Professional Documents

Culture Documents

Injector Specification: Page 1 of 2

Uploaded by

johnny sabinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Injector Specification: Page 1 of 2

Uploaded by

johnny sabinCopyright:

Available Formats

Page 1 of 2

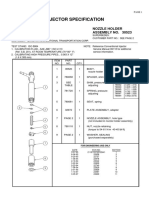

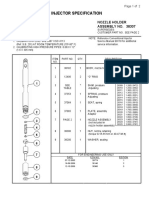

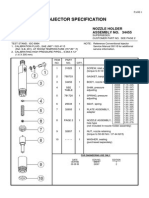

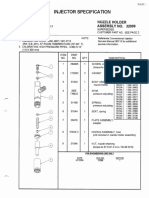

INJECTOR SPECIFICATION

EDITION: 2 NOZZLE HOLDER

APPLICATIONS : SEE PAGE 2 ASSEMBLY NO. 38395

DATED: 18-05-2006 SUPERSEDES:

CUSTOMER: YANMAR CUSTOMER PART NO. SEE PAGE 2

TEST STAND: ISO 8984 NOTE: Reference Conventional Injector

1. CALIBRATION FLUID: SAE J967 / ISO 4113 Service Manual 99118 for additional

(Ref. S.B. 201) AT ROOM TEMPERATURE (70°-80° F) service information.

2. CALIBRATING HIGH PRESSURE PIPES: 0.063 X 12"

(1.6 X 305 mm)

ITEM PART NO. QTY. DESCRIPTION

NO.

*(1 PREFERRED

1 38396 1 BODY, nozzle holder 2 MAX.)

PART THICKNESS

NO. mm (inches)

2 SEE TABLE * SHIM, 29305 1.000 (.0393)

pressure adjusting 29306 1.050 (.0413)

29307 1.100 (.0433)

29308 1.150 (.0453)

1 29309 1.200 (.0472)

3 37353 1 SPRING, 29310 1.250 (.0492)

pressure adjusting 29311 1.300 (.0512)

29312 1.350 (.0531)

29313 1.400 (.0551)

2 29314 1.450 (.0571)

4 37064 1 SEAT, spring

29315 1.500 (.0591)

29316 1.550 (.0610)

29317 1.600 (.0630)

3 5 37065 1 PLATE ASSEMBLY, 29318 1.650 (.0650)

adapter 29319 1.700 (.0669)

29320 1.750 (.0688)

29321 1.800 (.0708)

4 29322 1.850 (.0728)

6 PAGE 2 1 NOZZLE ASSEMBLY, 29323 1.900 (.0748)

hole type (not included 29324 1.950 (.0767)

5 in the nozzle holder 29325 2.000 (.0787)

assembly)

7 37354 1 NUT, nozzle retaining

6 (torque to 40 – 48 Nm

or 30 - 35 lbf.ft)

FOR ENGINEERING USE ONLY

DATE ECN NO. EDITION

08-03-2006 29838 1

7 18-05-2006 410-M 2

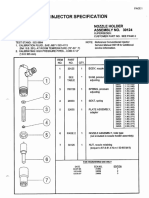

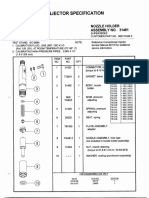

Page 2 of 2

APPLICATION AND SERVICE INFORMATION

FOR HOLDER ASSEMBLY 38395

INJECTOR NOZZLE

STANADYNE CUSTOMER INSCRIPTION STANADYNE CUSTOMER INSCRIPTION

PART NO. PART NO. CODE PART NO. PART NO. CODE APPLICATION

TALKING SHANK

CODE

38397

38394 714120-53100 394 SDSLA 150P 114120-53000 38397 L48N

38397

OPENING PRESSURE

NEW AND SERVICE

INJECTOR MPa (PSI) MAX VALVE LIFT NO. OF HOLES

NO. mm (inches) @ DIA. mm (inches)

38394 19.6 – 20.4 (2842 – 2958) 0.200 (.0079) 4 @ 0.185 (.0073)

For bar, multiply MPa by 10

Maximum valve lift for service : +0.05 mm beyond value shown in table.

