Professional Documents

Culture Documents

How To Determine Drive For Paper Machine (Simple Calculation) PDF

Uploaded by

Hgagselim SelimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Determine Drive For Paper Machine (Simple Calculation) PDF

Uploaded by

Hgagselim SelimCopyright:

Available Formats

Paper Machine Drives

General TAPPI NRL Power Constants Clutch Torque

Selections for all paper machine sections are The normal running load (NRL) constants given The torque requirement of the clutch is deter-

based upon TAPPI NRL* power requirements, in the table are indicative of the power required mined from:

the clutch shaft speed and a service factor. Be- to run the section under normal conditions. The

cause of the large inertia associated with dryer units used are horsepower per inch of width per Pt ⋅ 63025

Mc = · SF

sections, additional calculations are required to 100 feet per minute (HP/in width/100 fpm). The n

determine if the selected clutch has sufficient power is calculated from:

thermal capacity and breakaway and accelera- Mc: clutch torque (lb·in)

tion torque. N ⋅ NRL ⋅ L ⋅ v

PT =

100 n: clutch shaft speed (rpm)

PT: TAPPI HP SF: service factor from following table

N: Number of dryers Clutch selections are made by choosing a size

which provides a torque greater than or equal to

L: width of web (in) the required torque. Clutch types CB and VC are

recommended for all but the dryer sections. Be-

Use N=1 for other sections cause of the thermal load, only type VC is rec-

ommended for the dryer. Follow the selection

v: paper web speed (fpm) procedure given in Section B to determine the

clutch size to use. Limit the maximum friction

couple velocity to 4500 fpm (22 mps).

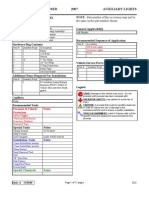

Power Requirements of Fourdrinier Machines Ê Power Requirements of Fourdrinier Machines Machine Section SF

Machine Section NRL Machine Section NRL Fourdrinier

Fourdrinier (total power) Dual press Couch w/plain bearings 2.2

A. Toweling and light wrapping 0.043 Side rolls only - each 0.020 Couch w/anti-friction bearings 1.8

B. Glassine and bond 0.064 Side rolls only - each 0.024 Press Sections

C. News, kraft, and book under 0.064 Suction pickup 0.010 Suction press w/plain bearings 2.2

1200 fpm with Millspaugh rolls Suction wringer 0.015 Suction press w/anti-friction bearings 1.8

D. News, kraft, and book 1200-2000 fpm 0.086 Suction wringer Ì 0.018 Plain press w/plain bearings 1.8

E. News, kraft and book above 2000 fpm 0.086 Suction felt Í 0.010 Ë Plain press w/anti-friction bearings 1.5

F. Kraft board 0.09 Transfer 0.030 Smoothing press w/plain bearings 1.8

Fourdrinier Driven Rolls Smoothing press – marking press Smoothing press w/anti-friction bearings 1.5

0.007

pair of rolls

Wire return 0.0012 Breaker press w/plain bearings 1.8

Size press – pair of rolls 0.020

Lumpbreaker 0.001 Breaker press w/anti-friction bearings 1.5

Dryers: Paper and Felt

Calender Stacks (eight and nine Rolls) Size press w/plain bearings 1.8

60 inch diam. rolls - each 0.0018

Up to 70 lb paper 0.035 Size press w/anti-friction bearings 1.5

48 inch diam. rolls - each 0.0014

70 to 90 lb paper 0.056 Transfer press w/anti-friction bearings 1.8

42 inch diam. rolls - each 0.0013

90 to 130 lb paper 0.056 Dryer

36 inch diam. rolls - each 0.0011

130 lb and above 0.056 w/plain bearings and helper drive see

Yankee Dryer 0.05 text

Reel w/plain bearings and no helper drive

Doctors (each)

Up to 125 lb - except kraft 0.008 w/anti-friction bearings and helper drive 2

Metal 0.001

Above 125 lb - except kraft 0.008 w/anti-friction bearings and no helper drive 2

Laminated plastic 0.0015

All kraft paper 0.008 Yankee Dryer 2.5

Fiberglass 0.0017

Presses Calendar

Main press: (plain or suction) pair of main rolls 0.024 w/plain bearings 4.5

w/anti-friction bearings 3.5

*TAPPI NRL = Technical Association of the Pulp Copyright, 1962, by Technical Association of the

and Paper Industry Normal Running Load. Pulp and Paper Industry, and reprinted by

permission of the copyright owner.

