Professional Documents

Culture Documents

Cee 5111 - Chapter 2

Uploaded by

Harrison Daka LukwesaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cee 5111 - Chapter 2

Uploaded by

Harrison Daka LukwesaCopyright:

Available Formats

The University of Zambia

School of Engineering

Dept. of Civil & Environmental Engineering

CEE 5111: Construction Management

Lecturer: Mr. C. Kaliba

2

CHAPTER 2 JOB PLANNING AND

MANAGEMENT

CEE 5111 Lecture Notes Chapter 2

3

Planning

CEE 5111 Lecture Notes Chapter 2

4

INTRODUCTION

The specific approach to construction begins with a complete analysis of the job down

to its smallest part

Construction of each element is planned in terms of materials, taking into account

labour and equipment resources

The whole projects is then fitted into a closely integrated programme of construction,

the ideal being that:

flow of work should be logical and in a single direction;

distances travelled and amount of lifting and handling of materials during this flow should be

minimised;

Equipment and labour should be employed to capacity without breaks or delays due to

shortages or errors in the programme.

CEE 5111 Lecture Notes Chapter 2

5

It would therefore suffice to say that:

Construction planning is generally concerned with completing a contract in the shortest

possible time, within budget and according to specifications.

On the other hand, management is the art of physically making the plan work.

CEE 5111 Lecture Notes Chapter 2

6

Principles of planning

Planning should:

give the client intended completion or hand-over dates.

notify suppliers and sub-contractors when their goods or services will be required.

give contractor knowledge of future commitments to staff, labour, and plant.

Before starting site operations, adequate time should be made available for:

proper planning of equipment and methods

ordering of materials.

preparation of a balanced programme.

CEE 5111 Lecture Notes Chapter 2

7

Each operation should commence as soon as possible:

without necessarily waiting for the completion of the preceding work activity; and

should continue without interruption at maximum practical speed.

Balanced gangs must be established on repetitive work-cycle and continuous work

made available until each is due to leave the site.

High productivity entails:

elimination of double–handling;

Careful timing of bulky materials deliveries; and

strategic siting of mixing plant, casting bays, hoists and stock piles.

CEE 5111 Lecture Notes Chapter 2

8

Advantages of Planning

Planning shows possible problems in advance and thus provide opportunities for their

avoidance.

Increased productivity is made possible by reduction in double-handling, and improved

operational methods devised by work study techniques also result in reduced labour

and plant costs.

The continuity essential for early completion of the works can be maintained by

introduction of financial incentives scheme, this gives a higher level of earning and

motivation to the operatives.

CEE 5111 Lecture Notes Chapter 2

9

Faster, more efficient construction means a shorter contract period, with less on-costs

and lower overheads, so that the resultant total cost is effectively reduced.

Programmes also provide a useful basis for ordering materials and a comparative

reference for assessing progress.

To all these advantages, add the growing record of comprehensive and realistic

company standards made possible by the detailed analysis of achievement against

plans for completed jobs, which in due course is reflected in more accurate and keener

estimating.

CEE 5111 Lecture Notes Chapter 2

10

Construction Stages

Construction stages (work packages) –which might contain different operations.

On large construction projects, it may be desirable or essential to divide the project into several

construction stages, which may be constructed independently or in conjunction with each other.

Each of the stages may be constructed under a separate contract. The aim for dividing the project into

stages is to make known the quantities of work and the duration of construction for each in advance in

order that each may be constructed in the proper sequence.

The construction of a new water supply for a city might include the following stages:

clearing the reservoir site

earth-fill dam

concrete dam, spill way and controls

pump station

transmission line, tunnels, etc.

water treatment plant.

CEE 5111 Lecture Notes Chapter 2

11

The reservoir site must be cleared before the dam is completed and the storage of

water begins.

It may be necessary to complete the concrete portion of the dam, and to install control

gates in order that this structure may serve as a means of diverting the water in the

stream while the earth fill is being placed.

The pump station, transmission line and treatment plant should be completed by the

time the reservoir has stored sufficient quantity of water to be usable.

CEE 5111 Lecture Notes Chapter 2

12

Construction Operations (specialisations)

Projects are usually divided into construction operations to facilitate job planning. A

construction operation is a portion of a project which may be performed by a

classification of labourers or a single type of equipment.

In constructing a reinforced concrete retaining wall, the project might be divided into

the following operations:

Excavation, machine

Excavation, hand

Formwork

steel fixing

Concreting.

CEE 5111 Lecture Notes Chapter 2

13

In planning the construction of a highway requiring a new location, the project might be

divided into the following operations (which in this case can be stages):

moving to the project and setting up equipment

cleaning and grubbing the right of way

Earthwork, cut and fill

Drainage structures, box culverts.

Pavement

Clean-up and removal of plant.

CEE 5111 Lecture Notes Chapter 2

14

To estimate the progress in constructing a project, the job planner should determine the

quantity of work to be constructed for each operation, expressed in an appropriate unit.

Then estimation should be made of probable rate at which work will be performed,

allowing for estimated loss in time due to bad weather or any other cause.

From this information, it is possible to estimate the total time required to complete each

operation.

It can be seen that stages may comprise various operations. If a project is thoroughly

analysed and the operation durations and sequence in each construction stage are

known, total estimated project duration can be arrived at.

CEE 5111 Lecture Notes Chapter 2

15

Assignment 1

Project 1:Construction of a multi-storey shopping complex on a built up site in Lusaka

inner city. The complex will have an underground basement with a pile supported

foundation.

Project 2:Construction of 85Km of the Senanga-Sesheke Road in Western Province. The

road is to be upgraded to bituminous standards.

Q: For each project, Sequentially identify the various construction stages and

operations in each stage.

CEE 5111 Lecture Notes Chapter 2

16

Construction Schedules

A schedule is a time-table. In scheduling construction operation, the job planner should

consider the desirable sequential relationships between the operations. E.g., in

constructing a concrete foundation unit, it will be necessary to complete the

excavation before concrete can be placed.

A construction schedule is usually in the form of a bar chart, which shows for a given

project; the operations, quantity, unit and rate of construction for each operation and

the estimated date of starting and completing each operation.

The schedule should have provision for reporting or indicating the actual amount of

work completed on each operation at any given date, end of week or month. If the

actual progress is indicated on the schedule, it is possible to determine very quickly

whether construction is progressing according to the original plan.

CEE 5111 Lecture Notes Chapter 2

17

Projects with durations of less than a year may be divided into weeks, while schedules

for projects requiring more than a year generally will be divided into months. The

schedule should show the dates clearly. If the time is divided into weeks, it is good

practice to show the end of the week, Saturday, as the effective date, with a notation

reading “For week ending.”

