Professional Documents

Culture Documents

Aquamon SMARTPRO 8966 - PH Pipe & Wall Mount Manual

Uploaded by

kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aquamon SMARTPRO 8966 - PH Pipe & Wall Mount Manual

Uploaded by

kumarCopyright:

Available Formats

Aquamon SMARTPro 8966

HART© Smart Two wire pH/ORP transmitter

Instruction Manual

CENG:IM:PH:0812:001:01

Copyright©2008

All rights reserved

Forbes Marshall group of companies

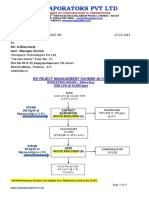

FORBES MARSHALL PVT LTD Page 1

SMARTPro 8966 Preface

This manual serves to explain the use and operation of Aquamon

SMARTPro instruments. The manual functions in two ways, firstly as

a step by step guide to help the user operate the instrument and

secondly as a handy reference guide.

This instruction manual is written to cover as many anticipated

applications of the SMARTPro as possible. If you have any doubts

concerning the use of the instrument, please do not hesitate to contact

the nearest office of Forbes Marshall Pvt. Ltd.

The information presented in this manual is subject to change without

notice as improvements are made, and does not represent any

commitment whatsoever on the part of Forbes Marshall Pvt. Ltd.

Forbes Marshall Pvt. Ltd. Cannot accept any responsibility for damage

or malfunction of the unit due to improper use of the instrument

Copyright©2008

All rights reserved

Forbes Marshall group of companies

The phrases Aquamon SMARTPro 8966

SMARTPro 8966

SMARTPro

Are used interchangeably in this manual and point to the same

instrument Aquamon SMARTPro 8966

FORBES MARSHALL PVT LTD Page 2

SMARTPro 8966 Index

Preface 2

Index 3-4

Safety Information 5-6

1.0 Introduction

1.1 General description 7

1.2 Specifications 8-10

Dimensional details 11

Display 12

1.3 Operating Principle 13-14

2.0 Installation

2.1 Unpacking and Inspection 15

2.2 Tools required for installation 16

2.3 Location and Mounting 17-18

2.4 Cabling 19

2.5 Power Supply requirements 19

2.6 Power Supply and Sensor wiring locations 20

2.7 Power supply wiring 21-22

2.8 Power supply wiring precautions 23

2.9 Open collector contacts wiring (Optional) 24-25

Open collector contacts wiring precautions 26

Sensor wiring

3.1 Sensor wiring 27

3.2 Sensor cable 27-28

3.3 Temperature sensor 29

3.4 Terminations 30

3.5 Cable terminals 30

3.6 Cable terminations on board I 31

3.7 Cable terminations on board II 32

3.8 Calibration and Commissioning 33

FORBES MARSHALL PVT LTD Page 3

SMARTPro 8966 Index

4.0 Operation

Index 34-35

5.0 HART ©Communication

5.1 HART © communication configurations 65

©

5.2 HART Communication 66-67

6.0 Maintenance

6.1 Probe care and Maintenance 68

6.2 How to store the electrode for long time 68

6.3 Storage after use in process 68

6.4 How to clean the electrode 69

6.5 How to Rehydrate the bulb 70

6.6 Do’s and Don’ts for pH (Glass) electrodes 71

7.0 Trouble Shooting

7.0 Trouble Shooting 72-73

7.1 Causes and solution to problems 74

7.2 Problem in temperature measurement and 75

calibration

7.3 pH reading not matching with lab reading 76

7.4 Is the transmitter working OK (mV input) 77

7.5 Is the transmitter working OK (Temp Input) 78

Annexure

I pH verses mV table 79

II Temperature in ºC verses resistance in ohms 80

FORBES MARSHALL PVT LTD Page 4

SMARTPro 8966 Safety

Information

The Forbes Marshall SMARTPro transmitter shall be installed and

operated only in manner specified in the Instruction Manual. Only

skilled, Trained and authorized pers on should carry out installation,

set up and operation of the transmitter.

Before powering up the unit, make sure that power source it is

connected to, and the polarity of the source is as specified on the

transmitter. Failure to do so may result in permanent damage to the

transmitter.

FORBES MARSHALL PVT LTD Page 5

SMARTPro 8966 Safety

Information

Thank you for purchasing the SMARTPro Transmitter. To maximize

the benefits of this instrument we request you to read this manual

thoroughly before installing.

The instruction manual identifies safety instructions and

additional information by means of following symbols

This symbol draws attention to safety instructions and

warning of potential danger which, if neglected, could

result in injury to persons and /or damage the property and /or

damage to the instrument itself.

This symbol identifies additional information and

instructions which, if neglected, could lead to inefficient

operation and possible loss of production

This symbol identifies the information which is necessary for

the trouble free operation of the instrument

The instruction manual must be stored at easily available to the

persons working on SMARTPro

If you have questions, which are not or insufficiently answered in this

instruction manual, Please contact your nearest office of Forbes

Marshall Pvt. Ltd. Our engineers will be glad to assist you.

FORBES MARSHALL PVT LTD Page 6

SMARTPro 8966 Introduction

Section 1.0

1.1 General Description

©

The SMARTPro 8966 is HART For pH, automatic temperature

compatible Microcontroller based compensation through PT100 or

two wire transmitter. It takes PT1000 sensors is provided

inputs from various pH sensors

and transmits it in terms of The transmitter has rugged,

4-20mA HART© output. weatherproof housing.

The enclosure meets IP67

This transmitter is capable of Protection.

measuring pH, mV and

temperature. Thus pH sensor in The output of this transmitter is

combination with temperature fully scalable over the total range

sensor or REDOX sensor can be of sensor. During fault conditions

used as process sensors. The the output can be programmed

measurement results are for 3.55mA or 22mA as per need.

displayed on LCD display.

SMARTPro

FORBES MARSHALL PVT LTD Page 7

SMARTPro 8966 Introduction

Section 1.0

1.2 Specifications

Product Specifications

Supply

Type 2 wire

Supply voltage 12-36VDC

Load Resistance 600V @24VDC NOTE1

Accuracy

Display pH ±0.01pH

Display mV ±1mV

Display Temperature ±0.5%FSD

Output Current ±0.1mA

Outputs

Current 4-20mA HART©

Logic outputs 3 User configurable

“Open collector” outputs

NOTE2

Display 2 Line 10 Character per

line LCD

Inputs

Primary Sensors pH/ORP

Secondary sensors PT100/PT1000

Data Input 3 Button Keypad and

Magnetic pin

programming

FORBES MARSHALL PVT LTD Page 8

SMARTPro 8966 Introduction

Section 1.0

Ranges

pH 0-14pH

ORP -2000mV to 2000mV

Temperature -20 ºC to 200ºC

Spans

pH 2pH – 14pH

ORP 200mV- 4000mV

Compensation

Temperature Auto/Manual

Range -20ºC to 200ºC

Calibration

pH sensor slope 70% to 110% NOTE3

pH sensor zero ±2pH NOTE3

Method Single /Double Point

Notes

1.Load Calculation Method:

Load(in V) For 30V

=(Supply Voltage-12V)/0.02 supply Load is

Load=(30V-12V)/0.02 =

900 V

Also refer section 2.5 for power supply requirements

2. Refer section 2.9 for more details

3. Not both of them simultaneous

FORBES MARSHALL PVT LTD Page 9

SMARTPro 8966 Introduction

Section 1.0

1.2 Specifications

Product Specifications

ApprovalsNOTE 4

5

Immunity EN61000-6-2

Emission 5 EN61000-6-4

6

Intrinsic Safety Exd [ia] IIC, T6

Enclosure

Material Die cast Aluminium

Grade LM6

Protection IP67

Operating Conditions

Temperature -20 to 70 ºC

Relative Humidity 0 to 90%

(non condensing)

Notes

4. Applied, Approval pending

5. EMC directive 2004/108/EEC

O

6. Tamb : -20 ... + 55 C

FORBES MARSHALL PVT LTD Page 10

SMARTPro 8966 Introduction

Section 1.0

1.2 Specifications

Dimensional details

SMARTPro Dimensional Drawing

101

3.93

310

12.20

120

4.72

120 35 20 125

4.72 1.37 0.78 4.92

280

MILIMETER 11.02

INCH

FORBES MARSHALL PVT LTD Page 11

SMARTPro 8966 Introduction

Section 1.0

1.2 Specifications

Display

MAGNETIC PROGRAMMING

KEY

Forbes

Marshall SMARTPro pH 8966

2 LINE

10 CHARACTER

DOT MATRIX

LCD

PROGRAM KEYS

FORBES MARSHALL PVT LTD Page 12

SMARTPro 8966 Introduction

Section 1.0

1.3 Operating Principle

The SMARTPro 8966 is a two wire transmitter with nominal

working voltage of 24VDC. In two wire configuration the

transmitter draws power from the loop itself.

The transmitter draws current of 4-20mA from supply. This

current is proportional to the measured variable.

The mV signal from the pH electrode is given to the high input

impedance preamplifier. This amplifier is internal to the

transmitter when the sensor is very close to the transmitter.

