Professional Documents

Culture Documents

Shifter Fork and Rod 7. Transfer Case

Uploaded by

Jeff Pascoe0 ratings0% found this document useful (0 votes)

12 views1 pageThe document provides specifications and service data for a shifter fork and rod as well as a transfer case. It lists part numbers and markings for 1st-2nd, 3rd-4th, and 5th shifter forks with details on rod end clearances and fork positions. It also lists part numbers and markings for a reverse accent shaft, reverse check plate adjustment, and reverse check plate angle with notes on their positions and functions.

Original Description:

Original Title

MSA5T0124A27655.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides specifications and service data for a shifter fork and rod as well as a transfer case. It lists part numbers and markings for 1st-2nd, 3rd-4th, and 5th shifter forks with details on rod end clearances and fork positions. It also lists part numbers and markings for a reverse accent shaft, reverse check plate adjustment, and reverse check plate angle with notes on their positions and functions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageShifter Fork and Rod 7. Transfer Case

Uploaded by

Jeff PascoeThe document provides specifications and service data for a shifter fork and rod as well as a transfer case. It lists part numbers and markings for 1st-2nd, 3rd-4th, and 5th shifter forks with details on rod end clearances and fork positions. It also lists part numbers and markings for a reverse accent shaft, reverse check plate adjustment, and reverse check plate angle with notes on their positions and functions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

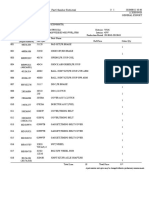

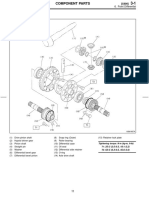

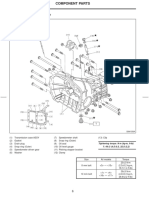

3-1 [S600] SPECIFICATIONS AND SERVICE DATA

6. Shifter Fork and Rod

6. Shifter Fork and Rod 7. Transfer Case

Select suitable shifter forks so that both coupling Neutral position adjustment

sleeve and reverse driven gear are positioned in

the center of their synchromesh mechanisms. Adjustment shim

Rod end clearance Part No. Thickness mm (in)

A: 1st-2nd — 3rd-4th 32190AA000 0.15 (0.0059)

0.4 — 1.4 mm (0.016 — 0.055 in) 32190AA010 0.30 (0.0118)

B: 3rd-4th — 5th

0.5 — 1.3 mm (0.020 — 0.051 in) Reverse accent shaft

Part No. Mark Remarks

1st-2nd shifter fork Neutral position is

32188AA090 3

Part No. Mark Remarks closer to 1st gear.

Approach to 1st gear 32188AA100 0 Standard

32804AA060 1

by 0.2 mm (0.008 in) Neutral position is

32188AA110 1

32804AA070 No mark Standard closer to reverse gear.

Approach to 2nd gear

32804AA080 3 Reverse check plate adjustment

by 0.2 mm (0.008 in)

3rd-4th shifter fork Reverse check plate

Part No. Mark Remarks Angle

Part No. Mark Remarks

θ

Approach to 4th gear

32810AA061 1 Arm stops closer to

by 0.2 mm (0.008 in) 32189AA000 0 28°

5th gear.

32810AA071 No mark Standard

Arm stops closer to

Approach to 3rd gear 32189AA010 1 31°

32810AA101 3 5th gear.

by 0.2 mm (0.008 in)

Arm stops in the cen-

33189AA020 2 34°

5th shifter fork ter.

Part No. Mark Remarks Arm stops closer to

32189AA030 3 37°

Approach to 5th gear reverse gear.

32812AA201 7 Arm stops closer to

by 0.2 mm (0.008 in) 32189AA040 4 40°

32812AA211 No mark Standard reverse gear.