Every construction schedule should be identified with the particular project by placing

on it:

the job number;

the name of the project;

the name of the client;

the location; and

possibly names of consulting firms.

CEE 5111 Lecture Notes Chapter 2

18

Preparing a construction schedule

Before preparing a construction schedule:

a project should be divided into desirable operations;

the amount of work in each operation should be determined;

the rate of performing the work should be estimated for each operation; and

an appropriate allowance should be made for loss of time due to bad weather.

CEE 5111 Lecture Notes Chapter 2

19

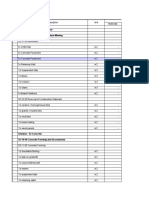

Example

In the preparations of a construction schedule, consider a project requiring the

relocation of a highway. The project will involve the following quantities and operations.

Length, 13.786 km

Width of right of way, 30.478 m.

Clearing and grubbing, 64 acres, medium timber, distributed along the project.

Drainage structures, 12 multi-box concrete culverts, 3 openings, average length, 9.75 m.

Earth fill in excess of cut, from borrow pits, with average haul distance of 1.2km, a total of

104,524 m3 bank volume.

Concrete pavement, width 7.3m, average thickness 0.23m, total area 100 638m2

CEE 5111 Lecture Notes Chapter 2

20

Job description:

The area in timber is slightly more than one-half of the total area of the right of way. The

specifications require the contractor to remove all trees and roots to a depth of 0.46m and to

burn the timber on the right of way.

The earth is a mixture of sand and clay, whose average borrow-pit weight is 1488 kg/m3. The

average swell will be 25%. It is estimated that the average initial moisture content will be 8% by

weight. Specifications require a moisture content of 12% during compaction. The earth is to be

placed in layers not exceeding 20cm in thickness when loose, and compacted to a density of

1554kg/m3

Task

Prepare a construction schedule for the job.

CEE 5111 Lecture Notes Chapter 2

21

Solution

Identify the various operations and their sequence in the job.

Operations:

Moving in

clearing and grubbing

drainage structures

Earth-fill

concrete pavement

general clean-up and moving out.

In the operations identified, it is assumed unforeseen circumstances cause delays amounting to

approximately 20% of the actual time required for construction. In preparing the schedule, a

week is considered to be 5 days of 8 hours each.

CEE 5111 Lecture Notes Chapter 2

22

Moving in

The moving-in operation consists of transporting to and setting up at the project:

a two compartment aggregate - batching bin

a bulk-cement storage bin

a tools warehouse

offices

testing laboratory

equipment - repair and servicing facilities

construction equipment required for the project.

The equipment that will be needed first should be moved to the project as early as possible,

though it may not be desirable to transport all the construction equipment to the project prior to

beginning construction.

It is estimated that 1 week will be required for moving in and setting up the plant.

CEE 5111 Lecture Notes Chapter 2

23

Clearing and grubbing

Bulldozers mounted on diesel crawler tractors developing 96.2 KW drawbar power will be used in

clearing timber from the right of way. It is estimated that a bulldozer can clear 1 acre per day or 5

acres per week. Two bulldozers will be used to clear 10 acres per week.

The total time to remove the timber will be;

Actual operating time, 64 acres @ 10 acres per week = 6.4WK

Add 20% for lost time = 1.3WK

Total time = 7.7WK

Roundup time out to 8 weeks

A single crawler tractor, pulling a rooter, should be able to remove all tree roots to a depth of 46 cm at

the same time that the bulldozers push down the trees. The roots will be stacked on piles of trees, by

labourers and burnt.

It should be possible to start this operation before moving in is completed. Therefore the construction

schedule should provide for clearing to start immediately.

CEE 5111 Lecture Notes Chapter 2

24

Drainage structures

If water courses are dry during the construction of drainage structures, the operations will consist

of excavating to the required grade and constructing the concrete slab, walls, roof and wing

walls.

If flowing water is expected during construction, it may be desirable to construct temporary

earth dams upstream and downstream the structure to divert the water through a ditch dug to

the side of the culvert, using a bulldozer to excavate the earth from the ditch.

The actual time required to construct a culvert may be determined as follows:

Bulldozer constructing temporary dams, excavating diversion ditch, and excavating culvert base

1 day

Fine grading, by hand 1 day

Erecting forms & placing reinforcing steel for base 1.5 days

Placing concrete for base 0.5 days

CEE 5111 Lecture Notes Chapter 2

25

Erecting forms for walls and roof & placing reinf. steel 3 days

Placing wall & roof concrete 1 day

Removing & cleaning forms 1 day

Total 9 days

Add 20% for lost time 2 days

Total time 11 days

CEE 5111 Lecture Notes Chapter 2

26

It is not necessary to complete one culvert prior to starting another. Assume that three culverts

are under construction at the same time. Under this schedule, one culvert should be finished

each week, with time allowed for the curing of concrete. Thus, a total of 12 weeks will be

required to complete the culverts.

Construction on the culverts should not be started until a sufficient portion of the right of way is

cleared to permit the construction to be continued without interruption. The culverts will be

started 2 weeks after clearing is started.

Earth fill

The earth for the fill will be excavated with a 1.14m3 power shovel, whose output should be

approximately 114m3 per hour bank volume. A truck having a struck capacity of 4.56m3 should

haul 4.56m3 bank volume if the heaped capacity is 5.6m3 loose measure.

Under reasonably good haul-road conditions, a truck should make a round trip in 12 min. If it is

assumed that a truck will operate an average of 50min per hr, because of necessary delays, the

number of trucks required will be obtained as follows:

CEE 5111 Lecture Notes Chapter 2

27

Trips per hr per truck, 50min/hr ÷ 12min/trip = 4.17

Volume hauled per hr per truck, 4.17×4.56m3 = 19 m3

Number of trucks required, 114m3/hr ÷19m3 = 6

An extra truck should be provided as a stand-by unit for use in the event of a breakdown by one

of the trucks.

Volume of earth placed in a week will be, 114m3/hr x40 = 4560m3

Time required to complete the fill will be;

Working time, 104 524 m3 @ 4560m3 per week = 22.9wks

Lost time = 5.7wks

Total time = 28.6 wks

Round time to: 29 weeks

CEE 5111 Lecture Notes Chapter 2

28

In addition to the shovel and trucks, it will be necessary to provide one or more heavy-duty

graders to smooth and shape the earth in the fill and to maintain the haul roads, one or more

sheep’s-foot rollers to compact the earth, and enough sprinkler trucks to supply the required

water.

It is estimated that placing the fill can be started 2 weeks after clearing & grubbing is started.

Pavement

Area of concrete pavement =100,638m2

Volume will be 100,638x0.23= 23,147m3 (with no allowance for wastage or overrun in thickness)

A 34E dual-drum paving mixer, producing 1.156 m3 of concrete per batch, can mix a batch in 1

min. under favourable conditions.