Reprinted from TAPPI, Vol. 45, No. 2, February

1962

Notes:

Ê For machines of 90 inch minimum width. Ì For nip pressures up to 100 lb/in.

Ë Recommended Drive Constant Í For nip pressures over 100 lb/in.

Copyright Eaton Corporation, 1997, All rights reserved. X - 20

Paper Machine Drives

Dryer Sections

Normally dryer clutch sizing is determined by For dryer sections having plain journal bearings,

thermal capacity and the resulting clutch selec- the clutch must be capable of overcoming the

tion will have torque capacities that exceed breakaway torque of the bearings. This torque

those indicated by the above calculations. En- can be estimated from:

ergy capacities are primarily a function of fric-

Wt ⋅ d ⋅ v

tion area. The recommended clutch friction area Mf = 0.48·

is determined from: D ⋅ n

Wk 2 ⋅ v 2 Mf: breakaway torque (lb·in)

A=

D ⋅ 1.21E + 06

2

Wt: total weight of dryers, gears and one-half of

A: clutch friction area (in2) felt and feeney dryers*

Wk2: inertia of dryer section (lb·ft2) d: journal bearing diameter (in)

D: dryer roll diameter (in) SF: service factor from following table:

Service Factors for dryers equipped with journal

bearings

If the Wk2 of the section is not known, it can be Paper Speed Without With

estimated from: fpm Helper Drive Helper Drive

0 to 500 3.0 1.5

Wk2 = N·L·K 500 to 750 3.5 2.0

750 to 1000 4.0 2.5

Wk2: estimated Wk2 of section (lb·ft2) 1000 to 1500 4.5 3.0

1500 to 1800 5.0 3.5

N: number of dryer rolls

K: factor from dryer constants table

*If total weight is not known, it can be esti-

mated from:

For sections having a large number of dryer Wt = N·[K1· L+K2]

rolls and the paper speed is high, an air cooled

clutch may not be suitable. A special VC wa- K1 & K2 : factors from dryer constant table

ter-cooled unit, having a different friction cou-

ple, can be furnished. The friction area required In general, a clutch selection for a dryer section

for water-cooling is 1/6 of that required for an is usually based upon the required friction area

air-cooled clutch; however, the clutch torque A. The selection is then checked to determine if

rating must be reduced by 40%. its torque capacity is capable of torques Mc, Ma

and Mf with the available applied air pressures.

The clutch must also be capable of accelerating If not specified, selections should be based on

the dryer in a reasonable time. The acceleration 40 psi.

torque can be calculated from:

Dryer Constants

Dryer Roll

Wk 2 ⋅ v Dia. in Shell Thickness in K K1 K2

Ma = 0.74· 2

D ⋅n 24 0.50 12 16.5 1000

36 0.63 51 24 1600

42 0.75 97 29 2150

Ma: acceleration torque (lb·in)

48 0.81 157 34 2500

Z: acceleration rate (fpm/sec) 48 1.00 197 40 2500

60 1.00 378 48 6000

Use 50 to 60 fpm/sec if the acceleration rate is 60 1.25 467 60 6000

not specified. 60 1.38 518

72 1.44 936

72 1.50 966

X - 21 Copyright Eaton Corporation, 1997, All rights reserved.

Paper Machine Drives

Example Example

A clutch is required for the third dryer section of a paper machine Determine the clutch torque required for the transfer press for the pa-

which operates under the following conditions: per machine given in the first example.

Web L: 188 inch NRL = 0.030

Speed v: 2500 fpm N ⋅ NRL ⋅ L ⋅ v 0.030 ⋅ 188 ⋅ 2500

PT = =

100 100

Dryer diameter D: 36 inch

= 141HP

No. of dryers N: 5

PT ⋅ 63025

Mc = · SF

Clutch speed n: 1000 n

Anti-friction bearings 141⋅ 63025

= · 1.8

1000

N ⋅ NRL ⋅ L ⋅ v 5 ⋅ 0.0011⋅ 188 ⋅ 2500

PT = =

100 100 = 16000 lb·in

PT = 26 HP

PT ⋅ 63025 26 ⋅ 63025

Mc = · SF = ·2

n 1000

= 3260 lb·in

Wk2 = N·L·K = 5 · 188 · 51= 48000 lb·ft2

Wk 2 ⋅ v

Ma = 0.74· 2 ·Z

D ⋅n

48000 ⋅ 2500

=0.74· · 50

36 ⋅ n

2

= 3430 lb·in

Wk 2 ⋅ v 2

A=

D ⋅ 1.21E + 06

2

48000 ⋅ 2500 2

= 2

36 ⋅ 1.21E + 06

= 191 in2

Clutch selection is made from friction area required.