Become distant from

32812AA221 9 5th gear by 0.2 mm

(0.008 in)

You might also like

- Suspensión Subaru Legacy Ej20Document4 pagesSuspensión Subaru Legacy Ej20RubenNo ratings yet

- Transmission and Differential SectionDocument242 pagesTransmission and Differential Sectionclaudiux78No ratings yet

- Spare Parts List: Rammer MS 695Document32 pagesSpare Parts List: Rammer MS 695ampacpartsNo ratings yet

- 5mt Manual Trans DiffDocument84 pages5mt Manual Trans DiffAlifan BachruddinNo ratings yet

- LDocument40 pagesLHoracio Martin Basualdo FioreNo ratings yet

- 5MT Manual Trans & DiffDocument82 pages5MT Manual Trans & DiffghotimeNo ratings yet

- Manual TransmissionDocument35 pagesManual Transmissionlinda5healNo ratings yet

- Service Bulletin: The Magnet Disengages From The Front CoverDocument1 pageService Bulletin: The Magnet Disengages From The Front CoverondemandprintNo ratings yet

- 2G1 019 PDFDocument1 page2G1 019 PDFondemandprintNo ratings yet

- Retrofit Kit For Adapting From 3WE52 CDO To 3WL1: 3WL9 111-0CA10-0AA0 3WL9 111-0CA16-0AA0Document8 pagesRetrofit Kit For Adapting From 3WE52 CDO To 3WL1: 3WL9 111-0CA10-0AA0 3WL9 111-0CA16-0AA0seil iexNo ratings yet

- Part Number Retrieval: A Part Number and A Price May Be Changed Without A Preliminary AnnouncementDocument2 pagesPart Number Retrieval: A Part Number and A Price May Be Changed Without A Preliminary AnnouncementaaaaerNo ratings yet

- Conversion Table/ General Tightening Torque SpecificationsDocument6 pagesConversion Table/ General Tightening Torque SpecificationsioNo ratings yet

- 01 4TNV98T-ZCSTY 规格参数表-英文Document4 pages01 4TNV98T-ZCSTY 规格参数表-英文Eric CNo ratings yet

- Insert PhisicsDocument17 pagesInsert PhisicsHimanshu MishraNo ratings yet

- Part List Ms 840Document32 pagesPart List Ms 840ZANDY ARIALDO VELANDIANo ratings yet

- M-3 Part ListDocument4 pagesM-3 Part ListMena TawfikNo ratings yet

- SUZUKI DT30 Servisnaya InformatsiyaDocument4 pagesSUZUKI DT30 Servisnaya InformatsiyaRedyard PravdorubNo ratings yet

- Manual Nissan Sentra (2006) (126 Páginas)Document3 pagesManual Nissan Sentra (2006) (126 Páginas)Moran LópezNo ratings yet

- M18 Onefhiwf34Document3 pagesM18 Onefhiwf34winduNo ratings yet

- Tools & Consumables Consumption Report Rev 1Document6 pagesTools & Consumables Consumption Report Rev 1Mihai CozmaNo ratings yet

- Caterpillar 3116 Overhaul Kit: IIF1023 and IIF1158 Instruction SheetsDocument2 pagesCaterpillar 3116 Overhaul Kit: IIF1023 and IIF1158 Instruction SheetsRicky IbarraNo ratings yet

- I NYECTORDocument2 pagesI NYECTORDiesel MotorsNo ratings yet

- ctl00 - 2022-07-01T101134.022Document108 pagesctl00 - 2022-07-01T101134.022francisco santiago gallardoNo ratings yet

- Changes Around The Thread Take-Up Lever in The AMS-210EN and AMS-221EN SeriesDocument5 pagesChanges Around The Thread Take-Up Lever in The AMS-210EN and AMS-221EN Seriesanton acohNo ratings yet

- Rotor - Bearing - 20230308 - 075335Document2 pagesRotor - Bearing - 20230308 - 075335Mohammad AlmafarjehNo ratings yet

- Previous Pageblock Return To Previous Menu Next Pageblock: Pratt & WhitneyDocument81 pagesPrevious Pageblock Return To Previous Menu Next Pageblock: Pratt & WhitneyKarina FloresNo ratings yet

- Plano Electrico Cx210 Cx240Document844 pagesPlano Electrico Cx210 Cx240Geovane PereiraNo ratings yet

- MT PDFDocument36 pagesMT PDFHéctorHernándezDíazNo ratings yet

- Magnetic Pickups Models MP3298, MP7905 and MP7906Document2 pagesMagnetic Pickups Models MP3298, MP7905 and MP7906andreshuertascalderon02No ratings yet