Assume that the mixer will actually operate 50min. per hr, an average of 50 batches per hr can

be mixed and placed.

CEE 5111 Lecture Notes Chapter 2

29

This is equal to, 1.16x50 = 58 m3 per hour or 58×40÷(1/0.23) = 10,087m2 per wk.

Time required to complete the operation will be:

Working time, 100,638 m2 @ 10,087 m2 per wk = 10 wks

Add 20% for lost time = 2 wks

Total 12 weeks

Unless it is practical to increase the rate of placing the fill, the concrete pavement should not be

started until 21 weeks after the construction of the fill is started. This will permit the last portion of

the fill to cure 4 weeks prior to placing the last pavement, as required by the specifications.

General clean-up & moving out

Assuming this operation will take 2 weeks, it can be started 11 weeks from the date work started

on the pavement.

CEE 5111 Lecture Notes Chapter 2

30

Resource Leveling and

Smoothing

CEE 5111 Lecture Notes Chapter 2

31

Resource levelling/smoothing

There are the two basic possibilities of utilising available resources. In the case of

resource levelling, available resources are fixed crew right from the beginning to the

end whilst in resource smoothing there is variation in number of crews to be used but the

variation is not large.

In the example below in resource levelling 3 persons have been used from first to the last day of

the work while in resource smooth 3 persons have been used for 6 days and there is variation in

number of persons from 2 to 4 persons depending upon the amount of work to be executed.

In construction (building and civil), resource smoothing is applied mostly. The nature of

construction works does not make resource levelling economical.

CEE 5111 Lecture Notes Chapter 2

32

Resource levelling Resource smoothing

Crew Crew

Duration in days Duration in days

CEE 5111 Lecture Notes Chapter 2

33

Resource Aggregation

This involves the summing together of resources on all activities during the same period.

For activities having float time, there is a choice between aggregating the resources

anywhere between the earliest time and the latest time.

CEE 5111 Lecture Notes Chapter 2

34

Classification of Resource Scheduling

Problem

Time-Constrained Project:

A project that must be completed by an imposed date

Time is fixed, resources are flexible: if additional resources are required to ensure project meets

schedule, they may be obtainable.

Resource-Constrained Project:

A project in which the level of resources available cannot be exceeded

Resources are fixed, time is flexible: inadequate resources will simply delay the project.

CEE 5111 Lecture Notes Chapter 2

35

Time-Constrained Projects

…Are projects that must be completed by an imposed date

Require the use of levelling techniques that focus on balancing or smoothing resource

demands by using slack to manage resource utilization over the duration of the project:

Peak resource demands are reduced.

Resources over the life of the project are reduced.

Fluctuation in resource demand is minimized.

CEE 5111 Lecture Notes Chapter 2

36

Example: Botanical Garden Project

Given the following project network, we would like to:

minimize total resources (rented backhoes) used

smooth capacity requirements (avoid large fluctuations)

CEE 5111 Lecture Notes Chapter 2

37

Pre and Post Resource Smoothing

CEE 5111 Lecture Notes Chapter 2

38

Time-Constrained Projects

Resource Demand Levelling Techniques for Time- Constrained Projects

Advantages

Peak resource demands are reduced.

Resources over the life of the project are reduced.

Fluctuation in resource demand is minimized.

Disadvantages

Loss of flexibility that occurs from reducing slack

Increases in the criticality of all activities

CEE 5111 Lecture Notes Chapter 2

39

Resource-Constrained Projects

…Are projects that involve resources that are limited in quantity or by their availability

There are two fundamental approaches to Resource-Constrained allocation problems:

Heuristic Methods

Optimization Models

Heuristic approaches employ rules of thumb that have been found to work reasonably

well in similar situations

Optimization approaches seek the best solutions but are far more limited in their ability

to handle complex situations and large problems

CEE 5111 Lecture Notes Chapter 2

40

Heuristic-Based Resource Scheduling

Scheduling of activities through use of heuristics (rules-of- thumb), according to the

following priorities:

Start from beginning of project time and, when resources used exceed the resources available,

retain activities first by:

Minimum slack

Smallest (least) duration

Lowest activity identification number

…and push the others out further in time

An unarticulated rule: in later periods, do not move activities that have already started

Additional caveat: when considering activities not to delay, consider the resources each

activity uses.

CEE 5111 Lecture Notes Chapter 2

41

Example: Resource-Constrained Project

Assume we only have 3 people available to do the following project, and we cannot

afford to hire more.

CEE 5111 Lecture Notes Chapter 2

42

Before Resource Balancing

Early Start Resource Load Chart (slack shown in grey)

CEE 5111 Lecture Notes Chapter 2

43

Resource Load now Feasible

CEE 5111 Lecture Notes Chapter 2

44

The Impact of Resource-Constrained

Scheduling

Reduces delay but reduces flexibility

Increases sensitivity of the network

Increases scheduling complexity

Can break the sequence of events

May cause parallel activities to become sequential and change the critical path

CEE 5111 Lecture Notes Chapter 2

45

Materials Management

CEE 5111 Lecture Notes Chapter 2

46

Ordering materials

Construction schedule may be used as a guide in specifying the delivery dates for

materials. Materials should be delivered to a project far enough in advance of their

need to assure that there will be no delays.

However, it is not good practice to have materials at the job site too far in advance of

their need as they may:

deteriorate

be damaged

be lost

congest the working area

If proper information is given to material suppliers, they can arrange to furnish the

materials as they are needed. Revisions in delivery dates (from schedule) can be made,

if necessary, during the construction of the project.

CEE 5111 Lecture Notes Chapter 2

47

Stores

The term generally applies to all items and materials purchased for use in construction. It

includes issuable articles, tools, equipment, fixtures, etc.

Fool-proof arrangements for receipt and issue are essential for stores. The storage

department should be divided into the following three sections:

receipt section

holding section

issue section

Complete record of all the materials received and issued should be maintained.

CEE 5111 Lecture Notes Chapter 2

48

Objectives of materials management

to reduce materials cost

efficient control of inventories helps in releasing working capital for production purposes

ensure uniform flow of materials for production

ensure right quality at right price

establish and maintain good relations with suppliers

economy in using imported items and to find their substitutes.

CEE 5111 Lecture Notes Chapter 2

49

Scope of materials management

The following are areas covered by the materials management function:

materials planning and programming

storekeeping

inventory (formal detailed list of goods, e.g. stock) control

condition checking and standardisation in stores

transportation

materials handling

disposal of scrap and surplus.

CEE 5111 Lecture Notes Chapter 2

50

Selective control techniques

It is very costly and difficult to give equal attention to all the items of inventory

1. A-B-C Control Policy

A-B-C analysis is meant for relative inventory control in which maximum attention is given to

items which consume more money and a fair attention to medium value items, while the

attention to low value items can be reduced to routine procedure only

If a cost examination in terms of project materials consumption is undertaken, it will be found

that about:

10% of the items accounts for about 70% of the total project materials cost.

