Professional Documents

Culture Documents

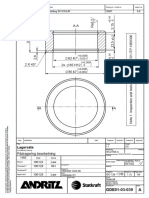

JFN01 05 032 C.

Uploaded by

luca.laniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JFN01 05 032 C.

Uploaded by

luca.laniCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Antal Det. Nr. Benämning Ritnings nr/Artikel nr Vikt/st

( ⌀ 937 )

No of Item No Description Drawing no/Article no Weight/pc

⌀ 833±0,1 3,2 110 2 1 Lagerhus svetsning No.4 JFN01-05-033 933

83

15

A A

35 4x G 1" 8 2 Skruv M6S 36x140 obh 8.8 ISO4014 10690 2

( ⌀ 1380 )

⌀ 842 4x ⌀ 55 4 3 Passkruv M36x38k6x140 obh8.8 DIN610 33919 -

34x ⌀ 60

50

Planas minsta möjliga. 2x 12 4 Mutter M6M 36 obh-8 ISO4032 10513 -

⌀ 40

195-0,1

Minimum machining.

0

34x ⌀ 26 2x 20 5 Bricka BRB 37x66x5 obh DIN125A 10514 -

C M2

B 2x 0

21,5° ⌀ 18 x 1,5 4 6 Bricka BRB 37x60x4 obh DIN125A 33921

,5 2 7 H-rör Ø18/14 S355J2H L=235 B 33948

8

2x

B +0,14 3,2 7 B

⌀ 827H8�-0 � B

15

A

⌀ 1190±0,5 I-I (1:5) a2

⟂ 0.05 A

16x M 10

⌖ ⌀0.5

261

870±0,1

3,2

�3�

924-0,5

0

930

25

C C

30

3x M 6

Borrdjupp // Drill depth - 15

65

Får ej genomborras! Gängdjupp // Thread depth - 20

Not allowed to drill thru!

Plan hålbotten 3,2

Botton of the hole to be planed G (1:2)

P P UNF-2B 1/4-28

⌀ 42 Borrdjupp // Drill depth - 7

D Gängdjupp // Thread depth - 6 D

4x ⌀ 20 ⌀ 57

Planas minsta möjliga //

Minimum machining

3,2

30

25

R 0,8 5° C

14x M 10

3,2 ⌖ ⌀0.5

E 33° 33° ( ⌀ 807 ) B E

6

+0,14

⌀ 840H8�-0 � B-B (1:5) D H-H (1:2)

A-A (1:5)

24x M 12

15 D (1:2)

° 35

⌀ 0

1100-0,5 C-C (1:5)

30 C

2 4 5 Not.2 // Note 2

140 44 3 4 5

Planas minsta möjliga 20x ⌀ 70 G

33°

Minimum machining Not.2 // Note 2

R

5°

7,5° 8x ⌀ 39

25

F +0,025 4x avlastning hål ⌀ 1030 ⌀ 875 F

2x ⌀ 38H7�-0 � 4x stress relief hole

33°

R

4x

C ⌀ 885

C

30

°

R-R (1:5)

33°

235

4x ( ⌀ 20 )

5

55,

90°

22,5

G G

°

5

55,

,5°

16

50°

A C

33

7,5°

Bottom view // Botten vy

180

°

I

7,5°

Not.4

C

B B

P-P (1:10) B C Ø1100 uppdaterad. Hål Ø26 var Ø24. 24 st M12 tilagd.

Toppvy uppdaterad sekction P-P och R-R tillagd.

80°

H I H

10 I Note.

°

180

Ø1100 updated. Hole Ø26 was Ø24. 24 st M12 added.

B B 3 4 5 Not.2 // Note 2

16X

Top view updated, section P-P och R-R added.

+0,025 Not.3

2x ⌀ 38H7�-0 �

°

10°

10

I 2x M52x4 hål tas bort, pos.7 var L=250. Djupp 6, 15 gänglängd tillagd,

50°

16,5°

Note 3

E E 1 2x M52 hole deleted, item no. L=250. Depth 6, 15 thread length added.

185

10°

J Not.2 Åtdragningsmoment 1784Nm J

3,2 3,2

Molykote 1000 penslas på gänga och under skruvskalle.

Note.2 Torque 1784 Nm

3,2 Apply Molykote 1000 on the thread and under the screws head.

3,2

11,25°

C Not.1 Bearbetas efter uppmätning av befintliga detaljer.

4x ⌀ 64 Planas minsta möjliga

15°

Minimum machining 2 4 6 Not.2 // Note 2 Note 1 Machining after taking measurment of excisting details.

F

44°

F

60

Kontroller enligt JFN01-ITP-1806200 eller högre

I

°

E-E (1:5) F-F (1:5) Controlls according to JFN01-1806200 or higher

K C K

6x

Date 12.09.2019 12.09.2019 12.09.2019

C Enligt not.4 // According to note.4

to others without express authorization is prohibited. Offenders will be held liable for the payment of damages.