- CTP Engine BearingsDocument4 pagesCTP Engine BearingsmkNo ratings yet

- CTP Engine BearingsDocument4 pagesCTP Engine BearingsAten HarisNo ratings yet

- 16n28 Brushed DC Motor DatasheetDocument1 page16n28 Brushed DC Motor DatasheetPaweł DoboszNo ratings yet

- Parts Catalog Engine Generator SDG100S 6A6Document30 pagesParts Catalog Engine Generator SDG100S 6A6Teddy NsNo ratings yet

- NC3120Document2 pagesNC3120Ardeleana TisaNo ratings yet

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BADocument2 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BAjuanda sinagaNo ratings yet

- 14.02.1998 SKRS 9042 IntraaxDocument8 pages14.02.1998 SKRS 9042 IntraaxBKONo ratings yet

- Precious Metal Commutation Ø22Mm 8.8 MNM: Electrical Data 216P 216E 213E 210E 208E 105Document1 pagePrecious Metal Commutation Ø22Mm 8.8 MNM: Electrical Data 216P 216E 213E 210E 208E 105johnNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 28657Document2 pagesInjector Specification: Nozzle Holder Assembly No. 28657Ventas DamNo ratings yet

- C56 SpecsDocument3 pagesC56 SpecsFelipe CINo ratings yet

- Dates Gear and Camshaft PDFDocument1 pageDates Gear and Camshaft PDFDimitrijs SilinsNo ratings yet

- Md310 Quick ManualDocument55 pagesMd310 Quick ManualHitesh PanigrahiNo ratings yet

- Ball and Socket Joints: Thread (Hand) D D L D D L Min. X GDocument2 pagesBall and Socket Joints: Thread (Hand) D D L D D L Min. X GGembonz Crew Gon'z SpeedNo ratings yet

- Variable Speed Unit VARIMOT DF46: Sew-Eurodrive, IncDocument2 pagesVariable Speed Unit VARIMOT DF46: Sew-Eurodrive, Inccarlos aguileraNo ratings yet

- EC480D - Swing Gearbox, Maintenance StandardDocument4 pagesEC480D - Swing Gearbox, Maintenance Standardeck yuwanNo ratings yet

- CRF 250 2013 SchedaDocument1 pageCRF 250 2013 SchedaFedericoFoxFossaluzzaNo ratings yet

- Massey Ferguson Mf8260 Parts CatalogueDocument20 pagesMassey Ferguson Mf8260 Parts Cataloguebillie98% (59)

- Nordberg MP Series Cone Crusher: Reference ManualDocument91 pagesNordberg MP Series Cone Crusher: Reference ManualJOSE CARRASCONo ratings yet

- Sdg100as 3a6Document36 pagesSdg100as 3a6КонстантинNo ratings yet

- Part Number Retrieval: A Part Number and A Price May Be Changed Without A Preliminary AnnouncementDocument1 pagePart Number Retrieval: A Part Number and A Price May Be Changed Without A Preliminary AnnouncementLuisTurpoNo ratings yet

- SMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesDocument5 pagesSMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesVictor NoschangNo ratings yet

- Variable Speed Unit VARIMOT DF36: Sew-Eurodrive, IncDocument2 pagesVariable Speed Unit VARIMOT DF36: Sew-Eurodrive, Inccarlos aguileraNo ratings yet

- RASRI24-004-Design1-RCBeamDes B1Document3 pagesRASRI24-004-Design1-RCBeamDes B1อมรฤทธิ์ พ่วงสมบัติNo ratings yet

- 98 Exciter 135 SE EXS1200Document72 pages98 Exciter 135 SE EXS1200wilsonmoto15No ratings yet

- Jenbacher: 1902-0228E Screwing and Tightening Torque J 6..GS-EDocument6 pagesJenbacher: 1902-0228E Screwing and Tightening Torque J 6..GS-EArîf100% (2)

- CrimpSpecs GH493-20-24-32Document2 pagesCrimpSpecs GH493-20-24-32Julián Ricardo RodriguezNo ratings yet

- Tiller Arm (Gas Strut) - Combilift Spare PartsDocument3 pagesTiller Arm (Gas Strut) - Combilift Spare PartsCristian Elías Cruces CaamañoNo ratings yet