20% of the items account for about 25% of the total material cost

70% account for 5% of the total material cost

The first category, small number of high cost consumption items are called A - items. The

second category of medium cost consumption value items are known as B- items. The third

category, large number of items with small total cost are C - items.

CEE 5111 Lecture Notes Chapter 2

100

51

Percentage of item used

C

30

10 B

A 70 95

Percentage of total cost

Graph between percentages of total items in each category Vs percentage of total project cost consumption

for each category

CEE 5111 Lecture Notes Chapter 2

52

A-B-C analysis does not depend on the unit cost of the item but on its project cost consumption.

It also does not indicate the importance of any item. The category of every item is important.

A-B-C analysis is a basic technique of materials management and can be applied over almost

all aspects of materials management such as:

Purchase

Sale

Inspection

inventory control

store keeping

The control policies for A, B and C items are based on two principles

to keep capital tied up inventory as low as practicable

to ensure that all the materials would be available when required.

CEE 5111 Lecture Notes Chapter 2

53

a)Policies for A - items

since they account for over 70% of the total materials value, they should be ordered more frequently, but

in small quantities, in order to reduce capital locked up at any time

the requirements of such items must be planned in advance for expected future use, so that only required

quantities arrive a little before they are used.

since A items should be stocked as minimum as possible, maximum effort should be made to expedite

delivery. Deliveries within a specific period of order must be adhered to

two or more suppliers for each item may be engaged, so as to avoid dependence on one supplier, as a

safe guard against failure to deliver by any one supplier.

ordering quantities, re-order points and minimum stock levels should be revised more frequently.

CEE 5111 Lecture Notes Chapter 2

54

b)Policies of B-items

the policies for B items in general are in between those for A and C items

orders for these items must be placed less frequently than for A items.

c) Policies for C items

since C items do not involve much capital tie up, the entire project stock for such items may be kept

half project or total project orders should be placed to reduce paper work and ordering costs and to get

advantage of quantity discounts for bulk purchases

CEE 5111 Lecture Notes Chapter 2

55

2 SDE Analysis

Items can be classified according to their use, consumption, value, etc. A-B-C analysis is the

oldest and commonly used method. SDE analysis is based on availability position of each item.

In this analysis:

S - refers to Scarce items, which are in short supply and their availability is scarce. This includes

imported items

D - refers to Difficult items, which cannot be produced easily

E - refers to Easily available items

CEE 5111 Lecture Notes Chapter 2

56

Materials handling

This is an art and science involving:

movement

packaging

storing of materials in any form

by means of:

gravity,

manual effort, or

power driven m/c

The cost of materials handling operations can be as high as 50% of the wage bill in any

industrial concern. Thus efforts must be made to reduce the cost of materials handling

and its time.

CEE 5111 Lecture Notes Chapter 2

57

Disposal of surplus materials

A periodical study is necessary for finding obsolete or surplus (not being used for a

considerable period) items.

Such items should be re-examined for their alternative use. If they cannot be used

anywhere, they must be disposed off.

Mode of disposal must be decided in the following priority:

send it back on resale to the original supplier if they are interested

sell it at best possible price. If not possible then

sell at any available price, even at scrap value

if it could not be sold at scrap or at any rate, give it away for keeping it year after year blocks

space

CEE 5111 Lecture Notes Chapter 2

58

Inventory control

This displays a detailed list of movable goods

raw materials

materials in process

finished products

general supplies and equipment

and gives quantity and value of each item

CEE 5111 Lecture Notes Chapter 2

59

Need for inventory control

To maintain a reserve of goods that will ensure requirements at the lowest possible

ultimate cost. Losses from improper inventory include:

purchases in excess than is needed

cost of slowed down production resulting from materials not being available when needed.

Proper inventory control can greatly reduce costs by

promoting smooth operations

preventing materials pile up

preventing m/c idle time

CEE 5111 Lecture Notes Chapter 2

60

Functions of inventory control

To run the stores effectively - This includes layout, storage media (bins, shelves, & open space,

etc.)

To ensure timely availability of materials and avoid build up of stock levels.

Technical responsibility for the state of materials; This includes:

methods of storing

maintenance procedures

studies of deterioration and obsolescence

Stock control system: Physical verification (stock taking) of records, ordering policies procedures.

Maintenance of specified raw materials: general supplies and component parts in sufficient quantities

to meet demand of production.

Protecting materials from losses due to improper handling and storing of goods and unauthorised

removal from stores

Pricing all materials supplied to the stores so as to estimate material cost.

CEE 5111 Lecture Notes Chapter 2

61

Advantages of inventory control

it creates buffer between input and output

it ensures against delays in deliveries

it allows for a possible increase in production

it allows advantage of quantity discounts

it takes care of problem of scarcity of materials in the market

it utilises the benefit of price fluctuations

CEE 5111 Lecture Notes Chapter 2

62

Inventory build-up

Inventory build up starts because, either:

items get ordered in excess of the requirements

they do not get used at the same rate at which they are received.

To overcome the first possibility, orders should be placed after considering the past

consumption data and knowing the utilisation programme of particular type of

equipment. The danger here is that such materials may:

deteriorate in storage;

get pilfered; or

get damaged.

CEE 5111 Lecture Notes Chapter 2

63

In the second possibility, consumption rate may fall because of any of the following

reasons:

due to change in production plans; or

due to change in utilisation programme of a particular type of equipment.

In this case, rescheduling of the deliveries, or reducing the quantities of the pending

order must be resorted to, or if necessary pending orders be cancelled

CEE 5111 Lecture Notes Chapter 2

64

Stock-taking (Physical verification)

Various records are kept in maintaining receipt and issue of materials such as;

receipt book

store issue register

bin cards

store ledger and issue indents, etc.

CEE 5111 Lecture Notes Chapter 2

65

To avoid theft or errors in accounts of stores, a set of procedure called stock-taking is

adopted. Main errors which are usually responsible for differences in actual stock and

book figures are:

clerical mistakes - wrong issue or wrong entries of issue or receipt in the record

improper storage-deterioration or loss due to evaporation

Pilferage

Careless handling

leakage loss e.g. industrial gases.

CEE 5111 Lecture Notes Chapter 2

66

Project Control and

Supervision

CEE 5111 Lecture Notes Chapter 2

67

Control

This is the process of putting the project back on track should adverse deviations from

what is planned occur. Control involves progress monitoring using the various

management instruments available and taking corrective action when deviations

occur.

At specified time intervals - daily, weekly, monthly; - reports should be submitted by

project supervisors to management, showing actual progress on each operation during

the specified time interval or at the effective date of the report.

