Professional Documents

Culture Documents

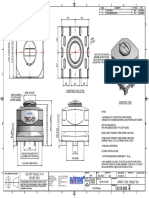

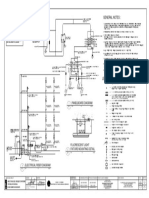

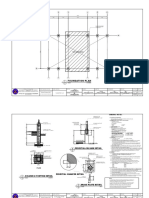

View A-A View B-B

Uploaded by

Arshad AnsariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

View A-A View B-B

Uploaded by

Arshad AnsariCopyright:

Available Formats

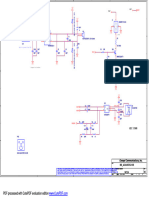

2016.2.

18 01 EADDNO

2016.5.15 02 EADIAK

2016.11.

PERPENDICULARITY 2019.11.

TOLERANCE TYPICAL FOR WHITE PAINT MARK AS SHOWN

ALL ENDS TO AID FITMENT OF HOSE TO 1 E3

2 F3

VEHICLE ANGULAR

Z

3 E4

Leak detection

3 4 F4

Z

2 2

2

15

3+0,5

-0,5

19+0,5

0

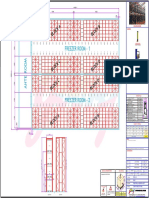

VIEW A-A VIEW B-B

C

B Clamp and marking center Clamp and marking center

1

E

E

E

D

4

2

Technical requirements:

1 SMTC 9 313 001 SMTC 5 320 003

Cooling circuit design meets SMTC 9 313 001 standards materials and performance in line with SMTC 5 320 003 standards,

A 3 B 2

parts standards test program consistent with the signed version of the test content outline prevail;

6 M

Inflection point coordinates cooling circuit, see the table in the drawing,the position of the center line of the

cooling circuit tolerance 6 M

3 DIN3021

Cooling circuit and clamp matching criteria designed to meet DIN3021

4 >EPDM< SMTC 1 200 021

X Y Z R Product printing logo:"SAICMOTOR Part Number>EPDM<production date",parts and material identification meets the

A 949.2 -75.9 462.9 20

-0.5

-1 standard requirements SMTC 1 200 021

5 SMTC 5 500 001

B 1022.9 -75.9 462.9 25 Parts materials banned and restricted substances in line with SMTC 5 500 001 standards

C 1052.9 -45.9 424.9 30 6

Note the size of the mold is not subject to a few

D 1083.0 -13.7 452.6 25 7 GB/T1804-C

2019.11.05

Not inject dimensional tolerances according GB/T1804-C standars;

E 1139.8 -13.7 452.6 18

-0.5

-1 1:1

8 30mm

spring clamp pre-assembled position from the ends of the rubber tube is not

1 4 25012030035 9.5g Magni-51 CR V4 less than 30mm

1 3 27012030005 11g Magni-51 CR V4 9 2.5bar

1 2 10243939-1 71.5g Pressure not less than the leak pipe assembly 2.5 bar ,Dwell time 30S;

A 1 10243939 10243939-11.CATPart 10243939-03.dwg 92g SMTC 5 500 00

HOSE/PIPE ASM-ENG TO HTR

MATERIAL

10243939

You might also like

- Openproject Basic ManualDocument13 pagesOpenproject Basic ManualArchie KinsNo ratings yet

- 2017 Hyundai Sonata L4-2.4L Engine Controls (Powertrain Management) - ALLDATA RepairDocument6 pages2017 Hyundai Sonata L4-2.4L Engine Controls (Powertrain Management) - ALLDATA RepairChino PlagaNo ratings yet

- Mil Nat Review 1Document3 pagesMil Nat Review 1Joshua CondeNo ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- AQE (FMEA) Selling DocumentDocument17 pagesAQE (FMEA) Selling DocumentArshad AnsariNo ratings yet

- PFMEA New FormatDocument63 pagesPFMEA New FormatArshad AnsariNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Uenr5152uenr5152 SisDocument2 pagesUenr5152uenr5152 Sisrigoberto otinianoNo ratings yet

- 500L Tablet IBCDocument1 page500L Tablet IBCYeswanth SuryadevaraNo ratings yet

- 100 Practical Ways To Improve Customer Experience Achieve End To End Customer Engagement in A Multichannel WorldDocument426 pages100 Practical Ways To Improve Customer Experience Achieve End To End Customer Engagement in A Multichannel WorldRoma DudarevNo ratings yet

- 14 - Generator Room Revised 16.05.2018-Layout1Document1 page14 - Generator Room Revised 16.05.2018-Layout1Lalantha KodikaraNo ratings yet

