Professional Documents

Culture Documents

Bulletin 62.3:377 specifications and temperature capabilities

Uploaded by

anon_179850881Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bulletin 62.3:377 specifications and temperature capabilities

Uploaded by

anon_179850881Copyright:

Available Formats

Bulletin 62.

3:377

Specifications

Available Configurations Temperature Capabilities

When supply pressure falls below the trip point, Nitrile Diaphragms and O-Rings: –40 to 180°F

Type 377D Trip Valve: Fails actuator piston down. (–40 to 82°C)

Includes check valve and volume tank Fluoroelastomer Diaphragms and O-Rings: 0 to

Type 377L Trip Valve: Locks actuator piston in the 220°F (–18 to 104°C)

last position

Type 377U Trip Valve: Fails actuator piston up. Volume Tank Maximum Internal Working Pressure

Includes check valve and volume tank.

Standard: 240 psig (14.5 bar) for Type 377D or

All 377 Series Trip Valves can be converted to any 377U

of the above fail modes with minor hookup changes ASME Approved: 135 psig (9.3 bar) for Type 377D

or 377U

Allowable Supply Pressure for Trip Valve

Maximum: 150 psig (10.3 bar) Volume Tank Sizing

Minimum: 55 psig (3.8 bar)

See sizing section

Outlet Pressure

Mounting

Normal Operation: Pressure from control device

Fail-Up or Fail-Down Mode: Maximum volume Top-Mounted: Manifold-mounted between the po-

tank pressure sitioner and 470 or 480 Series actuator (manifolds

Lock-In-Last-Position: Respective cylinder pressure cannot be supplied with 490, 585, 1061, 1066, and

1069 Series piston actuators)

Trip Point(1) Side-Mounted: Yoke mounted or bracket mounted

Adjustable from a minimum of 40 psig (2.8 bar) to a

maximum of 72 percent of supply pressure; see Approximate Weight

figure 3 Trip Valve: 4.5 pounds (2.0 kg)

Reset: 12.5 to 33 percent above adjusted trip point Mounting Manifold: 1.2 pounds (0.5 kg)

Volume Tank: Varies between 12 and 47 pounds

Flow Coefficients (cv)(2) (5.4 and 21 kg) depending on size

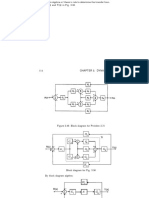

Depends on flow path (shown in figure 4) as follows

Port A to Port B: 0.47 Construction Materials

Port B to Port C: 0.56 Body, Spring Case, and Manifold—Aluminum

Port D to Port E: 0.48 Cover—25% mineral-filled thermoplastic polyester

Port E to Port F: 0.64 O-Rings—nitrile or fluoroelastomer

Diaphragms—nitrile or fluoroelastomer

Body Connections Interior parts—brass, aluminum, steel, and stain-

1/4-inch NPT female less steel

1. If the trip point is not specified, the trip point is factory-set at 72 percent of supply pressure 2. Values represent nominal Cv measures for each port pair using a trip valve/actuator com-

or 40 psig (2.8 bar), whichever is higher. bination.

Principle of Operation tain maximum supply pressure in the volume tank if

supply pressure drops.

Type 377D Trip Valve When supply pressure falls below the trip point pres-

In normal operation, supply pressure loads the upper sure in the fail-down mode (see figure 5), the exhaust

diaphragm (see figure 4) of the unit. The valve plug port opens, venting the supply pressure that is loading

spring keeps the exhaust port closed. Supply pressure the lower diaphragm. This causes the upper ports of

also loads the lower diaphragm through the restriction, the plug assemblies to close and shut off normal pres-

causing the plug assemblies to move down and isolate sure flow from the control device to the actuator.

ports C and F while connecting port A to B and port D

to E. Normal actuator control pressure flows from the Volume tank pressure then flows through ports C and

control device to the top of the cylinder through ports B to the top of the actuator cylinder, while pressure in

A and B and to the bottom of the cylinder through the bottom of the actuator cylinder is vented through

ports D and E. A volume tank is charged to maximum ports E and F. The pressure imbalance created forces

supply pressure through a check valve in order to re- the actuator piston down.

