Professional Documents

Culture Documents

Sun Hydraulics FDBA-LAN

Uploaded by

JustinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sun Hydraulics FDBA-LAN

Uploaded by

JustinCopyright:

Available Formats

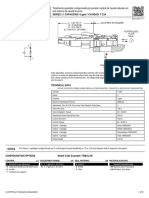

MODEL Fully adjustable pressure compensated flow control valve with reverse flow

FDBA check

SERIES 1 / CAPACITY: 6 gpm / CAVITY: T-13A

snhy.com/FDBA

CONFIGURATION

L Control Standard Screw Adjustment Fully adjustable, pressure-compensated flow controls with reverse-flow check provide precise flow regulation for

meter-in or meter-out applications where there may be wide pressure fluctuations. They are infinitely adjustable

A Adjustment Range .1 - 6 gpm (0,4 - 23 L/min.) from nearly closed up to the maximum flow. An integral high-capacity check valve provides unrestricted flow from

N Seal Material Buna-N port 2 to port 1.

(none) Material/Coating Standard Material/Coating

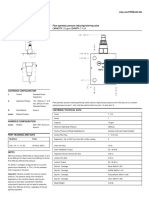

TECHNICAL DATA NOTE: DATA MAY VARY BY CONFIGURATION. SEE CONFIGURATION SECTION.

Cavity T-13A

Series 1

Capacity 6 gpm

Maximum Operating Pressure 5000 psi

Adjustment - No. of CCW Turns from Fully Closed to Fully Open 5

Valve Hex Size 7/8 in.

Valve Installation Torque 30 - 35 lbf ft

Adjustment Screw Internal Hex Size 5/32 in.

Locknut Hex Size 9/16 in.

Locknut Torque 80 - 90 lbf in.

Seal kit - Cartridge Buna: 990010007

Seal kit - Cartridge EPDM: 990010014

Seal kit - Cartridge Polyurethane: 990010002

Seal kit - Cartridge Viton: 990010006

Model Weight 0.32 lb.

NOTES For Series 1 cartridges configured with an O control (panel mount handknob), a .75 in. (19 mm) diameter hole is required in the panel.

CONFIGURATION OPTIONS Model Code Example: FDBALAN

CONTROL (L) ADJUSTMENT RANGE (A) SEAL MATERIAL (N) MATERIAL/COATING

L Standard Screw Adjustment A .1 - 6 gpm (0,4 - 23 L/min.) N Buna-N Standard Material/Coating

H Calibrated Handknob with Detent Lock B .1 - 2 gpm (0,4 - 8 L/min.) E EPDM /AP Stainless Steel, Passivated

K Handknob V Viton /LH Mild Steel, Zinc-Nickel

Y Tri-Grip Handknob

c 2019 Sun Hydraulics

1 of 2

TECHNICAL FEATURES

All 2-port flow control cartridges are physically and functionally interchangeable (i.e. same flow path, same cavity for a given frame size). However, cartridge

extension dimensions from the mounting surface may vary.

A balanced adjustment mechanism allows for easy adjustment even at high pressures.

The sharp-edged orifice design minimizes flow variations due to viscosity changes.

Minimum leakage is .1 gpm (0,4 L/min) when the adjustment mechanism is turned to the shut-off position.

Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage

the seals.

PERFORMANCE CURVES

c 2019 Sun Hydraulics

2 of 2

You might also like

- SAMSUNG Compressor Catalogue 2018Document35 pagesSAMSUNG Compressor Catalogue 2018Riza Agus Faisal100% (4)

- Moog G122-829A DS A4 v2Document4 pagesMoog G122-829A DS A4 v2Hammad AshrafNo ratings yet

- Proportional Pressure Control Valves Series P2 & 4VP01Document12 pagesProportional Pressure Control Valves Series P2 & 4VP01abuzer1981No ratings yet

- Hägglunds - Choice of Hydraulic Fluid PDFDocument2 pagesHägglunds - Choice of Hydraulic Fluid PDFAnibal RiosNo ratings yet

- Mixer03 PDFDocument2 pagesMixer03 PDFJuan Miguel RobledoNo ratings yet

- TRITORC New 2017 Hydraulic and Bolting Catalogue PDFDocument45 pagesTRITORC New 2017 Hydraulic and Bolting Catalogue PDFSun ChenNo ratings yet

