Professional Documents

Culture Documents

I NYECTOR

Uploaded by

Diesel Motors0 ratings0% found this document useful (0 votes)

2 views2 pagesCALIBRARACION 37961

Original Title

iNYECTOR

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCALIBRARACION 37961

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views2 pagesI NYECTOR

Uploaded by

Diesel MotorsCALIBRARACION 37961

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Page 1 of 2

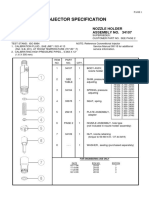

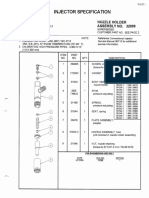

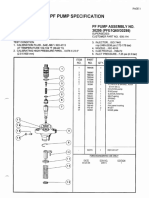

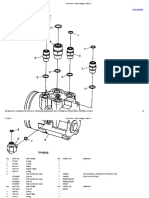

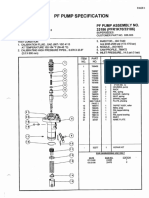

INJECTOR SPECIFICATION

EDITION: 1 NOZZLE HOLDER

APPLICATIONS : SEE PAGE 2 ASSEMBLY NO. 37961

DATED: 27-04-05 SUPERSEDES:

CUSTOMER: VAMO CUSTOMER PART NO. SEE PAGE 2

TEST STAND: ISO 8984 NOTE: Reference Conventional Injector

1. CALIBRATION FLUID: SAE J967 / ISO 4113 Service Manual 99118 for additional

(Ref. S.B. 201) AT ROOM TEMPERATURE (70°-80° F) service information.

2. CALIBRATING HIGH PRESSURE PIPES: 0.063 X 12"

(1.6 X 305 mm)

ITEM PART NO. QTY. DESCRIPTION

NO.

*(1 PREFERRED

1 31025 1 SCREW, inlet union 2 MAX.)

(torque to 8-10 Nm) PART THICKNESS

NO. mm (inches)

2 780733 2 GASKET, banjo 781229 1.000 (.0393)

781230 1.050 (.0413)

781231 1.100 (.0433)

781232 1.150 (.0453)

3 37959 1 BODY, nozzle holder 781233 1.200 (.0472)

781234 1.250 (.0492)

781235 1.300 (.0512)

4 SEE * SHIM, pressure 781236 1.350 (.0531)

TABLE Adjusting 781237 1.400 (.0551)

781238 1.450 (.0571)

781239 1.500 (.0591)

781240 1.550 (.0610)

5 31093 1 SPRING, pressure 781241 1.600 (.0630)

Adjusting 781242 1.650 (.0650)

781243 1.700 (.0669)

6 31044 1 SEAT, spring 781244 1.750 (.0689)

781245 1.800 (.0709)

781246 1.850 (.0728)

7 29418 1 PLATE, assembly adapter

8 PAGE 2 1 NOZZLE ASSEMBLY

(not included in nozzle holder assembly)

9 34109 1 NUT, nozzle retaining

(torque to 55-65 Nm or 40-47 lbf. ft)

.

FOR ENGINEERING USE ONLY

DATE ECN NO. EDITION

27-04-2005 28991 1

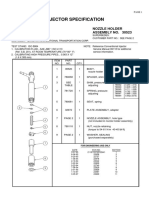

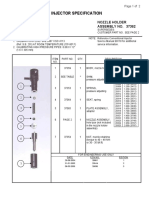

Page 2 of 2

APPLICATION AND SERVICE INFORMATION

FOR HOLDER ASSEMBLY 37961

INJECTOR NOZZLE

STANADYNE CUSTOMER INSCRIPTION STANADYNE CUSTOMER INSCRIPTION

PART NO. PART NO. CODE PART NO. PART NO. CODE APPLICATION

37960 - 960 37958 - SDLLA151P D4000I.S2

37958

OPENING PRESSURE

NEW AND SERVICE

INJECTOR MPa (PSI) MAX VALVE LIFT

NO. mm (inches)

37960 26.5 – 27.3 (3842 – 3958) 0.250 (.0098)

For bar, multiply MPa by 10

Maximum valve lift for service : +0.05 mm beyond value shown in table.