You might also like

- Ricoh mpc307 407 Parts ManualDocument244 pagesRicoh mpc307 407 Parts Manualmark adams50% (2)

- 377 Series Trip ValvesDocument8 pages377 Series Trip ValvesMijin28No ratings yet

- Pneumatic Actuator ElementsDocument49 pagesPneumatic Actuator Elementsdk.vermaNo ratings yet

- Mobile control block guideDocument14 pagesMobile control block guideDarshan Makwana100% (1)

- G77x_-77xK valve_catalogueDocument8 pagesG77x_-77xK valve_catalogueEzgi PelitNo ratings yet

- Adaptomode Inlet Pressure Regulators: ® Types: A4AS, A4AB, A4AD, A4AZDocument16 pagesAdaptomode Inlet Pressure Regulators: ® Types: A4AS, A4AB, A4AD, A4AZpedroNo ratings yet

- Engineering Information For PDC Butterfly Valves: Valve SizingDocument9 pagesEngineering Information For PDC Butterfly Valves: Valve SizingAnonymous NwnJNONo ratings yet

- d200318x012 PDFDocument12 pagesd200318x012 PDFLimuel EspirituNo ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- Hydraulic SystemDocument81 pagesHydraulic SystemMaritza Gabriela Arizabal MedinaNo ratings yet

- Ktm512 en MainDocument12 pagesKtm512 en MainFilip SerafimovNo ratings yet

- Fisher 377 Trip Valve: FeaturesDocument12 pagesFisher 377 Trip Valve: FeaturesGOPIKRISHNAHPTNo ratings yet

- Bermad: Level Control and Pressure Sustaining ValveDocument4 pagesBermad: Level Control and Pressure Sustaining ValveMaryoly BlancoNo ratings yet

- 771, 772, 773 Series ServovalvesDocument8 pages771, 772, 773 Series Servovalvesrafik1995No ratings yet

- Accumulator Charging Valve: 1 Product DescriptionDocument6 pagesAccumulator Charging Valve: 1 Product DescriptionVagabond HuynhNo ratings yet

- DS - Brodie Back Pressure Valve - BV60 (R9)Document4 pagesDS - Brodie Back Pressure Valve - BV60 (R9)DeonNo ratings yet

- Accumulator Charging Valve Spool Type Pilot-Operated - 350 Bar DLHSD (Manifold Mounting) DLHSR (Inline Mounting)Document4 pagesAccumulator Charging Valve Spool Type Pilot-Operated - 350 Bar DLHSD (Manifold Mounting) DLHSR (Inline Mounting)Luis Alberto Silva NavarroNo ratings yet

- Product Bulletin Fisher 377 Trip Valve en 125044Document10 pagesProduct Bulletin Fisher 377 Trip Valve en 125044Tomás MercadoNo ratings yet

- Fisher EZR Relief-Valve-Backpressure-Regulator-Instruction-ManualDocument28 pagesFisher EZR Relief-Valve-Backpressure-Regulator-Instruction-ManualChirasak PaksasornNo ratings yet

- A 4 D 03Document14 pagesA 4 D 03Eng-Mohammed SalemNo ratings yet

- Hydrolux en LQDocument4 pagesHydrolux en LQEduardo CramerNo ratings yet

- 010 - Denison Control Valve 3-EN2400-ADocument15 pages010 - Denison Control Valve 3-EN2400-Agustavo aguilarNo ratings yet

- 1HSH20 SDocument2 pages1HSH20 SIslam ElhabsheNo ratings yet

- 5 Amot 1672 Product DocumentDocument7 pages5 Amot 1672 Product DocumentThéodore NlendNo ratings yet

- DENISON HYDRAULICS Pressure Relief Valve R6V FeaturesDocument15 pagesDENISON HYDRAULICS Pressure Relief Valve R6V FeatureshaggNo ratings yet

- GCV & SRV ServovalveDocument11 pagesGCV & SRV ServovalvechdiNo ratings yet

- Valvula Reductora de PresionDocument2 pagesValvula Reductora de Presionsergio blandon lNo ratings yet

