Professional Documents

Culture Documents

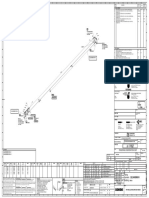

PE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1

Uploaded by

JOSUE FERNANDO FERNANDEZOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1

Uploaded by

JOSUE FERNANDO FERNANDEZCopyright:

Available Formats

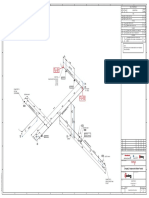

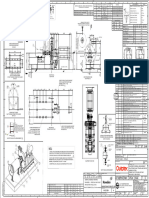

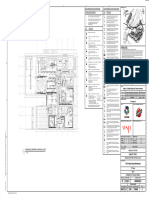

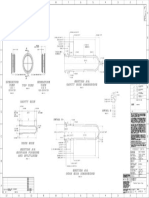

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

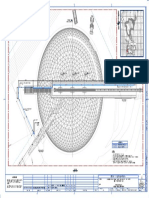

ERECTION MATERIALS

PT NPD WEIGHT

A NO DESCRIPTION (IN) QTY (lbm) A

1 GLOBE VALVE WITH HANDWHEEL, RF, SEE VALVE LIST, CL150 3 1 50.7

N 2 BLIND FLANGE, RAISED FACE, CL150, A105, ASME-B16.5 3 1 12.1

TOTAL FABRICATION WEIGHT 62.8

ERECTION MATERIALS

PT NPD WEIGHT

B NO DESCRIPTION (IN) QTY (lbm) B

3 FLAT RING GASKET, CL150, 0.079 inch Thick, Klingersil 3 2 -

C-4430, ASME-B16.21

4 STUD BOLT, A193-B7, HOT DIP GALVANIZED, LUBRICATED WITH 5/8 8 -

MOLYKOTE HSC PLUS, ASME B18.2.1 - 4.724 in. Length

5 HEX HEAD NUT, A194-2H HOT-DIP GALVANIZED, ANSI-B18.2.2 5/8 16 -

6 PLAIN WASHER, CARBON STEEL - HOT DIP GALVANIZED, ASME 5/8 16 -

B18.22.1 - TYPE A

TOTAL ERECTION WEIGHT -

C C

D N D

TIO

A

ENT

RUM

T

INS

IPING

P

* 12 1/4"

E E

2

G3 B4/5/6

G3 B4/5/6

CONN TO

F 00GAD10BB001/L1-Level Transmitter 1 F

3 in RFFE 150 S-STD STEM UP

00GAD10AA301

+X=+5223'-1 1/8"/

+Y=+5112'-0"/

+Z=+106'-11 1/2"

NOTES

1. BUILDING FLOOR LEVEL = +106'-7"(+63.25M)

G 2. FINISHED GROUND LEVEL = +106'-1"(+63.10M) G

3. COORDINATES ARE WITH RESPECT TO BENCH MARK

POINT P-3 (HAVING FOLLOWING CO-ORDINATES)

X=5000'-00" CORRESPONDS TO (E=313492.878M)

Y=5000'-00" CORRESPONDS TO (N=8618375.403M)

H NOTE: H

Butt weld end connections shall be as per fig. 2A or 3A of ASME B16.25, based on the

wall thickness and the `B' dimension shall have a max. tolerance of +0.010"to -0.040".

Y(Nortth)

DIMENSIONS MARKED * SHALL BE ADJUSTED BY REFER AXIS PLAN DRAWING NO.

PE1007-UC07-UZ-600003

CONTRACTOR BASED ON FINAL VALVE DRAWING Z

X(East) FOR DETAILS REGARDING PLANT GRID

J J

Summe Schweißnähte / Total numbers of welds:

Schweißplan Nr./ Welding procedure plan no:

Prüffolgeplan Nr./ Quality plan no:

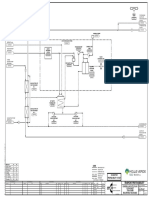

Projekt/Project PKZ/PC

SANTO DOMINGO DE LOS OLLEROS PE1007

UNID DCC/UA Inhaltskennzeichen

487408054 XJ00

Contents code

00GAD10

K Variante

Variant

Zähl-Nr.