Name nalmic01 nalhak02 nalpet05

22,5

The reproduction, distribution and utilization of this document as well as the communication of its contents

C I Index Modification ARC N° Prepared Checked T Checked P Approved

I

°

90° ⌀ 1280 8x ⌀ 20 Bill of Material

C H Hål för GKP

Hole for conical threaded pin

Dimension -Approved-

C WBS N° / Prod. 15-512 | GUIDE BEARING HOUSING | FV Type

H ⌀ 1140 GUIDE BEARING HOUSING Scale

All rights reserved in the event of the grant of a patent, utility model or design.

I

Guide bearing machining No.4 1:10 1:2; 1:5

L Weight Material L

Statkraft STYRLAGERHUS

Lagerhus bearbetning No.4 1891.4 kg

Customer Drawing N°

°

50

HSE Date Name Client

3x

2132-1559 Drawn 13.12.2018 nalmic01 Plant

Refer

to protection notice

ISO 16016 ISO 128

A Surface Finish 6,3 Broken Edges 1x45°

Surface

acc. ISO 1302:2002

Ra

General tolerances for length and

Checked T 24.01.2019 naljoa01 Project N° EUROPE

Ytjämnhet Checked P Contract N° Similar

C Acceptable deviations for non-toleranced machined surfaces

Ra in µm angle measurements acc. to

DIN ISO 2768 part 1 class M Approved 24.01.2019 nalpet05 Replace

1) 1) Item ID

from 0.5 3 6 30 120 400 1000 2000 4000 8000 12000 16000

1) 1) 1)

M

to 3 6 30 120 400 1000 2000 4000 8000 12000 16000 20000 General tolerances for form and position

acc.to DIN ISO 2768 part 2 class K 900469022 M

"Copyright reserved"

Tolerance 0.1 0.1 0.2 0.3 0.5 0.8 1.2 2 3 4 5 6

Local ID Index

General tolerances for welding design

Sheet 1

Top view // Toppvy

1) For nominal dimensions < 0.5 and > 4000, the limit sizes are not specified in DIN ISO 2768 part 1. acc. to ISO 13920 class BF JFN01-05-032 C of 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 A1

You might also like

- JFN01 05 033 ADocument1 pageJFN01 05 033 Aluca.laniNo ratings yet

- JFN01 05 027 CDocument1 pageJFN01 05 027 Cluca.laniNo ratings yet

- Lax02 05 120 DDocument1 pageLax02 05 120 Dluca.laniNo ratings yet

- Lax02 05 120 Pi BDocument1 pageLax02 05 120 Pi Bluca.laniNo ratings yet

- Gde01 03 029 BDocument1 pageGde01 03 029 Bluca.laniNo ratings yet

- A Detail: Piping Isometric BuildingDocument1 pageA Detail: Piping Isometric BuildingMohd Effiezool YaserNo ratings yet

- Eep 000097 0102148005 3 ST Det 0669 R02Document1 pageEep 000097 0102148005 3 ST Det 0669 R02Vikram DalalNo ratings yet

- 30lae25br004-Rev 2Document1 page30lae25br004-Rev 2Mohd Effiezool YaserNo ratings yet

- 10lab12br001-Rev 1 - 2Document1 page10lab12br001-Rev 1 - 2Mohd Effiezool YaserNo ratings yet

- Nomenclature:: - 31710MM - 31710MMDocument1 pageNomenclature:: - 31710MM - 31710MMjoselito navarroNo ratings yet

- Scubber Seal Tank (6a25-T12) 12kl-MasterDocument2 pagesScubber Seal Tank (6a25-T12) 12kl-MasterJayan VKNo ratings yet

- 30lbe51br302 - Rev 0Document1 page30lbe51br302 - Rev 0Mohd Effiezool YaserNo ratings yet

- 30LBF11BR411 - 2Document1 page30LBF11BR411 - 2Mohd Effiezool YaserNo ratings yet

- Lax02 05 116 BDocument1 pageLax02 05 116 Bluca.laniNo ratings yet

- Planilla de Aceros: Proyecto: Conjunto Residencial SantoriniDocument1 pagePlanilla de Aceros: Proyecto: Conjunto Residencial SantoriniMesias CheNo ratings yet

- Eep000094 01021480065 2 ST Det 0211Document1 pageEep000094 01021480065 2 ST Det 0211Vikram DalalNo ratings yet

- 10lab12br001-Rev 1 - 1Document1 page10lab12br001-Rev 1 - 1Mohd Effiezool YaserNo ratings yet

- 30lbf11br001-Rev 2Document1 page30lbf11br001-Rev 2Mohd Effiezool YaserNo ratings yet

- Iso 20lae05aa101Document1 pageIso 20lae05aa101Mohd Effiezool YaserNo ratings yet

- 30lbe51br301 - Rev 0Document1 page30lbe51br301 - Rev 0Mohd Effiezool YaserNo ratings yet

- How To Create Fabrication DrawingDocument1 pageHow To Create Fabrication DrawingSubhankar samantaNo ratings yet

- 30lbe51br303 - Rev 0Document1 page30lbe51br303 - Rev 0Mohd Effiezool YaserNo ratings yet

- Preliminar: Va A CCM Lavar de Unilever Reserva No Equipada para 630 ADocument1 pagePreliminar: Va A CCM Lavar de Unilever Reserva No Equipada para 630 AfracevNo ratings yet