For sensor cable lengths in excess of 10Meters external buffer

amplifier is used.

A special A/D Converter digitizes the analog voltage, suppresses

the noise on the signal and gives accurate pH and temperature

inputs to microcontroller. The Microcontroller further processes

the data, displays the results on LCD display and generates

retransmission current output with HART ©.

The Microcontroller accepts the inputs from keyboard during

programming and calibration. The application specific

parameters such as measuring range, temperature

compensation are user programmable through keyboard.

FORBES MARSHALL PVT LTD Page 13

SMARTPro 8966 Introduction

Section 1.0

Block Diagram

I+ with HART

Galvanic

Isolation

LCD Display 0V

4.5V

+3.3V Power Supply

0V

-3.3V

Microcontroller + output Signal

OPTO Coupler

EEprom 4.20 mA

Optical Optical

Transmitter Receiver I- with HART

OPTO Coupler

Optical Optical

Transmitter Receiver 3 Open collector

outputs

0V 4.5V

Keyboard A/D Converter

Preamplifier Preamplifier

Temperature pH/mV

sensor Signal

Input

FORBES MARSHALL PVT LTD Page 14

SMARTPro 8966 Installation

Section 2.0

2.1 Unpacking and Inspection

The packing list is as below

Inspect the shipping carton for

any damages. If there are no

visual damages open the carton.

1. SMARTPro 8966 -1No

Check all the items as per packing

list. If any of the items are 2. Instruction Manual -1No

missing please inform the same to

Forbes Marshall local 3. 2”NB/3”NB pipe mounting kit

representative. consisting of

(integral assembly 3.1+3.2+3.3)

If it is damaged then, Inform the

damages to the transporter for 3.1 U clamps – 2Nos

further action. It is recommended 3.2 M8 Hex nuts - 4Nos

to take photographs in case of any 3.3 BSW washers – 4Nos

insurance claims.

4. Bar magnet

FORBES MARSHALL PVT LTD Page 15

SMARTPro 8966 Installation

Section 2.0

2.2 Tools required for installation

1.Multimeter 3 ½ digit

2.pH buffersNOTE1 for sensor calibration

3.Screw Driver with blade width 3mm

4.Screw Driver with blade width 8mm

5.Spanner 13mm (U clamp)

6.Spanner 17mm(Pivot)

7.Spanner 24mm (Cable glands)

8.Calibrated reference thermometer

NOTE1 To be arranged by the purchaser

FORBES MARSHALL PVT LTD Page 16

SMARTPro 8966 Installation

Section 2.0

2.3 Location and Mounting

For best results install the transmitter in area where

temperature extremes, vibrations, electromagnetic and

Radio frequency interference are at its minimum.

Use Weatherproof cable glands to keep the water, oil and

moisture entering inside the transmitter.

Mount the transmitter as near to the sensor as possible

so as to keep the sensor cable length minimum.

With help of the U Clamp provided, mount the transmitter

on 50mm/75mm OD pipe.

Ensure that the transmitter and the mounting bracket are

held properly on the pipe.

PIVOT

U CLAMP

50mm/75mm PIPE

FORBES MARSHALL PVT LTD Page 17

SMARTPro 8966 Installation

Section 2.0

2.3 Location and Mounting

You can change the transmitter orientation, by swiveling

the transmitter around the pivot.

The picture shows the transmitter rotated at right angles,

with the help of pivot.

U CLAMP

50mm/75mm PIPE

FORBES MARSHALL PVT LTD Page 18

SMARTPro 8966 Installation

Section 2.0

2.4 Cabling

Supply cable wires should be clearly marked/color coded

for +24V and ground to avoid polarity reversal

If conduit is used, Ensure the conduit end is properly

terminated in cable gland on transmitter side.

The cable used for 24V supply to transmitter should be

routed through cable gland

The Supply cable should be routed away from the Power

cabling.

Use proper size of lug suitable for 0.5 to 1 sq mm wire

8 with length of 6-8 mm for terminations on transmitter

side.

2.5 Power Supply requirements

The SMARTPro 8966 works on wide range of supply

voltage from 12VDC to 36VDC.

The supply voltage at the transmitter input terminals

must be at least 12VDC.

The power supply should be capable of taking the loads

(minimum 250 Ohms for HART ©) and the cable

resistance.

For HART © communication the minimum load resistance

of 250 Ohms is a must. To supply 12VDC at Transmitter

end the power supply voltage must be at least 17.5VDC

The power supply should be capable of supplying the

surge current at start up.

FORBES MARSHALL PVT LTD Page 19

SMARTPro 8966 Installation

Section 2.0

2.6 POWER SUPPLY AND SENSOR WITRING LOCATIONS

REMOVE REAR COVER TO ACCESS "TB2"

POWER SUPPLY CONNECTIONS

OPEN COLLECTOR OUTPUTS CONNECTIONS

REMOVE JUNCTION BOX COVER TO ACCESS "TB1"

SENSOR CONNECTIONS

FORBES MARSHALL PVT LTD Page 20

SMARTPro 8966 Installation

Section 2.0

2.7 Power Supply wiring

Remove the rear cover for wiring of power supply as shown

on page 18

Use 2 core shielded cable. Terminate the wires at power

supply side. Connect the cable shield to earth point at supply

side.

Measure the supply at the transmitter side with the help of

multimeter. It should be within 12VDC to 36VDC.

(Refer section 2.5 for more details)

Mark, color code, Ferrule the wires with +ve and gnd.

Switch OFF the supply before connecting it to transmitter.

Route the cable through conduit to avoid mechanical

damages to cable.

Route this cable through a cable gland provided on the

transmitter.

Tighten the cable gland nuts tightly so that cables are hold

firmly by the rubber seal. This is necessary to prevent

ingress of dust and moisture.

FORBES MARSHALL PVT LTD Page 21

SMARTPro 8966 Installation

Section 2.0

2.7Power Supply wiring…

Connect the power supply wire +ve to TB2/1 and gnd toTB2/2

as shown.

SMARTPro POWER SUPPLY WIRING

TB2 8 7 6 5 4 3 2 1

- +

+ SUPPLY

VOLTAGE

- 12-36VDC @ 100mA

SHIELD CONNECTED TO EARTH

2 CORE X 0.5 SQ MM SHIELDED CABLE

AT POWER SUPPLY END

Switch ON the power Supply. Measure the voltage across

TB2/1 with TB2/2 as ground. It should be 12VDC to 36 VDC.

The display on transmitter comes ON.

Switch OFF the supply again and wire up the open collector

outputs

FORBES MARSHALL PVT LTD Page 22

SMARTPro 8966 Installation

Section 2.0

2.8 Power Supply wiring precautions

Please follow the transmitter grounding guidelines as shown

in the diagram

1. Use 2 core shielded wire.

2. Ground the shield at the power supply point.

3. Do not run signal wire nearby high voltage wire.

4. Use separate cable trays and conduits for signal and

power cables.

5. Keep power supply and signals wire at least 2m away

from motor cable, VFD cables and heavy electrical cables.

FORBES MARSHALL PVT LTD Page 23

SMARTPro 8966 Installation

Section 2.0

2.9 Open Collector contacts wiring (Optional)

You have already removed the rear cover as shown on page

18

Use 2 core cable with each core 0.5 sq mm. Do the relay

wiring on the panel side/Control side.

Measure the voltage at the transmitter end of the cable, With

help of multimeter. It should be within 12VDC to 24VDC.

Mark, color code, Ferrule the wires with +ve and gnd.

Switch OFF the Relay supply before connecting it to

transmitter.

Route the cable through conduit to avoid mechanical damages

to cable.

Route this cable through a cable gland provided on the

transmitter.

Tighten the cable gland nuts tightly so that cables are hold

firmly by the rubber seal. This is necessary to prevent ingress

of dust and moisture.

FORBES MARSHALL PVT LTD Page 24

SMARTPro 8966 Installation

Section 2.0

Connect the wires to respective terminals of TB2

Type Terminal no Polarity

Over Range TB2/3 +ve

TB2/4

Under Range TB2/5 +ve

TB2/6

Error TB2/7 +ve

TB2/8

TYPICAL CONFIGURATION FOR OPEN COLLECTOR OUTPUTS

DO NOT WIRE UP DIRELTLY TO LOADS.

USE RELAY CONTACTS AS SHOWN FOR "CONTROL ACTION"

USER SCOPE

+12V-24V MAXIMUM

OPEN COLLECTOR RELAY

OUTPUTS

+ + + NC

TB2 P

ER UR OR

NO

8 7 6 5 4 3

100mA MAX

GND

OR : OVER RANGE

UR : UNDER RANGE

ER : ERROR

FORBES MARSHALL PVT LTD Page 25

SMARTPro 8966 Installation

Section 2.0

Open Collector contacts wiring precautions

1. Use 0.5 Sq mm wire minimum.

2. Do not reverse the supply voltage polarity going to

Contacts. It will permanently damage the electronics

used.

3. The maximum allowed voltage is 24V, maximum Current

Through contact is 100mA.

4. Do not use these contacts to directly control the solenoids,

Contactors, Inductive loads and other high voltage

Devices.

