Professional Documents

Culture Documents

Wire Rope Clips: Rigging Hardware

Uploaded by

LC ChongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wire Rope Clips: Rigging Hardware

Uploaded by

LC ChongCopyright:

Available Formats

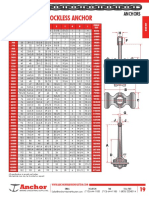

RIGGING HARDWARE

WIRE ROPE CLIPS

SIZES: 1/8 TO 1-1/2 IN.

BENEFITS & FEATURES

Precision manufactured and galvanized

to meet federal specifications

(FF-C-450 Type 1 Class 1) on 1/4"

and larger.

Drop forged base

E

B

A

D

F

H

G

Dimensions (in.) Minimum

Size Standard Product Number Torque Rope Weight

(in.) Package Code A B C D E F G H of Clips (ft./lbs.) Turnback (lbs.)

1/8 50 M244 1/8-24UNC 0.72 0.44 0.47 0.42 0.38 0.81 1.09 2 4-1/2 3-1/4 0.08

3/16 50 M245 1/4-20UNC 0.94 0.56 0.59 0.50 0.50 0.94 1.19 2 7-1/2 3-3/4 0.12

1/4 50 M246 5/16-18UNC 1.03 0.50 0.75 0.66 0.56 1.19 1.44 2 15 4-3/4 0.18

5/16 50 M247 3/8-16UNC 1.38 0.75 0.88 0.72 0.69 1.31 1.69 2 30 5-1/4 0.30

3/8 50 M248 7/16-14UNC 1.50 0.75 1.00 0.91 0.75 1.63 1.94 2 45 6-1/2 0.42

7/16 50 M249 1/2-13UNC 1.88 1.00 1.19 1.06 0.88 1.78 2.31 2 65 7 0.70

1/2 20 M250 1/2-13UNC 1.88 1.00 1.19 1.16 0.88 1.91 2.31 3 65 11-1/2 0.85

9/16 20 M296 9/16-12UNC 2.38 1.25 1.31 1.24 0.94 1.94 2.50 3 95 12 1.00

5/8 20 M251 9/16-12UNC 2.38 1.25 1.31 1.34 0.94 2.00 2.49 3 95 12 1.00

3/4 10 M252 5/8-11UNC 2.75 1.44 1.50 1.44 1.06 2.34 2.81 4 130 18 1.53

7/8 10 M253 3/4-10UNC 3.13 1.63 1.75 1.63 1.25 2.44 3.16 4 225 20 2.40

1 10 M254 3/4-10UNC 3.50 1.81 1.88 1.78 1.25 2.63 3.47 5 225 26 2.50

1-1/8 5 M255 3/4-10UNC 3.88 2.00 2.00 1.88 1.25 2.81 3.59 6 225 34 3.10

1-1/4 5 M256 7/8-9UNC 4.25 2.13 2.31 2.19 1.44 3.15 4.22 7 360 37 4.10

1-3/8 5 M257 7/8-9UNC 4.63 2.31 2.38 2.25 1.44 3.08 4.25 7 360 44 4.50

1-1/2 5 M258 7/8-9UNC 4.94 2.38 2.59 2.50 1.44 3.41 4.47 8 360 48 5.40

NOTE: 1/8" through 5/8" packed 1 piece per poly bag. 3/4" & larger shipped assembled in factory packs and tagged.

RIGGING HARDWARE

Live

PROPER USE OF WIRE ROPE CLIPS end

1. Refer to the chart above when following these instructions. Turn back specified

amount of rope from thimble or loop. Apply first clip one base width from dead

end of rope. Apply U-bolt over dead end of wire rope, ensuring live end rests in

saddle. Tighten nuts evenly, alternate from one nut to the other until reaching the Dead

End

recommended torque.

2. When two clips are required, apply the second clip as near the thimble or loop

as possible. Tighten nuts evenly, alternating until reaching the recommended Saddle

torque. When more than two clips are required, apply the second clip as near

the loop or thimble as possible and turn nuts on second clip firmly, but do not

tighten. Proceed to Step 3. U-bolt

3. When three or more clips are required, space additional clips equally between 1 2 3

the first two and take up rope slack. Then tighten nuts on each U-bolt evenly,

alternating from one nut to the other until reaching the recommended torque. Live Side

4. Apply an initial load equal to loads expected in use. Inspect for proper Dead End

orientation and spacing of clips and retighten the nuts to recommended torque. NOTE: Mechanical spliced or flemished eyes slings are the preferred method of wire rope sling construction.

OSHA does not allow the use of clips to form the eyes of wire rope slings.

CARE INSPECTION

Care should be exercised in the installation Visually inspect wire

and use of wire rope clips so that the clip, rope clips

wire rope, or thimble is not damaged. before each use. NEVER INSTALL THE U-BOLT

Do not over torque or under torque the nuts. Be certain threads are ON THE LIVE SIDE!

Too much torque can result in damage to the not stripped and that

clip and/or the wire rope. Too little torque can nuts are tight.

result in the wire rope slipping. Torque nuts Check torque of nuts

to the value specified in the accompanying periodically. INCORRECT

instructions. Replace distorted thimbles.

Clips should not be subjected to bending Shorten wire rope and form IMPROPER USE

or come in contact with sharp object. new loop if damaged. OF WIRE ROPE CLIPS

INCORRECT

Avoid exposure to corrosive mediums. Replace distorted thimbles.