Select 14VC500.

Friction couple velocity = 14·1000·0.262 = 3670 fpm.

The 14VC500 element meets all the requirements. Operating pressure

would be approximately 40 psi.

Copyright Eaton Corporation, 1997, All rights reserved. X - 22

You might also like

- AB60F Rebuild Manual PDFDocument652 pagesAB60F Rebuild Manual PDFFerry Darmawan67% (3)

- Static & Fatigue Analysis of Pressure Vessel: Project ReportDocument38 pagesStatic & Fatigue Analysis of Pressure Vessel: Project ReportHgagselim SelimNo ratings yet

- Static & Fatigue Analysis of Pressure Vessel: Project ReportDocument38 pagesStatic & Fatigue Analysis of Pressure Vessel: Project ReportHgagselim SelimNo ratings yet

- 96-QC20-J-415 - DESIGN CALCULATION OF STEEL TANK FOR GHAZYAL-REV (D) .pdf02Document35 pages96-QC20-J-415 - DESIGN CALCULATION OF STEEL TANK FOR GHAZYAL-REV (D) .pdf02Hgagselim Selim100% (2)

- S4000M05-N Gas Mobile Marine Workshop On Modernisation of Danube Vessels FleetDocument43 pagesS4000M05-N Gas Mobile Marine Workshop On Modernisation of Danube Vessels FleetbbssNo ratings yet

- Calculation API 650Document78 pagesCalculation API 650jamil93% (14)

- Api 610Document11 pagesApi 610prakasharmyNo ratings yet

- RT 8908LL Ingles PDFDocument254 pagesRT 8908LL Ingles PDFFernandoNo ratings yet

- Aluminum Geodesic Dome Roof Design Phases 1 PDFDocument10 pagesAluminum Geodesic Dome Roof Design Phases 1 PDFZahra Nser AldeinNo ratings yet

- m3 CalculationDocument45 pagesm3 CalculationHgagselim Selim100% (1)

- Principles of Wet-End ChemistryDocument14 pagesPrinciples of Wet-End Chemistrydinotim60% (5)

- Engine mechanical guideDocument204 pagesEngine mechanical guidehectorgonzalezm100% (6)

- Refinery and Petrochemical Line Sizing CriteriaDocument9 pagesRefinery and Petrochemical Line Sizing CriteriaAatish ChandrawarNo ratings yet

- Roof Air Rising of An Ammonia Storage Tank at KPICDocument12 pagesRoof Air Rising of An Ammonia Storage Tank at KPICHgagselim Selim100% (1)

- Presentation India Short Head BoxDocument63 pagesPresentation India Short Head BoxmjohnmartinNo ratings yet

- Autodesk Robot Structural Analysis Professional 2010 - Training Manual (Metric Version)Document178 pagesAutodesk Robot Structural Analysis Professional 2010 - Training Manual (Metric Version)ericfgNo ratings yet

- PressingDocument24 pagesPressingDiwakar Singh TanwarNo ratings yet

- Drying of PaperDocument38 pagesDrying of PaperLingga MediatamaNo ratings yet

- Single Col - Tank-2013Document35 pagesSingle Col - Tank-2013Hgagselim SelimNo ratings yet

- Stock and Water Systems of The Paper MachineDocument64 pagesStock and Water Systems of The Paper MachineEnrico75% (4)

- Size Press 1Document14 pagesSize Press 1Andreas Kurniawan100% (2)

- Air Cooler Piping Design Questionaries With AnswerDocument1 pageAir Cooler Piping Design Questionaries With AnswerVikash TiwariNo ratings yet

- MF1547Engine PDFDocument83 pagesMF1547Engine PDFAhmad Ali Nursahidin100% (1)

- Air Cushion Double Rectifier HeadboxDocument21 pagesAir Cushion Double Rectifier HeadboxDarmawan Muhaimin100% (1)

- Paper DefectsDocument4 pagesPaper DefectsJagathNo ratings yet

- Purge With NitrogenDocument5 pagesPurge With Nitrogendeion29100% (1)

- Headbox Design and Operation GuideDocument43 pagesHeadbox Design and Operation GuideSukallan Dhar89% (9)

- Paper Machine Design and Operation GuideDocument10 pagesPaper Machine Design and Operation GuideArtesira Yuna61% (23)