- 1-ModelDocument1 page1-Modeljoselito navarroNo ratings yet

- Eep 000097 0102148005 3 ST Det 0702 R02Document1 pageEep 000097 0102148005 3 ST Det 0702 R02Vikram DalalNo ratings yet

- Plano General Ferrari ParkDocument1 pagePlano General Ferrari ParkJuan David Romero PinillaNo ratings yet

- Electrical 2528C.fmDocument1 pageElectrical 2528C.fmmayobanex moyaNo ratings yet

- De 22 36 DWG PF CH PL 01 FF 120 00Document1 pageDe 22 36 DWG PF CH PL 01 FF 120 00Mahmoud A. HafeezNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- JFN01 05 028 BDocument1 pageJFN01 05 028 Bluca.laniNo ratings yet

- TECHNICALPart 5Document1,521 pagesTECHNICALPart 5সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- 30lbe51br002-Rev 1Document1 page30lbe51br002-Rev 1Mohd Effiezool YaserNo ratings yet

- 7061581-STR-DWG-KRP-3090 (Sheet 3 of 3)Document1 page7061581-STR-DWG-KRP-3090 (Sheet 3 of 3)Sibtain AliNo ratings yet

- Eletrico - 2 Pranchas - 02Document1 pageEletrico - 2 Pranchas - 02Renan LimaNo ratings yet

- De 22 36 DWG PF CH PL 00 FF 110 00Document1 pageDe 22 36 DWG PF CH PL 00 FF 110 00Mahmoud A. HafeezNo ratings yet

- Existing - Earthing - Layout For Bogra 230kV SubstationDocument1 pageExisting - Earthing - Layout For Bogra 230kV SubstationRashad SarwarNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- Vieqa0102 02Document1 pageVieqa0102 02nayan sutharNo ratings yet

- SP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Document1 pageSP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Hector HernandezNo ratings yet

- Bose Companion 5 Io SCHDocument2 pagesBose Companion 5 Io SCHFrancisco SanchezNo ratings yet

- Eep 000097 0102148005 3 ST Det 0682 R02Document1 pageEep 000097 0102148005 3 ST Det 0682 R02Vikram DalalNo ratings yet

- 30lbe51br001-Rev 2 - 2Document1 page30lbe51br001-Rev 2 - 2Mohd Effiezool YaserNo ratings yet

- De 22 36 DWG HV CH PL0B 400 01Document1 pageDe 22 36 DWG HV CH PL0B 400 01Mahmoud A. HafeezNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 16Document1 pageEpcc05 MDR 421 STR DWG 000 0072 16RANJEET PRATAP SINGHNo ratings yet

- 0-ModelDocument1 page0-Modeljoselito navarroNo ratings yet

- PE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1Document1 pagePE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- 7 5 Central Lubrication SystemDocument15 pages7 5 Central Lubrication Systemalexis aguirre espejoNo ratings yet

- 500.00 A 301 Detail ParapetDocument1 page500.00 A 301 Detail ParapetFerry AnggriawanNo ratings yet

- Tek Pu066Document1 pageTek Pu066François LenchonNo ratings yet

- Bhatinda R 2 SLDDocument1 pageBhatinda R 2 SLDvineets058No ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 15Document1 pageEpcc05 MDR 421 STR DWG 000 0072 15RANJEET PRATAP SINGHNo ratings yet

- B01 TL104MDocument1 pageB01 TL104Malysamir.eetdNo ratings yet

- Tata Steel Limited: Section B - B Section C - CDocument1 pageTata Steel Limited: Section B - B Section C - CTamil Arasu SNo ratings yet

- C.LY70.SE.84.1-F2010/FPR001 01: Important Remark: - Pipe Class For Natural Gas Piping General D16FhDocument1 pageC.LY70.SE.84.1-F2010/FPR001 01: Important Remark: - Pipe Class For Natural Gas Piping General D16FhEngr. AtiqNo ratings yet

- Detail A: Shuqaiq 3 Independent Water ProjectDocument1 pageDetail A: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- 13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Document1 page13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Anonymous BZQOJwWIh6No ratings yet

- B01 TL101MDocument1 pageB01 TL101Malysamir.eetdNo ratings yet

- 13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Document1 page13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Anonymous BZQOJwWIh6No ratings yet

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- Gde01 03 036 ADocument1 pageGde01 03 036 Aluca.laniNo ratings yet

- Gde01 03 039 ADocument1 pageGde01 03 039 Aluca.laniNo ratings yet

- Gde01 03 032 ADocument1 pageGde01 03 032 Aluca.laniNo ratings yet

- Lax02 05 117 Pi BDocument1 pageLax02 05 117 Pi Bluca.laniNo ratings yet

- Lax02 05 118 ADocument1 pageLax02 05 118 Aluca.laniNo ratings yet

- SUIS ADFORS Technical Fabrics EN Avril 2020Document9 pagesSUIS ADFORS Technical Fabrics EN Avril 2020luca.laniNo ratings yet

- SDX Supplier LetterDocument3 pagesSDX Supplier Letterluca.laniNo ratings yet