This permits close monitoring of progress on a project. If progress on one or more

operations or on the entire project is behind schedule, such information will be known

early enough to take corrective steps.

CEE 5111 Lecture Notes Chapter 2

68

It is better to take corrective steps during the early part of construction period instead of

waiting until there is no sufficient time to overcome the difficulties. Having to correct

time delays on short notice can be very expensive.

Project control is therefore a continuous activity. Effective control involves a regular

comparison of actual progress against required performance followed by appropriate

action to achieve desired objectives. This requires a constant interchange of

information which in turn pre-supposes good communications systems for effective

transmission of ideas, instructions and details.

CEE 5111 Lecture Notes Chapter 2

69

Supervision

Supervision is that aspect of construction which facilitates smooth execution of the

project. Project supervision mainly deals with organisational problems to ensure that

operations follow the planned schedule and practices of construction.

Two-way Radio System

The use of two-way radios, in supervising construction projects is very helpful in improving

communication on projects covering large areas. Among the advantages of using radios, are

the following:

Permits quick contacts among key personnel on the job.

Reduces time spent by key personnel in rushing from one operation to the other.

Saves time and cost by increasing efficiency on a project.

CEE 5111 Lecture Notes Chapter 2

70

Permits equipment to be shifted quickly from one operation to another, thereby reducing delays due to

equipment failure or reduces the amount of equipment required on a project because of efficient use.

Permits quick contact with the workshop in the event emergency repairs are required for equipment.

Expedites the distribution of materials to different operations.

Gives excellent control between concrete-mixing and placing operations. In the event of failure at either

location, the other can be notified immediately.

Permits quick calls for first aid or an ambulance in the event of injuries to personnel.

CEE 5111 Lecture Notes Chapter 2

71

Objectives of Project Supervision

The aim of project supervision is to carefully monitor each of the individual project

components to ensure efficiency and cost saving.

Such supervision involves the following elements:

Labour

A regular comparison with anticipated project requirements of particular tradesmen would be more

helpful. The maintenance of the requisite labour force must be judged in conjunction with the progress

record

Plant

The plant schedule, from the method statement, prepared during the planning stage should be used to

ensure that machines are brought to the site at the appropriate time. Equally important is the necessity to

return equipment as soon as its use is finished. Instruction in the correct use and insistence on regular

maintenance is essential if standing time due to breakdowns is to be avoided.

CEE 5111 Lecture Notes Chapter 2

72

Materials

Timed schedules of requirements prepared in conjunction with the contract programme should ensure that

materials are requisitioned and ordered in good time and assist the chasing of deliveries when suppliers fall

back or earlier despatch has to be effected. To check that all components are requisitioned, it is helpful to

prepare a materials scheduled for every drawing. This provides a means of supervising the initiation of

purchasing.

Information

It is necessary to institute a reliable record of site instructions in order to prevent later misunderstandings

and disputes. All verbal instructions given should be confirmed in writing and signed against.

Sub-contractors

Copies or abstracts of all relevant programmes, drawings, schedules, instructions, etc., must be passed on

to contractors concerned. Their labour strengths and progress achievements should be recorded and any

labour, material and information difficulties noted and followed up. Site meetings assist in settling queries.

CEE 5111 Lecture Notes Chapter 2

73

Methods of Project Supervision & Control

Putting together the various parts of a project is one half of site management, while the

practical application of control techniques for their integration is another.

Progress

All agents should keep a site diary in which to record:

weather observations

work executed

delays experienced

comments and any noteworthy occurrences

Physical progress can be indicated on the programme bar chart.

CEE 5111 Lecture Notes Chapter 2

74

Variations

The client, site conditions, or unforeseen circumstances, will inevitably produce a number of

variations as the contract proceeds. In order that financial adjustments may be settled

amicably, it is imperative that all changes should be methodically agreed and measured.

Original and final site levels, extra depths of excavation or concrete and all additional

construction details must be placed on record drawings and submitted signed.

works not immediately measurable should be recorded in day work sheets on a time and

material basis.

variation of price records should be kept right up-to-date and presented for regular inspection.

Grounds for claims should be notified in writing as quickly as circumstances allow, so that they

may be discussed and if possible settled at the next site meeting.

Prompt adjustment of variations is advantageous to all parties and promotes that friendly co-

operation so essential to a successful project execution.

CEE 5111 Lecture Notes Chapter 2

75

Quality

Quality control includes accurate setting-out and levelling, fair faced brickwork and concrete

finishes, etc. Maintenance of quality is a most important factor in modern construction.

Co-ordination

An efficient network of communication both written and verbal is necessary for linking together

the various separate members of the construction team. The following procedures are widely

known (though not always practised).

Site report

Such a report may include the following; labour strength, plant, material; subcontractor’s labour, plant and materials

and any other information considered important or subcontractor shortages, delays incurred with causes e.g. weather,

breakdowns, instructions received, etc. A weekly (or daily) report should be submitted in order that the pulse of the job

can be watched and any assistance provided.

CEE 5111 Lecture Notes Chapter 2

76

Weekly meetings

Such meetings for supervisory, technical and senior clerical staff together with chosen sub-contractors, are an excellent

way of exercising control. Progress can be related to the programme, shortages discussed and means of overcoming

them decided, anticipated problems settled or by-passed. Such a meeting every Friday to review the past week and

survey the week ahead can prove very useful.

Site meetings

Held at start of a contract and thereafter regularly each month, or as required during the progress of the work are highly

desirable. Well organised site meetings;

maintain the impetus of the job

help to avoid delays

can resolve differences before they generate friction and lead to misunderstanding.

CEE 5111 Lecture Notes Chapter 2

77

The agenda for such a meeting should always be sent out before hand. Any procedure for meetings should

include the following on its agenda;

list of persons present

acceptance of previous minutes

Matters arising from the minutes

progress of the works and causes of any delays; labour, plant or material shortages

outstanding information

review of nominated subcontractors and suppliers

variations/claims for extras

any other business and date of the next meeting

From what has been discussed it may seem that construction control and supervision is a

matter of checking and cross-checking. However, the sixth sense born of training and

experience is the irreplaceable of the personality in control because construction is subject to

chance in the form of weather, type of labour available and the vagaries of supplies.

CEE 5111 Lecture Notes Chapter 2

78

Cost Control

Losses may be made on a construction project because of one or several reasons, such as:

• low bid

• insufficient knowledge of job conditions

• increase in costs of materials and labour

• adverse weather conditions

• improper selection of construction equipment

• inefficient management and supervision

The elements of any control system are:

• observation

• comparison of observation with some desired stand

• corrective action to take if necessary

A cost control system should enable a manager to observe current cost levels, compare them with a

standard plan, and institute corrective action to keep costs within acceptable bounds. The system should

help to identify where corrective action is necessary and to provide pointers as to what action should be.

