Professional Documents

Culture Documents

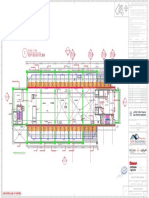

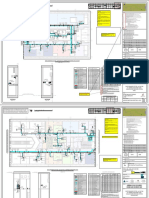

PE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1

Uploaded by

JOSUE FERNANDO FERNANDEZCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1

Uploaded by

JOSUE FERNANDO FERNANDEZCopyright:

Available Formats

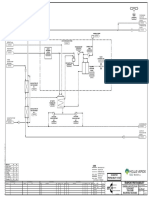

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

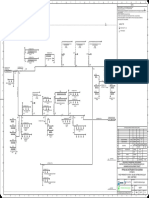

ERECTION MATERIALS

PT NPD WEIGHT

A 3 1/2" NO DESCRIPTION (IN) QTY (lbm) A

+X=+5191'-4 7/8"/ 9"

1 PIPING, S-STD, BE, A106-B, ASME-B36.10M 6 47.7' 904.8

N +Y=+5125'-7 1/8"/

F5 G11 B12/13/14 2 STANDARD SOCKOLET, CL 3000, BE / SWE, A105, MSS-SP97 6X1 1 0.7

3 3 90 DEG ELBOW LONG RADIUS (90. deg), S-STD, BE, A234-WPB, 6 2 45.0

ASME-B16.9

6"NPD 4 45 DEG ELBOW LONG RADIUS (45. deg), S-STD, A234-WPB, 6 1 11.3

ASME-B16.9

5 WELDING NECK FLANGE, CL150, RAISED FACE , S-STD, A105, 6 1 23.8

3'-5 13/16"

9" ASME-B16.5

B 6 BUTTERFLY VALVE LUGGED WITH LEVER OPERATOR, SEE VALVE

LIST, CL150

6 1 25.0 B

7 HOSE COUPLING 6 1 -

8 7/8"

PIPE SUPPORTS

CONN TO

8 Guide Radial (GR) 6 2 91.9

00GAD10BB001/N1_Water filling with internal standpipe

6 in RFFE 150 S-STD 9 Sliding Base (SB) 6 2 59.6

+X=+5192'-1 3/4"/ 8 7/8" 10 Sliding Base+Guide Horizontal (SB+GH) 6 1 29.8

C +Y=+5124'-10 1/4"/ TOTAL FABRICATION WEIGHT 1191.7 C

+Z=+135'-5 1/2" S8

00GAC10BQ005 ERECTION MATERIALS

GR

PT NPD WEIGHT

NO DESCRIPTION (IN) QTY (lbm)

11 FLAT RING GASKET, CL150, 0.079 inch Thick, Klingersil 6 1 -

C-4430, ASME-B16.21

12 STUD BOLT, A193-B7, HOT DIP GALVANIZED, LUBRICATED WITH 3/4 8 -

MOLYKOTE HSC PLUS, ASME B18.2.1 - 5.512 in. Length

13 HEX HEAD NUT, A194-2H HOT-DIP GALVANIZED, ANSI-B18.2.2 3/4 16 -

D D

17'-1 5/16"

14 PLAIN WASHER, CARBON STEEL - HOT DIP GALVANIZED, ASME 3/4 16 -

B18.22.1 - TYPE A

TOTAL ERECTION WEIGHT -

TP

23'-2 7/8"

-B

CL

IEN

T

E E

BO

P

4"

F S8 F

+X=+5186'-0"/ 00GAC10BQ004

+Y=+5147'-0"/

GR

+Z=+107'-6"

1

7

HOSE COUPLING

1 NOTES

6"N

PD 6 1. BUILDING FLOOR LEVEL = +106'-7"(+63.25M)

15

G '-4

1/4

STEM N 45 W 2. FINISHED GROUND LEVEL = +106'-1"(+63.10M) G

" 00GAC10AA001 3 1/2"

S10 3. COORDINATES ARE WITH RESPECT TO BENCH MARK

00GAC10BQ001 S9

2

2 3/16" * POINT P-3 (HAVING FOLLOWING CO-ORDINATES)

00GAC10BQ002

SB+GH

SB

6X1"NPD

3 1/2" X=5000'-00" CORRESPONDS TO (E=313492.878M)

9'- S9

ORIENT

DOWN 45.0 E 45.0 N

Y=5000'-00" CORRESPONDS TO (N=8618375.403M)

6"

00GAC10BQ003

2'-5 3/8" *

3 3/4" SB

9"

H 5'-11" 7 15/16" NOTE: H

Butt weld end connections shall be as per fig. 2A or 3A of ASME B16.25, based on the

2'- 3 3/4" wall thickness and the `B' dimension shall have a max. tolerance of +0.010"to -0.040".