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 38183Document2 pagesInjector Specification: Nozzle Holder Assembly No. 38183johnny sabinNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 30163Document2 pagesInjector Specification: Nozzle Holder Assembly No. 30163Miguel RojasNo ratings yet

- StadyneDocument2 pagesStadynePatrick MalmbergNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 34107Document2 pagesInjector Specification: Nozzle Holder Assembly No. 34107johnny sabinNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 34107Document2 pagesInjector Specification: Nozzle Holder Assembly No. 34107DIESEL MOTORSNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 34107Document2 pagesInjector Specification: Nozzle Holder Assembly No. 34107Miguel RojasNo ratings yet

- Inyector 36897Document2 pagesInyector 36897Diesel MotorsNo ratings yet

- Injector Specification: Stanadyne"Document2 pagesInjector Specification: Stanadyne"Miguel Rojas100% (1)

- Stanadyne injector specification and nozzle holder assemblyDocument2 pagesStanadyne injector specification and nozzle holder assemblyEduardo David Castillo QuijandriaNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 28657Document2 pagesInjector Specification: Nozzle Holder Assembly No. 28657Ventas DamNo ratings yet

- 780321Document3 pages780321Miguel RojasNo ratings yet

- Injector UDocument3 pagesInjector Umecanik.veracruzNo ratings yet

- Stanadyne 30523Document3 pagesStanadyne 30523Erick RodriguezNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 30523Document3 pagesInjector Specification: Nozzle Holder Assembly No. 30523David BenavidesNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 29229Document2 pagesInjector Specification: Nozzle Holder Assembly No. 29229Eduardo David Castillo QuijandriaNo ratings yet

- Injector Specification: Page 1 of 2Document2 pagesInjector Specification: Page 1 of 2johnny sabinNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 38465Document2 pagesInjector Specification: Nozzle Holder Assembly No. 38465johnny sabinNo ratings yet

- Injector Specification: Page 1 of 2Document2 pagesInjector Specification: Page 1 of 2johnny sabinNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 38307Document2 pagesInjector Specification: Nozzle Holder Assembly No. 38307johnny sabinNo ratings yet

- Injector Specification SheetDocument1 pageInjector Specification Sheetjohnny sabinNo ratings yet

- Injector Specification: Assembly No: 36211Document1 pageInjector Specification: Assembly No: 36211johnny sabinNo ratings yet

- Injector Specification (RSN) : Assembly No: 35107Document1 pageInjector Specification (RSN) : Assembly No: 35107RENENo ratings yet

- Injector Specification: Assembly No: 35102Document1 pageInjector Specification: Assembly No: 35102johnny sabinNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Eduardo David Castillo QuijandriaNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"DIESEL MOTORSNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- Injector Specification SheetDocument1 pageInjector Specification Sheetjohnny sabinNo ratings yet

- Injector Specification: Assembly No: 35542Document1 pageInjector Specification: Assembly No: 35542johnny sabinNo ratings yet

- Injector Specification: Stanadyne"Document2 pagesInjector Specification: Stanadyne"Ventas R11No ratings yet

- Injector Specification SheetDocument1 pageInjector Specification Sheetjohnny sabinNo ratings yet

- Injector Specification: Assembly No: 36710Document1 pageInjector Specification: Assembly No: 36710johnny sabinNo ratings yet

- Volkswagen Injector Specification SheetDocument2 pagesVolkswagen Injector Specification Sheetjohnny sabinNo ratings yet

- 4TNV88 GgeaDocument30 pages4TNV88 GgeaKevin TanNo ratings yet

- Generator Parts Specification and DrawingsDocument30 pagesGenerator Parts Specification and DrawingsAnindra Ahmad Farras100% (2)

- 4TNV84T GgeaDocument31 pages4TNV84T GgeaKevin TanNo ratings yet

- Injector Specification: Assembly No: 32144Document1 pageInjector Specification: Assembly No: 32144Miguel RojasNo ratings yet

- Injector Specification (RSN) : Assembly No: 38414Document1 pageInjector Specification (RSN) : Assembly No: 38414johnny sabinNo ratings yet

- John Deere Parts Catalog Frame 5Document2 pagesJohn Deere Parts Catalog Frame 5Jorge Mendoza100% (1)

