Professional Documents

Culture Documents

p32 PDF

p32 PDF

Uploaded by

Alessandro Silva Vila NovaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

p32 PDF

p32 PDF

Uploaded by

Alessandro Silva Vila NovaCopyright:

Available Formats

ANNEX

Compressed Air

Air Compressors An after cooler will reduce the temperature of the compressed

air. This will result in the water vapor condensing into droplets

We can supply air compressors for all types of environmental which will collect in the bottom of the receiver. An auto drain

applications. From 3/4 HP oil-less designs for ground water fitted to the receiver will open automatically, allowing the

sampling up to 15 HP models for remediation projects. water to drain.

Selecting the optimum air compressor system will ensure

efficient operation and reduce the need for maintenance and

repairs. A correctly sized, good quality air compressor will

provide years of trouble free operation. Tech Tip:

Formula for determining total air flow (cfm)

Two factors need to be considered when selecting the optimum requirements:

size and type of compressor, air volume and pressure. The

air volume required, usually expressed as CFM (cubic feet Total cfm required x 1.5 = Total cfm

per minute). This is the actual volume of air delivered by the

compressor as measured when discharged to the atmosphere Example: If you are using two MVP IV Pumps

at a set pressure. Once the CFM requirements have been each producing 3 gpm (1 cfm required per gallon

determined, the compressor can be selected. It is important to pumped), your actual air requirements will be 6

allow for a 50% duty cycle for the compressor to prevent the cfm. Multiply this number by 1.5 (50% duty cycle)

system from cycling continuously. (See Tech Tip Below) and your total cfm requirement will be 9 cfm.

A compressor will turn approximately 7 cubic feet of ambient

air into 1 cubic foot of compressed air. The net result is

seven times as much moisture and contamination inside the

compressor receiver and air lines. The compression process

will also increase the ambient temperature of the air inside

the receiver. Air compressors can generate over 20 gallons

of water in an 8-hour operating period. If not removed, the

moisture and contaminants can cause premature failure of

the air lines and pumping equipment. Compressors should

therefore include the following accessories: an aftercooler, a

receiver autodrain and, depending on the climatic conditions

where the compressor will be used, an air dryer.

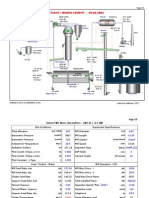

Air Flow & Pressure Loss

Flow Flow Rate Tube Size

(cfm) (lb/hr)

1/4” Tubing (.250” ID) 1/2” Tubing (.500” ID) 3/4” Tubing (.750” ID) 1” Tubing (1.00” ID)

Velocity Pressure Drop Velocity Pressure Drop Velocity Pressure Drop Velocity Pressure Drop

(ft/sec) (psi/100 ft) (ft/sec) (psi/100 ft) (ft/sec) (psi/100 ft) (ft/sec) (psi/100 ft)

0.5 15.01 24.45 0.60 6.11 0.019 2.72 0.012 1.53 0.01

1 30.02 48.91 2.39 12.23 0.075 5.43 0.050 3.06 0.04

2 60.04 97.81 9.57 24.45 0.299 10.87 0.199 6.11 0.15

4 120.07 195.63 38.27 48.91 1.196 21.74 0.797 12.23 0.60

8 240.15 391.25 153.08 97.81 4.784 43.47 3.189 24.45 2.39

16 480.30 782.51 612.32 195.63 19.135 86.95 12.757 48.91 9.57

32 960.59 1565.01 2449.27 391.25 76.540 173.89 51.026 97.81 38.27

64 1921.19 3130.03 9797.07 782.51 306.158 347.78 204.106 195.63 153.08

Dry Air @ 80ºF and 100psi Wh = Flow Rate, lb/hr = (60) x (Density, lb/ft3) x (Flow Rate, cfm)

Density = PV/RT Velocity, ft/sec =( (183.4) x (Wh, lb/hr) ) / ( (3600) x (d, in)2 x (Density, lb.ft3) )

P = Pressure, psi Pressure Drop, lb/in2 = [ ( (L, ft) x (Velocity, ft/sec)2 ) / ( (25000) x (d, in) ) ] / (16 oz/lb) = psi

V = Volume, ft3 Density, lb/ft3 = 0.50

R = Gas Constant (for Air) = 53.33

T = Temperature, degR Cells highlighted in dark blue are for non-recommended flows.

32 www.durhamgeo.com solutions@durhamgeo.com Tel: 1-800-837-0864 770-465-7557

You might also like

- (Uav) - Hovercraft Thrust Calculation in A Duct Fan Assembly For HovercraftDocument14 pages(Uav) - Hovercraft Thrust Calculation in A Duct Fan Assembly For Hovercraftlyly209No ratings yet

- Calculation of Thrust in A Ducted Fan Assembly For HovercarftDocument14 pagesCalculation of Thrust in A Ducted Fan Assembly For HovercarftAndrew Whipple100% (2)

- Calculation of Air Pipe SizeDocument6 pagesCalculation of Air Pipe SizePhyu Mar Thein Kyaw100% (1)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Solid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityFrom EverandSolid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityRating: 5 out of 5 stars5/5 (2)

- HVAC Formulas by AEMEPDocument9 pagesHVAC Formulas by AEMEPZen LohNo ratings yet

- PUMPS and CALCULATIONSDocument7 pagesPUMPS and CALCULATIONSkenoly123No ratings yet

- Compressed Air ReceiversDocument6 pagesCompressed Air Receiverstruong sanh NguyenNo ratings yet