CEE 5111 Lecture Notes Chapter 2

79

Two fundamental points in cost control

methods

All costs must be allocated on a cost coding arrangement.

If some costs are ignored as minor, the whole site might be incurring disastrous hidden losses.

There must always be a standard against which to compare recorded costs. In simple

projects, this might be the bill of quantities. However, a properly prepared and

appropriately updated contract budget forms a better basis.

CEE 5111 Lecture Notes Chapter 2

80

Disadvantage of Cost Control System

Most control systems have a long response time. Even the best current system provides

information on what was happening the previous week or month.

As the work is part of a one-off project, it is quite likely that the information is only partly

relevant to the work going on.

The system might, for example, indicate on May 1, that the formwork operation in March

cost too much. If formwork operations are still continuing, the Manager will give this

work particular attention, but if formwork is complete, nothing can be done to correct

the situation.

CEE 5111 Lecture Notes Chapter 2

81

Cost Control System in Current use

The selection of a system depends in part on the size and complexity of the contact, but

more on the attitudes and level of sophistication of top management.

Overall Profit or Loss

The contractor waits until the contract is complete and then compares the sums of money that have been

paid to him with the monies incurred in purchasing materials, payment for labour, subcontractors, plant

and overheads.

This system is useful only on very small contracts of short duration. It scarcely qualifies as a control system as

the information it produces can only be used to avoid recurrence of gross errors in later contracts.

CEE 5111 Lecture Notes Chapter 2

82

Profit or Loss on each Contract or Valuation

The total cost to date are compared with valuation gross of retentions. Cost of materials already delivered

and built into the works though not invoiced must be included but cost of materials on site not yet built into

the permanent work should be excluded.

Disadvantage - There is no breakdown of profit or loss figure between types of work; it therefore provides

guidance only on which contract requires management attention.

CEE 5111 Lecture Notes Chapter 2

83

Unit costing

Costs of various types of work, such as mixing and placing concrete are recorded separately.

The costs, both on a periodic basis and cumulatively, are divided by the quantity of work of each type that

has been done. This provides unit cost which can be compared with those in tender.

Care must be taken to ensure that all costs are accounted for as mentioned earlier.

Any miscellaneous costs must be recorded and allowed for in some way, e.g., by proportional distribution

over the defined work types.

It is usually best to record site costs only and compare these with bill rates net of contribution for profit and

head office overheads.

CEE 5111 Lecture Notes Chapter 2

84

Optimum cost control

Any cost control involves an addition Total cost

to overheads.

As expenditure on cost control

Break-even point

increases, the direct cost on the

project can be expected to decrease.

Direct cost of project

Cost

However, there will come a point at

which extra effort will ensure no further Cost of control

cost reduction Optimum cost control level

Expenditure on control as % of direct cost of project

CEE 5111 Lecture Notes Chapter 2

You might also like

- Systematic Project ManagementDocument7 pagesSystematic Project ManagementKarl Angelo CuellarNo ratings yet

- Pm-5104-Pc-Fm-Final Project-30-12-2021Document18 pagesPm-5104-Pc-Fm-Final Project-30-12-2021sunainaNo ratings yet

- Spec 2 Case StudyDocument14 pagesSpec 2 Case StudyDave DamalerioNo ratings yet

- Labuan Square Redevelopment WbsDocument8 pagesLabuan Square Redevelopment WbsBreeNo ratings yet

- Project Time Management and Budget PlanningDocument68 pagesProject Time Management and Budget PlanningLindelani ndalaNo ratings yet

- 3 Jetty 2 Project - Ormp Plan 02 - Ok UpdatedDocument11 pages3 Jetty 2 Project - Ormp Plan 02 - Ok Updatedonome ohwerhiNo ratings yet

- Mobilization Plan for Fayy Health Polyclinic ProjectDocument6 pagesMobilization Plan for Fayy Health Polyclinic Projectadeniyi abiola80% (5)

- Chap 3c Project ManagementDocument9 pagesChap 3c Project ManagementArianNo ratings yet

- Project Management Plan OverviewDocument38 pagesProject Management Plan Overviewgelgelai29No ratings yet

- Chapter 6 - SchedulingDocument21 pagesChapter 6 - SchedulingAiden SolomonBrNo ratings yet

- 02 Handout 1Document3 pages02 Handout 1Rey Visitacion MolinaNo ratings yet

- Stochastic Scheduling To Minimize Expected Duration of Construction ProjectDocument62 pagesStochastic Scheduling To Minimize Expected Duration of Construction ProjectBatool Al-kharabshehNo ratings yet

- Construction Project Management IntroductionDocument40 pagesConstruction Project Management IntroductionRitz Paul SerranoNo ratings yet

- Project Stages & ManagementDocument43 pagesProject Stages & ManagementGamer4Life awmNo ratings yet

- Unit 2Document30 pagesUnit 2Shubham KureNo ratings yet

- Curs3 2017Document111 pagesCurs3 2017Paul Gabriel BălteanuNo ratings yet

- Chapter-Four: Time Control and MonitoringDocument7 pagesChapter-Four: Time Control and MonitoringBikila M. KejelaNo ratings yet

- مشروع 2 ادارة2021Document78 pagesمشروع 2 ادارة2021Batool Al-kharabshehNo ratings yet

- UNIT IV_session 4Document23 pagesUNIT IV_session 4sherril siddhardhNo ratings yet

- 10-Exhibit X - Project Management and Project ControlsDocument15 pages10-Exhibit X - Project Management and Project ControlsMartino Ojwok AjangnayNo ratings yet

- CVEN90045 Assignment 2-2019Document5 pagesCVEN90045 Assignment 2-2019YooNo ratings yet

- PMD 913 - Module 2 - Project Time Control May22 R1Document31 pagesPMD 913 - Module 2 - Project Time Control May22 R1Abdallah HabeebNo ratings yet

- Edragon MEPFS Project ManagementDocument78 pagesEdragon MEPFS Project ManagementRolly Socorro100% (3)

- Project PhasesDocument2 pagesProject PhasesEng-Mukhtaar CatooshNo ratings yet

- Macaraig, Ryan M., 2016-02810-MN-0, CM600 Assignment No. 3Document12 pagesMacaraig, Ryan M., 2016-02810-MN-0, CM600 Assignment No. 3RyanNo ratings yet

- Project Management: Organizing the Project StepsDocument14 pagesProject Management: Organizing the Project StepsThalia LaputNo ratings yet

- EKB 3172 Project ManagementDocument29 pagesEKB 3172 Project ManagementRishintiran GovindarajanNo ratings yet