- 4990 Cargo Pump ManualDocument32 pages4990 Cargo Pump ManualPrajesh T VNo ratings yet

- STP Equipment Layout 1: Control Room 1-02 Laboratory 1-01Document20 pagesSTP Equipment Layout 1: Control Room 1-02 Laboratory 1-01Archi Tonskie100% (1)

- Duster Ph2 2017 F4RDocument1 pageDuster Ph2 2017 F4RtroublezaurNo ratings yet

- Airport Management SystemDocument19 pagesAirport Management Systemtheodeena63% (19)

- Freezer Room - 1: Block A Block BDocument1 pageFreezer Room - 1: Block A Block BFuG aZiNo ratings yet

- Top Plan of 2P X 15 Mms Table: Solar PV Project SolapurDocument1 pageTop Plan of 2P X 15 Mms Table: Solar PV Project Solapurisan.structural TjsvgalavanNo ratings yet

- Preliminary Print 07-FEB-2022: M A T LDocument8 pagesPreliminary Print 07-FEB-2022: M A T LZouheir SnouciNo ratings yet

- C D E F I G H J B A: Project Title-Sheet TitleDocument1 pageC D E F I G H J B A: Project Title-Sheet TitleHarshavardhan Reddy AshuNo ratings yet

- Reflected Ceiling PlanDocument1 pageReflected Ceiling PlanCarlo M. FloresNo ratings yet

- G026a-Pv-15001 String Wiring Layout Block 1-15001Document1 pageG026a-Pv-15001 String Wiring Layout Block 1-15001Daniel BanawaNo ratings yet

- F5NUSUHJ38WK47XDocument1 pageF5NUSUHJ38WK47XJhon VelascoNo ratings yet

- Cold Storage & Working Light Hydraulic Valves 18 Power OutputDocument9 pagesCold Storage & Working Light Hydraulic Valves 18 Power OutputALEJONo ratings yet

- Retroexacavadora 430 F Planos HidraulicosDocument2 pagesRetroexacavadora 430 F Planos Hidraulicosedison barrionuevoNo ratings yet

- L&T Electrical & Automation: Scheme LegendsDocument1 pageL&T Electrical & Automation: Scheme LegendsSivachandran RNo ratings yet

- Sony Ericsson j100 SCHDocument18 pagesSony Ericsson j100 SCHLiam & NahiNo ratings yet

- 002 Plano Clave Tramo 3Document1 page002 Plano Clave Tramo 3Rojas Juarez MauroNo ratings yet

- BL458-C03-90-009 Moshopha Access Roads Typical Cross Section and LayerworksDocument1 pageBL458-C03-90-009 Moshopha Access Roads Typical Cross Section and LayerworksBonolo SetumeNo ratings yet

- La Bicicleta Blanca - Arreglo de Acompan Amiento 1Document3 pagesLa Bicicleta Blanca - Arreglo de Acompan Amiento 1Luis AguilarNo ratings yet

- Take Off Sketch 20230316Document8 pagesTake Off Sketch 20230316Emmanuel OtienoNo ratings yet

- General Notes:: Panelboard DiagramDocument1 pageGeneral Notes:: Panelboard DiagramRM DulawanNo ratings yet

- Drawn On Zuken E3 File Stored in Teamcenter Engineering Do Not Scale Do Not Modify Manually All Dimensions in MMDocument10 pagesDrawn On Zuken E3 File Stored in Teamcenter Engineering Do Not Scale Do Not Modify Manually All Dimensions in MMPhomma KhinphommavongNo ratings yet

- Ele3 4Document1 pageEle3 4Kawthar AlaaliNo ratings yet

- E1 E2 E3 E4 E4 E5 E3 E2 E1: HS St. LS Sens 100% 2 1 1 2 Off Delay 1 Sensor Off OnDocument1 pageE1 E2 E3 E4 E4 E5 E3 E2 E1: HS St. LS Sens 100% 2 1 1 2 Off Delay 1 Sensor Off Onhuan tranNo ratings yet

- 12 CorollaDocument7 pages12 CorollaISAAC SIDIBENo ratings yet

- Exhaust System Must Support Its Own Weight Turbochargers and Flex Expansion Joints Must Not Be Loaded Up Please Refer S-08242 For More Exhaust System Installation GuidelinesDocument1 pageExhaust System Must Support Its Own Weight Turbochargers and Flex Expansion Joints Must Not Be Loaded Up Please Refer S-08242 For More Exhaust System Installation GuidelinesDmitryNo ratings yet

- Finish Section Developing Diffusion Wash-Off Section Section Section Dryer Rinse SectionDocument1 pageFinish Section Developing Diffusion Wash-Off Section Section Section Dryer Rinse SectionJázio OliveiraNo ratings yet