C H A I N & R I G G I N G AT TA CHM ENT S (CM RP -6 )

104 PHONE: 800.888.0985 WWW.C M W OR K S .C OM

RIGGING HARDWARE

MID-GRIP WIRE ROPE CLIPS

SIZES: 3/16 TO 3/4 IN.

BENEFITS & FEATURES

Allows for full arc wrench swing for

quicker installation, retightening

and disassembly.

Saddles are made of forged steel for

strength and wearability. Full assembly

is mechanical galvanized per

ASTM B695-04 Class 25 Type 1.

Size, manufacturer and trace code

are clearly marked on the saddle

for easy identification.

Meets or exceeds performance

requirements of FF-C-450 specifications,

Type III, Class 1 and will provide

maximum holding strength.

NEW & IMPROVED NEW STYLE OLD STYLE

HEX BOLT & NUT DESIGN Available in 3/16" through 5/8" Available in 3/4" only

TIGHT, SECURE FIT N M

Hexagon bolt head fits securely into hex-shaped

E

socket for exceptional rotation resistance.

This prevents spinning even after repeated

use and re-torqueing. G C

L

F

PRECISE THREADING

Precise threading on bolt and nut ensures

tight alignment and exceptional strength. A

B D

FEWER LOOSE PARTS TO DROP

Hex bolt is knurled and machine pressed into

socket to securely couple with the saddle.

Dimensions (in.) Minimum Rope

Size Standard Product Torque Weight

HARDWARE

L Number Turn-Back

800

(in.) Package Code A B C D E Thread F G M N of Clips (in.) (ft./lbs.) (lbs.)

Approx.

®

HERC-ALLOY

New Style

3/16 20 M2546 0.37 1.53 0.44 1.06 3/8 - 16 0.50 1.50 1.93 0.69 1.74 2 4 30 0.38

RIGGING

1/4 20 M2546 0.37 1.53 0.44 1.06 3/8 - 16 0.50 1.50 1.93 0.69 1.74 2 4 30 0.38

5/16 20 M2547 0.34 1.48 0.44 1.06 3/8 - 16 0.63 1.50 1.90 0.69 1.80 2 5 30 0.38

3/8 20 M2548 0.46 1.67 0.54 1.13 7/16 - 14 0.75 1.84 2.26 0.75 2.00 2 5.5 45 0.49

7/16 20 M2550 0.65 2.03 0.59 1.31 1/2 - 13 1.05 2.23 2.74 0.88 2.40 2 6.5 65 0.84

1/2 20 M2550 0.65 2.03 0.59 1.31 1/2 - 13 1.05 2.23 2.74 0.88 2.40 3 11 65 0.84

9/16 20 M2551 0.78 2.46 0.73 1.63 5/8 - 11 1.38 2.81 3.44 1.06 2.90 3 12.75 130 1.55

5/8 20 M2551 0.78 2.46 0.73 1.63 5/8 - 11 1.38 2.81 3.44 1.06 2.90 3 13.5 130 1.55

Old Style

3/4 20 M2252 0.81 2.69 0.88 1.81 3/4 - 10 1.50 3.38 5.00 1.25 3.02 3 16 225 1.79

INSPECTION, CARE & USE

PROPER USE OF MID-GRIP CLIPS

1. Refer to chart above when following these instructions. 3. When three or more clips are required,

Turn back specified amounts of rope from thimble or loop. space additional clips between first 1

Apply first clip one base width from dead end of rope. two and take up rope slack. Then tighten

Tighten nuts evenly, alternating from one nut to the other nuts on all clips, alternating from one nut

until reaching the recommended torque. to the other until reaching the

2. When two clips are required, apply the second clip as recommended torque.

near the loop or thimble as possible. Tighten nuts evenly, 4. Apply an initial load equal to loads 2

alternating until reaching the recommended torque. When expected in use. Inspect for proper

more than two clips are required, apply the second clip spacing and retighten the nuts to

as near the loop or thimble as possible and turn nuts on the recommended torque.

second clip firmly, but do not tighten. Proceed to step 3.

For more information, visit us at 3

www.cmworks.com

CHAI N & R I GGI NG ATTACHMEN TS (C MR P -6)

W WW. C M W O R K S . CO M PHONE: 800.888.0985 105

RIGGING HARDWARE

®

PIGGYBACK WEDGE SOCKET CLIPS

SIZES: 3/8 TO 1-1/2 IN.

BENEFITS & FEATURES

Forged saddles include size, USA and CM logo

Drop-forged base for superior function and wearability

Galvanized finish

F G

E C

B A

Dimensions (in.) Heavy

Size Standard Product Saddle U-Bolt Hex Nut Torque Min

Min. Tail Weig

Weight

(in.) Package Code A B C D E F G Galv. (ft./lbs.) (in.) (lbs.)