6" 1

9" Y(Nortth)

DIMENSIONS MARKED * SHALL BE ADJUSTED BY +X=+5186'-0"/

4

22" REFER AXIS PLAN DRAWING NO.

45° PE1007-UC07-UZ-600003

CONTRACTOR BASED ON FINAL VALVE DRAWING +Y=+5131'-0"/ Z

X(East) FOR DETAILS REGARDING PLANT GRID

J 5'-

47 " 3 J

/8" 4 7/8 +Z=+107'-6" Summe Schweißnähte / Total numbers of welds:

5'-

Schweißplan Nr./ Welding procedure plan no:

Prüffolgeplan Nr./ Quality plan no:

Projekt/Project PKZ/PC

SANTO DOMINGO DE LOS OLLEROS PE1007

SEE ISO UNID DCC/UA Inhaltskennzeichen

485767948 XJ00

Contents code

00GAC10BR601

+X=+5190'-7"/ 00GAC10

K +Y=+5126'-9 3/16"/

Variante

Variant

Zähl-Nr.

Serial no. 446301 K

Ursprung-Nr. erstellt mit Abtlg. BR005

+Z=+107'-3 1/16" Origin no. Created with SP3D Dept. E F ES SPEL EN P3

Branch Orientation Legend

1 2013-05-22 MADHUR JEM GENERALLY REVISED

1. Orientation With Annotation in Isometric

2. Orientation Without Annotation in Isometric 0 2012-11-07 AJEESH JEM FIRST ISSUE

Annotion in Isometric: Index Datum bearb. geprüft

90° Angle Direction as per Isometric

80

Änderungshinweise/Details of revision

<Direction> <Angle> <Direction> Rev.

Gewicht

Date

Format

Coord.

Maßstab

Checked

Spez.

Weight Format Scale Specs.

a. Example for b. Example for Example Example Datum / Date Name / Name Titel/Title

L

Maße nicht abgreifbar / Not to scale

Vertical Lines: N 45.0 E Horizontal Lines: N 45.0 DOWN

NORTH 45

UP

NORTH UP

gezeich.

Drawn

bearb.

2012-11-07 AJEESH

2012-11-07 AJEESH

Piping Isometrics

° Coord.

geprüft

Checked 2012-11-07 JEM 00GAC10BR005

Isolierung 0 in

Copyright (C) Siemens 2012

All Rights Reserved

Building: 00UGF

Insulation

WEST EAST SOUTH NORTH WEST EAST SOUTH NORTH Handhabung

Standard ASME-B31.1-2010 Handling

Remarks Standard

45°

+Z Zeichnungs-Nr. Index/Rev.

Drawing no.

max. zul. Betriebstemp.

M +Y +X

- welds are fixed by contractor

FW= Field weld; SW= Shop weld

max. allow. work. temperature

115.00 F

PE1007-00GAC10-XJ00-446301 1

20

SOUTH DOWN SOUTH DOWN - Final dimensions of valves and In- Line max. zul. Betriebsüberdruck 150.00 psig Blatt-Nr.

max. allow. work. pressure Sheet no.

components to be checked by contractor

PLAN VIEW ELEVATION VIEW PLAN VIEW ELEVATION VIEW - all pipes without fitting length Prüfdruck

test pressure

225.00 psig 1 /1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

00GAC10BR005 Today's Date (Locale Sensitive format) : 5/22/2013 2:53:36 PMToday's Date (Your format) : 22/05/13Today's Date (ISO8601 Small) : 2013-05-22 14:53:36

You might also like

- Bhatinda R 2 SLDDocument1 pageBhatinda R 2 SLDvineets058No ratings yet

- Auditing Theory - Audit ReportDocument26 pagesAuditing Theory - Audit ReportCarina Espallardo-RelucioNo ratings yet