- John Deere - Parts Catalog - Frame 5Document2 pagesJohn Deere - Parts Catalog - Frame 5Jorge MendozaNo ratings yet

- Grove 9926113276 - Switch Assy. PressureDocument2 pagesGrove 9926113276 - Switch Assy. PressureMarcela FooliniNo ratings yet

- SSIService PartsDocument19 pagesSSIService PartssamNo ratings yet

- BM-MSF Nozzle Tip ExchangeDocument5 pagesBM-MSF Nozzle Tip Exchangemartin.weisshaarNo ratings yet

- 30124Document2 pages30124Miguel RojasNo ratings yet

- Engine Data Sheet As4006 m5 3tnm72 GHFCLDocument15 pagesEngine Data Sheet As4006 m5 3tnm72 GHFCLBW MechanicalNo ratings yet

- Injector Specification: Assembly No: 36497Document1 pageInjector Specification: Assembly No: 36497johnny sabinNo ratings yet

- Radiator - Coolant Recovery SystemDocument2 pagesRadiator - Coolant Recovery SystemBillNo ratings yet

- PF Pump Specification: Stanadyne'Document2 pagesPF Pump Specification: Stanadyne'Eduardo David Castillo QuijandriaNo ratings yet

- Herramienta Sello EspejoDocument2 pagesHerramienta Sello EspejoeliecerNo ratings yet

- AMM - 01-Aug-2019 - 79-21-10-400-004-A - Installation of The Lubrication UnitDocument11 pagesAMM - 01-Aug-2019 - 79-21-10-400-004-A - Installation of The Lubrication UnitIrfan05No ratings yet

- Block-Camshaft and PistonsDocument4 pagesBlock-Camshaft and PistonsNikailNo ratings yet

- AN6204Document4 pagesAN6204CTN2010No ratings yet

- 2020 YZF R6 Kit Manual enDocument70 pages2020 YZF R6 Kit Manual enLillo VetroNo ratings yet

- Toyota Camshaft PDFDocument6 pagesToyota Camshaft PDFChristian RedinNo ratings yet

- Ipc P&WC Chapter 73-10-05Document4 pagesIpc P&WC Chapter 73-10-05LUCIENE ORECCHIO VIEIRANo ratings yet

- Ata 78 I-Aea1Document29 pagesAta 78 I-Aea1Antonio CorteNo ratings yet

- STMADYNE PF PUMP SPECIFICATIONDocument2 pagesSTMADYNE PF PUMP SPECIFICATIONMiguel RojasNo ratings yet

- STMADYNE PF PUMP SPECIFICATIONDocument2 pagesSTMADYNE PF PUMP SPECIFICATIONDIESEL MOTORSNo ratings yet

- Inyector 36897Document2 pagesInyector 36897Diesel MotorsNo ratings yet

- Inyector 36897Document2 pagesInyector 36897Diesel MotorsNo ratings yet

- CALIBREDocument4 pagesCALIBREDiesel MotorsNo ratings yet

- Injection Pump Test Specifications With Dst-1 HU096500-600#: 1. Setup ConditionDocument4 pagesInjection Pump Test Specifications With Dst-1 HU096500-600#: 1. Setup ConditionMiguel RojasNo ratings yet

- Injection Pump Test Specifications With Dst-1 HU096500-600#: 1. Setup ConditionDocument4 pagesInjection Pump Test Specifications With Dst-1 HU096500-600#: 1. Setup ConditionMiguel RojasNo ratings yet

- 01EJ5012Document8 pages01EJ5012Mohamed ElsabahyNo ratings yet

- 01EJ5020Document3 pages01EJ5020Miguel RojasNo ratings yet

- Class 7 Chapter 5 WaterDocument10 pagesClass 7 Chapter 5 WaterANIRBAN DAMNo ratings yet

- CHN Notes SummaryDocument6 pagesCHN Notes SummaryAlec AnonNo ratings yet

- Praying in The Spirit Series-Conceiving in The SpiritDocument11 pagesPraying in The Spirit Series-Conceiving in The SpiritPrecious O. OkaforNo ratings yet

- Intelli Trac X1Document2 pagesIntelli Trac X1nadjibnetNo ratings yet

- Analiza PESTDocument16 pagesAnaliza PESTIoana Ciobanu100% (1)

