Professional Documents

Culture Documents

Shibaura Machine S NEW Model SCARA Robot THE400

Uploaded by

123qweOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shibaura Machine S NEW Model SCARA Robot THE400

Uploaded by

123qweCopyright:

Available Formats

Shibaura Machine s NEW model SCARA robot THE400

-Suitable for assembly and inspection process of electronics

Shibaura Machine s New Series SCARA robot equipment and automobile components where precision is

required.

THE400

-Accurate movement trajectory. High speed operation and

high load performance are achieved.

(Cycle time 0.39 second (with 2 kg load). Maximum payload

5 kg. Allowable moment of inertia 0.06 kgm²),

-A new model SCARA robot with thoroughly-redesigned

mechanism and control functions.

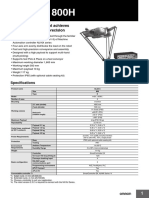

Robot Specifications

Model THE400

Type Horizontal multi-joint

No. of controlled axes 4

Arm length 400 mm(225 mm + 175 mm)

Working envelope Axis 1 ±130 deg

Axis 2 ±145 deg

Axis 3 (Z-axis) 0 160 mm

Axis 4 (Z-axis rotation) ±360 deg

Maximum speed *1

Axis 1 672 deg/sec

Axis 2 780 deg/sec

Axis 3 (Z-axis) 1,120 mm/sec

Axis 4 (Z-axis rotation) 1,800 deg/sec

Composite (Axis 1 and 2 composite) 7.0 m/sec

Maximum payload mass * 1 5 kg

Standard cycle time (with 2 kg load) * 2 0.39 sec

Allowable moment of inertia * 1 0.06 kgm²

Positioning X‒Y ±0.01 mm

repeatability*3 Z (axis 3) ±0.01 mm

C(axis 4, rotation) ±0.007 deg

Hand wiring*4 8 inputs and 8 outputs

Hand pneumatic joint*4 Provided by user

Position detection Absolute

Robot controller cable 3.5 m

Power supply 2.6 kVA

Mass 15 kg

*1:Acceleration/deceleration rates may be limited according to the motion pattern, load

mass and amount of offset.

*2:Horizontal 300 mm, vertical 25 mm, round-trip with coarse positioning. Continuous

operation is not possible beyond the effective load ratio.

*3:Positioning repeatable accuracy in one-direction movement, when the environmental

temperature and robot temperature are constant. It is not the absolute positioning

accuracy. Positioning repeatability for X-Y and C are for when Z-axis is at the upper-

most position. Trajectory accuracy is not ensured.

*4:Optional design duct for hand wiring and tubing is planned.

Controller Specifi cations

Model TSL3000

No. of Controlled Axes 4

Motion Mode PTP (point-to-point), CP (continuous path; Linear,

Circular), Short-Cut, Arch Motion

Storage capacity Total: Approx. 6,400 points + 12,800 steps

1 program: Approx. 2,000 points + 3,000 steps

No. of registrable Programs Max. 256 (247 User files, 9 System files)

Teaching Unit (Optional) Teach Pendant TP1000, TP3000

Programming by PC Software TSAssist

External input/output signals 8 inputs and 8 outputs

External Input Program selection, start, stop, program reset, etc.

operation signals Output Servo ON, operation ready, fault, cycle stop, etc.

Communication port RS232C 1 port (HOST or TCPRG)

RS232C 1 port (General-purpose COM1 )

RS4285 1 port (for I/O expansion)

RS422 1 port (for TP1000)

Ethernet

Other functions and Torque control, Interruptive functions, self-diagnosis, I/O

designs control and communications during motion, Coordinate

calculations, Built-in PLC, Fan-less design etc.

Power supply Single-phase, 190 to 240V AC, 50/60 Hz

Outer dimensions and mass*5 150 (W) × 266 (H) × 304 (D) mm, 7 kg

PC Software (Optional) TSAssist : Robot Programming assist tool

High-performance 3D simulation, program editor,

Controller Optional Controller teaching function, etc.