- 10083a 1X M6 Ab 00006 04Document1 page10083a 1X M6 Ab 00006 04wael zakariaNo ratings yet

- Vol 6 A Drawing Civil PortionDocument58 pagesVol 6 A Drawing Civil PortiondebapriyoNo ratings yet

- S-03710 P42118-Rev. 3-P18-Steam DrumDocument1 pageS-03710 P42118-Rev. 3-P18-Steam Drumwylie01No ratings yet

- HMSWeb - Handover Management SystemDocument21 pagesHMSWeb - Handover Management SystemGG GRNo ratings yet

- 1081 Camid Vs Op DigestDocument2 pages1081 Camid Vs Op DigestLennart Reyes67% (3)

- Gek 106852aDocument10 pagesGek 106852awednetoxNo ratings yet

- Human Behavior in OrganizationsDocument5 pagesHuman Behavior in OrganizationsJennybabe Peta100% (1)

- Dhi-Ehs-Hsm-028 Work Over Water Rev0Document5 pagesDhi-Ehs-Hsm-028 Work Over Water Rev0Phạm Đình NghĩaNo ratings yet

- HOUSEKEEPING SESSION PLANDocument2 pagesHOUSEKEEPING SESSION PLANScarlette Beauty Enriquez100% (1)

- Trains-Dutch-East-Indies - Dirk TeweuenDocument30 pagesTrains-Dutch-East-Indies - Dirk TeweuenMohamad AliwafaNo ratings yet

- BPM Governance Platform Progress Business ProcessDocument22 pagesBPM Governance Platform Progress Business ProcessLando ReyesNo ratings yet

- 30lbf11br001-Rev 2Document1 page30lbf11br001-Rev 2Mohd Effiezool YaserNo ratings yet

- 10lab12br001-Rev 1 - 1Document1 page10lab12br001-Rev 1 - 1Mohd Effiezool YaserNo ratings yet

- 05-KSCPP-B-1906 - A - Code 2Document1 page05-KSCPP-B-1906 - A - Code 2Mohd KhaidirNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- Piping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Document1 pagePiping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Mohd KhaidirNo ratings yet

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- 10187286-00A MMC 4l45 r4 AssyDocument1 page10187286-00A MMC 4l45 r4 AssymmNo ratings yet

- 30lae25br004-Rev 2Document1 page30lae25br004-Rev 2Mohd Effiezool YaserNo ratings yet

- GT A GT B GT D GT F GT G GT E GT C: 400Kv Switchyard EquipmentDocument1 pageGT A GT B GT D GT F GT G GT E GT C: 400Kv Switchyard EquipmentS Rao CheepuriNo ratings yet

- 30lbe51br002-Rev 1Document1 page30lbe51br002-Rev 1Mohd Effiezool YaserNo ratings yet

- Scubber Seal Tank (6a25-T12) 12kl-MasterDocument2 pagesScubber Seal Tank (6a25-T12) 12kl-MasterJayan VKNo ratings yet

- 30lbe51br001-Rev 2 - 2Document1 page30lbe51br001-Rev 2 - 2Mohd Effiezool YaserNo ratings yet

- Ellectric Office - 1Document1 pageEllectric Office - 1kom1984No ratings yet

- Allia IGS 3 Allia IGS 5 - MIS Maps - SM - 5871315-1EN - 3Document2 pagesAllia IGS 3 Allia IGS 5 - MIS Maps - SM - 5871315-1EN - 3service iyadMedicalNo ratings yet

- Legend: Project Name: LPIC EPC1 SCUDocument1 pageLegend: Project Name: LPIC EPC1 SCUjeswinNo ratings yet

- 2800-106-VE-7100-00001_005Document5 pages2800-106-VE-7100-00001_005Mahmoud IbrahimNo ratings yet

- Reference Drawing Bill of Material For This Drawing General Notes Topographic Symbols Pipeline Symbols Soil SymbolsDocument26 pagesReference Drawing Bill of Material For This Drawing General Notes Topographic Symbols Pipeline Symbols Soil SymbolssubudhiprasannaNo ratings yet

- VG 1002 070820Document1 pageVG 1002 070820api-3698996No ratings yet

- Rbs College StationDocument1 pageRbs College StationPooja waniNo ratings yet

- Key Plan: RSXX-DT Capacitor Bank RSXX-CAP-01Document6 pagesKey Plan: RSXX-DT Capacitor Bank RSXX-CAP-01Mrinal KayalNo ratings yet