- FliesDocument14 pagesFliesaguilarmvzNo ratings yet

- Uwezo-SAT-W-L-In Class-SET 1 - WMDocument15 pagesUwezo-SAT-W-L-In Class-SET 1 - WMAditya KantipudiNo ratings yet

- Quality Management System: ISO 9001 - 2000 ClausesDocument18 pagesQuality Management System: ISO 9001 - 2000 ClausesRambabuNo ratings yet

- Algae and Aquatic Biomass For A Sustainable Production of 2nd Generation BiofuelsDocument258 pagesAlgae and Aquatic Biomass For A Sustainable Production of 2nd Generation BiofuelsjcbobedaNo ratings yet

- SmoothiesDocument4 pagesSmoothiesapi-537172848No ratings yet

- Site Visit ReportDocument7 pagesSite Visit ReportAhmad0% (1)

- Customer Feedback AnalysisDocument11 pagesCustomer Feedback Analysisjyoti soodNo ratings yet

- 3.14 Doxy PleurodesisDocument2 pages3.14 Doxy PleurodesisRheinald Joel BiscaroNo ratings yet

- The Abreviated Ajahn Brahm - Concise Instructions For Skillful Meditation PDFDocument8 pagesThe Abreviated Ajahn Brahm - Concise Instructions For Skillful Meditation PDFJean Bessaudou Jan BessNo ratings yet

- Madeline Reitman Capstone Proposal 2Document6 pagesMadeline Reitman Capstone Proposal 2api-446158134No ratings yet

- 2009 The Neuroanatomic Basis of The Acupuncture Principal MeridiansDocument21 pages2009 The Neuroanatomic Basis of The Acupuncture Principal MeridiansAna Maria MartinsNo ratings yet

- Calculation of The Reorder Point For Items With Exponential and Poisson Distribution of Lead Time DemandDocument10 pagesCalculation of The Reorder Point For Items With Exponential and Poisson Distribution of Lead Time DemandRaj ChauhanNo ratings yet

- Year 9 Biology InvestigationDocument2 pagesYear 9 Biology Investigationapi-222503660No ratings yet

- The McKenzie Method Powerpoint - 2008Document57 pagesThe McKenzie Method Powerpoint - 2008aslooclt100% (2)

- Tm1tEMPLATES-SWBL-Forms 1.1-1.4 (1) (Back Up)Document17 pagesTm1tEMPLATES-SWBL-Forms 1.1-1.4 (1) (Back Up)Norrodin MangatongNo ratings yet

- Work Procedure For Temporary Fence GateDocument19 pagesWork Procedure For Temporary Fence GateAlbert OquindoNo ratings yet

- Unified Alloys ANSI Pipe Chart 6-28-2018Document2 pagesUnified Alloys ANSI Pipe Chart 6-28-2018Manual SourceNo ratings yet

- CHALLENGES - IN - DEVELOPING - MARGINAL - FIELD - COMPLEXITY, - CO MPILATION - & - IMPROVEMENT - NEEDED - Nik - Edit - 3Document22 pagesCHALLENGES - IN - DEVELOPING - MARGINAL - FIELD - COMPLEXITY, - CO MPILATION - & - IMPROVEMENT - NEEDED - Nik - Edit - 3Wan Mohd ShaharizuanNo ratings yet

- Psychosocial Support Activity Pack PSAP FINAL - 20211123Document108 pagesPsychosocial Support Activity Pack PSAP FINAL - 20211123Ruben HatamosaNo ratings yet

- CSFDocument5 pagesCSFjalan_zNo ratings yet

- PowerStop Shock Absorber CatalogDocument24 pagesPowerStop Shock Absorber CatalogAfiyat Nur100% (1)

- MEP Final Corrected 2Document17 pagesMEP Final Corrected 2Prakhyati RautNo ratings yet

- 2.2.5 Respiration WorksheetDocument7 pages2.2.5 Respiration WorksheeterikabeltranNo ratings yet

- Final Duct Wraps Brochure 98-0213-4600-6rrDocument8 pagesFinal Duct Wraps Brochure 98-0213-4600-6rrDiego Armando Martinez GutierrezNo ratings yet

- Evidence-Based Eating GuideDocument11 pagesEvidence-Based Eating GuideDarioNo ratings yet