Serial no. 446303 K

Ursprung-Nr. erstellt mit Abtlg. BR301

Origin no. Created with SP3D Dept. E F ES SPEL EN P3

Branch Orientation Legend

1 2013-05-22 MADHUR JEM GENERALLY REVISED

1. Orientation With Annotation in Isometric

2. Orientation Without Annotation in Isometric 0 2012-11-07 AJEESH JEM FIRST ISSUE

Annotion in Isometric: Index Datum bearb. geprüft

90° Angle Direction as per Isometric

80

Änderungshinweise/Details of revision

<Direction> <Angle> <Direction> Rev.

Gewicht

Date

Format

Coord.

Maßstab

Checked

Spez.

Weight Format Scale Specs.

a. Example for b. Example for Example Example Datum / Date Name / Name Titel/Title

L

Maße nicht abgreifbar / Not to scale

Vertical Lines: N 45.0 E Horizontal Lines: N 45.0 DOWN

NORTH 45

UP

NORTH UP

gezeich.

Drawn

bearb.

2012-11-07 AJEESH

2012-11-07 AJEESH

Piping Isometrics

° Coord.

geprüft

Checked 2012-11-07 JEM 00GAD10BR301

Isolierung 0 in

Copyright (C) Siemens 2012

All Rights Reserved

Building: 00UGF

Insulation

WEST EAST SOUTH NORTH WEST EAST SOUTH NORTH Handhabung

Standard ASME-B31.1-2010 Handling

Remarks Standard

45°

+Z Zeichnungs-Nr. Index/Rev.

Drawing no.

max. zul. Betriebstemp.

M +Y +X

- welds are fixed by contractor

FW= Field weld; SW= Shop weld

max. allow. work. temperature

115.00 F

PE1007-00GAD10-XJ00-446303 1

20

SOUTH DOWN SOUTH DOWN - Final dimensions of valves and In- Line max. zul. Betriebsüberdruck 150.00 psig Blatt-Nr.

max. allow. work. pressure Sheet no.

components to be checked by contractor

PLAN VIEW ELEVATION VIEW PLAN VIEW ELEVATION VIEW - all pipes without fitting length Prüfdruck

test pressure

225.00 psig 1 /1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

00GAD10BR301 Today's Date (Locale Sensitive format) : 5/21/2013 3:53:53 PMToday's Date (Your format) : 21/05/13Today's Date (ISO8601 Small) : 2013-05-21 15:53:53

You might also like

- The Effect of Error Correction On Learners' Ability To Write AccuratelyDocument18 pagesThe Effect of Error Correction On Learners' Ability To Write AccuratelyWiqoyil IslamaNo ratings yet

- C-STR-DWG-000-31008-0 - PR-102 Structural Steel GA - Plan & Det at Base PL LevelDocument1 pageC-STR-DWG-000-31008-0 - PR-102 Structural Steel GA - Plan & Det at Base PL LevelHUSSEIN FNEISHNo ratings yet

- Portable Appliance Testing (Pat) Report/Certificate: Copy Certificate Certificate Reference NumberDocument3 pagesPortable Appliance Testing (Pat) Report/Certificate: Copy Certificate Certificate Reference NumberPete KomorNo ratings yet

- Solenoid Valve - TestDocument10 pagesSolenoid Valve - TestFausto100% (6)

- Plumbing and Fire Fighting Sample BoqDocument30 pagesPlumbing and Fire Fighting Sample BoqNajeeb Ahmad Khan100% (2)

- SAP BW ExtractionDocument161 pagesSAP BW ExtractionKuldeep Jain100% (3)

- Bhatinda R 2 SLDDocument1 pageBhatinda R 2 SLDvineets058No ratings yet

- Gas Lift Design With Self-Well GasDocument12 pagesGas Lift Design With Self-Well GasMohanad HussienNo ratings yet

- API 650 Design TanksDocument34 pagesAPI 650 Design TanksSyedZainAli100% (13)

- SET P&ID - Filter Cellar - Tibasosa PDFDocument9 pagesSET P&ID - Filter Cellar - Tibasosa PDFJairo Hernando Rojas PulidoNo ratings yet

