1/2

18 1 mm = .03937" 1" = 25.40 mm 445TS 16-1/2 5-3/16 22-7/8 22-3/8 2-3/8 4-3/4 19-9/16 4-1/2

500 447TS 20 4-15/16 22-15/16 23-3/4 2-3/8 4-3/4 4NPT 21-11/16 4-1/2

355 S 610 19.690 254 355 85 170 * 759 683 719 102 449TS 25 4-15/16 22-15/16 23-3/4 2-3/8 4-3/4 4NPT 21-11/16 4-1/2

L 24 630 10 13.980 3.346 6.693 29.900 26.880 28.320 4

24.800

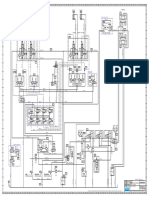

Horizontal Shaft Arrangements

IP Protection - Baldor Enclosures SUMMARY OF IP PROTECTION NUMBERS 5000 NEMA C-Face BA Dimensions

Frame D

NEMA FRAMES PRIOR TO 1953

E F N U V BA

2005

First # Second #

IP22 = Open Drip Proof Protection Against Solid Objects Protection Against Liquids FRAME D E 2F H O P U V AA AB BA 143-5TC 2-3/4 66 4-1/8 2-15/16 2-1/2 2-1/4 3/4 2-1/4 3-1/8

203 5 4 2-3/4 2-7/16 3/4 2 3-1/8

AC or DC Motors. IP TESTS O NO PROTECTION 182-4TC 3-1/2 204 3-1/4

B3 B5 B6 B7 B8 B14 B17

FOOT MOUNTED. "D" TYPE FLANGE AT FOOT WALL MOUNT WITH FOOT WALL MOUNT WITH CEILING MOUNTED WITH "C" TYPE FACE AT DRIVE 2 "C" OR "D" TYPE IP54 = All standard TEFC O NO PROTECTION 1 Protection against vertical drops of water. 224 5-1/2 4-1/2 3-3/8 3-1/4 1 3 3-1/2

DRIVE END, NO FEET. FEET ON LEFT HAND SIDE FEET ON RIGHT HAND FEET ABOVE MOTOR. END, NO FEET. FLANGES, FOOT 1 Protection against solid objects up to (E.G. Condensation.) 5007S 12-1/2 10 22 15/16 26-27/32 30 2-1/2 6-1/2 4-NPT 26-7/8 8-1/2 213-5TC 4-1/4 225 3-3/4

WHEN VIEWED FROM SIDE WHEN VIEWED MOUNTED. AC and DC Motors. 50 mm. (E.G. Accidental touch by hands.) 2 Protection against falling water up to

DRIVE END. FROM DRIVE END. 5007L 12-1/2 10 22 15/16 26-27/32 30 3-7/8 11-1/8 4-NPT 26-7/8 8-1/2 254-6TC 4-3/4 254 6-1/4 5 4-1/8 3-7/16 1-1/8 3-3/8 4-1/4

IP55 = All TEFC Chemical 2 Protection against solid objects up to 15 degrees from the vertical. 284 7 5-1/2 4-3/4 4-1/4 1-1/4 3-3/4 4-3/4

Vertical Shaft Arrangements Processing, Dirty Duty, and 12 mm. (E.G. Fingers) 3 Protection against falling water up to 324 8 6-1/4 5-1/4 5-3/8 1-5/8 4-7/8 5-1/4

3 Protection against solid objects over 60 degrees from the vertical. 5009S 12-1/2 10 28 15/16 26-27/32 30 2-1/2 6-1/2 4-NPT 26-7/8 8-1/2 326 6

Washdown Duty Motors 2.5 mm. (E.G. Tools,Wires) 4 Protection against splashing water from all 364 9 7 5-5/8 5-5/8 1-78/8 5-3/8 5-7/8

4 Protection against solid objects over directions, limited ingress. 5009L 12-1/2 10 28 15/16 26-27/32 30 3-7/8 11-1/8 4-NPT 26-7/8 8-1/2 365 6-1/8

1 mm. (E.G. Tools, Wires, and Small 5 Protection against low pressure jets of 404 10 8 6-1/8 6-3/8 2-1/8 6-1/8 6-5/8

BALDOR ELECTRIC COMPANY Wires) water from all directions, limited ingress. BALDOR ELECTRIC COMPANY 405 6-7/8

V1 V3 V5 V6 V18 V19 V22 P.O. BOX 2400 5 Protection against dust - limited ingress 6 Protection against strong jets of water. 5011S 12-1/2 10 36 15/16 26-27/32 30 2-1/2 6-1/2 4-NPT 26-7/8 8-1/2 P.O. BOX 2400 444 11 9 7-1/4 7-1/8 2-3/8 6-7/8 7-1/2