5. Wire up 24V relays as shown, use contacts of this

Relay for further control circuitry.

We have mounted the transmitter with U clamps and connected the

Power supply.

In next section we will connect sensor to the transmitter.

FORBES MARSHALL PVT LTD Page 26

SMARTPro 8966 Sensor Wiring

Section 3.0

3.1 Sensor Wiring

The model SMARTPro 8966 is configured at factory to work with

standard pH sensors. The sensor wiring is shown is for the typical Forbes

Marshall sensor.

If you are using any other make of sensor,

please refer the specific sensor manual.

3.2 Sensor cable

The cable of the pH sensor consists of a screw cap at one end. This

screw cap fits to the sensor end. The two wires on the other side are to

be terminated at the transmitter end.

There are two types of sensor cables available and configuration of both

the types is as shown.

Do not short, conductor (Glass) and shield (reference) or

conductor (Glass) and conducting layer black.

If short the transmitter will show pH 7 continuously.

FORBES MARSHALL PVT LTD Page 27

SMARTPro 8966 Sensor Wiring

Section 3.0

The sensor cable type 2 is as shown below

This type is used for pH sensors with inbuilt temperature sensor

Connect the screw cap to the sensor for both types of cables.

Connect the sensor cable to TB1 as shown

For pH sensors without the temperature sensor use separate RTD

sensor.

FORBES MARSHALL PVT LTD Page 28

SMARTPro 8966 Sensor Wiring

Section 3.0

3.3 Temperature sensor

It necessary to use temperature sensor for the auto correction of

the pH values.SMARTPro 8966 takes the input from RTD sensor.

The typical cable for the RTD is shown below.

RTD 2 CORE CABLE

CONDUCTOR1

LUG

T1

T2

SHEATH

CONDUCTOR2

Temperature sensor is used as temperature input during pH

sensor calibration with buffer.

Put this temperature sensor in buffer solution while

calibrating the pH electrode.

FORBES MARSHALL PVT LTD Page 29

SMARTPro 8966 Sensor Wiring

Section 3.0

3.4 Terminations

Use lugs suitable for 0.5-1mm wire and length 6-8mm

8

3.5 Cable terminals

Remove the junction box cover to access “TB1” for sensor

connection. Route the sensor cable through the cable gland

provided on the junction box.

Tighten the cable gland nuts tightly so that cables are hold firmly

by the rubber seal. This is necessary to prevent ingress of dust and

moisture.

1.Connect the wire shown as “Glass” to the transmitter terminal

marked as glass(Teflon bush)

2. Connect the wire shown as “Reference” to the transmitter

terminal marked as “Ref”.

3. Connect the wire shown as “T1” to transmitter terminal marked

As ”PT100” or “PT1”

4. Connect the wire shown as “T2” to transmitter terminal marked

as “PT100” or “PT2”

Calibrate every time you change the sensor

FORBES MARSHALL PVT LTD Page 30

SMARTPro 8966 Sensor Wiring

Section 3.0

3.6 Cable termination on Board I

FORBES MARSHALL PVT LTD Page 31

SMARTPro 8966 Sensor Wiring

Section 3.0

3.7 Cable termination on Board

Some pH sensors are with inbuilt temperature sensors. Terminate

these sensor wires on the terminals marked as PT1,PT2.

FORBES MARSHALL PVT LTD Page 32

SMARTPro 8966 Sensor Wiring

Section 3.0

3.8 Calibration and commissioning.

We have mounted and wired up the transmitter.

Now we are ready to calibrate the sensor.

Power ON the transmitter

Calibrate the sensor with the help of buffer solution.

Refer section 4.0, Menu 3.6.1 for calibration process.

Calibrate the temperature sensor with standard thermometer.

Refer section 4.0, Menu 3.5.4 for calibration process.

Check and set transmitter range as required by the process.

Refer section 4.0 Range setting.

Mount the sensor carefully in the process pipe, flow through

chamber or tank as per the application.

Transmitter + sensor combination is ready for use.

FORBES MARSHALL PVT LTD Page 33

SMARTPro 8966 Operation

Section 4.0

SMARTPro series of transmitters allow user to set different

Parameters. The user menus available as follows

NO MENU DESCRIPTION Default

1.1.1 PH UNIT To change the pH unit PH

1.1.2 TEMP UNIT To change the temperature units ºC

1.1.4 TIMECON To set the time constant 1.00

1.1.5 CYCLE DISP To set cyclic display ON OFF

1.2.3 RELAY OPT To set the relay trip conditions Default

1.2.6 ERROR To set error messages ON ON

MSG.

1.3.2 FORCE OP I To Enable current output ON

1.3.3 RANGE I To set the current output range 4-20mA

NO MENU DESCRIPTION Default

2.1.1 TEST DISP. To test the display OFF

2.1.2 TEST I To test the Loop current OFF

2.1.3 TEST CONT To test re lay contacts Default

2.1.4 DATE SLOPE To check the sensor slope after *

sensor calibration

FORBES MARSHALL PVT LTD Page 34

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

3.1.1 PH MA VAL To set the range for 4-20mA *

output as per pH value

3.1.3 SENS TYPE To set the sensor type pH

3.2.2 CODE1 To set user menu password OFF

3.2.4 LOCATION To set the location of transmitter 00

3.2.7 POLL ADDR. To set the polling address of 00

Transmitter

3.5.4 T SEN CALB To calibrate temperature sensor *

3.6.1 SENS CALB TO calibrate the sensor *

* To be done during installation

To go to user menus 1.1.1 to 3.6.1 press up arrow key on

display keyboard. Use combination of Up key, right Key and

Enter key to move through the menus.

Refer display diagram on page no 10 of this manual to see the

key layout.

FORBES MARSHALL PVT LTD Page 35

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.1.1 PH UNIT To change the pH unit pH

FLOW CHART FOR DISPLAY UNIT SELECTION

1.1.1

A

PH UNIT

PH M VOLT M AMP SPECIAL B

UNIT UNIT UNIT UNIT

PH DISPLAYS IN PH

M VOLT DISPLAYS IN MILIVOLTS

M AMP DISPLAYS IN MILIAMPS

SPECIAL DISPLAYS IN SPECIAL UNITS

PH M VOLT M AMP XXXXXXXX

DISP. ON DISP. ON DISP. ON DISP. ON C

MENU MENU A SPECIAL B

CONT. NO CONT. YES UNIT

SAVE PARM. SAVE PARM. PH XH

NO YES UNIT UNIT

00001.0000 00000.5000

A1 COEFF A1 COEFF.

XXXXXXXX

A C

DISP. ON

FORBES MARSHALL PVT LTD Page 36

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.1.1 PH UNIT Continued pH

This menu is used to set the measuring unit. We can select the

units pH, mV, mA and Special.

It is necessary to save the parameters after the selection.

The special unit is very rarely used. We can select the

coefficient and display the value in user defined units

pH Displays the measured value in terms of pH units.

mV Displays the measured value in terms of mili volts.

This unit is used generally with ORP electrodes

mA Displays the measured value in terms of mili Amps.

The value shown depends on the mA range set by

the menu 3.1.1

This is the actual loop current flowing through the

Transmitter

Special Displays the measured value in user defined units.

User can apply the coefficient if required

If coefficient of 0.5 is applied the measured value is

multiplied by the factor of 0.5

FORBES MARSHALL PVT LTD Page 37

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.1.2 TEMP To change the Temperature unit ºC

UNIT

FLOW CHART FOR TEMPERATURE UNIT SELECTION

1.1.2

A TEMP UNIT

MANUAL USER SET TEMPERATURE INPUT

AUTO GETS THE INPUT FROM THE TEMP SENSOR

1.1.2 1.1.2

MANNUAL AUTO

DEG. C DISPLAYS IN DEG CENTIGRADE

DEG. F DISPLAYS IN DEG FARANHITE

KELVIN DISPLAYS IN KELVIN

SPECIAL DISPLAYS IN SPCIAL UNIT

DEG C DEG. F KELVIN SPECIAL B

UNIT UNIT UNIT UNIT

DEG.C DEG.C

DISP.ON DISP. OFF

ON DISPLAYS ON SCREEN

AUTO MANUAL

OFF NO DISPLAY ON SCREEN

C D B

SEE NEXT PAGE

FORBES MARSHALL PVT LTD Page 38

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.1.2 TEMP Continued ºC

UNIT

C D A B

AUTO MANUAL

0000025.00 SPECIAL

DEG.. C UNIT

MENU MENU DEG. C UNIT XEG. C UNIT

C CONT. NO CONT. YES A

SAVE PARM. SAVE PARM. 00001.0000 00000.5000

NO YES AO OFFSET AO OFFSET

1.1.1 XXXXXXXX

PH UNIT DISP. ON C

This menu is used to set the temperature unit. We can set the

temperature in manual mode or Auto mode.

In auto mode the temperature input is taken from the

temperature sensor and is displayed on the screen. This

temperature is used for temperature compensation.

In manual mode user feeds the temperature and same

temperature is used for calculations.