- Applied Thermodynamics by Onkar Singh.0001 PDFDocument330 pagesApplied Thermodynamics by Onkar Singh.0001 PDFanon_688074713No ratings yet

- Answer All The Questions Section A.: True of Science?Document4 pagesAnswer All The Questions Section A.: True of Science?hyeazsNo ratings yet

- Companion 5 - DSP SCH PDFDocument4 pagesCompanion 5 - DSP SCH PDFManimaran MaranNo ratings yet

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- SA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointDocument4 pagesSA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- 30lbe51br302 - Rev 0Document1 page30lbe51br302 - Rev 0Mohd Effiezool YaserNo ratings yet

- BOM for GRP pipe systemDocument2 pagesBOM for GRP pipe systemABAID ULLAHNo ratings yet

- 30lae25br004-Rev 2Document1 page30lae25br004-Rev 2Mohd Effiezool YaserNo ratings yet

- FJ-02 Fj-02-A: SPL-03 S.JDocument2 pagesFJ-02 Fj-02-A: SPL-03 S.JABAID ULLAHNo ratings yet

- PPG01 RB01 MTL03 15434 Ou110184323 R2Document2 pagesPPG01 RB01 MTL03 15434 Ou110184323 R2Mahmoud AllamNo ratings yet

- Shuqaiq 3 Independent Water Project: Ro Building T7 GDF02-001Document1 pageShuqaiq 3 Independent Water Project: Ro Building T7 GDF02-001ABAID ULLAHNo ratings yet

- 30lbe51br301 - Rev 0Document1 page30lbe51br301 - Rev 0Mohd Effiezool YaserNo ratings yet

- SA04C2-03-WP-D-42013-01-5: 3. FJ - Field Joint 4. SJ - Shop JointDocument4 pagesSA04C2-03-WP-D-42013-01-5: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- 30lbe51br303 - Rev 0Document1 page30lbe51br303 - Rev 0Mohd Effiezool YaserNo ratings yet

- J3BGDF02BR030 09 02Document1 pageJ3BGDF02BR030 09 02Nauman TahirNo ratings yet

- A Detail: Piping Isometric BuildingDocument1 pageA Detail: Piping Isometric BuildingMohd Effiezool YaserNo ratings yet

- 1eec E4012Document1 page1eec E4012UP MOCHINo ratings yet

- 30LBF11BR411 - 2Document1 page30LBF11BR411 - 2Mohd Effiezool YaserNo ratings yet

- Iso 20lae05aa101Document1 pageIso 20lae05aa101Mohd Effiezool YaserNo ratings yet

- NL2 - Main Single Line and Protection DiagramDocument1 pageNL2 - Main Single Line and Protection DiagramĐỗ Hồng SơnNo ratings yet

- 07 522213 4800000612 WSP SLT DRG 100002 - CDocument1 page07 522213 4800000612 WSP SLT DRG 100002 - CMOHD NAZEEF KHANNo ratings yet

- 10lab12br001-Rev 1 - 2Document1 page10lab12br001-Rev 1 - 2Mohd Effiezool YaserNo ratings yet

- J3BGDF02BR025 01 01Document1 pageJ3BGDF02BR025 01 01saleem naheedNo ratings yet

- Scubber Seal Tank (6a25-T12) 12kl-MasterDocument2 pagesScubber Seal Tank (6a25-T12) 12kl-MasterJayan VKNo ratings yet

- Ahw 10 Pdfeed MP 2343 00001 0091 01 PDFDocument1 pageAhw 10 Pdfeed MP 2343 00001 0091 01 PDFchandana kumarNo ratings yet

- Shougang Hierro Peru S.A.A.: Plano No. Plano NoDocument1 pageShougang Hierro Peru S.A.A.: Plano No. Plano NoFrank Jerry Aylas TejedaNo ratings yet

- Eep 000097 0102148005 3 ST Det 0669 R02Document1 pageEep 000097 0102148005 3 ST Det 0669 R02Vikram DalalNo ratings yet

- L - Ar-100.1part PlansDocument1 pageL - Ar-100.1part PlansAslam YaseenNo ratings yet