- Advanced Engineering Fluid Mechanics - K. Muralidhar and G. BiswasDocument20 pagesAdvanced Engineering Fluid Mechanics - K. Muralidhar and G. BiswasAli Adnan100% (1)

- 250 Piping Design GuideDocument779 pages250 Piping Design GuideBetty Giai Levra95% (21)

- Sun Hydraulics-Cbca Lan EccDocument5 pagesSun Hydraulics-Cbca Lan EcchendntdNo ratings yet

- Flow Control ManifoldsDocument4 pagesFlow Control ManifoldsBrayan AguileraNo ratings yet

- Moog G122-829-001 - Catalog1Document2 pagesMoog G122-829-001 - Catalog1Jean-Roch JacquesNo ratings yet

- Pressure relief and anti-cavitation valves for mobile applicationsDocument12 pagesPressure relief and anti-cavitation valves for mobile applicationsOleg080No ratings yet

- ALISON HIDRAULIC - Catalogue PDFDocument250 pagesALISON HIDRAULIC - Catalogue PDFbaba0% (1)

- 4wre 6-10 Sew1xDocument12 pages4wre 6-10 Sew1x2267airportNo ratings yet

- Bomba ParkerDocument80 pagesBomba Parkerhugo lunaNo ratings yet

- TECNI AR Parker Store Brasil HY11 3362 Press Control PPCC UKDocument30 pagesTECNI AR Parker Store Brasil HY11 3362 Press Control PPCC UKItamar SchuhNo ratings yet

- Technical Manual ICVD 1111Document24 pagesTechnical Manual ICVD 1111Angelo MedinaNo ratings yet

- 160S 1Document51 pages160S 1Ahmad Mustaghfiri AsrarNo ratings yet

- ActairDocument16 pagesActairvj100% (1)

- Abbreviations HydraulicDocument1 pageAbbreviations HydraulicAbdul Junaedi0% (1)

- CROWN Esd Brochure Usa 3 2Document4 pagesCROWN Esd Brochure Usa 3 2Ahmed Ayman Yassin100% (1)

- Mico - Selection Procedures For BrakesDocument4 pagesMico - Selection Procedures For BrakesJenner Volnney Quispe ChataNo ratings yet

- Amtrobox: Limit Switch Box For Pneumatic Actuators Actair and Dynactair, and Manual Actuators MRDocument12 pagesAmtrobox: Limit Switch Box For Pneumatic Actuators Actair and Dynactair, and Manual Actuators MRRijal HarunNo ratings yet

- MC-3200 EX DatasheetDocument2 pagesMC-3200 EX DatasheetCarlos HuamaníNo ratings yet

- TDS 9 SpecificationsDocument3 pagesTDS 9 SpecificationsKhaled El-FaramawyNo ratings yet

- Lenntech APP Pump Data SheetDocument12 pagesLenntech APP Pump Data SheetilieoniciucNo ratings yet

- Sun Logic Valves ExampleDocument13 pagesSun Logic Valves ExamplerammysiNo ratings yet

- Atos - Modular Relief Valve - HMP HM KMDocument4 pagesAtos - Modular Relief Valve - HMP HM KMClaudecir PereiraNo ratings yet

- Automatic pre-relieving switch unit for dual stage bottom-ram pressesDocument4 pagesAutomatic pre-relieving switch unit for dual stage bottom-ram pressesSasko Dimitrov100% (1)

- Easygen 3500 Product SpecificationDocument4 pagesEasygen 3500 Product SpecificationPur WantoNo ratings yet

- Products That Perform...By People Who CareDocument20 pagesProducts That Perform...By People Who CareFalak KhanNo ratings yet

- Selenoid Have VP 1z PDFDocument8 pagesSelenoid Have VP 1z PDFHiskia Napoleon KacaribuNo ratings yet

- Senr1343senr1343 01 SisDocument2 pagesSenr1343senr1343 01 SisJaime Ventura ZenaNo ratings yet

- SPRAGUE J Pump BrochureDocument8 pagesSPRAGUE J Pump BrochurechauduonguyenNo ratings yet