FORBES MARSHALL PVT LTD Page 39

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.1.4 TIMECON To Set the Time constant 2.00

FLOW CHART FOR TIME CONSTANT SELECTION

1.1.4

A

TIME CONST

Set the counts with up and right key

02.0000000 12.0000000 To shift decimal point --

SEC SEC Take the cursor to decimal point and

then use up key

MENU MENU A

CONT. NO CONT. YES

SAVE PARM. SAVE PARM.

NO YES

1.1.1

PH UNIT

Low pass filter time constantin sec.

It decides instrument response time to process inputs

Increase if you observe abnormal fluctuations on display.

FORBES MARSHALL PVT LTD Page 40

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.1.4 TIMECON Continued 2.00

Enter a low pass filter value in seconds to be applied to process

input. A value of zero indicates that the low pass filter is

bypassed.

With this variable it is possible to compromise between a steady

indication (on display and current output) and the response

time (process changes).

It is factory set to 2.0.You may increase it if you observe

abnormal fluctuations on display.

FORBES MARSHALL PVT LTD Page 41

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.1.5 CYCLE To Set cyclic display ON NO

DISP

FLOW CHART FOR CYCLIC DISPLAY SELECTION

1.1.5

A

CYCLIC DISP

DISPLAYS SELECTED

PRIMARY VARIABLE

CYCLIC DISP CYCLIC DISP PH AND TEMPERATURE

NO YES ALTERNATLEY

YES

MENU MENU

A

CONT. NO CONT. YES

SAVE PARM. SAVE PARM.

NO YES

UNIT COMES TO 1.1.1

NORMAL MODE PH UNIT

FORBES MARSHALL PVT LTD Page 42

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.1.5 CYCLE To Set cyclic display ON NO

DISP

If we select YES,

It means display will cycle automatically. This means a

measured parameter is shown in the selected units for about

6seconds and then the next parameter is shown for 6 seconds

and so on.

If we select NO,

It means display shows last selected measured parameter.

To toggle from one parameter to other press up arrow key.

FORBES MARSHALL PVT LTD Page 43

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.2.3 RELAY To set the “Open collector outputs” NA

OPT

1.2.3

A RELAY OPT

RELAY OPT RELAY OPT

RELAY OVER RELAY UNDR

RELAY OPT RELAY OPT

PH VAL PH VAL

14.00 0.00

PH PH

RELAY OPT RELAY OPT

C CONT. NO CONT. YES

B

MENU MENU

A CONT. YES CONT. NO

SAVE PARM. SAVE PARM.

YES NO

1.1.1

PH UNIT

FORBES MARSHALL PVT LTD Page 44

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.2.3 RELAY Contd... NA

OPT

RELAY OPT RELAY OPT

B RELAY UNDR RELAY OVER

RELAY OPT RELAY OPT RELAY OPT

PH VAL % HYSTERIS SEC. DELAY

002 002

% HYSTERIS SEC DELAY

With the help of this menu we can set the tripping points for the

lower limit and the upper limit for “Open collector outputs”

These outputs can be used as alarm inputs HI and LO

Additionally we can set the hysteresis and time delay as per the

process requirement.

For wiring of these outputs please refer section 2.9

FORBES MARSHALL PVT LTD Page 45

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.2.6 ERROR To set the error messages ON YES

MSG.

FLOW CHART FOR ERROR MESSAGES SELECTION

1.2.6

A

ERROR MSG.

DISPLAYS ERROR

ERROR MSG ERROR MSG

NO YES MESSAGES DURING

NORMAL MEASURING

YES

MODE

MENU MENU

A

CONT. NO CONT. YES

SAVE PARM. SAVE PARM.

NO YES

UNIT COMES TO 1.1.1

NORMAL MODE PH UNIT

Choose YES so that the error messages appear between the display

of parameters in the normal measuring mode, otherwise NO

FORBES MARSHALL PVT LTD Page 46

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.3.2 FORCE OP I To Enable current output NO

FLOW CHART FOR FORCE OUTPUT I SELECTION

1.3.2

A

FORCE OP I

FORCE OP I FORCE OP I ENABLES THE OUTPUT

NO YES CURRENT AS PER THE

SET VALUE

YES

MENU MENU

A

CONT. NO CONT. YES

SAVE PARM. SAVE PARM.

NO YES

UNIT COMES TO 1.1.1

NORMAL MODE PH UNIT

If set to YES the output current is enabled as per the process

variable value.

The actual value of the output current depends on the settings

in 3.1.1 PH MA VAL

See also 3.1.2 RANGE I

FORBES MARSHALL PVT LTD Page 47

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

1.3.3 RANGE I To Set the output current range 4-20mA

FLOW CHART FOR RANGE I SELECTION

1.3.3

A

RANGE I

1.3.3 1.3.3 1.3.3

4-20mA 4-20/22E 4-20/3.55E

4-20mA RANGE 4-20mA WITHOUT ERROR INDICATION

4-20/22E OUTPUT IS FORCED 22mA ON FAULT

4-20/3.55E OUTPUT IS FORCED TO 3.55mA ON FAULT

MENU MENU A

CONT. NO CONT. YES

SAVE PARM. SAVE PARM.

NO YES

UNIT COMES TO 1.1.1

NORMAL MODE PH UNIT

We can select out of three ranges.

When range with suffix of 22E or 3.55E is selected the current

output is forced to 22mA and 3.55mA in case of fault

respectively.

Range 4-20mA is without any error detection on current output.

FORBES MARSHALL PVT LTD Page 48

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

2.1.1 TEST To Test the display NO

DISP.

FLOW CHART FOR TEST DISP. SELECTION

2.1.1

A

TEST DISP

2.1.1 2.1.1

YES NO

8888888888

8888888888

MENU MENU A

CONT. NO CONT. YES

1.1.1

PH UNIT

To test the display. If all digits are shown as 8.

The display is OK.

FORBES MARSHALL PVT LTD Page 49

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

2.1.2 TEST I To Test the output current OFF

FLOW CHART FOR TEST I SELECTION

2.1.2

A

TEST I

TEST I

4 MA

NOTE METER READING

TEST I

8 MA

TEST I TEST I

CONT YES CONT NO

TEST I

12 MA

A MENU MENU

CONT YES CONT NO

TEST I

16 MA

1.1.1

PH UNIT

TEST I

20 MA

This menu is used to test the loop current.

To check the current, break the loop and put mA meter in

series. Use accurate current meter with resolution of 00.00 mA.

The displayed current values should be in range the of ±0.1mA.

This menu can be used to check the control panel side

instruments such as signal isolators/Repetors.

FORBES MARSHALL PVT LTD Page 50

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

2.1.3 TEST “Open collector contacts” testing NA

CONT

2.1.3

A TEST CONT

CONT TEST CONT TEST CONT TEST

B CONTACT 1 CONTACT 2 CONTACT 3

CONT TEST CONT TEST

CONT NO CONT YES B

MENU MENU

CONT. NO CONT. YES

A

1.1.1

PH. UNIT

This menu is used to test the open collector contacts.

The user can utilize this facility to check the panel side wiring

for correctness. For relay wiring details please refer section 2.9

FORBES MARSHALL PVT LTD Page 51

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

2.1.4 DATE Shows the sensor slope after NA

SLOPE calibration

FLOW CHART FOR TEST DISP. SELECTION

2.1.4

A

DATE SLOPE

DISPLAY DISPLAY DISPLAY

DD MM YY % SLOPE ZERO OFSET

02/11/07 XXX.XXXX X.XXXX

DD MM YY % SLOPE ZERO OFFSET

DISPLAY DISPLAY A

CONT. NO CONT. YES

MENU MENU A

CONT. NO CONT. YES

1.1.1

PH UNIT

SHOWS DATE OF SENSOR CALIBRATION, SENSOR SLOPE

AND OFFSET AT THE TIME OF CALIBRATION

The date , slope and zero offset shown as per calibrated with

menu 3.6.1 SENS CALB

FORBES MARSHALL PVT LTD Page 52

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

3.1.1 PH MA To set the range for 4-20mA

VAL output as per pH value

FLOW CHART FOR PH MA VAL SELECTION

3.1.1 B

A

PH MA VAL

ENT PH VAL ENT PH VAL

VAL 4MA VAL 20MA

00.0000000 DISPLAY

C

VAL 4MA DD MM YY

ENTER PH VALUE FOR ENTER PH VALUE FOR

4mA CURRENT OUTPUT 20 mA CURRENT OUTPUT

MENU MENU A

CONT. NO CONT. YES

1.1.1

PH UNIT

Set the current output as per pH values. Minimum span is 2pH.

eg:-

If you set 4pH as 4mA set value

and 6pH as 20mA set value , then the current at

5pH will be 12mA

FORBES MARSHALL PVT LTD Page 53

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

3.1.3 SENS To set the sensor type pH

TYPE

FLOW CHART FOR SENS TYPE SELECTION

3.1.3

A

SENS TYPE

3.1.3 3.1.3

PH REDOX

MENU MENU A

CONT. NO CONT. YES

SAVE PARM. SAVE PARM.

NO YES

1.1.1

PH UNIT

We can set the sensor type with the help of this parameter.