- 79 SeriesDocument12 pages79 SeriesUdayraj KawariNo ratings yet

- 3 En230 B R4VPDocument11 pages3 En230 B R4VPAlessandro OliveiraNo ratings yet

- B74GIM Norgren MK3Document2 pagesB74GIM Norgren MK3Ζαχος ΤσελιοςNo ratings yet

- Ruelco Self Contained Product Manual Rev 4Document11 pagesRuelco Self Contained Product Manual Rev 4DDani3214No ratings yet

- PRV Cheat SheetDocument5 pagesPRV Cheat SheetswathiNo ratings yet

- Sprague S-216-J PumpsDocument4 pagesSprague S-216-J PumpseolorojasNo ratings yet

- PVP 23-33Document10 pagesPVP 23-33ahmed.abdelhameedNo ratings yet

- PRV - CatalogueDocument6 pagesPRV - CatalogueSarbendu PaulNo ratings yet

- vr4r10Document8 pagesvr4r10Daniel Sandoval FernándezNo ratings yet

- Motion control valvesDocument1 pageMotion control valvesSLK Amg55No ratings yet

- Prop. Pressure-Reducing/Relieving Cartridge, Size SAE 08Document6 pagesProp. Pressure-Reducing/Relieving Cartridge, Size SAE 08galih kalokaNo ratings yet

- Variable Volume Piston Pumps Technical SpecsDocument10 pagesVariable Volume Piston Pumps Technical SpecsDaniel MarNo ratings yet

- R4R 3 EN2700 B Pilot Valve CartridgeDocument14 pagesR4R 3 EN2700 B Pilot Valve Cartridgecorsini999No ratings yet

- Data Sheet Avdo Automatic By-Pass Valve: ApplicationDocument4 pagesData Sheet Avdo Automatic By-Pass Valve: ApplicationganaaNo ratings yet

- 3512B 扭矩Document4 pages3512B 扭矩linkangjun0621No ratings yet

- Flow Controller DesignDocument2 pagesFlow Controller DesignBrunno VasquesNo ratings yet

- VT-BAYARD-Automatic Control Valves-FloatDocument8 pagesVT-BAYARD-Automatic Control Valves-Floatsiva ramakrishnanNo ratings yet

- E5118 Sre1-4Document4 pagesE5118 Sre1-4Ravi Kishore BNo ratings yet

- ThermoelectricDocument6 pagesThermoelectricsyNo ratings yet

- Thermal Bypass ValveDocument4 pagesThermal Bypass ValveRamu PamuruNo ratings yet

- Catalog 14 en 1630606 PDFDocument560 pagesCatalog 14 en 1630606 PDFJose DominguezNo ratings yet

- Proportional Pressure Control Valve EPDRD3-04Document9 pagesProportional Pressure Control Valve EPDRD3-04josemiguel1992No ratings yet

- HD 101 Deluge Valve Model ADocument15 pagesHD 101 Deluge Valve Model APiyush JainNo ratings yet

- Product Data Sheets PDFDocument12 pagesProduct Data Sheets PDFtree_99No ratings yet

- Bermad: Booster Pump Control and Pressure Sustaining ValveDocument4 pagesBermad: Booster Pump Control and Pressure Sustaining ValveLeo NovoxNo ratings yet

- Control Valve2Document20 pagesControl Valve2Roshny PFNo ratings yet

- Hydac dr10p Pressure Reducing ValveDocument2 pagesHydac dr10p Pressure Reducing ValveAhmad Y. AbughaushNo ratings yet

- Vickers: Proportional Pressure Control Valve With Integrated ElectronicsDocument8 pagesVickers: Proportional Pressure Control Valve With Integrated ElectronicsAlex KarimNo ratings yet

- SP4P2-B3: Proportional Pressure Reducing - Relieving Valve, Pilot OperatedDocument2 pagesSP4P2-B3: Proportional Pressure Reducing - Relieving Valve, Pilot OperatedДима ПолищукNo ratings yet

- Control Valve Sizing for Dowtherm Q LiquidDocument13 pagesControl Valve Sizing for Dowtherm Q LiquidEkundayo JohnNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Rule of Thumb: Distillation and Gas AdsorptionDocument2 pagesRule of Thumb: Distillation and Gas AdsorptionChristina Joana GuzmanNo ratings yet