- TECHNICALPart 5Document1,521 pagesTECHNICALPart 5সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- 30LBF11BR411 - 2Document1 page30LBF11BR411 - 2Mohd Effiezool YaserNo ratings yet

- Uvls.2 Uqair-A.12 PDFDocument1 pageUvls.2 Uqair-A.12 PDFAnonymous BZQOJwWIh6No ratings yet

- 10lab12br001-Rev 1 - 2Document1 page10lab12br001-Rev 1 - 2Mohd Effiezool YaserNo ratings yet

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- SS-0150-TJR-DWG-ELE-004 - Auxiliary Single Line Diagram (Along With UPS) - PV2-MCRDocument1 pageSS-0150-TJR-DWG-ELE-004 - Auxiliary Single Line Diagram (Along With UPS) - PV2-MCRtukaram.pawarNo ratings yet

- Va 1302 070822Document1 pageVa 1302 070822api-3698996No ratings yet

- 250MW Gov With EHA 2-2180-07Document2 pages250MW Gov With EHA 2-2180-07Siva KulanjiNo ratings yet

- 13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Document1 page13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Anonymous BZQOJwWIh6No ratings yet

- Balcon-C1Document1 pageBalcon-C1Laura GeorgianaNo ratings yet

- CH BB SLD El 01 06Document1 pageCH BB SLD El 01 06Ahmed MarzokNo ratings yet

- 00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 002Document9 pages00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 002tiantaufikNo ratings yet

- Notes: Piping & Instrument Diagram Osbl Fire Water System Main Fire Water PumpDocument1 pageNotes: Piping & Instrument Diagram Osbl Fire Water System Main Fire Water PumpHadi SuagungNo ratings yet

- A Detail: Piping Isometric BuildingDocument1 pageA Detail: Piping Isometric BuildingMohd Effiezool YaserNo ratings yet

- DENON AVR-1905 SchematicDocument13 pagesDENON AVR-1905 SchematicGuillaume HubertNo ratings yet

- Schematic diagrams and input/volume board details for AVR-1905/785 AVC-1590 audio equipmentDocument13 pagesSchematic diagrams and input/volume board details for AVR-1905/785 AVC-1590 audio equipmentWinger ZsNo ratings yet

- MCC Schematics - Highlighted StartersDocument8 pagesMCC Schematics - Highlighted Startersshrikanth5singhNo ratings yet

- B011 000 16 50 01201 - Rev 2Document1 pageB011 000 16 50 01201 - Rev 2GLOBUS ENGINEERSNo ratings yet

- 3rd Storey Plumbing Layout Plan Rev 0 (Color, Revit)Document1 page3rd Storey Plumbing Layout Plan Rev 0 (Color, Revit)ZenChanNo ratings yet

- Clay Tiles Shop Drawing - SDDocument1 pageClay Tiles Shop Drawing - SDAhmed MohamedNo ratings yet

- Dom Bagaha We LaDocument1 pageDom Bagaha We Labuildings departmentNo ratings yet

- Vu 1108 070822Document1 pageVu 1108 070822api-3698996No ratings yet

- A2400 ChassisDocument29 pagesA2400 ChassisdoomanNo ratings yet

- CBD Bp18a C127D2 SDW Co Co NL 07025 01Document1 pageCBD Bp18a C127D2 SDW Co Co NL 07025 01rakeshamechNo ratings yet

- OSC-00-SS6-0101_04Document1 pageOSC-00-SS6-0101_04akın bektaşNo ratings yet

- 3 Top Roof Plan: SCALE: 1:150Document1 page3 Top Roof Plan: SCALE: 1:150Zeeshan LiaquatNo ratings yet

- AGCC02-AFC-WRD-JMD-ECS-0302Document1 pageAGCC02-AFC-WRD-JMD-ECS-0302Hitesh SrivastavaNo ratings yet

- Samsung Bn44-00354a Bn44-00355a Power-Supply SCH PDFDocument4 pagesSamsung Bn44-00354a Bn44-00355a Power-Supply SCH PDFAnonymous vgeqhfZcNo ratings yet

- P4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2011Document1 pageP4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2011ManojNo ratings yet