- Donaldson Differential Pressure Switches & Gauges GuideDocument2 pagesDonaldson Differential Pressure Switches & Gauges GuideManikandan SenthilNo ratings yet

- F1+ AccesoriosDocument28 pagesF1+ AccesoriosRodrigo Andrade ScarpaNo ratings yet

- SSV Control System SHUT DOWN VALVEDocument12 pagesSSV Control System SHUT DOWN VALVEglobal3tNo ratings yet

- Relief Cartridge ValvesDocument16 pagesRelief Cartridge Valvesvivek_11111987No ratings yet

- 010 - Denison Control Valve 3-EN2400-ADocument15 pages010 - Denison Control Valve 3-EN2400-Agustavo aguilarNo ratings yet

- Saufer Danfoss Load Sensing Steering UnitsDocument92 pagesSaufer Danfoss Load Sensing Steering UnitsaapereirazNo ratings yet

- Hydraulic Remote ControlsDocument64 pagesHydraulic Remote Controlswalk111No ratings yet

- Hydraulic Valve BlockDocument86 pagesHydraulic Valve BlockFERNS100% (1)

- W1500 Series Hydraulic Pump: Concentric ABDocument12 pagesW1500 Series Hydraulic Pump: Concentric ABvut73 a100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document13 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Star SealNo ratings yet

- Drawworks Disc Brake HPU Proportional ValveDocument4 pagesDrawworks Disc Brake HPU Proportional ValveNoureddine AdjNo ratings yet

- Introduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Document20 pagesIntroduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Narasimha DNo ratings yet

- Katalog - Rexroth - Bosch - 2016Document76 pagesKatalog - Rexroth - Bosch - 2016sava88No ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document6 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Rachmad BuntoroNo ratings yet

- Allison Transmission BrochureDocument3 pagesAllison Transmission Brochurem mainNo ratings yet

- Integrated Brake in Hydraulic Motor For Winch Applications: Emil LanttoDocument71 pagesIntegrated Brake in Hydraulic Motor For Winch Applications: Emil LanttoArbainn Al-RantawiNo ratings yet

- Injector Head Operation Graphs: HR 560 HR 580 HR 440 HR 480Document14 pagesInjector Head Operation Graphs: HR 560 HR 580 HR 440 HR 480jose perozoNo ratings yet

- Maintain Hydac Pressure FiltersDocument9 pagesMaintain Hydac Pressure FiltersAbbasNo ratings yet

- P1 PD CompensatorsDocument13 pagesP1 PD CompensatorsxxshNo ratings yet

- ISO 9001 Flexible Couplings CatalogDocument16 pagesISO 9001 Flexible Couplings CatalogAnonymous 4MwmDaNbNo ratings yet

- HYDAC Understanding Hydraulics3 JAN 2015Document3 pagesHYDAC Understanding Hydraulics3 JAN 2015marc271986No ratings yet

- GE Industrial Push Buttons CatalogDocument134 pagesGE Industrial Push Buttons CatalogMilton SantoNo ratings yet

- HY11-3362 Press Control PPCC UKDocument40 pagesHY11-3362 Press Control PPCC UKLucas Cardoso100% (1)

- Novam SeriesDocument35 pagesNovam Serieshidraulica inteligenteNo ratings yet

- 3.5 Mpa Hydraulic Cylinder 3.5 Mpa Hydraulic CylinderDocument18 pages3.5 Mpa Hydraulic Cylinder 3.5 Mpa Hydraulic CylinderĐen BáoNo ratings yet

- Hyundai Contactors HiMCDocument12 pagesHyundai Contactors HiMCMawaz Khan MirzaNo ratings yet

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoDocument2 pagesModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaNo ratings yet

- FDBALAN en Us LetterDocument1 pageFDBALAN en Us LetterDAGNo ratings yet

- FDBA en Metric LetterDocument1 pageFDBA en Metric LetterY.EbadiNo ratings yet

- D.C. Hydraulic Power Systems: Bucher Hydraulics M-3000 Series Compact Designs, Integrated and Manifold Valve CircuitsDocument144 pagesD.C. Hydraulic Power Systems: Bucher Hydraulics M-3000 Series Compact Designs, Integrated and Manifold Valve CircuitsMMM-MMMNo ratings yet