TSL3000 TSL3000E TC-WORX : PLC programming

Optional specifications*6 I/O signal polarity ( N-type or P-type ), I/O

extension, Field network (PROFIBUS, DeviceNet, CC-

Link, EtherNet/IP, EtherCAT, PROFINET)

Teach Pendant Optional Controller Specifications

(Optional) Model TSL3000E

Storage capacity Total: Approx. 12, 800 points + 25,600 steps

1 program: Approx. 2,000 points + 3,000 steps

Outer dimensions and mass*5 320 (W) × 266 (H) × 304 (D) mm, 13 (kg)

Optional specifications High-speed input signal, conveyor synchronization,

for TSL3000E CE compliance

*5:Height values include rubber feet. Space clearance is required for cable routing etc.

Please inquire us about the full details of dimensions.

*6:Ethernet is a registered trademark of XEROX Corp. in the U.S.A. CC-Link is a registered

trademark of CC-Link Partner Association. DeviceNet and EtherNet/IP are registered

trademarks of ODVA. PROFIBUS and PROFINET are registered trademarks of PROFIBUS

TP1000 TP3000 User Organization. EtherCAT is registered trademark and patented technology,

licensed by Beckhoff Automation GmbH, Germany.

Catalog TH40061-CES-03

Shibaura-THE400-A4_English.indd 1 2020/03/18 13:19

THE400

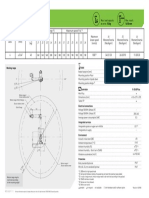

■ THE400[External View]

Optional Specifications -Simple Dust protection with cap and

bellows

Simple Dust Bracket for THE400-T

protection with cap camera mount Ceiling-mount

-T o o l f l a n g e f o r h a n d ( e n d - e f f e c t o r )

mounting

-Bracket for vision camera mounts

-Hollow shaft ball screw spline for wiring

-Robot-controller cable customized length

-Ceiling-mounted

-Movable robot-controller cable

-Robot Programming Assist Tool TSAssist

(Planned)

-Simple Cleanroom Design

-IP (Dust- and splash-proof) Design

-Duct for hand wiring and tubing

-Built-in LAN cable for hand wiring

Tool flange for hand Specifications and images are under developme

Simple Dust (end-effector) mounting nt and may change.

protection bellows

shibaura-machine.co.jp/jp/product/robot/index.html

www.tmrobotics.co.uk SM20093-1000-EI

tmrobotics.com Printed in Japan

Contents included in this catalog are subject to change without prior notice to reflect improvements.

Shibaura-THE400-A4_English.indd 2 2020/03/18 13:19

You might also like

- Easy-to-Teach and Easy-to-Operate Arc Welding Robot-Satisfies User's Needs For Saving Space and High ProductivityDocument2 pagesEasy-to-Teach and Easy-to-Operate Arc Welding Robot-Satisfies User's Needs For Saving Space and High Productivityanh thoNo ratings yet

- Arc Welding Solution: With Yaskawa MotomanDocument26 pagesArc Welding Solution: With Yaskawa MotomanMayank Jain0% (1)

- Train LapbookDocument34 pagesTrain LapbookSebõk KatalinNo ratings yet

- Grade 12 marketing principles course outlineDocument4 pagesGrade 12 marketing principles course outlineE-dlord M-alabanan100% (3)

- THL1200 enDocument2 pagesTHL1200 enjet.heNo ratings yet

- SCARA Robot THL SeriesDocument2 pagesSCARA Robot THL Series123qweNo ratings yet

- Shibaura (New) Scara The 600Document4 pagesShibaura (New) Scara The 600Pame MelussiNo ratings yet

- SC700 Standard SpecificationsDocument15 pagesSC700 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- Smzen 114 003 - MZ01 01 CFDDocument20 pagesSmzen 114 003 - MZ01 01 CFDmfsNo ratings yet

- Scara DatasheetDocument25 pagesScara Datasheetminegames1983No ratings yet

- MELFA RH-3CH SCARA Robot Brochure PDFDocument2 pagesMELFA RH-3CH SCARA Robot Brochure PDFVirendra ZopeNo ratings yet

- FS03NDocument1 pageFS03NSylwia KryszczyszynNo ratings yet

- VM 6083 - 60B1 Data SheetDocument3 pagesVM 6083 - 60B1 Data SheetMinh HoàngNo ratings yet

