Professional Documents

Culture Documents

Skirt Support Analysis Transport

Uploaded by

Hunnymijie NorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Skirt Support Analysis Transport

Uploaded by

Hunnymijie NorCopyright:

Available Formats

PV Elite 2020 Licensee: Sime Darby Joy Industries Sdn Bhd 1

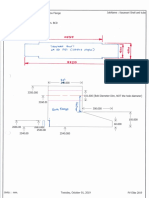

FileName : S-4111AB Skirt Analysis Transport -------------

Skirt Opening Stress Calcs: Step: 16 11:03am Jul 6,2020

Skirt Support Analysis Per EN 13445-3: 2009(E) Issue 1 (2009-07):

Item: Head 1

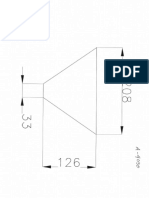

Type B Skirt per EN-13445 Figure 16.12-2:

Design Pressure P 13.400 bars

Total vessel (empty) weight Fg 89528.320 N

Head Weight below section 2-2 DeltaFg 2650.700 N

Weight of vessel contents (liquid) Ff 0.000 N

Vessel Gross Weight Fg + Ff = F4 89528.320 N

Skirt Mean Diameter Dz 1410.400 mm.

Skirt Analysis Thickness (Corroded) ez 12.000 mm.

Skirt Height H 827.000 mm.

Force at section 1-1 F1 86877.617 N

Moment at section 1-1 M1 158524.312 N-m

Applied Moment - Bottom of Skirt Mb 229466.375 N-m

Weight Above the Skirt W 89528.320 N

Access Opening: 1 Cuts through the top of the skirt.

Access Opening: 1 Cuts through the bottom of the skirt.

Access Opening: 2 Cuts through the top of the skirt.

Access Opening: 2 Cuts through the bottom of the skirt.

Note:

If an opening cuts the skirt top or bottom, this is not a problem.

This becomes a 'Sentry Box' or 'Mouse Hole' type Opening.

Layout Cntr. Dist. Obround

Access No Width/Dia Angle From Bottom Cntr-Cntr

mm. Deg mm. mm.

-------------------------------------------------------

1 500.0000 90.0000 0.0000 827.0000

2 500.0000 270.0000 0.0000 827.0000

Access Opening Frame Dimension

Access No Width Thick

mm. mm.

-------------------------------

1 0.0000 0.0000

2 0.0000 0.0000

Interference check:

Access Access Pitch Ligament

mm. mm.

---------------------------------------------

1 2 2215.4509 1704.3370

1 2 2215.4509 1704.3370

INTERFERENCE CHECK: No Interference Detected between Openings

Minimum Pitch between openings is: 2215.4509 mm.

Minimum Ligament between Openings is: 1704.3370 mm.

Recommended minimum Ligament:

= 2 * Sqrt( D * t )

= 2 * Sqrt( 1410.4 * 12.0 ) = 260.191 mm.

Please evaluate the suitability of this result

Section properties at least metal area [A]:

Number of Openings At Critical Height = 2

PV Elite 2020 Licensee: Sime Darby Joy Industries Sdn Bhd 2

FileName : S-4111AB Skirt Analysis Transport -------------

Skirt Opening Stress Calcs: Step: 16 11:03am Jul 6,2020

Access No Layout Angle 1 Layout Angle 2

Deg. Deg.

---------------------------------------------------

1 69.2366 110.7634

2 249.2366 290.7634

The points for integrating Ixx, Iyy is as follows:

FROM THETA1 TO THETA2

Deg Deg

--------------------------

110.763 249.237

-69.237 69.237

Height of Weakest Section H 0.000 mm.

Rotation of Principle Axes a -0.000 Deg.

Centroid Position in X direction g 0.000 mm.

Centroid Position in Y direction h -0.000 mm.