- Non Contact SealDocument24 pagesNon Contact Sealsetiadi pratondoNo ratings yet

- TIP 0404-20 (Physical Characterization of Press FabricsDocument10 pagesTIP 0404-20 (Physical Characterization of Press FabricsHuy Nguyen100% (1)

- Topic 14 Papermaking Pressing TextDocument21 pagesTopic 14 Papermaking Pressing Textronaldsacs100% (1)

- CompletPresentationA AnDocument288 pagesCompletPresentationA AnDinhnamsgpNo ratings yet

- Theory and Operation of The Fourdrinier Paper MachineDocument641 pagesTheory and Operation of The Fourdrinier Paper MachinePeter de Clerck75% (4)

- Roll Crowning Calculator - Determine Crown for Metal RollsDocument4 pagesRoll Crowning Calculator - Determine Crown for Metal RollsSrinu Gudala100% (1)

- PP-435 Paper Mill Calculations PDFDocument2 pagesPP-435 Paper Mill Calculations PDFAnil Singh86% (7)

- Water Removal TIPs ReviewDocument12 pagesWater Removal TIPs Reviewvemanreddy29No ratings yet

- Edr 01 Dec 2018Document21 pagesEdr 01 Dec 2018AMALENDU PAULNo ratings yet

- TIP 0404-07 (Paper Machine Dry Rate)Document0 pagesTIP 0404-07 (Paper Machine Dry Rate)Huy NguyenNo ratings yet

- Toaz - Info Tappi Handbook of Pulping and Papermaking PRDocument14 pagesToaz - Info Tappi Handbook of Pulping and Papermaking PRJepri MarpaungNo ratings yet

- FRIM Centrifugal CleanersDocument12 pagesFRIM Centrifugal CleanersKristin WeberNo ratings yet

- Cleaning and Conditioning Forming and Press Section 3000 USDocument12 pagesCleaning and Conditioning Forming and Press Section 3000 USF Cikal AntariksaNo ratings yet

- PressingDocument36 pagesPressingSanjeev Gautam100% (1)

- Paper Machine Energy ConservationDocument25 pagesPaper Machine Energy ConservationEr Mahendra KeshriNo ratings yet

- Paper Machine Vacuum Selection FactorsDocument19 pagesPaper Machine Vacuum Selection FactorsJean Dias100% (7)

- 2 DKSinghalDocument48 pages2 DKSinghalMostafizur Rahman100% (1)

- Optimization of Wire Vacuum by D K SinghalDocument7 pagesOptimization of Wire Vacuum by D K SinghalnazeerNo ratings yet

- Paper Machine 2010 FinalDocument116 pagesPaper Machine 2010 FinalRedGlassesed Barney Liu75% (4)

- Latest Head Box TechnologyDocument12 pagesLatest Head Box TechnologySukallan DharNo ratings yet

- Science in the Pulp & Paper Mill ... A Personal PerspectiveFrom EverandScience in the Pulp & Paper Mill ... A Personal PerspectiveRating: 1 out of 5 stars1/5 (1)

- DIP PROCESS Khanna PaperDocument265 pagesDIP PROCESS Khanna Paperruhi672767% (3)

- Headbox Control Maintenance GuideDocument22 pagesHeadbox Control Maintenance GuideSukallan Dhar100% (1)

- Continuous cleaning and conditioning of paper machine fabrics and rolls using high pressure showersDocument20 pagesContinuous cleaning and conditioning of paper machine fabrics and rolls using high pressure showersSoma NathanNo ratings yet

- New Developments in Paper and Board DryingDocument10 pagesNew Developments in Paper and Board DryingSahil DesaiNo ratings yet

- Book Chapter Refining of Chemical PulpDocument59 pagesBook Chapter Refining of Chemical Pulpjoatanmelo6775100% (1)

- Formula PT PapermakingDocument48 pagesFormula PT Papermakingsivakumar100% (1)

- Paper Machine Vacuum Selection FactorsDocument8 pagesPaper Machine Vacuum Selection FactorsKeerthi0% (1)

- Fundamentals of Paper DryingDocument49 pagesFundamentals of Paper DryingSushil MeshramNo ratings yet

- TAPPI 0404-07 - Paper Machine Drying RateDocument28 pagesTAPPI 0404-07 - Paper Machine Drying RateSebastian Cardona GarciaNo ratings yet

- CALCULATE PRESSURE ANYWHERE IN A PUMP SYSTEMDocument7 pagesCALCULATE PRESSURE ANYWHERE IN A PUMP SYSTEMmirza_adil99100% (1)