You might also like

- Introduction ..FoundryDocument160 pagesIntroduction ..FoundryDhananjay ShimpiNo ratings yet

- CSA Welding Standards OverviewDocument57 pagesCSA Welding Standards OverviewAlexanderTomasik100% (1)

- Injector Specification: Nozzle Holder Assembly No. 30523Document3 pagesInjector Specification: Nozzle Holder Assembly No. 30523David BenavidesNo ratings yet

- v2500lm01r02 General PDFDocument28 pagesv2500lm01r02 General PDFKamalVirk100% (1)

- Fasteners StandardsDocument98 pagesFasteners StandardsRahul Betgeri100% (4)

- Creep and Hygrothermal Effects in Concrete StructuresDocument960 pagesCreep and Hygrothermal Effects in Concrete StructuresMohamed MoawadNo ratings yet

- Chapter 5Document55 pagesChapter 5Arjun Kumar100% (1)

- Space Frame: Section of Typical Module Section at PeripheryDocument1 pageSpace Frame: Section of Typical Module Section at PeripheryVaishali PardhiNo ratings yet

- StadyneDocument2 pagesStadynePatrick MalmbergNo ratings yet

- Walking Column Detailed DesignDocument1 pageWalking Column Detailed DesignTommaso Pascon100% (1)

- Injector Specification: Assembly No: 36710Document1 pageInjector Specification: Assembly No: 36710johnny sabinNo ratings yet

- Stanadyne 30523Document3 pagesStanadyne 30523Erick RodriguezNo ratings yet

- 6.6 KV BreakerDocument29 pages6.6 KV Breakerdan_geplNo ratings yet

- 780321Document3 pages780321Miguel RojasNo ratings yet

- Substructure Design & Intro Exercise TU DelftDocument62 pagesSubstructure Design & Intro Exercise TU DelftManish Shrivastava100% (1)

- Sandvik DT820Document4 pagesSandvik DT820Boni Christian100% (3)

- Injector Specification: Page 1 of 2Document2 pagesInjector Specification: Page 1 of 2johnny sabinNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 38465Document2 pagesInjector Specification: Nozzle Holder Assembly No. 38465johnny sabinNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 38307Document2 pagesInjector Specification: Nozzle Holder Assembly No. 38307johnny sabinNo ratings yet

- Volkswagen Injector Specification SheetDocument2 pagesVolkswagen Injector Specification Sheetjohnny sabinNo ratings yet

- 30124Document2 pages30124Miguel RojasNo ratings yet

- Injector Specification: Stanadyne"Document2 pagesInjector Specification: Stanadyne"Ventas R11No ratings yet

- I NYECTORDocument2 pagesI NYECTORDiesel MotorsNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 30163Document2 pagesInjector Specification: Nozzle Holder Assembly No. 30163Miguel RojasNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 28657Document2 pagesInjector Specification: Nozzle Holder Assembly No. 28657Ventas DamNo ratings yet

- Injector Specification (RSN) : Assembly No: 38414Document1 pageInjector Specification (RSN) : Assembly No: 38414johnny sabinNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 34107Document2 pagesInjector Specification: Nozzle Holder Assembly No. 34107DIESEL MOTORSNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 34107Document2 pagesInjector Specification: Nozzle Holder Assembly No. 34107Miguel RojasNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 34107Document2 pagesInjector Specification: Nozzle Holder Assembly No. 34107johnny sabinNo ratings yet

- Injector Specification: Assembly No: 36211Document1 pageInjector Specification: Assembly No: 36211johnny sabinNo ratings yet

- Injector Specification SheetDocument1 pageInjector Specification Sheetjohnny sabinNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 29229Document2 pagesInjector Specification: Nozzle Holder Assembly No. 29229Eduardo David Castillo QuijandriaNo ratings yet

- Injector Specification SheetDocument1 pageInjector Specification Sheetjohnny sabinNo ratings yet

- Injector Specification SheetDocument1 pageInjector Specification Sheetjohnny sabinNo ratings yet

- Injector Specification (RSN) : Assembly No: 35107Document1 pageInjector Specification (RSN) : Assembly No: 35107RENENo ratings yet

- Injector Specification: Assembly No: 35102Document1 pageInjector Specification: Assembly No: 35102johnny sabinNo ratings yet

- Injector Specification: Assembly No: 32144Document1 pageInjector Specification: Assembly No: 32144Miguel RojasNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 38183Document2 pagesInjector Specification: Nozzle Holder Assembly No. 38183johnny sabinNo ratings yet

- 34455Document2 pages34455Alex Robledo OlarteNo ratings yet

- Injector Specification: Assembly No: 35542Document1 pageInjector Specification: Assembly No: 35542johnny sabinNo ratings yet

- GPD150 N-Max Leg ShieldDocument1 pageGPD150 N-Max Leg ShieldwekdutvkNo ratings yet

- Inyector 36897Document2 pagesInyector 36897Diesel MotorsNo ratings yet

- Injector Specification: Stanadyne"Document2 pagesInjector Specification: Stanadyne"Miguel Rojas100% (1)