Principle Moment of Inertia Ixx 738089.188 cm**4

Principle Moment of Inertia Iyy 1296098.625 cm**4

Distance to Extreme Fiber ybar 711.200 mm.

Distance to Extreme Fiber xbar 711.200 mm.

Minimum Section Modulus W4 10378091.000 mm.^3

Metal Area at the Cutting Plane A4 409.041 cm²

Half Opening Width Subtended Angle at Weakest Section: [Delta]:

= Asin(Largest(Opening Width) / Dz)

= Asin(500.0/1410.4 ) = 0.3624 rad (20.7634 deg)

Note: The Largest Opening Width is Considered

Skirt Mean Radius at Section 4-4 [r]:

= Dz/2 = 1410.4/2 = 705.2 mm.

Analysis of the Section at Weakest Section Modulus [Section 4-4]:

Skirt Corroded Thickness [ez]:

= ex(new) - ci - cext = 12.0 - 0.0 - 0.0 = 12.0 mm.

Please note:

There is more than one opening in the skirt

EN-13445 and AD-2000 considers only one opening per Figure 16.12-4

this skirt has 2 openings. Please check results

Note: At least one of the openings cuts the Top Of the Skirt (Ok)

Note: At least one of the openings cuts the Bottom Of the Skirt (Ok)

Find the moment acting at the Critical Height [M4]:

= (Mbottom - Mtop)*(H - CutHeight)/H + Mtop

= (229466.375 - 158524.312)*(9924.0 - 0.0)/9924.0 + 158524.312

= 229466.375 N-m

Compute the section modulus [Zxx and Zyy]

Zxx = Ixx/ybar = 738089/711.2 = 10378091 mm.³

Zyy = Iyy/xbar = 1296099/711.2 = 18224124 mm.³

Z = Min(Zxx, Zyy) = Min(10378091,18224124) = 10378091 mm.³

The balance of the calculations are per EN-13445, and

they may be treated as academic if the designated code

is not EN-13445

Radius of Gyration of Skirt at 4-4 [rg]:

(rg is not included in the analysis of EN 13445)

PV Elite 2020 Licensee: Sime Darby Joy Industries Sdn Bhd 3

FileName : S-4111AB Skirt Analysis Transport -------------

Skirt Opening Stress Calcs: Step: 16 11:03am Jul 6,2020

= sqrt( Min( Ixx, Iyy ) / Area(A4) )

= sqrt( Min( 738089, 1296099 )/409.041 ) )

= 424.787 mm.

Skirt Slenderness Ratio [r/L]:

= 424.787/827.0 = 0.514

Location of the Skirt Centroid at critical height [e]:

ex = 0. : ey = -0.0

e = Sqrt(ex² + ey²) = Sqrt( 0.²+-0.0²)

= 0. mm.

Moment Increment at Centroid [DeltaM4]:

= ( Fg + Ff ) * e = F4 * e

= ( 89528.32 + 0.0 ) * 0.00003 = 0.002 N-m

Nomenclature per EN-13445 (not AD-2000)

For the skirt at the opening/weakest part: Equations 16.12-70 & 71:

Actual Stresses:

Sm4p = ( M4 + DeltaM4 ) / W4 - F4 / A4

= (229466.391 + 0.002)/18224124 - 89528.32/409.041

= 10.4 N./mm² - Equation 16.12-70

Sm4q = -( M4 + DeltaM4 ) / W4 - F4 / A4

= -(229466.391+ 0.002)/18224124- 89528.32/409.041

= -14.78 N./mm² - Equation 16.12-71

Allowable stresses at the opening/weakest part: Equations 16.12-72 & 73:

Max stress for Sm4p and Sm4q: Equations 16.12 72 & 73:

= fz = 138.0 N./mm²

Skirt stress at the openings / critical section:

Sm4p 10.40 138.00 Pass 70

Sm4q -14.78 138.00 Pass 71

The stresses are satisfactory in the region with the opening(s).