- 22-Execution Plan-Epc-250 MW Power PlantDocument28 pages22-Execution Plan-Epc-250 MW Power PlantP Eng Suraj Singh100% (1)

- Lecture%Document21 pagesLecture%tiktokNo ratings yet

- CEng 572 Construction Scheduling TechniquesDocument21 pagesCEng 572 Construction Scheduling Techniquesmuliye tarekegnNo ratings yet

- CNM2801 02SDocument24 pagesCNM2801 02Sjoseph SpiteriNo ratings yet

- Minimize Time and Cost For Successful Completion of A Large Scale Project Applying Project Crashing Method PDFDocument9 pagesMinimize Time and Cost For Successful Completion of A Large Scale Project Applying Project Crashing Method PDFMugabe GomosNo ratings yet

- Module 2aDocument6 pagesModule 2afourty twoNo ratings yet

- Question 2 (A) Above.: Look at The Logical Links Between ActivitiesDocument9 pagesQuestion 2 (A) Above.: Look at The Logical Links Between ActivitiesMuhammad Aidid Mohamad ShariffNo ratings yet

- Construction Project Cycle: From Conception to BiddingDocument13 pagesConstruction Project Cycle: From Conception to BiddinglarraNo ratings yet

- Project Planning and ManagementDocument61 pagesProject Planning and ManagementKannha AggarwalNo ratings yet

- Project Management (CENG 6101) : BY Tadesse Ayalew (PHD)Document12 pagesProject Management (CENG 6101) : BY Tadesse Ayalew (PHD)matebbuNo ratings yet

- Unit 5Document28 pagesUnit 5Kuldeep DekaNo ratings yet

- Construction Project Management FundamentalsDocument10 pagesConstruction Project Management FundamentalsAris AmbosNo ratings yet

- Gicale - Chapter 6&7 SummaryDocument2 pagesGicale - Chapter 6&7 SummaryJaymark GicaleNo ratings yet

- Construction Project Planning and ManagementDocument32 pagesConstruction Project Planning and Managementሽታ ዓለሜ100% (1)

- Analysis of Project Acceleration With Crashing Method On The Rehability and Renovation Project Work of Iain Ambon LibraryDocument13 pagesAnalysis of Project Acceleration With Crashing Method On The Rehability and Renovation Project Work of Iain Ambon LibraryIJAERS JOURNALNo ratings yet

- GCU Technical Approach and MethodologyDocument13 pagesGCU Technical Approach and Methodologyqsultan100% (2)

- Construction Project Schedule Example-Residential Building: Civilverse Admin 2 May 2021Document7 pagesConstruction Project Schedule Example-Residential Building: Civilverse Admin 2 May 2021wockaflocka92No ratings yet

- Dpe Notes, Project PlanningDocument7 pagesDpe Notes, Project PlanningAnam JabbarNo ratings yet

- Construction Planning & Scheduling (CoTM4211) Lecture NotesDocument16 pagesConstruction Planning & Scheduling (CoTM4211) Lecture NotesMekuannint DemekeNo ratings yet

- Project Control For EngineeringDocument11 pagesProject Control For EngineeringKurniawanNo ratings yet

- INTRODUCTION (Lecture 1 & 2)Document30 pagesINTRODUCTION (Lecture 1 & 2)Muhammad Aleem nawazNo ratings yet

- Lec-1 Introduction PDFDocument23 pagesLec-1 Introduction PDFRajesh ThoratNo ratings yet

- CVX6546 - Lesson - 01-Site MobilizationDocument14 pagesCVX6546 - Lesson - 01-Site MobilizationharshanaouslNo ratings yet

- Civil Engg Project Management CE404Document351 pagesCivil Engg Project Management CE404Kokjal Khonir DalaNo ratings yet

- Construction ProjectsDocument13 pagesConstruction ProjectsMuhammad SafdarNo ratings yet

- Project Management Basics and Resource AllocationDocument73 pagesProject Management Basics and Resource Allocationmelake yigezuNo ratings yet

- 23-Project Plan EPC 225 MW Gas Power Combined CycleDocument33 pages23-Project Plan EPC 225 MW Gas Power Combined CycleP Eng Suraj SinghNo ratings yet

- Al-Fadhli 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012040Document12 pagesAl-Fadhli 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012040عبدالسلام البرهوNo ratings yet

- CDC Up Project Management Plan TemplateDocument30 pagesCDC Up Project Management Plan TemplateMohmmed AhmedNo ratings yet

- PNAAR483Document16 pagesPNAAR483Peshogai PeshoNo ratings yet

- Analysis of Cost Control and Project Time in Performance Process With Earned Value Method, Case Study Improvement of Maliku-Bantanan Road in Pulang Pisau District, IndonesiaDocument7 pagesAnalysis of Cost Control and Project Time in Performance Process With Earned Value Method, Case Study Improvement of Maliku-Bantanan Road in Pulang Pisau District, IndonesiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- WP8 LPDS PDFDocument7 pagesWP8 LPDS PDFKevin Pool Curi VicenteNo ratings yet

- Business Summary For Modular FormworkDocument5 pagesBusiness Summary For Modular FormworkHarrison Daka LukwesaNo ratings yet

- BoQ - IOM Benin CBR Fish Farm ProjectDocument3 pagesBoQ - IOM Benin CBR Fish Farm ProjectHarrison Daka LukwesaNo ratings yet

- A Bu415eDocument17 pagesA Bu415eHarrison Daka LukwesaNo ratings yet

- Conquering The SeaDocument7 pagesConquering The SeaHarrison Daka LukwesaNo ratings yet

- Climate Change and Agriculture in Zambia: Impacts, Adaptation and Mitigation OptionsDocument3 pagesClimate Change and Agriculture in Zambia: Impacts, Adaptation and Mitigation OptionsHarrison Daka LukwesaNo ratings yet

- Planning, Designing and Construction of Aqua Farm: Gulshan Kumar School of FisheriesDocument25 pagesPlanning, Designing and Construction of Aqua Farm: Gulshan Kumar School of FisheriesHarrison Daka LukwesaNo ratings yet

- 1 HTDocument12 pages1 HTHarrison Daka LukwesaNo ratings yet

- Planning, Designing and Construction of Aqua Farm: Gulshan Kumar School of FisheriesDocument25 pagesPlanning, Designing and Construction of Aqua Farm: Gulshan Kumar School of FisheriesHarrison Daka LukwesaNo ratings yet

- s10584 010 9975 6 PDFDocument37 pagess10584 010 9975 6 PDFHarrison Daka LukwesaNo ratings yet

- Techniques For Estimating Uncertainty in Climate Change Scenarios and Impact StudiesDocument19 pagesTechniques For Estimating Uncertainty in Climate Change Scenarios and Impact StudiesHarrison Daka LukwesaNo ratings yet