3/8 10 M248D 1X248 2X248L 7/16-14UNC 1.00 2.38 0.75 0.69 1.94 1.62 602224 45 6 0.8

7/16 10 M249D 1X249 2X250L 1/2-13UNC 1.19 2.62 1.00 0.66 2.31 1.78 602225 65 6 1.3

1/2 10 M250D 1X250 2X250L 1/2-13UNC 1.19 2.62 1.00 0.72 2.31 1.91 602225 65 6 1.4

9/16 10 M296D 1X296 2X251L 9/16-12UNC 1.31 3.19 1.25 0.77 2.50 1.97 602226 95 6 1.7

5/8 10 M251D 1X251 2X251L 9/16-12UNC 1.31 3.19 1.25 0.87 2.50 2.00 602226 95 6 1.7

3/4 10 M252D 1X252 2X252L 5/8-11UNC 1.50 3.50 1.50 0.91 2.81 2.34 602227 130 6 2.5

7/8 5 M253D 1X253 2X253L 3/4-10UNC 1.75 3.88 2.00 1.07 3.16 2.44 602228 225 6 3.6

1 5 M254D 1X254 2X254L 3/4-10UNC 1.88 4.25 2.00 1.22 3.47 2.62 602228 225 6 3.9

1-1/8 5 M255D 1X255 2X255L 3/4-10UNC 2.00 4.50 2.00 1.31 3.59 2.81 602228 225 6-3/4 4.9

1-1/4 5 M256D 1X256 2X256L 7/8-9UNC 2.31 5.25 2.38 1.50 4.22 3.15 602246 360 7-1/2 6.5

RIGGING HARDWARE

1-3/8 5 M257D 1X257 2X257L 7/8-9UNC 2.38 5.62 2.38 1.56 4.25 3.08 602246 360 8-1/4 7.1

1-1/2 5 M258D 1X258 2X258L 7/8-9UNC 2.59 6.00 2.38 1.75 4.47 3.41 602246 360 9 8.2

LIVE LOAD LIVE LOAD

PROPER USE OF PIGGYBACK BEARING ROPE BEARING ROPE

WEDGE SOCKET CLIPS

Dead end wire rope tail length should be at least DEAD END

6 rope diameters, but not less than 6 inches beyond ROPE

DEAD END

the wedge socket. See Figure 1. ROPE

Apply U-bolt and first saddle on dead end rope and

the second saddle on live end rope. Install nuts. CLAMPING CLAMPING

SIDE SIDE TAIL

See Figures 1 & 2. OF CLIP OF CLIP LENGTH

Position the dual saddle clip so that 3 to 4 inches

of dead end rope remain beyond the clip. 3 to 4 IN.

LOOSE

See Figures 1 & 2. SIDE

OF CLIP

Tighten nuts evenly. Alternate tightening each TAIL LENGTH

nut until reaching the required torque specified.

See Figure 2.

Check that clip does not pinch or clamp the

live wire rope. Apply an initial test load equal to

the loads expected in regular use. Be certain rope WEDGE WEDGE

is secured properly in the wedge socket prior to SOCKET SOCKET

any use.

Inspect for proper rope alignment with wedge socket

and retighten the nuts to the specified torque. FIGURE 1 FIGURE 2

C H A I N & R I G G I N G AT TA CHM ENT S (CM RP -6 )

106 PHONE: 800.888.0985 WWW.C M W OR K S .C OM

RIGGING HARDWARE

BUNDLING CLIP

SIZES: 3/4 TO 1-1/8 IN.

BENEFITS & FEATURES

Galvanized and painted U-bolt with rolled

threads. Interchangeable and replaceable

with our standard wire rope clip U-bolts.

Forged and galvanized saddles come

with FORGED USA, size, CM logo A B

and trace code forged in.

Meets B30.26 plus traceability.

Performs to rated capacities.

After inspection, the CM B

Bundling Clip is reusable. C

Available for use with 3/4", 7/8",

F

1" and 1-1/8" wire rope chokers.

G

E

Size Standard Product Dimensions (in.) Torque Weight

(in.) Package Code A B C D E F G (ft./lbs.) (lbs.)

3/4 10 M252B 2.81 2.81 3.30 0.75 1.50 1.38 5/8"-11 UNC 130 2.5

7/8 5 M253B 3.16 2.44 3.80 0.88 1.75 1.63 3/4"-10 UNC 225 3.6

1 5 M254B 3.47 2.63 4.16 1.00 1.88 1.81 3/4"-10 UNC 225 3.9

1-1/8 5 M255B 3.60 2.81 4.54 1.13 2.00 2.00 3/4"-10 UNC 225 4.9

SEE BUNDLING CLIPS IN ACTION

http://www.youtube.com/user/ColumbusMcKinnon

SWAGE SOCKET (OPEN)

OPEN)

SIZES: 1/4 TO 1-3/4 IN.

HARDWARE

800

BENEFITS & FEATURES

Forged from fine grain, special bar quality

®

HERC-ALLOY

C-1035 steel

Spheroidized annealed for cold swaging

RIGGING

Recommended for use on 6" x 19" or

6" x 37" IWRC regular lay wore ropes.

Can also be used on galvanized bridge rope.

Not for use on fiber core or lang lay ropes. A D

O

Sockets have 100% efficiency rating based M

on catalog strength of wire rope when H B Y

properly applied E

L

F

Dimensions (in.) After

Size Product Swage Weight

(in.) Code A B D E F H L M O Y Diameter (lbs.)

(in.)