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2020

PV Elite 2020 Licensee: Sime Darby Joy Industries Sdn Bhd 4

FileName : S-4111AB Skirt Analysis Transport -------------

Basering Calculations: Step: 18 11:03am Jul 6,2020

Skirt Data :

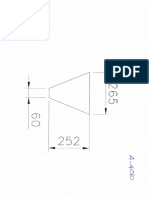

Skirt Outside Diameter at Base SOD 1422.4000 mm.

Skirt Thickness STHK 12.0000 mm.

Skirt Internal Corrosion Allowance SCA 0.0000 mm.

Skirt External Corrosion Allowance 0.0000 mm.

Skirt Material SA-516 70 [Normalized]

Basering Input: Type of Geometry: Simple Basering No Gussets

Thickness of Basering TBA 50.0000 mm.

Design Temperature of the Basering 37.78 °C

Basering Matl SA-36

Basering Operating All. Stress BASOPE 114.00 N./mm²

Basering Yield Stress 248.00 N./mm²

Inside Diameter of Basering DI 1350.0000 mm.

Outside Diameter of Basering DOU 1600.0000 mm.

Nominal Diameter of Bolts BND 36.0000 mm.

Bolt Corrosion Allowance BCA 0.0000 mm.

Bolt Material SA-193 B7

Bolt Material Class/Thickness Range <= 64

Bolt Operating Allowable Stress SA 172.38 N./mm²

Number of Bolts RN 12

Diameter of Bolt Circle DC 1524.5000 mm.

Are Gussets to be used ( Yes/No ) GUSYN N

External Corrosion Allowance CA 0.0000 mm.

Dead Weight of Vessel DW 89528.3 N

Operating Weight of Vessel ROW 89528.3 N

Earthquake Moment on Basering EQMOM 229466.4 N-m

Wind Moment on Basering WIMOM 12076.8 N-m

Percent Bolt Preload ppl 100.0

Use AISC A5.2 Increase in Fc and Bolt Stress No

Use Allowable Weld Stress per AISC J2.5 No

Factor for Increase of Allowables Fact 1.0000

Results for Basering Analysis : Analyze Option

Basering Thickness Calculation method used : Simplified (Steel on Steel)

Calculation of Bolt Loads for Multiple Loading Conditions:

Operating Bolt Load, Earthquake Operating Case:

= (( 4 * M/DC ) - W ) / RN per Jawad & Farr, Eq. 12.3

= (( 4 * 229466/1524.5) - 89528 )/12

= 46422.4 N

Operating Bolt Load, Windload Empty Case:

= (( 4 * M/DC ) - W ) / RN per Jawad & Farr, Eq. 12.3

= (( 4 * 12077/1524.5) - 89528 )/12

= -4821.1 N

Operating Bolt Load, Windload Vortex Shedding Case:

= (( 4 * M/DC ) - W ) / RN per Jawad & Farr, Eq. 12.3

= (( 4 * 0/1524.5) - 89528 )/12

= -7460.7 N

Calculation of Maximum Load per Bolt [W/Bolt], Earthquake + Operating Condition:

W = ROW - Yforce (from gy Accleration or user force), M = EQMOM

PV Elite 2020 Licensee: Sime Darby Joy Industries Sdn Bhd 5

FileName : S-4111AB Skirt Analysis Transport -------------

Basering Calculations: Step: 18 11:03am Jul 6,2020

= (( 4 * M/DC ) - W ) / RN per Jawad & Farr, Eq. 12.3

= (( 4 * 229466/1524.5) - 44764 )/12

= 46422.4 N

Required Area for Each Bolt, Based on Max Load 2.6933 cm²

Area Available in a Single Bolt (Corr) 7.3802 cm²

Area Available in all the Bolts (Corr) 88.5618 cm²

Bolt Stress Based on Simplified Analysis 62.9 N./mm²

Allowable Bolt Stress 172.4 [Fact] 172.38 N./mm²

Concrete Contact Area of Base Ring CCA 5792.31 cm²

Concrete Contact Section Modulus of Base Ring 0.1983E+09 mm.³

Concrete Load (Simplified method), Earthquake in Operating Condition [Sc]:

= ((ppl/100*(Abt*Sa)+W)/Cca) + M/CZ per Jawad & Farr Eq. 12.1

= (1.0(88.5618*172+134292)/5792.31) + 229466/.19832E+09

= 4.02 N./mm²

Concrete Allowable Stress 8.27 N./mm²

Determine Maximum Bending Width of Basering Section [Rw1,Rw2]:

Rw1 = (Dou - SkirtOD)/2, Rw2 = ( SkirtID - Di + 2*Sca )/2

Rw1 = (1600.0-1422.4)/2, Rw2 = (1398.4-1350.0 + 2*0.0)/2

Rw1 = 88.8, Rw2 = 24.2 mm.

Calculation of required Basering Thickness, (Simplified) [Tb]:

Allowable Bending Stress 1.5 Basope = 170.997 N./mm²

= Max(Rw1,Rw2) * ( 3 * Sc / S )½ + CA per Jawad & Farr Eq. 12.12

= Max(88.8,24.2) * ( 3 * 4.024/170.997 )½ + 0.0

= 23.5946 mm.

Basering Stress at given Thickness [Sb]

= 3 * Sc * ( Max[Rw1, Rw2]/(Tb - Ca) )²

= 3 * 4.024 * ( Max[88.8, 24.2]/(50.0 - 0.0) )²

= 38.078, must be less than 170.997 N./mm²

Summary of Basering Thickness Calculations:

Required Basering Thickness (simplified) 23.5946 mm.

Actual Basering Thickness as entered by user 50.0000 mm.

Weld Size Calculations per Steel Plate Engineering Data - Vol. 2

Compute the Weld load at the Skirt/Base Junction [W]

= SkirtStress * ( SkirtThickness - CA )

= 15.752 * ( 12.0 - 0.0 )

= 189.01 N/mm.

Results for Computed Minimum Basering Weld Size [BWeld]

= W / [( 0.4 * Yield ) * 2 * 0.707]

= 189/[( 0.4 * 244 ) * 2 * 0.707]

= 1.37 mm.

Summary of Required Weld Sizes:

Required Basering to Skirt Double Fillet Weld Size 4.7625 mm.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2020

You might also like

- Tailing LugDocument3 pagesTailing LugSajad AbdulNo ratings yet

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Design of base plate for columnDocument6 pagesDesign of base plate for columnsoumyaNo ratings yet

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- Ccsviiid1 2260Document2 pagesCcsviiid1 2260DieguitoOmarMoralesNo ratings yet

- Junction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6Document3 pagesJunction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6met-calcNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Flange calculation as per ASME Section VIIIDocument9 pagesFlange calculation as per ASME Section VIIIDarshan PanchalNo ratings yet

- External Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitDocument1 pageExternal Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitSachinNo ratings yet

- CAL-ST-070!17!01 Rev01 Shipping Saddles CalculationDocument11 pagesCAL-ST-070!17!01 Rev01 Shipping Saddles CalculationgiubelloNo ratings yet

- Comp 2Document9 pagesComp 2YYo YudiNo ratings yet

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanNo ratings yet

- Rehabilitation and upgrade of Stallionaire tank farmDocument4 pagesRehabilitation and upgrade of Stallionaire tank farmorode franklynNo ratings yet

- Pa5 MC SH 01 c14 003 - 00 - Calculation For Platform Beam of ChimneyDocument33 pagesPa5 MC SH 01 c14 003 - 00 - Calculation For Platform Beam of ChimneyHmilkNo ratings yet

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNo ratings yet

- Design of Large Opening Nozzle by Bulletin WRC-107Document12 pagesDesign of Large Opening Nozzle by Bulletin WRC-107ALONSO GOMEZNo ratings yet