"D" TYPE FLANGE AT "D" TYPE FLANGE AT VERTICAL FOOT, WALL VERTICAL FOOT, WALL "C" TYPE FACE AT "C" TYPE FACE AT SKIRT MOUNTING, (No harmful deposits) (E.G. Use on ship decks, limited ingress.) 445 8-1/4

DRIVE END , SHAFT DRIVE END, SHAFT UP, MOUNTED, SHAFT MOUNTED, SHAFT UP DRIVE END, SHAFT DRIVE END, SHAFT UP, SHAFT DOWN, NO FEET. FORT SMITH, ARKANSAS 6 Totally protected against all dust. 7 Protection against immersion. 5011L 12-1/2 10 36 15/16 26-27/32 30 3-7/8 11-1/8 4-NPT 26-7/8 8-1/2 FORT SMITH, ARKANSAS

DOWN, NO FEET. NO FEET. DOWN. DOWN, NO FEET NO FEET.

504 12-1/2 10 8 8-5/8 2-7/8 8-3/8 8-1/2

72902-2400 U.S.A. 8 Protection against submersion. 72902-2400 U.S.A. 505 9

You might also like

- Eep 000097 0102148005 3 ST Det 0682 R02Document1 pageEep 000097 0102148005 3 ST Det 0682 R02Vikram DalalNo ratings yet

- Poster g4 Druck Englisch 0718Document1 pagePoster g4 Druck Englisch 0718Dardo GoyaNo ratings yet

- Dig 525 (061017)Document19 pagesDig 525 (061017)Bernard MendisNo ratings yet

- Current Revision Approved: Base Unit Hydraulics, 68H/SbsDocument2 pagesCurrent Revision Approved: Base Unit Hydraulics, 68H/Sbscapslive_001No ratings yet

- FX5-30 DimensionDocument1 pageFX5-30 DimensionHugo José Abreu de SouzaNo ratings yet

- 797F - Kenr8379-02Document6 pages797F - Kenr8379-02Marco Antonio Pampa CondoriNo ratings yet

- Gde01 03 029 BDocument1 pageGde01 03 029 Bluca.laniNo ratings yet

- MH 101Document1 pageMH 101Aslam YaseenNo ratings yet

- MP 101Document1 pageMP 101Aslam YaseenNo ratings yet

- Bucket Tilt Boom Lift Steering SAHR Brakes: Ejector (Option)Document1 pageBucket Tilt Boom Lift Steering SAHR Brakes: Ejector (Option)J Carrizales MoreyraNo ratings yet

- Hayabusa Colored Wiring DiagramDocument1 pageHayabusa Colored Wiring DiagramEder NH PereiraNo ratings yet

- Engine Performance Caterpillar C-15 Bxs1Document3 pagesEngine Performance Caterpillar C-15 Bxs1Andy Chalifoux50% (2)

- Tata Steel Limited: Section B - B Section C - CDocument1 pageTata Steel Limited: Section B - B Section C - CTamil Arasu SNo ratings yet

- H047&H048-CMS-SD-04-12-2 - Cctv-General Position - As Built DrawingDocument1 pageH047&H048-CMS-SD-04-12-2 - Cctv-General Position - As Built DrawingDedeNazaludinNo ratings yet

- JFN01 05 033 ADocument1 pageJFN01 05 033 Aluca.laniNo ratings yet

- How To Create Fabrication DrawingDocument1 pageHow To Create Fabrication DrawingSubhankar samantaNo ratings yet

- Schematic - Ab Fullbridge - 2023-06-02Document1 pageSchematic - Ab Fullbridge - 2023-06-02kdcelectric berauNo ratings yet

- E19 - E5 - E18 - E11 - E10 - E9 - E8 - E16 - E12 - E30: StromlaufplanDocument1 pageE19 - E5 - E18 - E11 - E10 - E9 - E8 - E16 - E12 - E30: StromlaufplanAlex RobledoNo ratings yet

- JFN01 05 032 C.Document1 pageJFN01 05 032 C.luca.laniNo ratings yet

- Layout Plan 132kV SubstationDocument1 pageLayout Plan 132kV SubstationShuhan Mohammad Ariful Hoque0% (1)

- 2 Ou T of 3 Tes Table S Afety Valve Bloc K: Steam T U RbineDocument5 pages2 Ou T of 3 Tes Table S Afety Valve Bloc K: Steam T U RbineRafa NisaNo ratings yet

- Stainless Steel Rollup DoorDocument2 pagesStainless Steel Rollup Doorتوان امتياس سامسدينNo ratings yet

- SunRays Panel PlacementDocument1 pageSunRays Panel Placementjhon smithNo ratings yet

- COPIER (B264/B265) Point To Point Diagram: Bicu PCB 1Document14 pagesCOPIER (B264/B265) Point To Point Diagram: Bicu PCB 1josdavisNo ratings yet