If you change the sensor from pH to Redox and vice versa

then it is necessary to change

1.1.1 PH UNIT

1.3.3 RANGE I

3.1.1 PH MA VAL

This transmitter is not field configurable from pH to ORP

or vice versa on site. Please consult factory

FORBES MARSHALL PVT LTD Page 54

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

3.2.2 CODE1 To enable user menu password NO

FLOW CHART FOR CODE 1 SELECTION

3.2.2

A

CODE 1

3.2.2 3.2.2

NO YES

YES PASSWORD IS ACTIVATED

FOR USER MENU

MENU MENU A

CONT. NO CONT. YES

SAVE PARM. SAVE PARM.

NO YES

1.1.1

PH UNIT

FORBES MARSHALL PVT LTD Page 55

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

3.2.4 LOCATION To set the location of the 000

transmitter

FLOW CHART FOR LOCATION SELECTION

3.2.4

A

LOCATION

0000000000 0000NPT001

LOCATION LOCATION

USE UP ARROW AND RIGHT ARROW

ENTER ALPHANUMERIC

INSTRUMENT LOCATION

MENU MENU A

CONT. NO CONT. YES

SAVE PARM. SAVE PARM.

NO YES

1.1.1

PH UNIT

This is the location referred by HART © communication.

FORBES MARSHALL PVT LTD Page 56

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

3.2.7 POLL To set the polling address of the 000-015

ADDR. transmitter

FLOW CHART FOR POLL ADDR. SELECTION

3.2.7

A

POLL ADDR.

000 010

0 TO 15 0 TO 15

USE UP ARROW AND RIGHT ARROW

ENTER ALPHANUMERIC

INSTRUMENT POLL ADDR

MENU MENU A

CONT. NO CONT. YES

SAVE PARM. SAVE PARM.

NO YES

1.1.1

PH UNIT

This is the address referred by HART © communication.

By default it is set to “00” for single point operation.

It is set in the range of “00-15” in multi drop configuration.

See section 5.0 for HART © Communication

FORBES MARSHALL PVT LTD Page 57

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

3.5.4 T SEN To calibrate temperature sensor DISABLE

CALB

3.5.4

A T SEN CALB

3.5.4 3.5.4

DISABLE ENABLE

0000025.00

ENT. TEMP

XX.XX

ACT. TEMP

MENU MENU

CONT. NO CONT. YES

A

SAVE PARM. SAVE PARM.

NO YES

1.1.1

PH UNIT

FORBES MARSHALL PVT LTD Page 58

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

3.5.4 T SEN Contd...

CALB

This menu is used to calibrate the temperature sensor.

SmartPro uses 2 wire RTD PT100/PT1000 as temperature sensor.

This sensor gives temperature in terms of resistance. (See Annex 2).

As the sensor cable length increases, the resistance of the cable adds up in

the RTD resistance.

If the resistance of the sensor cable is say 1.0 Ohms the the reading shown on

the transmitter is 2 to 3 °C more than the actual temperature. For small cable

lengths this can be neglected and no need for calibration.

To calibrate the sensor, dip the temp sensor and standard thermometer water

at ambient temperature. Ensure that the temperature sensor and the

standard thermometer are completely submerged. Allow the system to

stabilize for about 20 minutes. Follow the procedure as indicated in above

flow chart.

Also see section 7.2

Check that the standard thermometer, RTD, thermistor that

is used for reference is calibrated and accurate.

FORBES MARSHALL PVT LTD Page 59

SMARTPro 8966 Operation

Section 4.0

pH cell Calibration

The pH sensor is made up of thin glass membrane. This glass membrane is

sensitive to pH changes. The pH cell when dipped in a solution, generates

mili volts proportional to the pH of the solution.

The mili volts generated depends on the sensitivity of the glass membrane.

The sensitivity of the glass membrane drops as the membrane ages out. This

needs to be corrected with regular calibration of the cell/electrode. This is

done with the help of standard pH buffers.

Two point calibration as indicated in following flow chart is recommended

always.

The transmitter can also be standardized. In standardization we force the

transmitter reading to match with the reading from second pH instrument.

This can be done with the help of “single point calibration” as detailed out

below

During the process of calibration we find out sensor slope and offset. The

transmitter notes down these values and uses this during further

calculations.

FORBES MARSHALL PVT LTD Page 60

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

3.6.1 SEN To calibrate the sensor *

CALB

FLOW CHART FOR SEN. CALB SELECTION

3.6.1

A

SEN. CALB

UESR CAN SELECT DIFFERENT TEMP UNITS

NOT SHOWN HERE FOR CLARITY

CALB TYPE CALB TYPE

DUAL PT. SINGLE PT.

ENT TEMP. ENT TEMP. ENT TEMP. ENT TEMP.

MANUAL AUTO MANUAL AUTO

DEG. C DEG. C DEG. C DEG. C

UNIT UNIT UNIT UNIT

0000025.00 30.00 0000025.00 30.00

DEG. C DEG. C DEG. C DEG. C

B C

CONTINUE DUAL POINT CONTINUE SINGLE POINT

CALIBRATION CALIBRATION

This procedure is to be followed every time the sensor is

changed or to be recalibrated. It is advisable to use two point

calibration always. In this procedure, the sensor is dipped in

buffer solutions of known pH value.

Messages of calibration error, Slope error are given on display

to indicate bad sensor. It is advisable to change the sensor in

such cases.

FORBES MARSHALL PVT LTD Page 61

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

3.6.1 SEN CONTINUED *

CALB

FLOW CHART FOR SEN. CALB SELECTION CONTD

CALB PH/RX

B C

1ST POINT

00.00000000 04.00000000

ENTER PH ENTER PH

177.87 177.87

PLS. WAIT READY

2ND POINT 2ND POINT

ENTER PH ENTER PH

00.00000000 09.00000000 00.00000000 09.00000000

ENTER PH ENTER PH ENTER PH ENTER PH

-118.28 -118.28 -118.28 -118.28

PLS. WAIT READY PLS. WAIT READY

D CONTINUE CALIBRATION

FORBES MARSHALL PVT LTD Page 62

SMARTPro 8966 Operation

Section 4.0

“Dual point calibration”

The flow chart above for "Dual point calibration" is shown

considering two buffer solutions pH 4 and pH 9.

Dip the sensor in the buffer solution with pH 4.

Press Enter when ready.

Dip the sensor in the buffer solution with pH 9.

Press enter when ready.

%slope, Zero Offset are shown. Enter the date.

These parameters can be seen in future in menu

2.1.4 DATE SLOPE

"Single point calibration"

The flow chart also shows "Single point calibration" method,

also called as standardization. In this method the pH value of

the solution is measured with the standard pH instrument. The

sensor is dipped in this solution, and earlier measured pH value

is fed during calibration.

FORBES MARSHALL PVT LTD Page 63

SMARTPro 8966 Operation

Section 4.0

NO MENU DESCRIPTION Default

3.6.1 SEN CONTINUED *

CALB

FLOW CHART FOR SEN. CALB SELECTION CONTD

100.119

D

% SLOPE

-0.0312

ZERO OFFSET

19/10/07

ENTER DATE

MENU MENU A

CONT. NO CONT. YES

SAVE PARM. SAVE PARM.

NO YES

1.1.1

PH UNIT

FORBES MARSHALL PVT LTD Page 64

SMARTPro 8966 HART © Communication

Section 5.0

5.1 HART© communication configurations

The SMARTPro 8966 is equipped with HART© communication.

The transmitter can be used in multi drop configuration or as a

Single HART© instrument.

Following configuration is used to set the SMARTPro 8966

transmitter

SMARTPro

TEST POINTS

TO CONNECT HART

HART

TB2 COMMUNICATOR

8 7 6 5 4 3 2 1

- +

24VDC

4/20mA + DIGITAL +

-

MINIMUM LOAD

250 Ohms SUPPLY

VOLTAGE

12-36VDC

Connect the HART© communicator to terminals provided

on the power supply PCB to configure /monitor the

transmitter parameters.

FORBES MARSHALL PVT LTD Page 65

SMARTPro 8966 HART © Communication

Section 5.0

5.2 HART© Communication

Single point configuration is shown below.

This configuration is used to set and check the transmitters locally

FORBES MARSHALL PVT LTD Page 66

SMARTPro 8966 HART © Communication

Section 5.0

5.2 HART© Communication

Multipoint configuration is shown below.

This configuration is used to set and check up to 15 transmitters.

The cables carry only digital signals, The loop current is set to 4mA.

Monitoring data is available on control system/ PC as shown.

MULTIDROP CONFIGURATION

SMARTPro

+ DIGITAL SIGNALS ONLY +

- -

MINIMUM LOAD

250 Ohms SUPPLY

VOLTAGE

12-36VDC

UPTO 15 BRIDGE

TRANSMITTERS

PC /

COMMUNICATOR CONTORL SYSTEM

HART

Notes

Use HART© communicator to set up SMARTPro 8966

For trouble free and effective communication ensure

loop load to be 250 Ohms minimum.