- Cdo CalcDocument3 pagesCdo CalcJeric FarinNo ratings yet

- Moment Baseplate Design Rev. 0Document3 pagesMoment Baseplate Design Rev. 0Bok MortegaNo ratings yet

- Master Foods 12 MDocument16 pagesMaster Foods 12 MSarfarazNo ratings yet

- Analysis of a rectangular pressure vesselDocument7 pagesAnalysis of a rectangular pressure vesselPressure VesselNo ratings yet

- 194 2427 194 T Tot H H : Input OutputDocument19 pages194 2427 194 T Tot H H : Input Outputxuankhoi doanvanNo ratings yet

- Saddle design calculationsDocument9 pagesSaddle design calculationsduf fuNo ratings yet

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- Use of Asme Code Case 2695Document2 pagesUse of Asme Code Case 2695G.SWAMINo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- Clamped Cover Plate DesignDocument7 pagesClamped Cover Plate DesignChiedu OkonduNo ratings yet

- Rectangular Tanks:: Rectangle Tank DesignDocument23 pagesRectangular Tanks:: Rectangle Tank Designshna jabarNo ratings yet

- Design of JointsDocument41 pagesDesign of JointsVivek LevinNo ratings yet

- Design of fillet weld as per BS EN 1993 1 8 CL 4.5.3Document2 pagesDesign of fillet weld as per BS EN 1993 1 8 CL 4.5.3Giri DharanNo ratings yet

- Bab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselDocument36 pagesBab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselTri AgungNo ratings yet

- WRC Check List CriteriaDocument1 pageWRC Check List CriteriaAlvin Smith100% (1)

- Saddle Road Transportation Analysis 1Document2 pagesSaddle Road Transportation Analysis 1vpjagannaathNo ratings yet

- 4 - PFC To Hanging Plate ConnDocument13 pages4 - PFC To Hanging Plate Connabdul khaderNo ratings yet

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionSung Woong MoonNo ratings yet

- IS.5216 1982part2Document27 pagesIS.5216 1982part2Mahendra SuryavanshiNo ratings yet

- Agitator Nozzle Load Data SheetDocument1 pageAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBENo ratings yet

- ASCE 7-05 Table 15-4-2Document1 pageASCE 7-05 Table 15-4-2barouniamineNo ratings yet

- Davit With ElbowDocument2 pagesDavit With Elbownitin400No ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- 6 - CE 511 - Base Plate Design PDFDocument33 pages6 - CE 511 - Base Plate Design PDFJayson RamosNo ratings yet

- DESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTDocument12 pagesDESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTfarahanisiliasNo ratings yet

- Chimney Calculation SheetDocument14 pagesChimney Calculation SheetSrinivasa Rao VenkumahanthiNo ratings yet

- Tank Volume Calculator ResultsDocument1 pageTank Volume Calculator ResultsEleazar MendozaNo ratings yet

- Rectangular TankDocument6 pagesRectangular TankEsapermana RiyanNo ratings yet

- Technical DataDocument48 pagesTechnical Datashekhar2681No ratings yet

- Beam Spreadsheet: Ignore Lateral Torsional BucklingDocument5 pagesBeam Spreadsheet: Ignore Lateral Torsional BucklingPurnima ArkalgudNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Calculo de Brida Segun ASMEDocument29 pagesCalculo de Brida Segun ASMEakarcz6731No ratings yet

- Clip PlatformDocument24 pagesClip Platformwisnu_bayusaktiNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument4 pagesSample Design Calculation - Vessel Supported On LugsAbhay Upadhyay0% (1)

- Cover Pages For PV Elite VenvelDocument14 pagesCover Pages For PV Elite VenvelSakthi VelNo ratings yet