- 30lbe51br002-Rev 1Document1 page30lbe51br002-Rev 1Mohd Effiezool YaserNo ratings yet

- 3 Pro SLD FinalDocument1 page3 Pro SLD FinalNeneng KunaNo ratings yet

- 270 S.J. S.J.: ID QTY DN Description Sch/Cla SSDocument2 pages270 S.J. S.J.: ID QTY DN Description Sch/Cla SSABAID ULLAHNo ratings yet

- Bill of Materials ID QTY DN Description Sch/Cla SS: Shuqaiq 3 Independent Water ProjectDocument3 pagesBill of Materials ID QTY DN Description Sch/Cla SS: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Vieqa0102 02Document1 pageVieqa0102 02nayan sutharNo ratings yet

- As Built: Matchline To Dwg. NoDocument1 pageAs Built: Matchline To Dwg. NoMohamed RamadanNo ratings yet

- 07 522213 4800000612 WSP SLT DRG 210002 - CDocument1 page07 522213 4800000612 WSP SLT DRG 210002 - CMOHD NAZEEF KHANNo ratings yet

- Detail 3 - Connection To The Earthing Grid of Metallic StructuresDocument1 pageDetail 3 - Connection To The Earthing Grid of Metallic StructuresAurelienNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 05Document1 pageEpcc05 MDR 421 STR DWG 000 0072 05RANJEET PRATAP SINGHNo ratings yet

- J3BGDF02BR025 01 06Document1 pageJ3BGDF02BR025 01 06Naheed AkhtarNo ratings yet

- 30lbf11br001-Rev 2Document1 page30lbf11br001-Rev 2Mohd Effiezool YaserNo ratings yet

- PreformDocument1 pagePreformsoudy salahNo ratings yet

- J3BGDF02BR009 01 01Document1 pageJ3BGDF02BR009 01 01saleem naheedNo ratings yet

- J3BGDF02BR010 01 05Document1 pageJ3BGDF02BR010 01 05Naheed AkhtarNo ratings yet

- J3BGDF02BR011 01 01Document1 pageJ3BGDF02BR011 01 01saleem naheedNo ratings yet

- J3BGDF02BR009 01 05Document1 pageJ3BGDF02BR009 01 05Naheed AkhtarNo ratings yet

- Secondary Sludge Thickener Feed Pump 1P-610-PUM-06D.: Plan ViewDocument22 pagesSecondary Sludge Thickener Feed Pump 1P-610-PUM-06D.: Plan ViewFaisal MumtazNo ratings yet

- J3BGDF02BR030 07 02Document1 pageJ3BGDF02BR030 07 02Nauman TahirNo ratings yet

- FL3B-474-P-2603 As BuiltDocument1 pageFL3B-474-P-2603 As BuiltAlbet MulyonoNo ratings yet

- 10lab12br001-Rev 1 - 1Document1 page10lab12br001-Rev 1 - 1Mohd Effiezool YaserNo ratings yet

- PSK1-E0000-0000-DDI - Single Line Diagram-Rev-ADocument1 pagePSK1-E0000-0000-DDI - Single Line Diagram-Rev-AAsep SaepudinNo ratings yet

- PE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1Document1 pagePE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- Eep000094 01021480065 2 ST Det 0211Document1 pageEep000094 01021480065 2 ST Det 0211Vikram DalalNo ratings yet

- 07 522213 4800000612 WSP SLT DRG 101001 - CDocument1 page07 522213 4800000612 WSP SLT DRG 101001 - CMOHD NAZEEF KHANNo ratings yet

- For Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-006: Otak InternationalDocument1 pageFor Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-006: Otak InternationalnaveenNo ratings yet

- H047&H048-CMS-SD-04-12-2 - Cctv-General Position - As Built DrawingDocument1 pageH047&H048-CMS-SD-04-12-2 - Cctv-General Position - As Built DrawingDedeNazaludinNo ratings yet

- Siemens: ASK DDocument1 pageSiemens: ASK DMurilo MonteiroNo ratings yet

- 7061581-STR-DWG-KRP-3090 (Sheet 1 of 3)Document1 page7061581-STR-DWG-KRP-3090 (Sheet 1 of 3)Sibtain AliNo ratings yet