- 3387 04 PL CC 01Document11 pages3387 04 PL CC 01Ha Kim BJNo ratings yet

- J3BGDF11BR001 01 04Document1 pageJ3BGDF11BR001 01 04Nauman TahirNo ratings yet

- Al Qadeem CL CHW SD CommentsDocument4 pagesAl Qadeem CL CHW SD CommentsrajatbdlNo ratings yet

- Final cable schedule provides load connectionsDocument1 pageFinal cable schedule provides load connectionsshrikanth5singhNo ratings yet

- Cable Trenc Layout Jmaui R0-ModelDocument1 pageCable Trenc Layout Jmaui R0-ModelManas MondalNo ratings yet

- No.20 - TBN Oil Piping 2of2Document1 pageNo.20 - TBN Oil Piping 2of2Adetunji Babatunde TaiwoNo ratings yet

- SD-L-SEI-TCH-0089 - Site Access For Grading SubcontractorDocument1 pageSD-L-SEI-TCH-0089 - Site Access For Grading SubcontractorJOSUE FERNANDO FERNANDEZNo ratings yet

- TIR PRE-ING Siemens 006 - ResponseDocument2 pagesTIR PRE-ING Siemens 006 - ResponseJOSUE FERNANDO FERNANDEZNo ratings yet

- SD R TCH Sei 0001Document1 pageSD R TCH Sei 0001JOSUE FERNANDO FERNANDEZNo ratings yet

- Energy, Inc.: Attached Document(s) Are Provided For Design/ConstructionDocument1 pageEnergy, Inc.: Attached Document(s) Are Provided For Design/ConstructionJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0087 - Customer Witness Point (Third Notice)Document3 pagesSD-L-SEI-TCH-0087 - Customer Witness Point (Third Notice)JOSUE FERNANDO FERNANDEZNo ratings yet

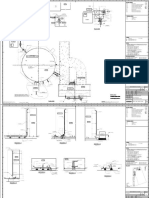

- Stuffing BoxDocument1 pageStuffing BoxJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0086 - Option Proposal For The Santo Domingo Project Top Soil Waste Material RemovalDocument2 pagesSD-L-SEI-TCH-0086 - Option Proposal For The Santo Domingo Project Top Soil Waste Material RemovalJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0090 - Certificate of Completion Offshore Work Payment Milestone 7, Site MobilizationDocument2 pagesSD-L-SEI-TCH-0090 - Certificate of Completion Offshore Work Payment Milestone 7, Site MobilizationJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0088 - Certificates of Insurane-Letter GG-SEI-061-2012Document7 pagesSD-L-SEI-TCH-0088 - Certificates of Insurane-Letter GG-SEI-061-2012JOSUE FERNANDO FERNANDEZNo ratings yet

- Guar Mix Tank and Cathode Stripping Crane DetailsDocument1 pageGuar Mix Tank and Cathode Stripping Crane DetailsJOSUE FERNANDO FERNANDEZNo ratings yet

- 1-A) BIS-711 Form - PRELLENADO POR FIRMARDocument1 page1-A) BIS-711 Form - PRELLENADO POR FIRMARJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XK01-MB-013100 - Customer Piping Connection Process InformationDocument11 pagesPE1007-XK01-MB-013100 - Customer Piping Connection Process InformationJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsDocument12 pagesPE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XH01-00UZ-470003 Piping GA Drawing - Above GroundDocument2 pagesPE1007-XH01-00UZ-470003 Piping GA Drawing - Above GroundJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XH01-00UZ-470001 Piping GA Drawing - Fire Hydrant Loop - Rev 1Document2 pagesPE1007-XH01-00UZ-470001 Piping GA Drawing - Fire Hydrant Loop - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- OTec Rev.00Document21 pagesOTec Rev.00JOSUE FERNANDO FERNANDEZNo ratings yet

- 000-FS-007 Rev 0Document1 page000-FS-007 Rev 0JOSUE FERNANDO FERNANDEZNo ratings yet

- PFD 1Document1 pagePFD 1JOSUE FERNANDO FERNANDEZNo ratings yet

- 000-FS-008 Rev 0Document1 page000-FS-008 Rev 0JOSUE FERNANDO FERNANDEZNo ratings yet

- S1 Strip Electrolyte Filtration ProcessDocument1 pageS1 Strip Electrolyte Filtration ProcessJOSUE FERNANDO FERNANDEZNo ratings yet