- CV for Oil & Gas Control Room OperatorDocument7 pagesCV for Oil & Gas Control Room Operatormsk649No ratings yet

- Device and Method For Adaptive Control of Blanks MachiningDocument4 pagesDevice and Method For Adaptive Control of Blanks MachiningspriditisNo ratings yet

- Soln p3 21Document5 pagesSoln p3 21Vinicius RamosNo ratings yet

- The 2005 World Sustainable Building Conference, Tokyo, 27-29 September 2005Document6 pagesThe 2005 World Sustainable Building Conference, Tokyo, 27-29 September 2005YunranNo ratings yet

- CS 303e, Assignment #10: Practice Reading and Fixing Code Due: Sunday, April 14, 2019 Points: 20Document2 pagesCS 303e, Assignment #10: Practice Reading and Fixing Code Due: Sunday, April 14, 2019 Points: 20Anonymous pZ2FXUycNo ratings yet

- Robot Gripper DesignDocument51 pagesRobot Gripper DesignDug McCallumNo ratings yet

- Thrust Into Space PDFDocument125 pagesThrust Into Space PDFruslanagNo ratings yet

- L Gate User ManualDocument161 pagesL Gate User ManualNguyen Manh ThangNo ratings yet

- Build A Whisky StillDocument12 pagesBuild A Whisky Stillsteved_43100% (2)

- VIEWIT: Computation of Seen Areas, Slope, and Aspect For Land-Use PlanningDocument67 pagesVIEWIT: Computation of Seen Areas, Slope, and Aspect For Land-Use PlanningPACIFIC SOUTHWEST RESEARCH STATION REPORTNo ratings yet

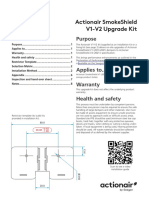

- en Actionair Installation Method Smokeshield Kit Web VersionDocument7 pagesen Actionair Installation Method Smokeshield Kit Web VersioniishdpsNo ratings yet

- Aplications of Engine RoomDocument10 pagesAplications of Engine Roomady.sabauNo ratings yet

- Trials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar FactoryDocument4 pagesTrials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar FactoryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CRJ 550-700 Normal ChecklistDocument6 pagesCRJ 550-700 Normal ChecklistDan KösterNo ratings yet

- BARACARBDocument1 pageBARACARBvava86No ratings yet

- C ProgrammingDocument60 pagesC ProgrammingKool RakeshNo ratings yet

- PFM-42-0 Document ReviewDocument9 pagesPFM-42-0 Document ReviewSIVAKUMAR NATARAJANNo ratings yet

- Design Approval Checklist 2nd Rev.Document3 pagesDesign Approval Checklist 2nd Rev.Daric Tesfaye0% (1)

- AN 10-001 Thermal-Paste ENG PDFDocument6 pagesAN 10-001 Thermal-Paste ENG PDFClovis GajoNo ratings yet

- Deformation Measurement Techniques and InstrumentationDocument42 pagesDeformation Measurement Techniques and InstrumentationjamniczuNo ratings yet

- IEEE STD'sDocument7 pagesIEEE STD'sRajmohanNo ratings yet

- USITT Lighting Design GraphicsDocument9 pagesUSITT Lighting Design Graphicstu papi sedNo ratings yet

- Air Outlets and Inlets PDFDocument7 pagesAir Outlets and Inlets PDFAdamNo ratings yet

- Ziegler-Mfm-3480 Manual-E1R0Document78 pagesZiegler-Mfm-3480 Manual-E1R0Naveed Syed MohammadNo ratings yet

- Cellular manufacturing: a lean system for grouping similar machinesDocument4 pagesCellular manufacturing: a lean system for grouping similar machinesPrashant AroraNo ratings yet

- Autosar Sws Spi HandlerdriverDocument76 pagesAutosar Sws Spi Handlerdriverkrnl386No ratings yet

- LNG R&D For The Liquefaction and Regasification Processes: 1.theme DescriptionDocument9 pagesLNG R&D For The Liquefaction and Regasification Processes: 1.theme DescriptionVikas PatelNo ratings yet

- Chapter 24 ProblemsDocument13 pagesChapter 24 Problemslynette-wuNo ratings yet