- FL3B-474-P-2636 As BuiltDocument1 pageFL3B-474-P-2636 As BuiltAlbet MulyonoNo ratings yet

- TIR PRE-ING Siemens 006 - ResponseDocument2 pagesTIR PRE-ING Siemens 006 - ResponseJOSUE FERNANDO FERNANDEZNo ratings yet

- SD R TCH Sei 0001Document1 pageSD R TCH Sei 0001JOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0090 - Certificate of Completion Offshore Work Payment Milestone 7, Site MobilizationDocument2 pagesSD-L-SEI-TCH-0090 - Certificate of Completion Offshore Work Payment Milestone 7, Site MobilizationJOSUE FERNANDO FERNANDEZNo ratings yet

- Energy, Inc.: Attached Document(s) Are Provided For Design/ConstructionDocument1 pageEnergy, Inc.: Attached Document(s) Are Provided For Design/ConstructionJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0087 - Customer Witness Point (Third Notice)Document3 pagesSD-L-SEI-TCH-0087 - Customer Witness Point (Third Notice)JOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0089 - Site Access For Grading SubcontractorDocument1 pageSD-L-SEI-TCH-0089 - Site Access For Grading SubcontractorJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsDocument12 pagesPE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsJOSUE FERNANDO FERNANDEZNo ratings yet

- 1-A) BIS-711 Form - PRELLENADO POR FIRMARDocument1 page1-A) BIS-711 Form - PRELLENADO POR FIRMARJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0086 - Option Proposal For The Santo Domingo Project Top Soil Waste Material RemovalDocument2 pagesSD-L-SEI-TCH-0086 - Option Proposal For The Santo Domingo Project Top Soil Waste Material RemovalJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1Document1 pagePE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- Stuffing BoxDocument1 pageStuffing BoxJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0088 - Certificates of Insurane-Letter GG-SEI-061-2012Document7 pagesSD-L-SEI-TCH-0088 - Certificates of Insurane-Letter GG-SEI-061-2012JOSUE FERNANDO FERNANDEZNo ratings yet

- 000-FS-008 Rev 0Document1 page000-FS-008 Rev 0JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XK01-MB-013100 - Customer Piping Connection Process InformationDocument11 pagesPE1007-XK01-MB-013100 - Customer Piping Connection Process InformationJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XH01-00UZ-470001 Piping GA Drawing - Fire Hydrant Loop - Rev 1Document2 pagesPE1007-XH01-00UZ-470001 Piping GA Drawing - Fire Hydrant Loop - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XH01-00UZ-470003 Piping GA Drawing - Above GroundDocument2 pagesPE1007-XH01-00UZ-470003 Piping GA Drawing - Above GroundJOSUE FERNANDO FERNANDEZNo ratings yet

- Gi29301008 100 10 PL 101 PDFDocument1 pageGi29301008 100 10 PL 101 PDFJOSUE FERNANDO FERNANDEZNo ratings yet

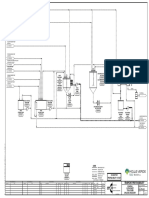

- S1 Strip Electrolyte Filtration ProcessDocument1 pageS1 Strip Electrolyte Filtration ProcessJOSUE FERNANDO FERNANDEZNo ratings yet

- PFD 1Document1 pagePFD 1JOSUE FERNANDO FERNANDEZNo ratings yet

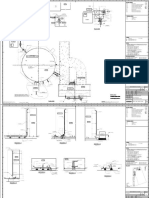

- Guar Mix Tank and Cathode Stripping Crane DetailsDocument1 pageGuar Mix Tank and Cathode Stripping Crane DetailsJOSUE FERNANDO FERNANDEZNo ratings yet

- OTec Rev.00Document21 pagesOTec Rev.00JOSUE FERNANDO FERNANDEZNo ratings yet

- 000-FS-007 Rev 0Document1 page000-FS-007 Rev 0JOSUE FERNANDO FERNANDEZNo ratings yet

- Therma Flow Inst and Oper. Maint. ManualDocument41 pagesTherma Flow Inst and Oper. Maint. ManualJOSUE FERNANDO FERNANDEZNo ratings yet