- Ventilator HidriaDocument1 pageVentilator HidriaIov IftodeNo ratings yet

- Fuji Core Type - Revised - 1Document18 pagesFuji Core Type - Revised - 1chrisNo ratings yet

- Eleve 2Document1 pageEleve 2sadafNo ratings yet

- A SM E U: View " A - A " of Support Type 12 Detail of Dynamic Anchor Bolt Detail of P/N 100Document1 pageA SM E U: View " A - A " of Support Type 12 Detail of Dynamic Anchor Bolt Detail of P/N 100Albet MulyonoNo ratings yet

- A SM E U: View " A - A " of Support Type 11 Detail of Dynamic Anchor Bolt Detail of P/N 100Document1 pageA SM E U: View " A - A " of Support Type 11 Detail of Dynamic Anchor Bolt Detail of P/N 100Albet MulyonoNo ratings yet

- P790 Electrical Circuit 336-E4169 - 1 - plm-2Document11 pagesP790 Electrical Circuit 336-E4169 - 1 - plm-2shivji007No ratings yet

- SIANA SPP - StructuralDocument5 pagesSIANA SPP - StructuralYugi Oh MelvzNo ratings yet

- Foundation Plan: Office of The District EngineerDocument5 pagesFoundation Plan: Office of The District EngineerEdmond SantosNo ratings yet

- Abs and VSC: 2005 PRIUS (EWD599U)Document13 pagesAbs and VSC: 2005 PRIUS (EWD599U)Sherman KillerNo ratings yet

- Lighting and Small Power Cable Routing Layout Drawing-Ss02: Lifting Eye (Typ)Document1 pageLighting and Small Power Cable Routing Layout Drawing-Ss02: Lifting Eye (Typ)RaeesNo ratings yet

- 3.DC ARNIEC Plan ConexiuniDocument1 page3.DC ARNIEC Plan ConexiuniRadu OprișNo ratings yet

- Schematic - Sim808 SSS - 2021-04-10Document1 pageSchematic - Sim808 SSS - 2021-04-10hasham nisar100% (2)

- 4 3 Wiring Diagram: Ae 1 Grounding 0 2: Gear Reduction StarterDocument1 page4 3 Wiring Diagram: Ae 1 Grounding 0 2: Gear Reduction StarterCésar Arturo Pajuelo EspinozaNo ratings yet

- Pump House - Drawings-2Document1 pagePump House - Drawings-2vishalNo ratings yet

- AJLickshot SirenDocument1 pageAJLickshot SirenGerardo MoleroNo ratings yet

- Notes 230901 151959-8Document1 pageNotes 230901 151959-8RocisneRocisneNo ratings yet

- Section 1-1: Concrete Grade - M40Document1 pageSection 1-1: Concrete Grade - M40Ankush SharmaNo ratings yet

- Id 001Document28 pagesId 001Robles DreschNo ratings yet

- Report On Substandard Floor Tiling Work in B6 Male BathroomDocument3 pagesReport On Substandard Floor Tiling Work in B6 Male BathroomYasith AbeywickramaNo ratings yet

- Snaider OutgoingDocument20 pagesSnaider OutgoingMuhammad Ikhsan MuisNo ratings yet

- Nissan MaximaDocument5 pagesNissan Maximayuvani sanchezNo ratings yet

- R12 T07B24 Ifmi XX XX SDW El 00063Document1 pageR12 T07B24 Ifmi XX XX SDW El 00063Abrar DigitalNo ratings yet

- 9 PDFDocument1 page9 PDFEko SulistyoNo ratings yet

- Foglight & Remote Control Mirror PDFDocument1 pageFoglight & Remote Control Mirror PDFguntoroNo ratings yet

- A3947 Liberty 4 NC QSGDocument2 pagesA3947 Liberty 4 NC QSGMichel JeanNo ratings yet

- 0530-DWG-BSC-37-004 Busbar Arrange Cable Access Rev02Document1 page0530-DWG-BSC-37-004 Busbar Arrange Cable Access Rev02Luis Marín DíazNo ratings yet

- Ab STR 108 B124Document1 pageAb STR 108 B124arainzada807No ratings yet

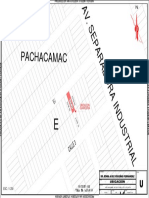

- Pachacamac 3°sector 3°etapa: Calle 1Document1 pagePachacamac 3°sector 3°etapa: Calle 1JOSE MANUEL ORTIZ ARRIETA LUJANNo ratings yet

- Bela Palanka - FlautaDocument3 pagesBela Palanka - Flautazoranstanisavljevic72No ratings yet