1/4 697120 0.50 0.27 0.69 1-1/2 4-3/4 2-1/8 4 5/16 11/16 1-3/8 0.44 0.55

3/8 697122 0.77 0.41 0.81 1-3/4 6-1/4 3-3/16 5-5/16 13/32 13/16 1-5/8 0.69 1.08

7/16 697123 0.98 0.48 1.00 2 7-13/16 4-1/4 6-11/16 1/2 1 2 0.88 2.30

1/2 697124 0.98 0.55 1.00 2 7-13/16 4-1/4 6-11/16 1/2 1 2 0.88 2.25

9/16 697125 1.26 0.61 1.19 2-1/4 9-9/16 5-5/16 8-1/8 5/8 1-1/4 2-1/2 1.13 4.60

5/8 697126 1.26 0.67 1.19 2-1/4 9-9/16 5-5/16 8-1/8 5/8 1-1/4 2-1/2 1.13 4.50

3/4 697127 1.55 0.80 1.38 2-3/4 11-11/16 6-3/8 10 3/4 1-1/2 3 1.38 7.80

7/8 697128 1.70 0.94 1.63 3-1/4 13-5/8 7-7/16 11-5/8 15/16 1-3/4 3-3/8 1.50 11.70

1 697129 1.98 1.06 2.00 3-3/4 15-5/8 8-1/2 13-3/8 1-1/32 2 4 1.75 17.80

1-1/8 697130 2.25 1.19 2.25 4-1/4 17-1/2 9-9/16 15 1-3/16 2-1/4 4-1/2 2.00 29.70

1-1/4 697131 2.53 1.33 2.50 4-3/4 19-7/16 10-5/8 16-1/2 1-3/16 2-1/2 5 2.25 36.00

1-3/8 697132 2.80 1.45 2.50 5-1/4 21-1/4 11-11/16 18-1/8 1-5/16 2-1/2 5-1/4 2.50 47.00

1-3/4 697134 3.39 1.86 3.50 6-3/4 27-1/8 14-7/8 23 1-11/16 3-1/2 7 3.00 93.00

CHAI N & R I GGI NG ATTACHMEN TS (C MR P -6)

W WW. C M W O R K S . CO M PHONE: 800.888.0985 107

RIGGING HARDWARE

SWAGE SOCKET (CLOSED)

SIZES: 5/16 TO 1-1/2 IN.

BENEFITS & FEATURES B A

Forged from fine grain, special bar

quality C-1035 steel

Spheroidized annealed for cold swaging

Recommended for use on 6" x 19" or H

L

6" x 37" IWRC regular lay wire ropes.

Can also be used on galvanized bridge rope. K

Not for use on fiber core or lang lay ropes.

Sockets have 100% efficiency rating based

on catalog strength of wire rope when

properly applied

D

E C

Size Product Dimensions (in.) After Swage Weight

(in.) Code Diameter (lbs.)

A B C D E H K L (in.)

5/16 697152 0.77 0.34 1-11/16 0.88 11/16 3-3/16 5-1/2 4-1/2 0.69 0.79

3/8 697153 0.77 0.41 1-11/16 0.88 11/16 3-3/16 5-1/2 4-1/2 0.69 0.78

7/16 697154 0.98 0.48 2 1.06 7/8 4-1/4 6-15/16 5-3/4 0.88 1.45

1/2 697155 0.98 0.55 2 1.06 7/8 4-1/4 6-15/16 5-3/4 0.88 1.38

9/16 697156 1.26 0.61 2-1/2 1.25 1-1/8 5-5/16 8-3/4 7-1/4 1.13 2.78

5/8 697157 1.26 0.67 2-1/2 1.25 1-1/8 5-5/16 8-3/4 7-1/4 1.13 2.75

7/8 697159 1.70 0.94 3-1/2 1.69 1-1/2 7-7/16 12-1/8 10-1/8 1.50 7.50

1-1/4 697162 2.53 1.33 5 2.56 2-1/4 10-5/8 17-1/4 14-3/8 2.25 23.00

1-3/8 697163 2.80 1.45 5-1/4 2.56 2-1/4 11-11/16 18-7/8 15-3/4 2.50 31.00

1-1/2 697164 3.08 1.58 5-1/2 2.81 2-1/2 12-3/4 20-3/8 17 2.75 39.00

RIGGING HARDWARE

SWAGE BUTTON

FOR ROPE DIAMETERS: 1/8 TO 1-1/8 IN.

BENEFITS & FEATURES

Fittings machined from specially selected

and processed low carbon steel

Buttons have 98% efficiency rating based on catalog

strength of wire rope when properly applied

Rope Diameter Product Dimensions (in.) Weight

(in.) Code Wi P (lbs.)

1/8 697101 0.38 0.63 0.03

3/16 697102 0.50 0.88 0.05

5/16 697104 0.75 1.38 0.16

3/8 697105 0.75 1.75 0.19

1/2 697107 1.13 2.19 0.54

5/8 697109 1.38 2.88 1.06

3/4 697110 1.50 3.25 1.36

7/8 697111 1.75 3.88 2.19

1 697112 2.00 4.38 3.15

1-1/8 697113 2.25 4.81 4.58

Wi

C H A I N & R I G G I N G AT TA CHM ENT S (CM RP -6 )

108 PHONE: 800.888.0985 WWW.C M W OR K S .C OM

RIGGING HARDWARE

SWAGING SLEEVE FOR FLEMISH EYE

FOR ROPE DIAMETERS: 1/4 TO 2-1/2 IN.