- 100 06 P 0001 PDFDocument1 page100 06 P 0001 PDFJOSUE FERNANDO FERNANDEZNo ratings yet

- Gi29301008 100 10 PL 101 PDFDocument1 pageGi29301008 100 10 PL 101 PDFJOSUE FERNANDO FERNANDEZNo ratings yet

- Curvas de Operacion Tag 2810-PU-032Document2 pagesCurvas de Operacion Tag 2810-PU-032JOSUE FERNANDO FERNANDEZNo ratings yet

- 185 06 P 0003 PDFDocument1 page185 06 P 0003 PDFJOSUE FERNANDO FERNANDEZNo ratings yet

- Manual de ValvulaDocument16 pagesManual de ValvulaRene CalliriNo ratings yet

- Therma Flow Inst and Oper. Maint. ManualDocument41 pagesTherma Flow Inst and Oper. Maint. ManualJOSUE FERNANDO FERNANDEZNo ratings yet

- CLP 7034Document2 pagesCLP 7034JOSUE FERNANDO FERNANDEZNo ratings yet

- Del Monte Golf Club in BukidnonDocument1 pageDel Monte Golf Club in BukidnonJackieNo ratings yet

- Sample PresentationDocument26 pagesSample PresentationMitali MishraNo ratings yet

- 12.CEH Module 3 Assignment 3.1Document7 pages12.CEH Module 3 Assignment 3.1piyuhNo ratings yet

- Matrix 210N Reference Manual 2017 PDFDocument167 pagesMatrix 210N Reference Manual 2017 PDFiozsa cristianNo ratings yet

- LTE Data Analysis - Project Proposal N.2Document22 pagesLTE Data Analysis - Project Proposal N.2Syed SafwanNo ratings yet

- Indian Standard: Methods For Sampling of Clay Building BricksDocument9 pagesIndian Standard: Methods For Sampling of Clay Building BricksAnonymous i6zgzUvNo ratings yet

- Post-Operative Nutrition: Things You Need To Know AboutDocument2 pagesPost-Operative Nutrition: Things You Need To Know AboutJannen CasasNo ratings yet

- Bank Account Details and Contact NumbersDocument38 pagesBank Account Details and Contact NumbersD-Blitz StudioNo ratings yet

- One SheetDocument1 pageOne Sheetadeel ghouseNo ratings yet

- Lb-Xp12-350-Pd-En-V1.3-201912 - EquivalenteDocument2 pagesLb-Xp12-350-Pd-En-V1.3-201912 - EquivalenteDaniel Oliveira Freitas RochaNo ratings yet

- ClassifiedrecordsDocument23 pagesClassifiedrecordsChetana SJadigerNo ratings yet

- Rsa Netwitness Endpoint: Detect Unknown Threats. Reduce Dwell Time. Accelerate ResponseDocument8 pagesRsa Netwitness Endpoint: Detect Unknown Threats. Reduce Dwell Time. Accelerate ResponseRaghavNo ratings yet

- Autoencoder Asset Pricing ModelsDocument22 pagesAutoencoder Asset Pricing ModelsEdson KitaniNo ratings yet

- Materials Storage and BuildingDocument3 pagesMaterials Storage and BuildingAmit GoyalNo ratings yet

- Ficha Técnica Lithonia-JcblDocument9 pagesFicha Técnica Lithonia-JcblEmiliano HernándezNo ratings yet

- Bloodborne Pathogens Program: Western Oklahoma State College Employee Training HandbookDocument35 pagesBloodborne Pathogens Program: Western Oklahoma State College Employee Training HandbookKashaNo ratings yet

- (GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-DevelopersDocument3 pages(GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-Developersdadme010% (2)

- VespaDocument5 pagesVespaAmirul AimanNo ratings yet

- Switches - Cisco Nexus 9000 - ArtDocument96 pagesSwitches - Cisco Nexus 9000 - ArtYasser OmarNo ratings yet

- MR Khurram Chakwal 6kw Hybrid - 024627Document6 pagesMR Khurram Chakwal 6kw Hybrid - 024627Shahid HussainNo ratings yet

- Coal Petroleum: Crude OilDocument25 pagesCoal Petroleum: Crude Oiljojo basenNo ratings yet