- Caterpillar 3116 Overhaul KitDocument2 pagesCaterpillar 3116 Overhaul KitRicky IbarraNo ratings yet

- CSH8581-125 - Piese de SchimbDocument27 pagesCSH8581-125 - Piese de SchimbLiviu PopaNo ratings yet

- BBBarBrochure - 2011 05 30 PDFDocument7 pagesBBBarBrochure - 2011 05 30 PDFKS LeeNo ratings yet

- Fuel System (G4ED-G4EE - GSL 1.6-1.4)Document308 pagesFuel System (G4ED-G4EE - GSL 1.6-1.4)Jeff PascoeNo ratings yet

- Engine Electrical System (G4ED-G4EE - GSL 1.6-1.4)Document36 pagesEngine Electrical System (G4ED-G4EE - GSL 1.6-1.4)Jeff PascoeNo ratings yet

- General IndexDocument22 pagesGeneral IndexJeff PascoeNo ratings yet

- Engine (D4FA-DSL 1.5)Document96 pagesEngine (D4FA-DSL 1.5)Jeff PascoeNo ratings yet

- Msa5t0124a27670 PDFDocument3 pagesMsa5t0124a27670 PDFJeff PascoeNo ratings yet

- General: A: PrecautionsDocument2 pagesGeneral: A: PrecautionsJeff PascoeNo ratings yet

- Drive Pinion AssemblyDocument7 pagesDrive Pinion AssemblyJeff PascoeNo ratings yet

- Emission Control System (G4HD-G4EE-G4ED - GSL 1.1-1.4-1.6)Document16 pagesEmission Control System (G4HD-G4EE-G4ED - GSL 1.1-1.4-1.6)Jeff PascoeNo ratings yet

- Transmission CaseDocument14 pagesTransmission CaseJeff PascoeNo ratings yet

- Engine Electrical System (D4FA - DSL 1.5)Document28 pagesEngine Electrical System (D4FA - DSL 1.5)Jeff PascoeNo ratings yet

- Transfer Case and Extension: A: RemovalDocument8 pagesTransfer Case and Extension: A: RemovalJeff PascoeNo ratings yet

- Msa5t0124a27668 PDFDocument5 pagesMsa5t0124a27668 PDFJeff PascoeNo ratings yet

- Transfer Case and ExtensionDocument1 pageTransfer Case and ExtensionJeff PascoeNo ratings yet

- Msa5t0124a27664 PDFDocument1 pageMsa5t0124a27664 PDFJeff PascoeNo ratings yet

- Extension Assembly 9. Front DifferentialDocument1 pageExtension Assembly 9. Front DifferentialJeff PascoeNo ratings yet

- Manual Transmission and DifferentialDocument1 pageManual Transmission and DifferentialJeff PascoeNo ratings yet

- Transmission CaseDocument1 pageTransmission CaseJeff PascoeNo ratings yet

- Center Differential: A: Disassembly and AssemblyDocument1 pageCenter Differential: A: Disassembly and AssemblyJeff PascoeNo ratings yet

- Manual TransmissionDocument1 pageManual TransmissionJeff PascoeNo ratings yet

- Shifter Fork and Shifter RodDocument1 pageShifter Fork and Shifter RodJeff PascoeNo ratings yet

- Msa5t0124a27661 PDFDocument1 pageMsa5t0124a27661 PDFJeff PascoeNo ratings yet

- Msa5t0124a27673 PDFDocument1 pageMsa5t0124a27673 PDFJeff PascoeNo ratings yet

- Manual Transmission and DifferentialDocument1 pageManual Transmission and DifferentialJeff PascoeNo ratings yet

- Drive Pinion Assembly 5. Reverse Idler GearDocument1 pageDrive Pinion Assembly 5. Reverse Idler GearJeff PascoeNo ratings yet

- PC Based Temperature Controller Using Digital Pid/Fuzzy Logic Controller ObjectiveDocument3 pagesPC Based Temperature Controller Using Digital Pid/Fuzzy Logic Controller ObjectiveRajasekaran S100% (1)