- Air Compressors, Screw Type, Altitude Corrections - 01 PDFDocument28 pagesAir Compressors, Screw Type, Altitude Corrections - 01 PDFluisbitron1527No ratings yet

- CA Distribution System - Part2Document6 pagesCA Distribution System - Part2Mohammad Abubakar SiddiqNo ratings yet

- Chiller Refrigeration TonsDocument6 pagesChiller Refrigeration Tonsrogel_ganaNo ratings yet

- Cost Savings - Steam Air MotorsDocument25 pagesCost Savings - Steam Air MotorsNouhaila BattahNo ratings yet

- Aeration System and Oxygen RequirementDocument7 pagesAeration System and Oxygen Requirementdzari6738No ratings yet

- Rules of Thumb-Chemical EngineeringDocument31 pagesRules of Thumb-Chemical Engineeringintania66No ratings yet

- Air Receiver Sizing PDFDocument3 pagesAir Receiver Sizing PDFTifano KhristiyantoNo ratings yet

- Charts and TablesDocument4 pagesCharts and TablesAbdul KharisNo ratings yet

- Desozone Odor ControlDocument5 pagesDesozone Odor Controlsolo7651No ratings yet

- Performance Test On Double Stage Reciprocating Air CompressorDocument8 pagesPerformance Test On Double Stage Reciprocating Air Compressormohammed rashidNo ratings yet

- HVAC DistributionSystemsSizingDocument56 pagesHVAC DistributionSystemsSizingAhmed OmarNo ratings yet

- Calculating Receivers in Compressed Air SystemsDocument4 pagesCalculating Receivers in Compressed Air Systemsdharwin100% (1)

- Ce Series Filters & Moisture Separator: Compressed Air & Power SolutionsDocument4 pagesCe Series Filters & Moisture Separator: Compressed Air & Power SolutionsTim MitchellNo ratings yet

- Experienced Based Rules of Chemical EngineeringDocument33 pagesExperienced Based Rules of Chemical Engineeringintania66No ratings yet

- Piping Systems Srac 1994Document6 pagesPiping Systems Srac 1994maheshNo ratings yet

- Hydro Design & ConstructionDocument81 pagesHydro Design & ConstructionSamNo ratings yet

- HKS GT2540Document3 pagesHKS GT2540Ashley MoggNo ratings yet

- HA Winter Vent Oct 2022Document51 pagesHA Winter Vent Oct 2022Jack RbNo ratings yet

- API Sizing Calculations WebSiteDocument13 pagesAPI Sizing Calculations WebSiteISTRANHANo ratings yet

- Cooling Tower ManualDocument80 pagesCooling Tower ManualBikas Saha100% (3)

- Air Compressors - Rules of ThumbDocument2 pagesAir Compressors - Rules of ThumbtylerstearnsNo ratings yet

- Sprinkler Irrigation Application Rates and DepthsDocument2 pagesSprinkler Irrigation Application Rates and DepthsKhurram SherazNo ratings yet

- Design Formulae: Reference CardDocument4 pagesDesign Formulae: Reference Cardcharge3No ratings yet

- Cement MillDocument28 pagesCement Millsaji kumar100% (2)

- Air RecieverDocument9 pagesAir RecieverMichael Belmonte UrdanetaNo ratings yet

- Kitchen Ventilation DesignDocument4 pagesKitchen Ventilation DesignJames Nyaga80% (5)

- Horizontal 2 Phase Separator SizingDocument10 pagesHorizontal 2 Phase Separator SizingJermaine Heath100% (1)

- Pressed Air System NDocument35 pagesPressed Air System Nvmramakrishnan100% (1)

- Cooling of CPU Fan PDFDocument10 pagesCooling of CPU Fan PDFLeonard LiangNo ratings yet

- Best Pratice Energy Efficiency in Compressed Air SystemDocument107 pagesBest Pratice Energy Efficiency in Compressed Air SystemNoor LishinNo ratings yet

- A4372 HVAC DistributionSystemsSizingDocument57 pagesA4372 HVAC DistributionSystemsSizingIdham ShukriNo ratings yet

- Conversion Chart Manuals and Instructions in PDF Format Glossary Recommended Books Web LinksDocument12 pagesConversion Chart Manuals and Instructions in PDF Format Glossary Recommended Books Web LinksAziz Khan KakarNo ratings yet

- Steam Distribution System Design GuideDocument70 pagesSteam Distribution System Design GuideMohamed RiyaazNo ratings yet

- Osc Leaflet en 2935082546Document2 pagesOsc Leaflet en 2935082546ramonNo ratings yet

- MWM TCG 2020Document4 pagesMWM TCG 2020MohammadFaisalAmjadNo ratings yet

- Fd60hz Secador Atlas Copco - ManualDocument8 pagesFd60hz Secador Atlas Copco - ManualEdvaldo França100% (1)

- CEB601 Lab Report 5Document8 pagesCEB601 Lab Report 5divikesh kumarNo ratings yet

- Petroleum Engineering Lab 1 (Pge313) Experiment 3 Determination of PermeabilityDocument20 pagesPetroleum Engineering Lab 1 (Pge313) Experiment 3 Determination of PermeabilityAli AbubakarNo ratings yet

- Filtro XPLORDocument28 pagesFiltro XPLORHéctor RomeroNo ratings yet

- Designing Auxiliary VentilationDocument12 pagesDesigning Auxiliary VentilationMardee Wantssomecandy RabosaNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.From EverandTransactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.No ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Dictionary of Textile Finishing: Deutsch/Englisch, English/GermanFrom EverandDictionary of Textile Finishing: Deutsch/Englisch, English/GermanRating: 1.5 out of 5 stars1.5/5 (3)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)