- VS-6556 and VS 6577 Technical Data SheetDocument3 pagesVS-6556 and VS 6577 Technical Data SheetKien Nguyen TrungNo ratings yet

- MZ07-02 Standard SpecificationsDocument18 pagesMZ07-02 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- ES12 BrochureDocument2 pagesES12 BrochureXanti Zabala Da RosaNo ratings yet

- ls6-b_scara_robot_product_specifications_cpd-57403Document2 pagesls6-b_scara_robot_product_specifications_cpd-57403lam minhNo ratings yet

- EZ03-02 Standard SpecificationsDocument28 pagesEZ03-02 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- Robot SCARA Cobra I600Document2 pagesRobot SCARA Cobra I600OM2019No ratings yet

- MZ04 Standard SpecificationsDocument29 pagesMZ04 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- Heavy duty handling robot lifts 350kg loadsDocument2 pagesHeavy duty handling robot lifts 350kg loadsXanti Zabala Da RosaNo ratings yet

- Flyer Scara Robot 3ia enDocument2 pagesFlyer Scara Robot 3ia enJafet ANo ratings yet

- Delta-Robots Datasheet en 201509 I44I-E-02 tcm849-110911 PDFDocument21 pagesDelta-Robots Datasheet en 201509 I44I-E-02 tcm849-110911 PDFMohammed Al HosiniNo ratings yet

- Proven Reliability and Performance, Plus Greater Versatility and Operating EaseDocument2 pagesProven Reliability and Performance, Plus Greater Versatility and Operating EaseKhoi NguyenNo ratings yet

- Comau Compact Catalogue RoboticsDocument8 pagesComau Compact Catalogue RoboticsDiHuBar InnovationsNo ratings yet

- DELTA IA-Robot SCARA C EN 20190516 WebDocument24 pagesDELTA IA-Robot SCARA C EN 20190516 WebKishan TalawattaNo ratings yet

- NRS EZ0302 StandardSpecificationDocument40 pagesNRS EZ0302 StandardSpecificationArifNo ratings yet

- MC400L BrochureDocument2 pagesMC400L BrochureXanti Zabala Da RosaNo ratings yet

- TS2 40 4 Axis Product Data Sheet ENDocument3 pagesTS2 40 4 Axis Product Data Sheet ENCHAMOUXNo ratings yet

- Scara SR 12ia Flyer enDocument2 pagesScara SR 12ia Flyer enJorge Israel Suárez AguilarNo ratings yet

- Ssraen 071 006 - Sra H 01 FD11Document30 pagesSsraen 071 006 - Sra H 01 FD11Eddy AlmeidaNo ratings yet

- DENSO Robotics Datasheet HM-G SeriesDocument2 pagesDENSO Robotics Datasheet HM-G SeriesMarius Constantin100% (1)

- Parallel Robot Quattro 800H Achieves High Speed PrecisionDocument2 pagesParallel Robot Quattro 800H Achieves High Speed PrecisionjorgemantillaNo ratings yet

- DENSO Robotics Datasheet Vs 068-087 SeriesDocument2 pagesDENSO Robotics Datasheet Vs 068-087 SeriesAdamNo ratings yet

- DELTA IA-Robot SCARA C EN 20170327Document24 pagesDELTA IA-Robot SCARA C EN 20170327chichialinNo ratings yet

- Nachi mz07 SpecificationDocument26 pagesNachi mz07 Specificationkhophimhd100% (1)

- Datasheet M 2ia 3SLDocument1 pageDatasheet M 2ia 3SLGabriel de OliveiraNo ratings yet

- HM-G Series Horizontal Articulated RobotDocument8 pagesHM-G Series Horizontal Articulated RobotAchinNo ratings yet

- Item # PK264M-03B, Stepper MotorDocument3 pagesItem # PK264M-03B, Stepper MotorVigneswaran KNo ratings yet

- CPP 45 BDocument2 pagesCPP 45 BWahyudi andhika comNo ratings yet

- Mesin Robot GreasingDocument2 pagesMesin Robot Greasingadventius S.SNo ratings yet