The Connection to HART© is optional

SMARTPro 8966 can be also set using the program

keys provided on Front. Refer section 4.0

FORBES MARSHALL PVT LTD Page 67

SMARTPro 8966 Maintenance

Section 6.0

6.1 Probe care and Maintenance

pH electrodes require maintenance at regular intervals. This interval is

decided by the user depending on the process fluid in which the

electrode is used. Typically in the range of one to three months.

It is necessary to check for tips on electrode care in

Instruction manual provided with the electrode.

6.2 How to store the electrode for long time

Always keep the pH bulb wet. Use electrode storage solution

Recommended by electrode manufacturer.

Use rubber cap or electrode storage bottle filled with

electrode storage solution.

You can use pH 4 buffer solution with 1/100 th part of

saturated KCL solution.

Don’t use distilled water for storage.

6.3 Storage after use in process

Use de ionized water to rinse the pH electrode an reference

junction

Store the electrode after rinsing as per 6.2

Before putting back to service ,clean the electrode with de

ionized water and dab dry with clean tissue paper

Never Rub or Wipe the electrode. This could give rise to

electrostatic charges which will increase the response time of

the electrode.

FORBES MARSHALL PVT LTD Page 68

SMARTPro 8966 Maintenance

Section 6.0

6.4 How to clean the electrode

The pH electrode is a electro-chemical sensor. When the pH electrode

is used, the junction and glass membrane contaminates because of

process fluid. This in turn increases the sensor response time.

Salt deposits

Immerse the electrode in tap water for 10/15 minutes. The salt

dissolves in water. Rinse the electrode with distilled water.

Oil/Grease film

Use mild detergent and water to gently wash the electrode bulb.

Rinse the electrode tip with distilled water.

Protein deposits

Dip the electrode in a solution prepared as 1% pepsin solution in 0.1M

of HCL for 10 minutes. Rinse the electrode with distilled water.

Clogged reference junction

Heat diluted KCL solution to 60 to 80 deg C. Place the sensing part of

the electrode into the heated solution for about 10 minutes. Allow the

electrode to cool in unheated KCL solution

FORBES MARSHALL PVT LTD Page 69

SMARTPro 8966 Maintenance

Section 6.0

6.5 How to Rehydrate the bulb

If the electrode is stored and cleaned as per the procedures indicated

above, it is ready for use always. But if because of some reasons the

bulb is dehydrated , follow the procedure to rehydrate the bulb

Immerse the electrode in pH 4 buffer solution for 10 to

30minutes. Rinse the electrode with distilled water. Check the

response of the electrode.

If this procedure fails and electrode doesn’t give any

response then consult the sensor manufacturer.

FORBES MARSHALL PVT LTD Page 70

SMARTPro 8966 Maintenance

Section 6.0

6.6 Do’s and Don’ts for pH (Glass) electrodes

Read the operating manual provided with the electrode

carefully.

Before actually putting the electrode in to work, Remove the

special transportation seal (If any) provided on the diaphragm

of this electrode using a sharp knife very carefully without

damaging the diaphragm.

Clean the pH electrode under low pressure tap water or any

suggested cleaning solution. Do not touch the diaphragm or tip

of the electrode during cleaning.

Tap dry the tip of the electrode using a clean and soft tissue

paper

Do not rub the tissue paper on the electrode as it may

generate static charges

Calibrate the transmitter with pH electrode as a pair. Use this

Calibrated pair to measure pH values. If you change/replace

transmitter and/or electrode it is necessary to recalibrate as a

pair.

Keep the electrode wet when not in use. Dip the electrode in

3M KCL solution (or any storage solution as recommended by

manufacturer)

Calibrate the sensor at regular intervals

FORBES MARSHALL PVT LTD Page 71

SMARTPro 8966 Trouble Shooting

Section 7.0

7.0 Trouble shooting

The SMARTPro 8966 is a microcontroller based transmitter which

gives out error messages on the display.

User can identify the possible causes of the problems and take the

corrective actions. The error messages and their meaning are given

below

Error Message Action

Temp sen open Check the temperature sensor wires for open or

loose connection. Reconnect the wires

Check link JP1 short for PT100/Open for PT1000

Check the resistance of the RTD element , It

should be

109.73 Ohms @ 25 deg C for PT100

1097.3 Ohms @ 25 deg C for PT1000

If open then replace the Temperature sensor

Temp sen short Check the temperature sensor wires for short

circuit on terminals in junction box

Check link JP1 short for PT100/Open for PT1000

Check the resistance of the RTD element , It

should be

100 Ohms @ 25 deg C for PT100

1000 Ohms @ 25 deg C for PT1000

If short then replace the Temperature sensor

FORBES MARSHALL PVT LTD Page 72

SMARTPro 8966 Trouble Shooting

Section 7.0

Error Message Action

Zero error This message is displayed during sensor

calibration. This shows that sensor “zero point” is

shifted by more than 1pH units from the ideal

value

Use the procedures to clean and rehydrate the

bulb. Check again. If the same message repeats

then replace the sensor.

Slope error This message is displayed during sensor

calibration. This shows that sensor “slope” is out

of the normal acceptable slope range 70% to

110%.

Use the procedures to clean and rehydrate the

bulb. Check again. If the same message repeats

then replace the sensor.

FORBES MARSHALL PVT LTD Page 73

SMARTPro 8966 Trouble Shooting

Section 7.0

7.1 Causes and solution to problems

Problem Causes Solutions

No display No power Apply power

Less power Ensure Power on

transmitter terminals to

be within 12-36VDC

Power Reverse polarity Correct the polarity

Loose connection Tighten the power supply

wires

In correct pH Sensor not calibrated for Recalibrate the sensor

Value long time.

Sensor mechanically Replace the sensor

damaged

dirty process fluid Clean the sensor as per

the procedures 6.4, 6.5

Sensor not dipped Ensure that process fluid

properly in process entirely covers the sensor

properly.

External noise pick up Follow proper grounding

and shielding procedures

as discussed in section

2.0

FORBES MARSHALL PVT LTD Page 74

SMARTPro 8966 Trouble Shooting

Section 7.0

7.2 Problem in temperature measurement and calibration

Temperature shown by the instrument does not match with the

reading from standard thermometer. (Difference more than ±1 ºC)

Check the following

Check that the standard thermometer, RTD, thermistor that is

used for reference is calibrated and accurate.

General purpose liquid in glass thermometers can have large

errors

Are the measurements done at the same point as of

transmitter?

If standard thermometer dipped up to correct level?

It is necessary to calibrate the temperature sensor during

installation and commissioning.

FORBES MARSHALL PVT LTD Page 75

SMARTPro 8966 Trouble Shooting

Section 7.0

7.3 pH reading not matching with lab reading

It is normal to have differences in pH readings made on on-line

instrument and lab instrument.

The online instrument is subjected to the actual process conditions

such as process temperature, stray voltages, process pressure, supply

voltage variations etc.

The lab instrument works at set standard conditions. Some impurities

are added, the temperature of the lab sample changes and the

differences are seen between both readings.

How to minimize the gap in readings?

You can check both the Lab and On-line instruments by using

the same buffer solution and comparing the readings

If not matching , calibrate both the instruments by the same

buffer solution

Use single point calibration method to match the readings.

See section 4.0, menu 3.6.1

FORBES MARSHALL PVT LTD Page 76

SMARTPro 8966 Trouble Shooting

Section 7.0

7.4 Is the transmitter working OK

In case of problems it is necessary first isolate the problem areas.

Sensor or the transmitter is giving problem?

To Simulate mV inputs

To check this, disconnect the sensor wires from transmitter end.

Connect milivolt source to transmitter. If the transmitter is working

properly it will show the accurate pH readings.

Follow the procedure below to check the transmitter

1 Turn off the transmitter supply. Disconnect the sensor wires from

the transmitter side by removing the junction box cover.

2 Connect the milivolt source to transmitter in place of sensor

3 Turn ON the transmitter, Turn Off auto temperature

compensation and set 25 deg c manually.

4 Simulate 118.4 mV from milivolt source.

5 Select unit of measure as “milivolts” M VOLT in menu 1.1.1

(Refer section 5.0 ,function 1.1.1 PH UNIT)

6 Come out of the menu

7 Display will show the 118.4mV

8 Check this for the range +414mV to -414mV

9 If all the mV readings shown on display are matching with the

simulated Milivolt source readings. The transmitter is working

OK.

10 Switch to normal measuring unit pH Select unit of measure as

“PH” in menu 1.1.1 (Refer section 5.0 ,function 1.1.1 PH UNIT)

Turn ON auto temperature compensation.

FORBES MARSHALL PVT LTD Page 77

SMARTPro 8966 Trouble Shooting

Section 7.0

7.5 Is the transmitter working OK

In case of problems it is necessary first isolate the problem areas.

Sensor or the transmitter is giving problem?

To Simulate temperature inputs

To check this, disconnect the temperature sensor wires from

Transmitter end. Connect resistance decade box to transmitter

Temperature input terminals. If the transmitter is working properly it

shows the accurate temperature readings.

Follow the procedure below to check the transmitter

1 Turn off the transmitter supply. Disconnect the sensor wires from

the transmitter side by removing the junction box cover.