- Rent ReceiptDocument4 pagesRent ReceiptArshad AnsariNo ratings yet

- Master Template For New Material Creation: FG Code Final Part Wt. (GMS)Document4 pagesMaster Template For New Material Creation: FG Code Final Part Wt. (GMS)Arshad AnsariNo ratings yet

- Iteach Schools - Introduction - 2018 - v5Document25 pagesIteach Schools - Introduction - 2018 - v5Arshad AnsariNo ratings yet

- April Expense Sheet 2019Document2 pagesApril Expense Sheet 2019Arshad AnsariNo ratings yet

- Polyrub Cooper Standard Fts PVT LTDDocument3 pagesPolyrub Cooper Standard Fts PVT LTDArshad AnsariNo ratings yet

- Arshad Resume - Dot PDFDocument6 pagesArshad Resume - Dot PDFArshad AnsariNo ratings yet

- GoAir - Boarding Pass KKDocument1 pageGoAir - Boarding Pass KKArshad AnsariNo ratings yet

- GR00003600 34Document10 pagesGR00003600 34dudurezNo ratings yet

- Spectra ACT 1000Document1 pageSpectra ACT 1000nareshbhardwajNo ratings yet

- CS2200 DiagnositcDocument2 pagesCS2200 DiagnositcChaewon MinNo ratings yet

- Bia Bia ASSESSMENT 1Document13 pagesBia Bia ASSESSMENT 1Marina PolycarpoNo ratings yet

- HT22user - English v10 0 (12Document145 pagesHT22user - English v10 0 (12yahto 121No ratings yet

- Sample of A Good Introduction For A Research PaperDocument6 pagesSample of A Good Introduction For A Research Papercats1yaxNo ratings yet

- 13.8 Water Supply Systems DesignDocument2 pages13.8 Water Supply Systems DesignAngelyn MarantalNo ratings yet

- BLDC Motor Control ThesisDocument4 pagesBLDC Motor Control Thesisafknkzkkb100% (2)

- 18PGHR11 - MDI - Aditya JainDocument4 pages18PGHR11 - MDI - Aditya JainSamanway BhowmikNo ratings yet

- Los Angeles Abrasion Test AASHTO 96Document4 pagesLos Angeles Abrasion Test AASHTO 96Lava HimawanNo ratings yet

- Oracle Q3 2021 RTGS: Server InformationDocument16 pagesOracle Q3 2021 RTGS: Server InformationFadel AndrezaNo ratings yet

- Fast Decoding ECC For Future MemoriesDocument12 pagesFast Decoding ECC For Future MemoriesMihir SahaNo ratings yet

- Automated Molting Detection System For Commercial Soft-Shell Crab (Portunus Pelagicus) ProductionDocument9 pagesAutomated Molting Detection System For Commercial Soft-Shell Crab (Portunus Pelagicus) ProductionjimNo ratings yet

- Ardora ReportDocument10 pagesArdora ReportJara Dominguez VanessaNo ratings yet

- Gas Mixer MM Flex UsaDocument2 pagesGas Mixer MM Flex UsaManuk ElfarukNo ratings yet

- Bank Locker Security System Based BaseDocument11 pagesBank Locker Security System Based BaseSuchith RajNo ratings yet

- Task C Inquiry SequenceDocument15 pagesTask C Inquiry SequenceAsh PeacockNo ratings yet

- Installation Instructions For M710 / M720 Input Modules, M721 Input / Output Module and M701 Output ModuleDocument4 pagesInstallation Instructions For M710 / M720 Input Modules, M721 Input / Output Module and M701 Output ModuleAntonioNo ratings yet

- Reduction of Delay at Pre-ProductionDocument13 pagesReduction of Delay at Pre-ProductionARYAN RATHORENo ratings yet

- Load CartDocument4 pagesLoad CartAkhmad SyarNo ratings yet

- Network Automation For EngineersDocument2 pagesNetwork Automation For EngineersJacobNo ratings yet

- Boarding Pass: Travelling With Check-In Bags? Travelling With Cabin (Carry On) Baggage Only? Airport Reporting TimingsDocument1 pageBoarding Pass: Travelling With Check-In Bags? Travelling With Cabin (Carry On) Baggage Only? Airport Reporting TimingsMahesh GajjelliNo ratings yet

- Boiler Handbook PDFDocument379 pagesBoiler Handbook PDFPANNER RNo ratings yet

- Professional Developer FinalDocument251 pagesProfessional Developer Finalminhtruong.hvctNo ratings yet

- Waterfall Methodology: OverviewDocument9 pagesWaterfall Methodology: OverviewjanematthewNo ratings yet