- Dr3ib 8l Flyer enDocument2 pagesDr3ib 8l Flyer enEdwin ReinosoNo ratings yet

- R7701e 3Document2 pagesR7701e 3Đinh LinhNo ratings yet

- Seatex MRU H PDFDocument2 pagesSeatex MRU H PDFCindy0% (1)

- SC400L-SC500 Standard SpecificationsDocument26 pagesSC400L-SC500 Standard SpecificationsXanti Zabala Da RosaNo ratings yet

- TS2 80 4 Axis Product Data Sheet EN 59276 PDF WebDocument3 pagesTS2 80 4 Axis Product Data Sheet EN 59276 PDF WebHoratiu HarNo ratings yet

- TS2 60 4 Axis Product Data Sheet enDocument3 pagesTS2 60 4 Axis Product Data Sheet enCHAMOUXNo ratings yet

- Outstanding Path Accuracy: Maximum Precision andDocument2 pagesOutstanding Path Accuracy: Maximum Precision andJorge GodielNo ratings yet

- A04b 0104 b181 Fanuc Axis Rotary TableDocument2 pagesA04b 0104 b181 Fanuc Axis Rotary Tableclogic26No ratings yet

- TX200 6 Axis Product Data Sheet ENDocument3 pagesTX200 6 Axis Product Data Sheet ENVăn Hiếu NguyễnNo ratings yet

- TS2 80 4 Axis Product Data Sheet ENDocument3 pagesTS2 80 4 Axis Product Data Sheet ENCHAMOUXNo ratings yet

- Lr10ia10 Flyer enDocument2 pagesLr10ia10 Flyer enmichelNo ratings yet

- CP-2HK Series: Dimension (MM)Document2 pagesCP-2HK Series: Dimension (MM)Gustavo YbañezNo ratings yet

- Item # PK266M-03B, Stepper Motor: SpecificationsDocument3 pagesItem # PK266M-03B, Stepper Motor: SpecificationsMyo Zin AungNo ratings yet

- rg6 Gripper Datasheet PDFDocument6 pagesrg6 Gripper Datasheet PDFRaj RajNo ratings yet

- R 2000ic 100P Flyer ENDocument2 pagesR 2000ic 100P Flyer ENperop123No ratings yet

- 1-Axis Servo Possition Maintenance ManualDocument126 pages1-Axis Servo Possition Maintenance Manualto0984903132No ratings yet

- CRX-10 Robot Working Range: 10 KG 1418 MMDocument1 pageCRX-10 Robot Working Range: 10 KG 1418 MMMelike KısmetNo ratings yet

- 4sdk4.7960Document2 pages4sdk4.7960Dominik PIWOWARCZYKNo ratings yet

- Datasheet 5 Axis Flight Motion Simulator AC55H S20 40 Hi DyDocument2 pagesDatasheet 5 Axis Flight Motion Simulator AC55H S20 40 Hi DyHung Nguyen NgocNo ratings yet

- 2 PDFDocument103 pages2 PDF123qweNo ratings yet

- 1 PDFDocument103 pages1 PDF123qweNo ratings yet

- Niryo One - User Manual (03-09-2019)Document54 pagesNiryo One - User Manual (03-09-2019)123qweNo ratings yet

- Libretto Istr. CEC71-CCT61-CCT71-CCT91Document16 pagesLibretto Istr. CEC71-CCT61-CCT71-CCT91123qweNo ratings yet

- 01 Hans Robot Elfin Maunal Hardware Installation EN PDFDocument36 pages01 Hans Robot Elfin Maunal Hardware Installation EN PDF123qweNo ratings yet

- 03 Hans Robot Elfin Maunal Software Installation EN PDFDocument183 pages03 Hans Robot Elfin Maunal Software Installation EN PDF123qweNo ratings yet

- Elfin-General Digital IO Controller PDFDocument4 pagesElfin-General Digital IO Controller PDF123qweNo ratings yet

- THE600 External View : Shibaura Machine's NEW Model SCARA Robot THE600Document2 pagesTHE600 External View : Shibaura Machine's NEW Model SCARA Robot THE600123qweNo ratings yet

- RC180 Safety ND A Installation: Read This Manual First Rev.17 EM121B2279FDocument116 pagesRC180 Safety ND A Installation: Read This Manual First Rev.17 EM121B2279F123qweNo ratings yet