- Injector Specification: ASSEMBLY NO: 36597Document1 pageInjector Specification: ASSEMBLY NO: 36597johnny sabinNo ratings yet

- Injector Specification: ASSEMBLY NO: 38145Document1 pageInjector Specification: ASSEMBLY NO: 38145johnny sabinNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"DIESEL MOTORSNo ratings yet

- Injector Specification: ASSEMBLY NO: 36601Document1 pageInjector Specification: ASSEMBLY NO: 36601johnny sabinNo ratings yet

- Injector Specification: ASSEMBLY NO: 36850Document1 pageInjector Specification: ASSEMBLY NO: 36850johnny sabinNo ratings yet

- Injector Specification: Assembly No: 36497Document1 pageInjector Specification: Assembly No: 36497johnny sabinNo ratings yet

- Ipc P&WC Chapter 73-10-05Document4 pagesIpc P&WC Chapter 73-10-05LUCIENE ORECCHIO VIEIRANo ratings yet

- Injector Specification: Assembly No: 36011Document1 pageInjector Specification: Assembly No: 36011johnny sabinNo ratings yet

- Stanadyne injector specification and nozzle holder assemblyDocument2 pagesStanadyne injector specification and nozzle holder assemblyEduardo David Castillo QuijandriaNo ratings yet

- GPD150 N-Max Side CoverDocument2 pagesGPD150 N-Max Side CoverwekdutvkNo ratings yet

- Fan ClutchDocument2 pagesFan ClutchAlvaro Escalona GtzNo ratings yet

- Injector UDocument3 pagesInjector Umecanik.veracruzNo ratings yet

- IRN Format...Document1 pageIRN Format...Tarun TomarNo ratings yet

- Gambar 33 Cowling 1: Nomor Refere Nomor Part Nama Part KeteranganDocument1 pageGambar 33 Cowling 1: Nomor Refere Nomor Part Nama Part KeteranganHarris Jum'aniandaNo ratings yet

- 330DL MWP2Document124 pages330DL MWP2Edgar Revok VelazquezNo ratings yet

- pm30 Operators ManualDocument38 pagespm30 Operators ManualLucas BarriosNo ratings yet

- FRLO 14410C T2 Fuller 10 Speed Parts Breakdown ManualDocument27 pagesFRLO 14410C T2 Fuller 10 Speed Parts Breakdown ManualFlorencio MaximilianoNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Eduardo David Castillo QuijandriaNo ratings yet

- 22.GPD155-F All New Nmax 155 Connected Version Front WheelDocument1 page22.GPD155-F All New Nmax 155 Connected Version Front Wheelandi yusufNo ratings yet

- MG-540 en InglesDocument24 pagesMG-540 en InglesJavier TurbopowerNo ratings yet

- Sag & Tension (GAP Conductor)Document1 pageSag & Tension (GAP Conductor)Subodh SontakkeNo ratings yet

- Engine overhaul quotation for generatorDocument2 pagesEngine overhaul quotation for generatorAhmad ShovaNo ratings yet

- DX210WA Spec SheetDocument59 pagesDX210WA Spec SheetAbdelrahman100% (1)

- Catalogo ATEXDocument153 pagesCatalogo ATEXWilber P ZuritaNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Kapalcrynski: Sufsrstdes ModelDocument3 pagesKapalcrynski: Sufsrstdes Modeljohnny sabinNo ratings yet

- Injection Pump Specification and SettingsDocument1 pageInjection Pump Specification and Settingsjohnny sabinNo ratings yet

- Injection P Specificat: Thsuilo70Document2 pagesInjection P Specificat: Thsuilo70johnny sabinNo ratings yet

- Supersides ModelDocument3 pagesSupersides Modeljohnny sabinNo ratings yet

- Wpersedes Model: DatedDocument3 pagesWpersedes Model: Datedjohnny sabinNo ratings yet

- M O-352 4all: Mobel Ex-Kmx43Document2 pagesM O-352 4all: Mobel Ex-Kmx43johnny sabinNo ratings yet

- Catalog page specifications for an injection pump modelDocument2 pagesCatalog page specifications for an injection pump modeljohnny sabinNo ratings yet

- ,Lfd'Lalag'Pkge:Ljfj 500 - 35 L5: - . ZZ!ZZ - Mm. Per Max. Y&R. Trans. PumpDocument2 pages,Lfd'Lalag'Pkge:Ljfj 500 - 35 L5: - . ZZ!ZZ - Mm. Per Max. Y&R. Trans. Pumpjohnny sabinNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced Documentsjohnny sabinNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 38183Document2 pagesInjector Specification: Nozzle Holder Assembly No. 38183johnny sabinNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced Documentsjohnny sabinNo ratings yet