- 79Document1 page79Hunnymijie NorNo ratings yet

- 2019 Crosby Catalog Metric-Rigging-Accessories-Master Link A-342Document1 page2019 Crosby Catalog Metric-Rigging-Accessories-Master Link A-342I-SignNo ratings yet

- Master Link A345Document1 pageMaster Link A345Hunnymijie NorNo ratings yet

- Wire Rope ThimbleDocument1 pageWire Rope ThimbleHunnymijie NorNo ratings yet

- 79Document1 page79Hunnymijie NorNo ratings yet

- Bill of Material Steel Parts ListDocument1 pageBill of Material Steel Parts ListHunnymijie NorNo ratings yet

- ISO 7919 5 1st Edition 1997 PDFDocument14 pagesISO 7919 5 1st Edition 1997 PDFHunnymijie NorNo ratings yet

- Minimum Gasket Width Calculation FormulaDocument1 pageMinimum Gasket Width Calculation FormulaHunnymijie NorNo ratings yet

- Sling SelectionDocument1 pageSling SelectionHunnymijie NorNo ratings yet

- Thermowell Calculation Guide V1.3Document19 pagesThermowell Calculation Guide V1.3Hunnymijie NorNo ratings yet

- Swing GateDocument1 pageSwing GateHunnymijie NorNo ratings yet

- Flange SketchDocument1 pageFlange SketchHunnymijie NorNo ratings yet

- Tundish Coneshape A-4010Document1 pageTundish Coneshape A-4010Hunnymijie NorNo ratings yet

- Uni-Drive Catalogue-1Document317 pagesUni-Drive Catalogue-1Hunnymijie NorNo ratings yet

- Tundish Coneshape A-4030Document1 pageTundish Coneshape A-4030Hunnymijie NorNo ratings yet

- HandBook Stuctural SteelDocument267 pagesHandBook Stuctural SteelOnn Lajer100% (9)

- 79Document1 page79Hunnymijie NorNo ratings yet

- Safe Distance During HTDocument2 pagesSafe Distance During HTHunnymijie NorNo ratings yet

- G-2130 / S-2130 Bolt Type Anchor ShacklesDocument1 pageG-2130 / S-2130 Bolt Type Anchor Shacklesramy abazaNo ratings yet

- U-Bolt DN 150 PDFDocument8 pagesU-Bolt DN 150 PDFHunnymijie NorNo ratings yet

- U-Bolt DN 150 PDFDocument8 pagesU-Bolt DN 150 PDFHunnymijie NorNo ratings yet

- User's Manual: & Technical DocumentationDocument20 pagesUser's Manual: & Technical DocumentationPODOSALUD HUANCAYONo ratings yet

- A Brazilian Furniture Industry Case StudyDocument17 pagesA Brazilian Furniture Industry Case StudyEnrique MabanoNo ratings yet

- Fuellas Vs CadanoDocument4 pagesFuellas Vs CadanoMutyaAlmodienteCocjinNo ratings yet

- Test Your Knowledge - Python and Automation - Coursera100Document1 pageTest Your Knowledge - Python and Automation - Coursera100Mario 1229No ratings yet

- Module 6Document2 pagesModule 6Carla Mae F. DaduralNo ratings yet

- Yukot, LeeYDocument5 pagesYukot, LeeYDevansh GoelNo ratings yet

- MPT Training CentreDocument11 pagesMPT Training CentreGrace PMNo ratings yet

- ch-1 Phy MEASUREMENT AND MOTIONDocument2 pagesch-1 Phy MEASUREMENT AND MOTIONRakesh GuptaNo ratings yet

- Subtraction Strategies That Lead To RegroupingDocument6 pagesSubtraction Strategies That Lead To Regroupingapi-171857844100% (1)

- 2015-10-26 Plaintiff's Letter To Defendant Regarding Discovery (Flores V DOJ) (FOIA Lawsuit)Document25 pages2015-10-26 Plaintiff's Letter To Defendant Regarding Discovery (Flores V DOJ) (FOIA Lawsuit)Progress QueensNo ratings yet