- Power Source ECT and A/T Indicator (From Aug. 2006 Production) ECT and A/T Indicator (From Aug. 2006 Production)Document1 pagePower Source ECT and A/T Indicator (From Aug. 2006 Production) ECT and A/T Indicator (From Aug. 2006 Production)Ardina Praja MartantoNo ratings yet

- Power Source ECT and A/T Indicator (From Aug. 2006 Production) ECT and A/T Indicator (From Aug. 2006 Production)Document1 pagePower Source ECT and A/T Indicator (From Aug. 2006 Production) ECT and A/T Indicator (From Aug. 2006 Production)Alha Ega AnadaNo ratings yet

- TJ356BD5LDocument16 pagesTJ356BD5LMehdi HassouneNo ratings yet

- Electrical System C9 Industrial Engine: Top ViewDocument4 pagesElectrical System C9 Industrial Engine: Top ViewReyes VargasNo ratings yet

- R410A Non-Inverter Outdoor Unit SpecDocument3 pagesR410A Non-Inverter Outdoor Unit SpechuntsecondlifeNo ratings yet

- 793D Off-Highway Truck Hydraulic System PDFDocument2 pages793D Off-Highway Truck Hydraulic System PDFHéctorHernándezDíazNo ratings yet

- For Construction: 2 No Beam Required As Drawn MKD ' L0R0011Be109PDocument1 pageFor Construction: 2 No Beam Required As Drawn MKD ' L0R0011Be109PrajendraNo ratings yet

- Projet PompesDocument44 pagesProjet Pompesrocceli nzoulouNo ratings yet

- E-F03. Plano Fundaciones (CABEZAL C4, C7 Y TABIQUE)Document1 pageE-F03. Plano Fundaciones (CABEZAL C4, C7 Y TABIQUE)Nicolas FernandezNo ratings yet

- RTPP CHP WT CVL 003 R1Document2 pagesRTPP CHP WT CVL 003 R1Sripara KrishnaNo ratings yet

- Section A-A Section B-B Section C-C: Table Ii - Option Suffixes Available For This E.DDocument1 pageSection A-A Section B-B Section C-C: Table Ii - Option Suffixes Available For This E.DEduardo ZamoranoNo ratings yet

- Good For Construction: Approval by NCRTC QR CodeDocument1 pageGood For Construction: Approval by NCRTC QR CodeZaid HussainNo ratings yet

- Pre Tsa 420Document1 pagePre Tsa 420Antonio Fernandes de JesusNo ratings yet

- 4873 501 630 33 - RotatedDocument1 page4873 501 630 33 - RotatedBerat DeğirmenciNo ratings yet

- Bucket Elevator: Feed and BiofuelDocument4 pagesBucket Elevator: Feed and BiofuelOcta IrawanNo ratings yet

- Scamec 2000 S 100129425 #FB214 Grease SystemDocument23 pagesScamec 2000 S 100129425 #FB214 Grease SystemIvan Andres Seguel BristiloNo ratings yet

- R2 Circuit DiagramDocument6 pagesR2 Circuit DiagramSubhasish ChakrabartyNo ratings yet

- RF24FSEDBSR AA Samsung Refrigerator Service ManualSDocument1 pageRF24FSEDBSR AA Samsung Refrigerator Service ManualSLynn BoydNo ratings yet

- CNN008311 Diagrams and DrawingsDocument40 pagesCNN008311 Diagrams and DrawingsandraNo ratings yet

- SD 1694975328338Document1 pageSD 1694975328338dubai eyeNo ratings yet

- Rotor GA DrawingDocument1 pageRotor GA DrawingcelonevesNo ratings yet

- MS-AJ1 MS-AJ2: Universal Sensor Mounting StandDocument2 pagesMS-AJ1 MS-AJ2: Universal Sensor Mounting StandAjay MayalNo ratings yet

- Charger E.12.9002600-02 (SCH) (V1.0.1)Document4 pagesCharger E.12.9002600-02 (SCH) (V1.0.1)Rodrigo FernandezNo ratings yet

- 01.take MeDocument41 pages01.take MejuaniscopelNo ratings yet

- Note Generale: Key NotesDocument1 pageNote Generale: Key NotesPablo BenedettoNo ratings yet

- 0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Document1 page0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Rizwan AhmadNo ratings yet

- Drawing Harmonic FilterDocument1 pageDrawing Harmonic Filtercr4ck3rjackNo ratings yet

- JFN01 05 027 CDocument1 pageJFN01 05 027 Cluca.laniNo ratings yet

- Estructura Losas 02Document1 pageEstructura Losas 02JULIO CESARNo ratings yet

- Dremel Accessories OverviewDocument1 pageDremel Accessories OverviewcoldfireNo ratings yet

- 7 5 Central Lubrication SystemDocument15 pages7 5 Central Lubrication Systemalexis aguirre espejoNo ratings yet