- TH Series: Wide Variations, Fast Motion and Heavy DutyDocument14 pagesTH Series: Wide Variations, Fast Motion and Heavy Duty123qweNo ratings yet

- ResearchDocument44 pagesResearchGwend MemoracionNo ratings yet

- Max Brooks - The Zombie Survival Guide (Scanned Book)Document270 pagesMax Brooks - The Zombie Survival Guide (Scanned Book)tusko88% (8)

- Underwater vessels, sensors, weapons and control systemsDocument1 pageUnderwater vessels, sensors, weapons and control systemsNguyễn ThaoNo ratings yet

- Oil Well Drilling Methods: University of Karbala College of Engineering Petroleum Eng. DepDocument8 pagesOil Well Drilling Methods: University of Karbala College of Engineering Petroleum Eng. DepAli MahmoudNo ratings yet

- Me f215 Mel Lab ManualDocument105 pagesMe f215 Mel Lab ManualpankazspamNo ratings yet

- Iag Narrative ReportDocument16 pagesIag Narrative ReportHoely SaintNo ratings yet

- Three Thousand Years of Longing 2022Document93 pagesThree Thousand Years of Longing 2022Ppper pepperNo ratings yet

- 3.19 Passive VoiceDocument10 pages3.19 Passive VoiceRetno RistianiNo ratings yet

- AMS 2750 E Heat Treatment Standards ComplianceDocument3 pagesAMS 2750 E Heat Treatment Standards ComplianceQualidadeTFNo ratings yet

- CCNA Security Instructor Lab Manual v1 - p8Document1 pageCCNA Security Instructor Lab Manual v1 - p8MeMe AmroNo ratings yet

- Slogan Goes Here: Local Store Importing CompanyDocument1 pageSlogan Goes Here: Local Store Importing Company5gt6kdfdqhNo ratings yet

- Akali NihangsDocument19 pagesAkali NihangsAngad YuvrajNo ratings yet

- Nanotechnology in TextilesDocument4 pagesNanotechnology in Textileskevin cagud PhillipNo ratings yet

- NHW Upper Intermediate 4e Wordlist HungarianDocument34 pagesNHW Upper Intermediate 4e Wordlist HungarianpcdmisNo ratings yet

- POMR Satiti Acute CholangitisDocument30 pagesPOMR Satiti Acute CholangitisIka AyuNo ratings yet

- Case StudiesDocument19 pagesCase StudiesSorin MarkovNo ratings yet

- Arizona State University DissertationsDocument5 pagesArizona State University Dissertationshoffklawokor1974100% (1)

- Pharmaco-pornographic Politics and the New Gender EcologyDocument14 pagesPharmaco-pornographic Politics and the New Gender EcologyMgalo MgaloNo ratings yet

- Pe 3 (Module 1) PDFDocument6 pagesPe 3 (Module 1) PDFJoshua Picart100% (1)

- Negros IslandDocument18 pagesNegros IslandGrace AmaganNo ratings yet

- Nescafe Cold CoffeeDocument24 pagesNescafe Cold CoffeeMuhammad Omer SaeedNo ratings yet

- Envi. Data AcquisitionDocument10 pagesEnvi. Data AcquisitionDexter John Gomez JomocNo ratings yet

- Implementing Cisco Application Centric Infrastructure: (Dcaci)Document2 pagesImplementing Cisco Application Centric Infrastructure: (Dcaci)radsssssNo ratings yet

- PhotosynthesisDocument30 pagesPhotosynthesisAngela CanlasNo ratings yet

- Effect of Grain Boundary Thermal Expansion on Silicon Nitride Fracture ToughnessDocument8 pagesEffect of Grain Boundary Thermal Expansion on Silicon Nitride Fracture Toughnessbrijesh kinkhabNo ratings yet

- Section 6 - Diagnostic ProceduresDocument13 pagesSection 6 - Diagnostic Proceduresanon_152488453100% (1)

- Югоизточна Европа под османско владичество 1354-1804Document531 pagesЮгоизточна Европа под османско владичество 1354-1804auroradentataNo ratings yet

- ASTM G 38 - 73 r95Document7 pagesASTM G 38 - 73 r95Samuel EduardoNo ratings yet