- (PDF) Calculation - Compress PDFDocument50 pages(PDF) Calculation - Compress PDFDhrupal PatelNo ratings yet

- Computational modelling of paper drying efficiencyDocument22 pagesComputational modelling of paper drying efficiencyrum43100% (1)

- Showering in The Wire and Press Section - in Which Direction PDFDocument20 pagesShowering in The Wire and Press Section - in Which Direction PDFF Cikal AntariksaNo ratings yet

- Tappi 0502-17 Papermaker FormulaDocument19 pagesTappi 0502-17 Papermaker FormulaMulyadi Moel86% (21)

- Board and Packaging Headbox TechnologyDocument15 pagesBoard and Packaging Headbox Technologysakariso100% (2)

- 2 Wire Fourdrinier Type Paper Machine For The Production of Corrugated Base Kraft Paper Width 2550mm PDFDocument35 pages2 Wire Fourdrinier Type Paper Machine For The Production of Corrugated Base Kraft Paper Width 2550mm PDFRahmath0% (1)

- 0502-14 Forming Section MonitoringDocument13 pages0502-14 Forming Section Monitoringbgpinu100% (1)

- Shoe Press c3Document32 pagesShoe Press c3Nipun DograNo ratings yet

- Screen CleanDocument182 pagesScreen CleanKristin Weber100% (2)

- Estimating Paper Machine CD Shrinkage Profiles From Headbox Actuator Data PDFDocument6 pagesEstimating Paper Machine CD Shrinkage Profiles From Headbox Actuator Data PDFBiantoroKunartoNo ratings yet

- Formula PT Papermaking PDFDocument22 pagesFormula PT Papermaking PDFsuresh67% (9)

- Vacuum AuditsDocument8 pagesVacuum AuditsBapu612345No ratings yet

- Retention ChemistryDocument86 pagesRetention Chemistryvivekbhuchem100% (1)

- How To Calculate Drum Nip LoadDocument1 pageHow To Calculate Drum Nip Loadsushil kumar100% (2)

- Advanced Training Course On Deinking - Dispersion and KneadingDocument38 pagesAdvanced Training Course On Deinking - Dispersion and KneadingGuido PeraltaNo ratings yet

- Paper Machine Water System Audits OptimizedDocument17 pagesPaper Machine Water System Audits OptimizedJeremy Lobo VillalobosNo ratings yet

- TAPPI TIP0404-01 Calculo de Remocion de Agua en PrensasDocument8 pagesTAPPI TIP0404-01 Calculo de Remocion de Agua en PrensasJean DiasNo ratings yet

- Tappi TIP 0404-63 PDFDocument25 pagesTappi TIP 0404-63 PDFmd ibrahim100% (1)

- Scope: TIP Category: Automatically Periodically Reviewed (Five-Year Review)Document6 pagesScope: TIP Category: Automatically Periodically Reviewed (Five-Year Review)Samsung KzoomNo ratings yet

- Expertip 7 Paper Machine Water CalculationsDocument5 pagesExpertip 7 Paper Machine Water Calculationsnotengofff100% (1)

- Parametric 3d Wind Loading On Hemispheric Dome StructuresDocument7 pagesParametric 3d Wind Loading On Hemispheric Dome StructuresHgagselim SelimNo ratings yet

- Wind Pressure Distribution On Domical Roofs: Astha Verma, Ashok K. AhujaDocument3 pagesWind Pressure Distribution On Domical Roofs: Astha Verma, Ashok K. AhujaerpublicationNo ratings yet

- Steel Domes Design GuideDocument14 pagesSteel Domes Design GuideHgagselim SelimNo ratings yet

- BunkerDocument7 pagesBunkerSrinivasan GanesanNo ratings yet

- Annals 2006 2 32 PDFDocument6 pagesAnnals 2006 2 32 PDFOctaviano Maria OscarNo ratings yet

- Seismic Design of Spherical Liquid Storage Tanks (COMPDYN 2011Document19 pagesSeismic Design of Spherical Liquid Storage Tanks (COMPDYN 2011paaryNo ratings yet

- Custom Incentives: Tank Insulation CalculatorDocument4 pagesCustom Incentives: Tank Insulation CalculatorManikandan MNo ratings yet

- Design For Pressure VesselDocument18 pagesDesign For Pressure VesselktejankarNo ratings yet

- Domes Eurosteel2011Document7 pagesDomes Eurosteel2011aquilesanchezNo ratings yet