- 51 F3 Modeldbgfcc431-3Latl: - . C!Talog Page'NoDocument2 pages51 F3 Modeldbgfcc431-3Latl: - . C!Talog Page'Nojohnny sabinNo ratings yet

- 1 JJ Model: C"A?Al - Og No: Eititfcc93T Part No. A 35776Document2 pages1 JJ Model: C"A?Al - Og No: Eititfcc93T Part No. A 35776johnny sabinNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced Documentsjohnny sabinNo ratings yet

- Catalog Page No: Injection Pump Model Df3Gfccwl-27Aj Specification Customer Part Hl0. 3577'4Document2 pagesCatalog Page No: Injection Pump Model Df3Gfccwl-27Aj Specification Customer Part Hl0. 3577'4johnny sabinNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced Documentsjohnny sabinNo ratings yet

- PF Pump Specification: Page 1 Di 2Document2 pagesPF Pump Specification: Page 1 Di 2johnny sabinNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced Documentsjohnny sabinNo ratings yet

- PF Pump SpecificationDocument3 pagesPF Pump Specificationjohnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- PF Pump Specification: Page 1 Di 2Document2 pagesPF Pump Specification: Page 1 Di 2johnny sabinNo ratings yet

- PF Pump SpecificationDocument3 pagesPF Pump Specificationjohnny sabinNo ratings yet

- PF Pump Specification: Page 1 Di 2Document2 pagesPF Pump Specification: Page 1 Di 2johnny sabinNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- Water Cooled Scroll ChillerDocument3 pagesWater Cooled Scroll ChillerRangga Prasetya BaitullahNo ratings yet

- 21 TR 02Document15 pages21 TR 02amin chaabenNo ratings yet

- Nit 1005 Mab Amd 1Document95 pagesNit 1005 Mab Amd 1Pradeep KumarNo ratings yet

- 1.design For Shear For Prestressed ConcreteDocument34 pages1.design For Shear For Prestressed ConcretealexNo ratings yet

- Motorav m36n 2 eDocument1 pageMotorav m36n 2 eimranakhtarNo ratings yet

- Arc Catalog of Products: Protec Tion Against Corrosion, Abrasion, Impac T, and Chemical at TackDocument40 pagesArc Catalog of Products: Protec Tion Against Corrosion, Abrasion, Impac T, and Chemical at TackcesarNo ratings yet

- Morotack CatalogueDocument42 pagesMorotack CatalogueTeodor BochevNo ratings yet

- Well Testing: Overview of Well Test AnalysisDocument18 pagesWell Testing: Overview of Well Test Analysisgeber39No ratings yet

- Kwik Bolt 3 Exp Anchor Hilti PDFDocument21 pagesKwik Bolt 3 Exp Anchor Hilti PDFarturoncNo ratings yet

- Shale Shaker Screens - KemtronDocument4 pagesShale Shaker Screens - KemtronWilliamNo ratings yet

- Sanitary Fittings (MS 02 124 E) R2Document4 pagesSanitary Fittings (MS 02 124 E) R2herysyam1980No ratings yet

- Preparing For Aluminum GTAW: Proper Equipment Setup and Workplace Preparation Reduce DefectsDocument5 pagesPreparing For Aluminum GTAW: Proper Equipment Setup and Workplace Preparation Reduce DefectsRaron1No ratings yet

- P3FH-RPT-QA/QC-00-010-A4: Manual & ProceduresDocument17 pagesP3FH-RPT-QA/QC-00-010-A4: Manual & ProceduresFriska ThaniaNo ratings yet

- Chill Down Process of Hydrogen Transport PipelinesDocument19 pagesChill Down Process of Hydrogen Transport PipelinesmsreerajvarmaNo ratings yet

- Ariel Engine and Frame Prefix Numbers 1926 To 1965Document3 pagesAriel Engine and Frame Prefix Numbers 1926 To 1965bsaheadNo ratings yet

- Evaluation of Various Turbulence Models For Shock-Wave Boundary Layer Interaction Flows - 2016Document62 pagesEvaluation of Various Turbulence Models For Shock-Wave Boundary Layer Interaction Flows - 2016NeoNo ratings yet

- High-Rise PrecastDocument7 pagesHigh-Rise PrecastAshu JainNo ratings yet

- AP-38 Leg B Foundation AnalysisDocument24 pagesAP-38 Leg B Foundation AnalysisHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Model 1 DS1703Document2 pagesModel 1 DS1703dreyko77No ratings yet