- Coils for Solenoid Valves Series D45/22Document4 pagesCoils for Solenoid Valves Series D45/22JustinNo ratings yet

- RDFALWN-CAM S Full en Us LetterDocument5 pagesRDFALWN-CAM S Full en Us LetterJustinNo ratings yet

- Filtration Calculator Results: DimensionsDocument1 pageFiltration Calculator Results: DimensionsJustinNo ratings yet

- Camlock Femaleto Male FittingsDocument1 pageCamlock Femaleto Male FittingsJustinNo ratings yet

- Dynex 8800 SpoolspecsDocument6 pagesDynex 8800 SpoolspecsJustinNo ratings yet

- DOCUMENTCMYK Pilot Operated Pressure Relief ValveDocument10 pagesDOCUMENTCMYK Pilot Operated Pressure Relief ValveDipti BhanjaNo ratings yet

- 406AA00289ADocument2 pages406AA00289AJustinNo ratings yet

- Air Operated Chassis Pump: A & A Hydraulic 800-992-9898Document16 pagesAir Operated Chassis Pump: A & A Hydraulic 800-992-9898JustinNo ratings yet

- Special: Edition: 02/05.2015 Replaces: SPV 01 T ADocument16 pagesSpecial: Edition: 02/05.2015 Replaces: SPV 01 T AJustinNo ratings yet

- PPFBLAN-BAJ Full en Us LetterDocument4 pagesPPFBLAN-BAJ Full en Us LetterJustinNo ratings yet

- PM No Mating ViewableDocument1 pagePM No Mating ViewableJustinNo ratings yet

- H1 Bent Axis Motors: Service ManualDocument69 pagesH1 Bent Axis Motors: Service ManualJustinNo ratings yet

- Spare parts catalogue for Festo linear driveDocument3 pagesSpare parts catalogue for Festo linear driveJustinNo ratings yet

- PARKER Hydraulic Pump & Motor Division TG Series: PART Number: TG0335US050BBBGDocument2 pagesPARKER Hydraulic Pump & Motor Division TG Series: PART Number: TG0335US050BBBGJustinNo ratings yet

- VONBERG-Check Valve - Poppet-INLINE-1900r SeriesDocument1 pageVONBERG-Check Valve - Poppet-INLINE-1900r SeriesJustinNo ratings yet

- REXROTH PGH Internal Gear PumpDocument3 pagesREXROTH PGH Internal Gear PumpJustinNo ratings yet

- PPDBLAN-EAJ Full en Us LetterDocument5 pagesPPDBLAN-EAJ Full en Us LetterJustinNo ratings yet

- Rexroth Ra64960 - 2005-01Document20 pagesRexroth Ra64960 - 2005-01JustinNo ratings yet

- Category Existing Model Conversion Model: ©danfoss 2017Document1 pageCategory Existing Model Conversion Model: ©danfoss 2017JustinNo ratings yet

- SGM2Y, and 3Y Hydraulic Motors l1022491Document20 pagesSGM2Y, and 3Y Hydraulic Motors l1022491JustinNo ratings yet

- Internal Gear Pump PGM Series 4X: RE 10235/09.2014, Bosch Rexroth AGDocument12 pagesInternal Gear Pump PGM Series 4X: RE 10235/09.2014, Bosch Rexroth AGJustinNo ratings yet

- D39EX D39PX: Tier 4 Final EngineDocument16 pagesD39EX D39PX: Tier 4 Final EngineJustinNo ratings yet

- Pump Specifications: Information OnlyDocument1 pagePump Specifications: Information OnlyJustinNo ratings yet

- Eaton 104-1259-006Document1 pageEaton 104-1259-006JustinNo ratings yet

- Product Specifications: EatonDocument1 pageProduct Specifications: EatonJustinNo ratings yet

- Category Existing Model Conversion ModelDocument1 pageCategory Existing Model Conversion ModelJustinNo ratings yet

- Pump Specifications: Information OnlyDocument1 pagePump Specifications: Information OnlyJustinNo ratings yet