- Estimation of TanksDocument1 pageEstimation of TanksHgagselim SelimNo ratings yet

- Air Vessel (Final Sent To AI) - 1Document38 pagesAir Vessel (Final Sent To AI) - 1hgagselim2012No ratings yet

- Dome Roof Calc.Document3 pagesDome Roof Calc.Hgagselim SelimNo ratings yet

- Head Section of Process Equipment DesignerDocument5 pagesHead Section of Process Equipment DesignerHgagselim SelimNo ratings yet

- Doklad Dome KUT 2014 enDocument7 pagesDoklad Dome KUT 2014 enHgagselim SelimNo ratings yet

- Qw/Qb-422 Ferrous/Nonferrous P-Numbers (Cont'D) Grouping of Base Metals For QualificationDocument7 pagesQw/Qb-422 Ferrous/Nonferrous P-Numbers (Cont'D) Grouping of Base Metals For QualificationHgagselim SelimNo ratings yet

- Domes Eurosteel2011Document7 pagesDomes Eurosteel2011aquilesanchezNo ratings yet

- Self - Supporting Dome Roof On Tank With V 70 000 M Capacity. New Approaches To DesignDocument6 pagesSelf - Supporting Dome Roof On Tank With V 70 000 M Capacity. New Approaches To DesignReda ArifNo ratings yet

- Domes Eurosteel2011Document7 pagesDomes Eurosteel2011aquilesanchezNo ratings yet

- A Biogas Decision Support System ToolDocument9 pagesA Biogas Decision Support System ToolHgagselim SelimNo ratings yet

- Line CardDocument2 pagesLine CardBruce SullivanNo ratings yet

- Mathematics: Wednesday 17 January 2024Document28 pagesMathematics: Wednesday 17 January 2024t.a.qafarovNo ratings yet

- Some Problems in The Design of Crawler Tractors: F. LittleDocument24 pagesSome Problems in The Design of Crawler Tractors: F. LittlegfhNo ratings yet

- Lecture 01 PDFDocument7 pagesLecture 01 PDFNuta Marius AlexandruNo ratings yet

- 28B-350E Spec Sheet 20 AUGUST 2007Document2 pages28B-350E Spec Sheet 20 AUGUST 2007Itzhak SchwartzmanNo ratings yet

- Catalog 63 English MetricDocument186 pagesCatalog 63 English MetricWilfredo Suarez TorresNo ratings yet

- Product Information on Servo-Hydraulic Load FramesDocument3 pagesProduct Information on Servo-Hydraulic Load FramesAnilNo ratings yet

- Study On Erection Control Scheme For Long Span Steel Arch Bridge and Its Application On Chaotianmen Yangtze River BridgesDocument14 pagesStudy On Erection Control Scheme For Long Span Steel Arch Bridge and Its Application On Chaotianmen Yangtze River BridgesMiguel PerezNo ratings yet

- Repair Instructions RHD1Document199 pagesRepair Instructions RHD1Jan SNo ratings yet

- Final Revision On Mechanics For Final Exam 2017 21-05-43Document97 pagesFinal Revision On Mechanics For Final Exam 2017 21-05-43mohamed sabryNo ratings yet

- Automotive ComponentsDocument12 pagesAutomotive ComponentsfightingfalconNo ratings yet

- 118 Worm Gear LubesDocument4 pages118 Worm Gear LubesWajahat RasoolNo ratings yet

- Material and Process For NDT Technologys PDFDocument164 pagesMaterial and Process For NDT Technologys PDFwajidNo ratings yet

- Toyota FJ Cruiser 2007 Auxiliary Lights Part Number: PT297-35061Document15 pagesToyota FJ Cruiser 2007 Auxiliary Lights Part Number: PT297-35061Ahmed SalemNo ratings yet

- Boiling point explainedDocument5 pagesBoiling point explainedimdad KURDINo ratings yet

- Retract Doc 01 (3) PDFDocument8 pagesRetract Doc 01 (3) PDFAlmeida FábioNo ratings yet

- Aircraft Load Analysis and Sizing ReportDocument62 pagesAircraft Load Analysis and Sizing ReportRizqy AgungNo ratings yet

- Unit 1 Fundamentals of RobotisDocument24 pagesUnit 1 Fundamentals of RobotisdeepakNo ratings yet

- Ecu TestDocument5 pagesEcu TestWawan SatiawanNo ratings yet

- Assignment Phy 2Document7 pagesAssignment Phy 2HanimNo ratings yet

- Physics 71Document9 pagesPhysics 71nik-koNo ratings yet