2 Connect the decade box to transmitter in place of sensor

3 Turn ON the transmitter

4 Simulate 109.73ohms from decade box.

5 The secondary display will show 25.00 deg C

6 You can check this for different set of Decade box inputs

7 The measured temperature may not exactly match with the table

values. This is because of the offset of temperature value added

or subtracted during the temperature sensor calibration.

8 The same offset is applied to these simulated inputs. The

controller is measuring the temperature correctly if the difference

between the two table readings and same two transmitter

readings is within +/- 0.5deg C.

9 If Offset of 2 ºC is added during calibration. The transmitter will

read the value 115.54 as 40 ºC, but display as 42 ºC.

10 Refer Annexure II for pt 100 resistance table

FORBES MARSHALL PVT LTD Page 78

SMARTPro 8966 Annexure

Annexure I

pH verses mV table

pH mV

0ºC 20ºC 25ºC 50ºC 80º C 100º C

0 379.4 407.1 414.4 448.8 490.5 518.2

1 325.2 349.0 355.2 384.7 420.5 444.2

2 271.0 290.8 296.0 320.6 350.4 370.2

3 216.8 232.6 236.8 256.5 280.3 296.1

4 162.6 174.5 177.6 192.3 210.3 222.1

5 108.4 116.4 118.4 128.3 140.2 148.1

6 54.2 58.15 59.2 64.1 70.05 74.0

7 0 0 0 0 0 0

8 -54.2 -58.15 -59.2 -64.1 -70.05 -74.0

9 -108.4 -116.4 -118.4 -128.3 -140.2 -148.1

10 -162.6 -174.5 -177.6 -192.3 -210.3 -222.1

11 -216.8 -232.6 -236.8 -256.5 -280.3 -296.1

12 -271.0 -290.8 -296.0 -320.6 -350.4 -370.2

13 -325.2 -349.0 -355.2 -384.7 -420.5 -444.2

14 -379.4 -407.1 -414.4 -448.8 -490.5 -518.2

FORBES MARSHALL PVT LTD Page 79

SMARTPro 8966 Annexure

Annexure II

Annexure II Temperature in ºC verses resistance in ohms

Temperature Pt100 Pt 1000 Temperature Pt100 Pt 1000

-20 92.16 921.6 65 125.16 1251.6

-10 96.09 960.9 70 127.07 1270.7

0 100.00 1000.0 80 130.89 1308.9

5 101.95 1019.5 90 134.70 1347.0

10 103.90 1039.0 100 138.50 1385.0

15 105.85 1058.5 110 142.29 1422.9

20 107.79 1077.9 120 146.06 1460.6

25 109.73 1097.3 130 149.82 1498.2

30 111.67 1116.7 140 153.58 1535.8

35 113.61 1136.1 150 157.31 1573.1

40 115.54 1155.4 160 161.04 1610.4

45 117.47 1174.7 170 164.76 1647.6

50 119.40 1194.0 180 168.46 1684.6

55 121.32 1213.2 190 172.16 1721.6

60 123.24 1232.4 200 175.84 1758.4

FORBES MARSHALL PVT LTD Page 80

You might also like

- Aquacon SMARTPRO 8967P PDFDocument87 pagesAquacon SMARTPRO 8967P PDFReddy Manoj100% (1)

- Aquacon SMARTPRO 8967PDocument87 pagesAquacon SMARTPRO 8967PKuppu Raman100% (2)

- AquaDO SMARTPRO 8968 Manual PDFDocument33 pagesAquaDO SMARTPRO 8968 Manual PDFkumar50% (2)

- Flowirl 8700Document77 pagesFlowirl 8700srinivasan0198150% (6)

- Condensate Recovery Meter CRM 485R: Energy Conservation - Environment - Process EfficiencyDocument6 pagesCondensate Recovery Meter CRM 485R: Energy Conservation - Environment - Process Efficiencyaftab0% (1)

- Hi-Rel-10 KVA UPS ManualDocument28 pagesHi-Rel-10 KVA UPS ManualAbdelwhab Elsafty100% (4)

- FIT393M ManualDocument15 pagesFIT393M ManualSaikrishna Guntha0% (2)

- Instruction Manual. Aquacon 2000 Plus. 2-Wire Conductivity Transmitter. 68X Rev 0 8 - 05Document36 pagesInstruction Manual. Aquacon 2000 Plus. 2-Wire Conductivity Transmitter. 68X Rev 0 8 - 05jugal rana33% (3)

- Autotune PID controller setup and operationDocument26 pagesAutotune PID controller setup and operationkarangoyals0375% (4)

- ADDMAS Electro-Magnetic Flow Meters Installation GuideDocument22 pagesADDMAS Electro-Magnetic Flow Meters Installation Guideinfo -ADDMAS100% (1)

- PositionerDocument13 pagesPositionerLeonidas PetrouNo ratings yet

- Falcon 1600Document45 pagesFalcon 1600manohar kumar100% (1)

- Manual For 3-Disp-Jumbo-USL PDFDocument9 pagesManual For 3-Disp-Jumbo-USL PDFYogesh RamdasiNo ratings yet

- Manual PDFDocument27 pagesManual PDFamirrineni100% (1)

- HollySys Distributed Control System OverviewDocument49 pagesHollySys Distributed Control System OverviewJohn WickNo ratings yet

- Masibus 85XXDocument50 pagesMasibus 85XXVenish Patel92% (12)

- User Manual MAM 890 - V01Document24 pagesUser Manual MAM 890 - V01Brian Steve Perez Quintero100% (1)

- 85XX+ User ManualDocument111 pages85XX+ User Manualsameershahzan100% (1)

- Selec PLC Programing ManualDocument104 pagesSelec PLC Programing ManualNILESH75% (4)

- 3de e (Bocr) ManualDocument6 pages3de e (Bocr) ManualNaveen Gupta100% (1)

- Microtapper controller operational manualDocument49 pagesMicrotapper controller operational manualgorakhdagade100% (7)

- Microscan TempscannerDocument10 pagesMicroscan TempscannerGIRI100% (1)

- GA700 Technical ManualDocument936 pagesGA700 Technical ManualTuanson Pham0% (1)

- Dcem2100 Ops Rev00 120313Document70 pagesDcem2100 Ops Rev00 120313Rakesh Karan Singh75% (4)

- Tuc 6 WF ManualDocument92 pagesTuc 6 WF ManualSunil Singh86% (7)

- Neuron II Elgi CompressorDocument42 pagesNeuron II Elgi CompressorOswaldo69% (16)

- NZ200 Manual 16003哪吒机Document38 pagesNZ200 Manual 16003哪吒机Daniel100% (3)

- Micro Controller Based 8-Stage Power Factor Controller Relay PFC8Document3 pagesMicro Controller Based 8-Stage Power Factor Controller Relay PFC8pinku_thakkar73% (11)

- Ador CoronaDocument32 pagesAdor CoronaPradeep Kumar82% (22)

- DS-451 (Ti-1232) Operation Manual Digit)Document7 pagesDS-451 (Ti-1232) Operation Manual Digit)Sarwar Alam100% (10)

- User Manual Stream Selector SS 301Document24 pagesUser Manual Stream Selector SS 301manish kumar60% (5)

- Kana - Bfc-10-Ch-Std-Ga-Ec-110 VacDocument6 pagesKana - Bfc-10-Ch-Std-Ga-Ec-110 VacJiyaul HaqueNo ratings yet

- Aimes Controller Conversion KitDocument13 pagesAimes Controller Conversion Kitrobert100% (3)

- ESP ManualDocument39 pagesESP Manualwwe_himanshu88% (8)

- ELF 3234 ManualDocument8 pagesELF 3234 ManualRajesh TKNo ratings yet

- Transweigh Weigh Feeder MaintanenceDocument62 pagesTransweigh Weigh Feeder MaintanenceKumar Gaurav100% (14)

- Logik16: Handbook Electronic Controller Logika Control S.R.LDocument20 pagesLogik16: Handbook Electronic Controller Logika Control S.R.LЕмил Гаврилов100% (5)

- Multispan TC-19Document4 pagesMultispan TC-19Karan SolankiNo ratings yet

- iMMR User ManualDocument163 pagesiMMR User ManualHARISH SHARMA100% (2)

- Installation Manual M1M 12Document2 pagesInstallation Manual M1M 12Ruben Arredondo Corpus100% (1)

- Schenck Intecont Plus PDFDocument87 pagesSchenck Intecont Plus PDFdoggermaNo ratings yet

- MIL8013 InstructionmanualDocument11 pagesMIL8013 InstructionmanualMasud Alam67% (3)

- NI 40-41 - Technical Reference ManualDocument47 pagesNI 40-41 - Technical Reference Manualchandraprakashhh88% (17)

- MPR300 RelayDocument4 pagesMPR300 RelayCma Anita Singh GautamNo ratings yet

- 2-Wire RH+T Transmitters with Dual LCD and IP65 ProtectionDocument6 pages2-Wire RH+T Transmitters with Dual LCD and IP65 ProtectionRavi Kant GuptaNo ratings yet