BENEFITS & FEATURES

Carbon steel sleeves come with unique Seamless construction

color change quality control feature – color Fits standard industry dies

changes intensity once sleeve has been Mill-certified, annealed low-carbon

pressed verifying that swaging has occurred steel provides consistent

Zinc plating extends shelf life swaging without cracking

and resists rusting No need for 16th size dies

Color coding helps determine size (O.D. of 16th sizes same as

and simplifies inventory next largest sleeve size).

Wi1 Wi Wo

P1

P

Rope Dimensions (in.) Wall Diameter

Diameter Color Standard Product Thickness

hickness After Swage Weight

(in.) Package Code P Wo Wi1 Wi P1 (in.) (in.) (lbs.))

(lbs

0.250 Gold 250 697180 1.00 0.66 0.33 0.47 0.28 0.09 0.50 0.04

0.312 Red 200 697181 1.50 0.91 0.44 0.61 0.47 0.14 0.73 0.14

0.375 Green 100 697182 1.50 0.91 0.47 0.66 0.47 0.13 0.73 0.12

0.500 Gold 50 697184 2.00 1.22 0.63 0.91 0.59 0.16 0.98 0.28

0.625 Green 25 697186 2.75 1.47 0.75 1.09 0.70 0.19 1.20 0.56

0.750 Blue 20 697187 3.19 1.72 0.92 1.28 0.86 0.22 1.41 0.88

0.875 Gold 10 697188 3.56 2.01 1.01 1.53 1.00 0.25 1.63 1.38

1.000 Self Colored 10 697189 4.00 2.28 1.16 1.72 1.13 0.28 1.88 1.90

1.250 Self Colored Bulk 697191 5.20 2.78 1.47 2.16 1.41 0.31 2.27 3.40

1.500 Self Colored Bulk 697193 6.25 3.25 1.69 2.63 1.69 0.31 2.65 5.00

1.750 Self Colored Bulk 697194 7.25 3.84 1.94 3.13 1.97 0.36 3.04 8.40

2.000 Self Colored Bulk 697195 8.50 4.38 2.25 3.63 2.25 0.38 3.50 11.30

HARDWARE

2.250 Self Colored Bulk 697196 9.56 5.03 2.50 4.03 2.53 0.50 4.06 19.20

800

2.500 Self Colored Bulk 697197 10.50 5.50 2.75 4.50 2.81 0.50 4.44 23.20

®

HERC-ALLOY

RIGGING

CHAI N & R I GGI NG ATTACHMEN TS (C MR P -6)

W WW. C M W O R K S . CO M PHONE: 800.888.0985 109

RIGGING HARDWARE

TURNBUCKLES

WORKING LOAD LIMIT: 400 TO 21,400 LBS.

BENEFITS & FEATURES

Turnbuckles can be used to apply tension Apply turnbuckles in a straight in-line

to wire rope or cable. manner only. Do not allow anything

Composed of a forged body and two end fittings. to contact the turnbuckle body or

End fittings can be eyes, jaws, or hooks. end attachment threaded shanks.

Must only be applied to loads within Apply load to the center of end

their working load limit as specified for attachment eyes and bowl of

the particular end fitting being applied. hooks. Do not tip load hooks

or side load eyes.

Eye & Eye Jaw & Eye Jaw & Jaw Thread Take

Eye & Eye WLL Weight

Product Weight Product Weight Product Weight Diameter Up (lbs.) (lbs.)

Code (lbs.) Code (lbs.) Code (lbs.) (in.) (in.)

0404EE 0.3 0404JE 0.3 0404JJ 0.4 1/4 4 500 0.4

Jaw & Eye 0504EE 0.5 0504JE 0.5 0504JJ 0.6 5/16 4.5 800 0.6

0606EE 0.8 0606JE 0.9 0606JJ 0.9 3/8 6 1,200 0.9

0806EE 1.5 0806JE 1.7 0806JJ 1.8 1/2 6 2,200 1.8

0809EE 1.9 0809JE 2.0 0809JJ 2.1 1/2 9 2,200 2.1

Jaw & Jaw 0812EE 2.3 0812JE 2.4 0812JJ 2.4 1/2 12 2,200 2.4

1006EE 2.5 1006JE 3.0 1006JJ 3.0 5/8 6 3,500 3.0

1009EE 3.3 1009JE 3.5 1009JJ 3.7 5/8 9 3,500 3.7

1012EE 3.8 1012JE 4.0 1012JJ 4.2 5/8 12 3,500 4.2

Hook & Eye 1206EE 3.9 1206JE 4.3 1206JJ 4.6 3/4 6 5,200 4.6

1209EE 4.8 1209JE 5.1 1209JJ 5.4 3/4 9 5,200 5.4

1212EE 5.4 1212JE 5.7 1212JJ 6.0 3/4 12 5,200 6.0

1218EE 7.0 1218JE 7.3 1218JJ 7.7 3/4 18 5,200 7.7

1412EE 7.4 1412JE 7.9 1412JJ 8.4 7/8 12 7,200 8.4

Hook & Hook

1418EE 9.6 1418JE 10.2 1418JJ 10.7 7/8 18 7,200 10.7

1606EE 9.0 1606JE 9.4 1606JJ 9.7 1 6 10,000 9.7

CARE & INSPECTION 1612EE 11.2 1612JE 11.6 1612JJ 11.9 1 12 10,000 11.9

Inspect turnbuckles before use for bent components 1618EE 13.8 1618JE 14.3 1618JJ 14.8 1 18 10,000 14.8

and worn threads. Do not use if body or end fitting 1624EE 17.1 1624JE 17.6 1624JJ 18.2 1 24 10,000 18.2

is bent more than 10º from the axial center line. 2012EE 20.9 – – 2012JJ 23.8 1-1/4 12 15,200 23.8

Do not use if threads are visibly worn or feel loose.