- Protein Expression HandbookDocument118 pagesProtein Expression HandbookLuis Arístides Torres SánchezNo ratings yet

- Cutaneous Abscess Furuncles and CarbuclesDocument25 pagesCutaneous Abscess Furuncles and Carbuclesazmmatgowher_1219266No ratings yet

- Communicating EffectivelyDocument7 pagesCommunicating EffectivelyPaulo LewisNo ratings yet

- Types of Guidance and CounsellingDocument3 pagesTypes of Guidance and CounsellingJyoti Bodade100% (1)

- PRACTICE-10 BảnDocument5 pagesPRACTICE-10 BảnBinh Pham ThanhNo ratings yet

- OCCUPATIONAL SAFETY REGULATIONSDocument126 pagesOCCUPATIONAL SAFETY REGULATIONSKarthikeyan Sankarrajan100% (3)

- Public High School Teachers' Strategies for Addressing Challenges in Conducting Action ResearchDocument75 pagesPublic High School Teachers' Strategies for Addressing Challenges in Conducting Action ResearchMilbert Loyloy SalmasanNo ratings yet

- National Scholars Program 2005 Annual Report: A Growing Tradition of ExcellenceDocument24 pagesNational Scholars Program 2005 Annual Report: A Growing Tradition of ExcellencejamwilljamwillNo ratings yet

- Ayala Land Title Superior in Land DisputeDocument2 pagesAyala Land Title Superior in Land DisputeAdolph Adolfo100% (1)

- Dade Girls SoccerDocument1 pageDade Girls SoccerMiami HeraldNo ratings yet

- Elon Musk AchievementsDocument13 pagesElon Musk AchievementsCarlos SuárezNo ratings yet

- Assignment ON Facility ManagementDocument10 pagesAssignment ON Facility ManagementVikram MayuriNo ratings yet

- JVC Mini DV and S-VHS Deck Instruction Sheet: I. Capturing FootageDocument3 pagesJVC Mini DV and S-VHS Deck Instruction Sheet: I. Capturing Footagecabonedu0340No ratings yet

- What Are The Difficulties With IELTS Listening Multiple Choice Questions?Document9 pagesWhat Are The Difficulties With IELTS Listening Multiple Choice Questions?leoNo ratings yet

- Intellectual DisabilitiesDocument23 pagesIntellectual DisabilitiesKim SorianoNo ratings yet

- ICT in Education ComponentsDocument2 pagesICT in Education ComponentsLeah RualesNo ratings yet

- NuisancesDocument64 pagesNuisancesMicah Jamero FelisildaNo ratings yet

- Cause and Effects of Social MediaDocument54 pagesCause and Effects of Social MediaAidan Leonard SeminianoNo ratings yet

- Math 8 Q3 Module 1 With Answer KeyDocument16 pagesMath 8 Q3 Module 1 With Answer KeyginaNo ratings yet

- Data Science ArticleDocument2 pagesData Science ArticleRamendra KumarNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Design and Operation of Human Locomotion SystemsFrom EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNo ratings yet

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Learning Robotics, with Robotics, by Robotics: Educational RoboticsFrom EverandLearning Robotics, with Robotics, by Robotics: Educational RoboticsNo ratings yet

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Modeling, Dynamics, and Control of Electrified VehiclesFrom EverandModeling, Dynamics, and Control of Electrified VehiclesRating: 5 out of 5 stars5/5 (1)

- Create Profitable Side Hustles with Artificial IntelligenceFrom EverandCreate Profitable Side Hustles with Artificial IntelligenceNo ratings yet

- Artificial Intelligence: Data Analytics and Innovation for BeginnersFrom EverandArtificial Intelligence: Data Analytics and Innovation for BeginnersRating: 5 out of 5 stars5/5 (3)

- RoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingFrom EverandRoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingNo ratings yet