- Operation and Maintenance Manual KES-15, KES-18, KES-22, KES-30Document84 pagesOperation and Maintenance Manual KES-15, KES-18, KES-22, KES-30Maroof AliNo ratings yet

- Pressure Transmitter SOPDocument2 pagesPressure Transmitter SOPambesh100% (1)

- Manual de Instrucao FD310-510Document48 pagesManual de Instrucao FD310-510Evaldo AgnolettoNo ratings yet

- CCS 3000 Operators Manual V1.0.ENG - KK03Document26 pagesCCS 3000 Operators Manual V1.0.ENG - KK03محمد فرحات91% (11)

- HOLLiAS MACS K Series Hardware ManualDocument505 pagesHOLLiAS MACS K Series Hardware Manualaref100% (1)

- Part List HX2T-50NP/D, HX2T - 60NP/DDocument32 pagesPart List HX2T-50NP/D, HX2T - 60NP/Danita shinde100% (3)

- TRICHECK Manual 8,16,24Document15 pagesTRICHECK Manual 8,16,24mytra50% (2)

- IPA Load Cel and TXR ManualDocument14 pagesIPA Load Cel and TXR ManualmaniNo ratings yet

- Tracer-AN(50-100A)-Manual-EN-V3.3Document40 pagesTracer-AN(50-100A)-Manual-EN-V3.3viktorybg2020No ratings yet

- SV8_Indicator_ControllerDocument10 pagesSV8_Indicator_ControllerComplexulValeaTrandafirilorNo ratings yet

- Analizador de AguaDocument92 pagesAnalizador de AguafulanoNo ratings yet

- Boeco S30 ManualDocument35 pagesBoeco S30 ManualJanos ImreNo ratings yet

- SAS-1 Plus Operators Manual SEODocument19 pagesSAS-1 Plus Operators Manual SEOJumbo James100% (1)

- SART Tester User ManualDocument19 pagesSART Tester User ManualD ArsenNo ratings yet

- sc200 pH/ORP/DO Module: User Manual Manuel D'utilisation Manual Del Usuario Manual Do UsuárioDocument62 pagessc200 pH/ORP/DO Module: User Manual Manuel D'utilisation Manual Del Usuario Manual Do UsuárioHenry 03350No ratings yet

- XE, XM & XH - CatalogueDocument6 pagesXE, XM & XH - CataloguekumarNo ratings yet

- Products DetailDocument9 pagesProducts DetailBijoy NayakNo ratings yet

- E Dose Pumps PDFDocument7 pagesE Dose Pumps PDFkumarNo ratings yet

- Catalog RozaiTotal eDocument9 pagesCatalog RozaiTotal ekrishna sharmaNo ratings yet

- BS03 Fixed Gas Detector1Document2 pagesBS03 Fixed Gas Detector1kumarNo ratings yet

- Ankom - Calibration ScopeDocument2 pagesAnkom - Calibration ScopekumarNo ratings yet

- Activated Carbon - Granular (: Coconut Shell Charcoal Base) Specification of The ProductDocument1 pageActivated Carbon - Granular (: Coconut Shell Charcoal Base) Specification of The ProductkumarNo ratings yet

- Dissolved Ozone Monitor BrochureDocument2 pagesDissolved Ozone Monitor BrochurekumarNo ratings yet

- Filmtec BW30-365Document2 pagesFilmtec BW30-365PT Deltapuro IndonesiaNo ratings yet

- LNT PricelistDocument104 pagesLNT PricelistmbhangaleNo ratings yet

- Activated Carbon - Granular (: Coconut Shell Charcoal Base) Specification of The ProductDocument1 pageActivated Carbon - Granular (: Coconut Shell Charcoal Base) Specification of The ProductkumarNo ratings yet

- Water Cooler NewDocument4 pagesWater Cooler NewkumarNo ratings yet

- Samsung Evaporator Technical Details Aug 17 PDFDocument9 pagesSamsung Evaporator Technical Details Aug 17 PDFkumarNo ratings yet

- Removing Iron from WaterDocument2 pagesRemoving Iron from Waterkumar100% (1)

- Activated Carbon - Granular (: Coconut Shell Charcoal Base) Specification of The ProductDocument1 pageActivated Carbon - Granular (: Coconut Shell Charcoal Base) Specification of The ProductkumarNo ratings yet

- Edose Operation & Maintenance Manual: SpecificationDocument7 pagesEdose Operation & Maintenance Manual: SpecificationkumarNo ratings yet

- Activated Carbon - Granular (: Coconut Shell Charcoal Base) Specification of The ProductDocument1 pageActivated Carbon - Granular (: Coconut Shell Charcoal Base) Specification of The ProductkumarNo ratings yet

- LNT PricelistDocument104 pagesLNT PricelistmbhangaleNo ratings yet

- LNT PricelistDocument104 pagesLNT PricelistmbhangaleNo ratings yet

- Odour ControlDocument4 pagesOdour ControlkumarNo ratings yet

- Reliable Interfacing of 3V and 5V SystemsDocument7 pagesReliable Interfacing of 3V and 5V SystemsrominaslNo ratings yet

- Multiphase PWM Regulator For Amd Fusion™ Mobile Cpus Using Svi 2.0Document37 pagesMultiphase PWM Regulator For Amd Fusion™ Mobile Cpus Using Svi 2.0Denis DenisovNo ratings yet

- GE Power Electronics BrochureDocument48 pagesGE Power Electronics BrochureDaniel CamosNo ratings yet

- LV 7000Document225 pagesLV 7000Sidnei PereiraNo ratings yet

- Power Suply Mac WT7515Document11 pagesPower Suply Mac WT7515Wade DyerNo ratings yet

- FlowMeter EDDDocument23 pagesFlowMeter EDDDiego OspinaNo ratings yet

- Data SheetDocument166 pagesData SheetJosé AdelinoNo ratings yet

- V Series Rectifier 102407 PDFDocument6 pagesV Series Rectifier 102407 PDFchiquilin2No ratings yet

- (Domotica) - X10 Communications Protocol and Power Line Interfaces psc04 and psc05 PDFDocument11 pages(Domotica) - X10 Communications Protocol and Power Line Interfaces psc04 and psc05 PDFALfredo ROldanNo ratings yet

- Fire Alarm Detectomat 2014 - Englisch - 1809 - 2014Document168 pagesFire Alarm Detectomat 2014 - Englisch - 1809 - 2014M Alim Ur RahmanNo ratings yet

- Digital Gauging System: Display SeriesDocument2 pagesDigital Gauging System: Display SeriesserviciobsasNo ratings yet

- KG934V1 electrical inputs and outputs guideDocument6 pagesKG934V1 electrical inputs and outputs guideNiten GuptaNo ratings yet

- Self-Powered Time Counter: Ordering InformationDocument13 pagesSelf-Powered Time Counter: Ordering InformationPaulo CardosoNo ratings yet

- Max 536Document24 pagesMax 536api-3825669No ratings yet

- Sony PCM-7040 1st EdDocument81 pagesSony PCM-7040 1st EdnicureddogsfloNo ratings yet

- LG T385 Service ManualDocument171 pagesLG T385 Service ManualciohaniNo ratings yet

- Dual-Output PWM Controller With 3 Integrated Drivers For AMD SVI2 GPU CORE Power SupplyDocument40 pagesDual-Output PWM Controller With 3 Integrated Drivers For AMD SVI2 GPU CORE Power SupplyaflNo ratings yet

- Otis TCB Guide LinesDocument39 pagesOtis TCB Guide Linesmike90% (10)

- Smart Highside Power SwitchDocument14 pagesSmart Highside Power SwitchEdson CostaNo ratings yet

- TA8275HQDocument16 pagesTA8275HQMarcio FreitasNo ratings yet

- BTS4175SGA: Smart High-Side Power SwitchDocument26 pagesBTS4175SGA: Smart High-Side Power SwitchDanny Alexander Bodegas pinedaNo ratings yet

- 50V 3-Phase BLDC Motor Driver - Homemade Circuit ProjectsDocument14 pages50V 3-Phase BLDC Motor Driver - Homemade Circuit ProjectsimadovNo ratings yet

- Ee 8351 DLC 2018Document312 pagesEe 8351 DLC 2018kanakarajNo ratings yet

- Maxim 1722Document12 pagesMaxim 1722beto_1_99No ratings yet

- MG20B602Document110 pagesMG20B602Diego Alejandro Gallardo IbarraNo ratings yet

- Minas A4 ProspektDocument32 pagesMinas A4 ProspektSihamaSihamNo ratings yet

- Technical Explanation: Skiip 3 V3Document49 pagesTechnical Explanation: Skiip 3 V3marco_christoforidisNo ratings yet

- Wireless GSM Based Electronic Notice BoardDocument7 pagesWireless GSM Based Electronic Notice BoardNagendramataNo ratings yet

- ACORN CNC Controller - Rev4 Specifications ManualDocument15 pagesACORN CNC Controller - Rev4 Specifications ManualsthollanderNo ratings yet

- Mass Flow Controller Data Sheet gf40Document12 pagesMass Flow Controller Data Sheet gf40jesus roblesNo ratings yet