HARDWARE

800

2018EE 25.7 – – 2018JJ 27.5 1-1/4 18 15,200 27.5

If in doubt, consult a rigging handbook or discuss

2024EE 29.7 – – 2024JJ 33.7 1-1/4 24 15,200 33.7

with a qualified person.

®

2412EE 29 – – 2412JJ 38.1 1-1/2 12 21,400 38.1

HERC-ALLOY

2418EE 35.2 – – 2418JJ 44.2 1-1/2 18 21,400 44.2

2424EE 40.7 – – 2424JJ 48.4 1-1/2 24 21,400 48.4

RIGGING

Imported.

Improper use or care of turnbuckles can result

in bodily injury or property damage. To avoid injury:

V Inspect turnbuckles for distortion and wear. Product Code Thread Diameter Take Up WLL Weight

V Do not use if anything is in contact with the turnbuckle (in.) (in.) (lbs.) (lbs.)

Hook & Eye Hook & Hook

body or an end fitting.

V Only apply load to center of eyes and bowl of hooks. 0404HE 0404HH 1/4 4 400 –

V Do not exceed working load limit. 0504HE 0504HH 5/16 4-1/2 700 –

0606HE 0606HH 3/8 6 1,000 0.8

0806HE 0806HH 1/2 6 1,500 1.5

0809HE 0809HH 1/2 9 1,500 1.9

0812HE 0812HH 1/2 12 1,500 2.3

TURNBUCKLEE 1006HE 1006HH 5/8 6 2,250 2.5

LOCK NUTS 1009HE 1009HH 5/8 9 2,250 3.3

Product Code 1012HE 1012HH 5/8 12 2,250 3.8

Size Weight 1206HE 1206HH 3/4 6 3,000 3.9

(in.) Right Hang Nut Left Hang Nut (lbs

(lbs.))

1209HE 1209HH 3/4 9 3,000 4.8

1/4 3X845 3X845L 0.005 1212HE 1212HH 3/4 12 3,000 5.4

5/16 – 3X846L 0.008 1218HE 1218HH 3/4 18 3,000 7.0

3/8 3X847 3X847L 0.010 1412HE 1412HH 7/8 12 4,000 7.4

1/2 3X849 3X849L 0.030 1418HE 1418HH 7/8 18 4,000 9.6

5/8 – 3X850L 0.050 1606HE 1606HH 1 6 5,000 9.0

3/4 – 3X851L 0.090 1612HE 1612HH 1 12 5,000 11.2

7/8 – 3X852L 0.130 1618HE 1618HH 1 18 5,000 13.8

1 – 3X853L 0.200 1624HE 1624HH 1 24 5,000 17.1

1-1/4 – 3X855L 0.410 2418HE 2418HH 1-1/2 18 7,500 31.2

1-1/2 – 3X866L 0.700 2424HE 2424HH 1-1/2 24 7,500 38.2

Imported. Hot Dip Galvanized. Imported.

CHAI N & R I GGI NG ATTACHMEN TS (C MR P -6)

W WW. C M W O R K S . CO M PHONE: 800.888.0985 103

You might also like

- GRAPAS CMDocument1 pageGRAPAS CMjm467191No ratings yet

- Catalogo Acoplamientos LovejoyDocument1 pageCatalogo Acoplamientos Lovejoythejuanvi84No ratings yet

- 1054-Tube Fittings 2011 WebDocument34 pages1054-Tube Fittings 2011 WebAli KianersiNo ratings yet

- Accessories MuellerDocument3 pagesAccessories MuellerFabio Moacir KorndoerferNo ratings yet

- Dimensiuni NPTDocument2 pagesDimensiuni NPTGrosu CosminNo ratings yet

- Rotary Turbine Vibrator Series OT 4Document1 pageRotary Turbine Vibrator Series OT 4Kalaimadasamy SubramanianNo ratings yet

- Pages From CatelogDocument21 pagesPages From CatelogMoAmen AtlamNo ratings yet

- Ficha Tecnica GrampasDocument1 pageFicha Tecnica GrampasValentina VelosoNo ratings yet

- Hoja de Metrados: Proyecto: Etapa: 0 #Parcial Partida Descripcion Cant. Veces Long. 1/4Document25 pagesHoja de Metrados: Proyecto: Etapa: 0 #Parcial Partida Descripcion Cant. Veces Long. 1/4Aldo Eduardo Orocaja MoránNo ratings yet

- Eye Bolt StandardsDocument5 pagesEye Bolt Standardsnilesh tadhaNo ratings yet

- CT-REINFORCING STEEL CUT LISTDocument1 pageCT-REINFORCING STEEL CUT LISTJonathan MartinezNo ratings yet