- Vulnerability Assessment - FHWADocument32 pagesVulnerability Assessment - FHWAHarrison Daka LukwesaNo ratings yet

- Cee 5111 - Chapter 3Document49 pagesCee 5111 - Chapter 3Harrison Daka LukwesaNo ratings yet

- Sample Literature ReviewDocument8 pagesSample Literature Review67890ThNo ratings yet

- Chapter Six - Examples 1Document20 pagesChapter Six - Examples 1Harrison Daka LukwesaNo ratings yet

- 032 Climate Proofing WASH in LusakaDocument42 pages032 Climate Proofing WASH in LusakaHarrison Daka LukwesaNo ratings yet

- Cee 5111 - Chapter 4 PDFDocument62 pagesCee 5111 - Chapter 4 PDFHarrison Daka LukwesaNo ratings yet

- Commutative AlgebraDocument172 pagesCommutative AlgebraHarrison Daka LukwesaNo ratings yet

- Discriptive Set Theory PDFDocument105 pagesDiscriptive Set Theory PDFHarrison Daka LukwesaNo ratings yet

- Scribd Test SolutionDocument1 pageScribd Test SolutionHarrison Daka LukwesaNo ratings yet

- Cee 5111 - Chapter 1Document55 pagesCee 5111 - Chapter 1Harrison Daka LukwesaNo ratings yet

- Construction Safety CostsDocument15 pagesConstruction Safety CostsHarrison Daka LukwesaNo ratings yet

- 1 The Story of Fermions: K K L L K KDocument7 pages1 The Story of Fermions: K K L L K KHarrison Daka LukwesaNo ratings yet

- 1 The Classical String: 1.1 Equations of MotionDocument7 pages1 The Classical String: 1.1 Equations of MotionHarrison Daka LukwesaNo ratings yet

- 4 3 1Document3 pages4 3 1rahulmnm007No ratings yet

- Scribd Test SolutionDocument1 pageScribd Test SolutionHarrison Daka LukwesaNo ratings yet

- Scribd Test SolutionDocument1 pageScribd Test SolutionHarrison Daka LukwesaNo ratings yet

- Assignment No1 2018Document1 pageAssignment No1 2018Harrison Daka LukwesaNo ratings yet

- Architectural Drawings CEE 5211 Design Project 2020 PDFDocument10 pagesArchitectural Drawings CEE 5211 Design Project 2020 PDFHarrison Daka LukwesaNo ratings yet

- Scribd Test SolutionDocument1 pageScribd Test SolutionHarrison Daka LukwesaNo ratings yet

- Altered Ventilatory Function Assessment at Pamantasan ng CabuyaoDocument27 pagesAltered Ventilatory Function Assessment at Pamantasan ng Cabuyaomirai desuNo ratings yet

- MMME 21 1st Long Exam Lecture NotesDocument74 pagesMMME 21 1st Long Exam Lecture NotesGraver lumiousNo ratings yet

- INA128 INA129: Features DescriptionDocument20 pagesINA128 INA129: Features DescriptionCDDSANo ratings yet

- Draconis CombineDocument11 pagesDraconis CombineMarco Moracha100% (1)

- European Journal of Internal MedicineDocument4 pagesEuropean Journal of Internal Medicinesamer battatNo ratings yet

- Gfk-1383a 05012Document108 pagesGfk-1383a 05012occhityaNo ratings yet

- BED 101 Voc & Tech. Course ContentDocument3 pagesBED 101 Voc & Tech. Course ContentSunday PaulNo ratings yet

- Armv8-A Instruction Set ArchitectureDocument39 pagesArmv8-A Instruction Set ArchitectureraygarnerNo ratings yet

- COR2-03 Admist The Mists and Coldest Frost PDFDocument16 pagesCOR2-03 Admist The Mists and Coldest Frost PDFLouis BachNo ratings yet

- SecASC - M02 - Azure Security Center Setup and ConfigurationDocument53 pagesSecASC - M02 - Azure Security Center Setup and ConfigurationGustavo WehdekingNo ratings yet

- Pick Pack Ship Public APIDocument19 pagesPick Pack Ship Public APIgauravpuri198050% (2)

- Unit Rates and Cost Per ItemDocument213 pagesUnit Rates and Cost Per ItemDesiree Vera GrauelNo ratings yet

- CARP Law NotesDocument5 pagesCARP Law NotesJustisia KaunlaranNo ratings yet

- Multibody Simulation of A Freight Bogie With Friction DampersDocument10 pagesMultibody Simulation of A Freight Bogie With Friction DampersGermán GoñiNo ratings yet

- Dedicated Teacher ResumeDocument2 pagesDedicated Teacher ResumeLei Pitallano ComboyNo ratings yet

- Download Zinc Surfaces A Guide To Alloys Finishes Fabrication And Maintenance In Architecture And Art 1St Edition L William Zahner all chapterDocument68 pagesDownload Zinc Surfaces A Guide To Alloys Finishes Fabrication And Maintenance In Architecture And Art 1St Edition L William Zahner all chapterdevin.brown498100% (7)

- Definition and Scope of Public FinanceDocument2 pagesDefinition and Scope of Public FinanceArfiya MubeenNo ratings yet

- Chapter 20: HealthDocument42 pagesChapter 20: HealthMajid KarimiNo ratings yet

- Xt600e 3tb-3uw 90-95Document46 pagesXt600e 3tb-3uw 90-95Kenneth SynnesNo ratings yet

- Su1 Assessment U01Document14 pagesSu1 Assessment U01Cristian Seas ArceNo ratings yet

- Greek Myth WebquestDocument9 pagesGreek Myth Webquesthollyhock27No ratings yet

- Quantification Skills in The Construction IndustryDocument34 pagesQuantification Skills in The Construction IndustryBRGRNo ratings yet

- Rock Support Optimization in Himalayan TunnelsDocument7 pagesRock Support Optimization in Himalayan TunnelsHarold TaylorNo ratings yet

- 2023 Catalog Score SummerDocument65 pages2023 Catalog Score Summermadhudasa0% (2)

- Syllabus PTSV3Document21 pagesSyllabus PTSV3Pablito Quispe RuizNo ratings yet

- Physical Science 1Document25 pagesPhysical Science 1EJ RamosNo ratings yet

- Power System Analysis and Design, SI EditionDocument5 pagesPower System Analysis and Design, SI EditionAkimeNo ratings yet

- Nelson Climate Change Plan UpdateDocument37 pagesNelson Climate Change Plan UpdateBillMetcalfeNo ratings yet

- Pharmacology Ain Shams 123 - Compress 1Document552 pagesPharmacology Ain Shams 123 - Compress 1ahmed hoty100% (1)

- Taylor Introms11GE PPT 03Document40 pagesTaylor Introms11GE PPT 03hddankerNo ratings yet