- Ewan Engineering Consultancy: Extr. 4 CM Heat InsulationDocument1 pageEwan Engineering Consultancy: Extr. 4 CM Heat InsulationAbid AyubNo ratings yet

- Lax02 05 120 Pi BDocument1 pageLax02 05 120 Pi Bluca.laniNo ratings yet

- Tolerances Except As Noted: Job# Ustom Ngineering &Document1 pageTolerances Except As Noted: Job# Ustom Ngineering &Anbazhagan AnnaduraiNo ratings yet

- 24 MP 0202.03 MP0202.03Document1 page24 MP 0202.03 MP0202.03ISH-QUENo ratings yet

- Manual Book Dryer HRD350 PDFDocument112 pagesManual Book Dryer HRD350 PDFGoswandi0% (1)

- Ecu Remap and Why DRD DIESEL TUTORIALDocument13 pagesEcu Remap and Why DRD DIESEL TUTORIALPetrus Van Schalkwyk100% (1)

- Cromax 42CrMo4 4140Document3 pagesCromax 42CrMo4 4140Iñigo Fernandez de LabastidaNo ratings yet

- LSL Beam and HeaderDocument36 pagesLSL Beam and HeadersteveNo ratings yet

- Lpile Group ModuleDocument2 pagesLpile Group ModuleMUHAMMAD ALINo ratings yet

- Antalia HeaterDocument1 pageAntalia HeaterDaniel MocanuNo ratings yet

- Stepped Columns - A Simplified Design MethodDocument23 pagesStepped Columns - A Simplified Design MethodwrayroNo ratings yet

- Electric Motor EE ST and L - EEA Comment Attended 22 July 2015Document193 pagesElectric Motor EE ST and L - EEA Comment Attended 22 July 2015gomeraNo ratings yet

- 3 - Miedema - Drag Embedded Anchor Holding CapacityDocument30 pages3 - Miedema - Drag Embedded Anchor Holding Capacitycxb07164100% (1)

- An Infinite Row of Collinear Cracks in An Infinite Elastic SheetDocument5 pagesAn Infinite Row of Collinear Cracks in An Infinite Elastic SheetXI CHENNo ratings yet

- Welder Qualification PDFDocument7 pagesWelder Qualification PDFnarutothunderjet216No ratings yet

- Thermal PhysicsDocument6 pagesThermal PhysicsDebojitNo ratings yet

- 2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeDocument13 pages2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeGonzalo MazaNo ratings yet

- MechanicalDocument2 pagesMechanicalHalar MaymonNo ratings yet

- Camel Intro 2Document34 pagesCamel Intro 2Inventor SolidworksNo ratings yet

- RR320306 HeattransferDocument8 pagesRR320306 HeattransferAnil Frivolous AbstemiousNo ratings yet

- Boom / Bucket HydraulicsDocument30 pagesBoom / Bucket HydraulicsEdgarNo ratings yet

- DRG PDFDocument4 pagesDRG PDFMustafa MowfakNo ratings yet

- Limited and Float InstallationDocument2 pagesLimited and Float InstallationGoran PetrovicNo ratings yet

- Tensile & Elongation PVC Compound VC 8500 BKR VC 8751 BKI VC 8751 GRI - 15102019Document1 pageTensile & Elongation PVC Compound VC 8500 BKR VC 8751 BKI VC 8751 GRI - 15102019Vinh DuongvanNo ratings yet

- 04 NAC Initial Transverse Stability (160213)Document21 pages04 NAC Initial Transverse Stability (160213)Gilles MathieuNo ratings yet

- Split Body Trunnion: Full Bore Ends AvailableDocument20 pagesSplit Body Trunnion: Full Bore Ends AvailableHùng DươngNo ratings yet

- Blast Valve PV-KK-WDocument2 pagesBlast Valve PV-KK-WyousufbashaNo ratings yet

- 1422 Chapt 15 ThermodynamicsDocument40 pages1422 Chapt 15 Thermodynamicstomm01No ratings yet

- SLD Magic 2Document12 pagesSLD Magic 2Deny Arisandi DarisandNo ratings yet

- Ip060-45!20!02 Orifice Plate Assembly (Buyer's Scope)Document5 pagesIp060-45!20!02 Orifice Plate Assembly (Buyer's Scope)Rahul DevaNo ratings yet

- Bag Making Machine: Reduce Design Time and Improve Performance For Bag Making ManufacturersDocument27 pagesBag Making Machine: Reduce Design Time and Improve Performance For Bag Making Manufacturershorse0678No ratings yet

- KC FLT 8809008 enDocument24 pagesKC FLT 8809008 enAnonymous l05hkK4yUV50% (4)

- Form QT4 (B)Document2 pagesForm QT4 (B)Bonaventure NzeyimanaNo ratings yet