- Dimensions of Sockolets Pressure Class 3000 and 6000 Lbs MSS SP97 PDFDocument3 pagesDimensions of Sockolets Pressure Class 3000 and 6000 Lbs MSS SP97 PDFmarkoredsNo ratings yet

- MBRF10200CT SangdestmicroelectronicsDocument7 pagesMBRF10200CT SangdestmicroelectronicsАлексей ГомоновNo ratings yet

- M - Stainless Steel Take Up FramesDocument4 pagesM - Stainless Steel Take Up FramesKyriakos MichalakiNo ratings yet

- Asc Instrumentation Catalogue PDFDocument59 pagesAsc Instrumentation Catalogue PDFAmardeep Steel SalesNo ratings yet

- I01 Series Output Power ChokesDocument2 pagesI01 Series Output Power ChokesPaul TurnetNo ratings yet

- Ind. Hyd - Adator Thread Data PDFDocument3 pagesInd. Hyd - Adator Thread Data PDFlangkanNo ratings yet

- Volume DM Plant FinalDocument28 pagesVolume DM Plant Finalkrisyanto krisyantoNo ratings yet

- Borewell Submersible PumpsDocument26 pagesBorewell Submersible PumpsAshokNo ratings yet

- How To Calculate Filler Metal ConsumptionDocument3 pagesHow To Calculate Filler Metal ConsumptionASHIL PRABHAKAR100% (2)

- WRC 329 1987 Accuracy of Stress Intensification Factors For Branch Connections Part3 PDFDocument11 pagesWRC 329 1987 Accuracy of Stress Intensification Factors For Branch Connections Part3 PDFHarsh MatoliyaNo ratings yet

- 45° Flare Fittings: Copper Flare Bonnets and GasketsDocument9 pages45° Flare Fittings: Copper Flare Bonnets and GasketsMinh VănNo ratings yet

- Project: Cadangan Klinik Kesihatan 4 Dengan Kuarters, Pengkalan Hulu, Hulu Perak, Perak (Ibs Sepenuhnya)Document5 pagesProject: Cadangan Klinik Kesihatan 4 Dengan Kuarters, Pengkalan Hulu, Hulu Perak, Perak (Ibs Sepenuhnya)faiz salimNo ratings yet

- Optimize the CHUMACERA CATALOG title to 40 characters or lessDocument37 pagesOptimize the CHUMACERA CATALOG title to 40 characters or lessGilberto Garcia100% (1)

- Hydradine o RingDocument1 pageHydradine o RingRomankoNo ratings yet

- Alc-10030c Alcotec Alloy Selection BrochureDocument2 pagesAlc-10030c Alcotec Alloy Selection BrochurefogdartNo ratings yet

- Dewpoint Copper DPC-0118-C Product CatalogueDocument2 pagesDewpoint Copper DPC-0118-C Product Cataloguemye ryeNo ratings yet

- Ancla Mecanica DylDocument1 pageAncla Mecanica Dyljose guzmanNo ratings yet

- Handtool AigoDocument10 pagesHandtool AigoDennis SetiawanNo ratings yet

- Descripcion: EstructurasDocument31 pagesDescripcion: EstructurasRenzo Vidalon NoriegasNo ratings yet

- Weatherproof cable gland dimensions and specificationsDocument1 pageWeatherproof cable gland dimensions and specificationsAkil VohraNo ratings yet

- 3"-48" Ductile Iron Mechanical Joint Fittings Class 350Document11 pages3"-48" Ductile Iron Mechanical Joint Fittings Class 350MIGUEL MIGUEL RIVAS SALCEDONo ratings yet

- DODGE Bearing PDFDocument39 pagesDODGE Bearing PDFFATHYNo ratings yet

- Autoclave DimensionsDocument1 pageAutoclave DimensionsAttila SolyomNo ratings yet

- Identification MarkingDocument13 pagesIdentification Markingsai harshaNo ratings yet

- HaydroDocument4 pagesHaydroyakob mesheshaNo ratings yet

- 2 Resorte Anchor Lamina Pulgadas PDFDocument16 pages2 Resorte Anchor Lamina Pulgadas PDFJhon Jairo VásquezNo ratings yet

- VDTE101016Document1 pageVDTE101016QA TEAMNo ratings yet

- Ficha TecnicaDocument1 pageFicha TecnicaDaniel VillalbaNo ratings yet

- 250-AF IomDocument2 pages250-AF IomyogitatanavadeNo ratings yet

- Straight Fittings: Male ConnectorsDocument1 pageStraight Fittings: Male ConnectorsdeckyirawansusantoNo ratings yet

- Volume GutterDocument2 pagesVolume GutterAnnisaNo ratings yet

- Section 1 Section 1: General InformationDocument1 pageSection 1 Section 1: General InformationNikNo ratings yet

- Form Work NO Length Width Area: 1 0.8 0.6 0.48 Axis F14, C11Document117 pagesForm Work NO Length Width Area: 1 0.8 0.6 0.48 Axis F14, C11halieyNo ratings yet

- (Inch) (MM) (Per Inch) (Per CM) (Kcmil) (MM ) ( /KM) ( /KFTDocument6 pages(Inch) (MM) (Per Inch) (Per CM) (Kcmil) (MM ) ( /KM) ( /KFTMuhammad Reihan IskandarNo ratings yet

- Bare copper conductor data and standardsDocument1 pageBare copper conductor data and standardsDiana AkmaliahNo ratings yet