- 520l0580 PDFDocument120 pages520l0580 PDFMarcoNo ratings yet

- Eaton 713-0091-032Document1 pageEaton 713-0091-032JustinNo ratings yet

- CE 14 HYDRAULICS SEMI-FINAL EXAMDocument4 pagesCE 14 HYDRAULICS SEMI-FINAL EXAMYedda M IlaganNo ratings yet

- IESOBJDocument387 pagesIESOBJsabya512No ratings yet

- Blue-Flame Gas Stove: Safety InstructionsDocument11 pagesBlue-Flame Gas Stove: Safety Instructionsi4004No ratings yet

- L .2 Hydraulic Pump NewDocument51 pagesL .2 Hydraulic Pump NewyohannesNo ratings yet

- Minimum Pressure Valve MPVL65FH and MPVL65FHSDocument2 pagesMinimum Pressure Valve MPVL65FH and MPVL65FHSСергей КолесниковNo ratings yet

- Pump Primer 2 AssDocument33 pagesPump Primer 2 AssGkou DojkuNo ratings yet

- P8-4 (Page 572 Fogler 4th Ed.) : K M V VDocument15 pagesP8-4 (Page 572 Fogler 4th Ed.) : K M V VSILPA ASTI NURANo ratings yet

- PE5970 ES Menon Gas Hydraulics Class NotesDocument59 pagesPE5970 ES Menon Gas Hydraulics Class NotesKevin Kivanc IlgarNo ratings yet

- 48" X 15' Three Phase Test SeparatorDocument2 pages48" X 15' Three Phase Test Separatorpraash bhattNo ratings yet

- CNG Refuelling - English Final 100504Document8 pagesCNG Refuelling - English Final 100504Worldwide Equipment SolutionsNo ratings yet

- Flow Measurement With Orifice Meter 1Document79 pagesFlow Measurement With Orifice Meter 1Dedy Chasan Aflah Mutohar100% (2)

- STR 2011 2 e 14 Menon eDocument4 pagesSTR 2011 2 e 14 Menon ePrashanthMNairNo ratings yet

- HB100 Hydraulics BenchDocument13 pagesHB100 Hydraulics BenchAira Joyce SalazarNo ratings yet

- Fixed Bed Adsorption Column M7Document3 pagesFixed Bed Adsorption Column M7Mayank VashishthaNo ratings yet

- Stainless steel IFR filter regulatorDocument1 pageStainless steel IFR filter regulatorGuillermo de la Fuente SantiagoNo ratings yet

- Expansion DevicesDocument26 pagesExpansion DevicesYogesh Yadav100% (1)

- Pipe Line FlowcalculatorDocument3 pagesPipe Line FlowcalculatorBalaji PNo ratings yet

- Unit 11 Boyle Charles GayLussac and Combined Gas Law Worksheet Gas WS 1 2010Document2 pagesUnit 11 Boyle Charles GayLussac and Combined Gas Law Worksheet Gas WS 1 2010Pablo AlconzNo ratings yet

- Two Phase - IDocument27 pagesTwo Phase - IMed SamoudNo ratings yet

- Refrigeration System DesignDocument8 pagesRefrigeration System DesignJustine BoqsNo ratings yet

- Custody Transfer Metering System: Industries Standard Features (Continued)Document2 pagesCustody Transfer Metering System: Industries Standard Features (Continued)kamala 123No ratings yet

- GTFC QueDocument13 pagesGTFC QueAjal Shajahan100% (1)

- British Petroleum Standard Multiphase Design ManualDocument547 pagesBritish Petroleum Standard Multiphase Design ManualSakhib100% (2)

- Principle of Operation: SpecificationsDocument2 pagesPrinciple of Operation: SpecificationsAlberto CastellanosNo ratings yet

- Amine Sweetening Process DesignDocument12 pagesAmine Sweetening Process Designswapnil2603100% (2)

- Site Visit ChecklistsDocument7 pagesSite Visit ChecklistsBenedict OgbaghaNo ratings yet

- Petrol Price in Ludhiana - Ludhiana Petrol Price Today - Petrol Cost Trend in LudhianaDocument6 pagesPetrol Price in Ludhiana - Ludhiana Petrol Price Today - Petrol Cost Trend in LudhianaBINNo ratings yet