- CSO Cheat SheetDocument4 pagesCSO Cheat SheetFreshyAndMessyNo ratings yet

- 3516 Engines ClassDocument75 pages3516 Engines ClassMohamed Bakheet89% (19)

- Machinery MaintenanceDocument13 pagesMachinery MaintenanceSyahirrashaharNo ratings yet

- Pleno Refill EN LowDocument16 pagesPleno Refill EN LowDanijelSeđakNo ratings yet

- Demobilisation Assurance ChecklistDocument3 pagesDemobilisation Assurance ChecklistNazrin SHONo ratings yet

- Full Text 01Document130 pagesFull Text 01Hans Cristian Brinkmann GoldsackNo ratings yet

- Checklist - Civil - Drgs.Document2 pagesChecklist - Civil - Drgs.Ramalingam PrabhakaranNo ratings yet

- Next Generation Power and Energy PDFDocument29 pagesNext Generation Power and Energy PDFjwpaprk1No ratings yet

- Blinding Concrete Works Contents Revised 19-04-16RDocument3 pagesBlinding Concrete Works Contents Revised 19-04-16RJoel Alcantara100% (1)

- FREUND Ernst The Police Power Public Policy and Constitucional RightsDocument923 pagesFREUND Ernst The Police Power Public Policy and Constitucional RightsGustavZatelliNo ratings yet

- Apcosil 605: Product DescriptionDocument3 pagesApcosil 605: Product DescriptionShravana PrasadNo ratings yet

- Lightworks v14.0.0 Quick Start GuideDocument38 pagesLightworks v14.0.0 Quick Start GuideSrL3onNo ratings yet

- Client-Side Web Security PDFDocument208 pagesClient-Side Web Security PDFneroliangNo ratings yet

- EATONCarterR Hydrant Coupler - API Style - Model 64810Document4 pagesEATONCarterR Hydrant Coupler - API Style - Model 64810Vaeco Đoàn Tncs HcmNo ratings yet

- Test 1 Unit 5 - Grade 10Document9 pagesTest 1 Unit 5 - Grade 10Hường NgôNo ratings yet

- LH 11 180 190 220 230 270 280 390 400 Breaker Safety & Operating InstructionsDocument304 pagesLH 11 180 190 220 230 270 280 390 400 Breaker Safety & Operating InstructionshadensandorNo ratings yet

- Induction Motor BasicsDocument19 pagesInduction Motor BasicsPUSHPAN DAHARWALNo ratings yet

- Phpshadow7.0 UserguideDocument21 pagesPhpshadow7.0 Userguidehenry rohitNo ratings yet

- Xavc 0711 Epr CB 0.D02 Esp 01Document138 pagesXavc 0711 Epr CB 0.D02 Esp 01AndrewNo ratings yet

- Silicon Dioxide Patinal: General InformationDocument4 pagesSilicon Dioxide Patinal: General InformationjorgeNo ratings yet

- Enventure Engineering-A Brief IntroductionDocument13 pagesEnventure Engineering-A Brief IntroductionAravind MadhuNo ratings yet

- See Distribution List: Building Plan & Management GroupDocument12 pagesSee Distribution List: Building Plan & Management GroupkksmileNo ratings yet

- Filetype PDF Electronic Data Interchange A Total Management GuideDocument2 pagesFiletype PDF Electronic Data Interchange A Total Management GuideMikeNo ratings yet

- Pe - 1969-03Document116 pagesPe - 1969-03Anonymous kdqf49qbNo ratings yet

- Jual ACER Aspire All-In-1 Multi Media PC AZ5710 - BeraniMurahDocument4 pagesJual ACER Aspire All-In-1 Multi Media PC AZ5710 - BeraniMurahDion DhieNo ratings yet

- Openhole CompletionsDocument9 pagesOpenhole CompletionsShaktim DuttaNo ratings yet

- Book Review The Concise Townscape by GorDocument2 pagesBook Review The Concise Townscape by GorJavier Monclús0% (1)

- Fluid Mechanics PDFDocument179 pagesFluid Mechanics PDFNishchay Choudhary100% (1)

- Unit Plan Final Assessment Rubrics PDFDocument2 pagesUnit Plan Final Assessment Rubrics PDFapi-282198214No ratings yet