- 100 06 P 0001 PDFDocument1 page100 06 P 0001 PDFJOSUE FERNANDO FERNANDEZNo ratings yet

- 185 06 P 0003 PDFDocument1 page185 06 P 0003 PDFJOSUE FERNANDO FERNANDEZNo ratings yet

- CLP 7034Document2 pagesCLP 7034JOSUE FERNANDO FERNANDEZNo ratings yet

- Curvas de Operacion Tag 2810-PU-032Document2 pagesCurvas de Operacion Tag 2810-PU-032JOSUE FERNANDO FERNANDEZNo ratings yet

- Manual de ValvulaDocument16 pagesManual de ValvulaRene CalliriNo ratings yet

- Chapter 4-Piezoelectric CeramicsDocument33 pagesChapter 4-Piezoelectric Ceramicssantsex111No ratings yet

- You Can Do The CubeDocument16 pagesYou Can Do The Cubedeborahmorton100% (1)

- Chap2 (B) Fits and TolerancesDocument20 pagesChap2 (B) Fits and TolerancesjojoNo ratings yet

- LC1 EE3706 C1 Basic ConceptsDocument16 pagesLC1 EE3706 C1 Basic ConceptsnamNo ratings yet

- Rust: The Electrochemical Process of Iron CorrosionDocument7 pagesRust: The Electrochemical Process of Iron CorrosionGagandeep SinghNo ratings yet

- Display, Operate, Switch, Control, Regulate and Communicate: For Sales and SupportDocument24 pagesDisplay, Operate, Switch, Control, Regulate and Communicate: For Sales and SupportVictor Rolando Tarifa BlancoNo ratings yet

- Lecture 06 InheritanceDocument37 pagesLecture 06 InheritanceUmer BeshirNo ratings yet

- OSY Practical No.1Document18 pagesOSY Practical No.1aniket bhoirNo ratings yet

- Construction and Building Materials: Weena Lokuge, Aaron Wilson, Chamila Gunasekara, David W. Law, Sujeeva SetungeDocument10 pagesConstruction and Building Materials: Weena Lokuge, Aaron Wilson, Chamila Gunasekara, David W. Law, Sujeeva SetungeAndrew PiNo ratings yet

- 4 Flash Fire Points by Cleveland Open CupDocument10 pages4 Flash Fire Points by Cleveland Open CupAs MihNo ratings yet

- Chapter 7 Buckling of BarsDocument19 pagesChapter 7 Buckling of BarshanipaNo ratings yet

- Apes Gum LabDocument3 pagesApes Gum Labapi-409641205No ratings yet

- Difequa Higherorderde PDFDocument119 pagesDifequa Higherorderde PDFJj DaneNo ratings yet

- Thread Types & IssuesDocument20 pagesThread Types & IssuesBilal Khan RindNo ratings yet

- Efficient Inverter Heat Pumps for Swimming PoolsDocument4 pagesEfficient Inverter Heat Pumps for Swimming PoolsAinars VizulisNo ratings yet

- Aptitude and Reasoning QuestionsDocument5 pagesAptitude and Reasoning Questionsvyom saxenaNo ratings yet

- BROADLEAF 6 ManualDocument109 pagesBROADLEAF 6 ManualBaseCubica ArquitectosNo ratings yet

- Soil Mechanics Lab Teaches Engineering ConceptsDocument4 pagesSoil Mechanics Lab Teaches Engineering Conceptskaas1992No ratings yet

- Icd Aidc Ver3Document95 pagesIcd Aidc Ver3Alvin Guillermo Rodriguez ArguelloNo ratings yet

- Chapter 7 - Phase Equilibrium of One ComponentDocument24 pagesChapter 7 - Phase Equilibrium of One ComponentPHƯƠNG ĐẶNG YẾNNo ratings yet

- Bagi Yang Masih Awam Memakai Google Sheet, File Ini Bisa Didownload Dengan Klik File Download MS. ExcelDocument67 pagesBagi Yang Masih Awam Memakai Google Sheet, File Ini Bisa Didownload Dengan Klik File Download MS. Excelwisnu pranata adhiNo ratings yet