- Zapata Solado Muros DetalleDocument28 pagesZapata Solado Muros DetalleErick Vasquez GutierrezNo ratings yet

- 02 Wear ChartDocument2 pages02 Wear ChartRIAN NOFENDRINo ratings yet

- HTL Nut Splitters: Features and BenefitsDocument2 pagesHTL Nut Splitters: Features and BenefitsJeffNo ratings yet

- SCI Bronze FittingsDocument10 pagesSCI Bronze Fittingsfire123123123No ratings yet

- Mil DTL 25995e - Amendment 1Document15 pagesMil DTL 25995e - Amendment 1Tejaswini DawareNo ratings yet

- Proposed pilot plant for pharmaceutical calcium carbonateDocument1 pageProposed pilot plant for pharmaceutical calcium carbonateHenry DiyokeNo ratings yet

- NEW Inverter Light: Samsung Slim 1-Way CassetteDocument2 pagesNEW Inverter Light: Samsung Slim 1-Way CassetteDinesh GuptaNo ratings yet

- Bar Bending Schedule LPG Area - CommentDocument1 pageBar Bending Schedule LPG Area - CommentRezkyNo ratings yet

- Tech Tips: Fitting Torque ChartDocument7 pagesTech Tips: Fitting Torque ChartAnthony David Martínez VallejoNo ratings yet

- Oval Flage DimensionsDocument2 pagesOval Flage DimensionsAnkit LonareNo ratings yet

- MVE 500/15E-40A0 Electric Motor SpecsDocument1 pageMVE 500/15E-40A0 Electric Motor SpecsAmol SarinNo ratings yet

- 19075.8.5 DS Generators Electrical 1Document2 pages19075.8.5 DS Generators Electrical 1Tran Thi DungNo ratings yet

- MOH Ratnapura02Document29 pagesMOH Ratnapura02isurupushNo ratings yet

- SW Synthetics Catalog PDFDocument27 pagesSW Synthetics Catalog PDFLC ChongNo ratings yet

- Suncor Catalog PDFDocument166 pagesSuncor Catalog PDFLC ChongNo ratings yet

- SW Synthetics Catalog PDFDocument27 pagesSW Synthetics Catalog PDFLC ChongNo ratings yet

- Grease Pump LAGG 18AE SKFDocument3 pagesGrease Pump LAGG 18AE SKFLC ChongNo ratings yet

- SennheisserDocument1 pageSennheisserLC ChongNo ratings yet

- Anchor Marine Page 19 PDFDocument1 pageAnchor Marine Page 19 PDFLC ChongNo ratings yet

- Usha Martin Wirerope HandbookDocument72 pagesUsha Martin Wirerope Handbookhaydarburedah100% (2)

- SW Synthetics Catalog PDFDocument27 pagesSW Synthetics Catalog PDFLC ChongNo ratings yet

- Anchor Marine Page 19Document1 pageAnchor Marine Page 19LC ChongNo ratings yet

- Chart Suggestions - A Thought-StarterDocument1 pageChart Suggestions - A Thought-StarterDoc AllaínNo ratings yet

- Standard Stockless Anchor Dimensions ChartDocument1 pageStandard Stockless Anchor Dimensions ChartLC ChongNo ratings yet

- R091952 PDFDocument5 pagesR091952 PDFLC ChongNo ratings yet

- Anchor DesignDocument1 pageAnchor DesignLC ChongNo ratings yet

- Anchor Marine Design 190 PDFDocument1 pageAnchor Marine Design 190 PDFLC ChongNo ratings yet

- Anchor Marine 190 PDFDocument1 pageAnchor Marine 190 PDFLC ChongNo ratings yet

- 01 Rail Track PDFDocument2 pages01 Rail Track PDFLC ChongNo ratings yet

- ZaDocument2 pagesZaLC ChongNo ratings yet

- D 471 - 06 PDFDocument13 pagesD 471 - 06 PDFLC Chong100% (1)

- Busbar System PDFDocument4 pagesBusbar System PDFLC ChongNo ratings yet

- AsdfDocument3 pagesAsdfLC ChongNo ratings yet

- R09414 PDFDocument9 pagesR09414 PDFLC ChongNo ratings yet

- SadDocument2 pagesSadLC ChongNo ratings yet

- SDS for LGGB 2 lubricantDocument6 pagesSDS for LGGB 2 lubricantLC ChongNo ratings yet

- Copper Alloy Continuous Castings: Standard Specification ForDocument9 pagesCopper Alloy Continuous Castings: Standard Specification ForLC ChongNo ratings yet

- Hoop StressDocument9 pagesHoop Stressalexintel100% (1)

- General Requirements For Copper Alloy CastingsDocument6 pagesGeneral Requirements For Copper Alloy CastingsLC Chong100% (1)

- Bolt Tightening TorqueDocument10 pagesBolt Tightening Torquekb7401100% (1)

- AAR M-201 - Norma Fundido para TremDocument66 pagesAAR M-201 - Norma Fundido para TremFlavioNocelliNo ratings yet

- List of ManufacturersDocument12 pagesList of Manufacturerswalid abou kachfeNo ratings yet

- Client: Hindustan Petroleum Corporation Limited Project: Vizag Refinery Modernization Project (VRMP)Document53 pagesClient: Hindustan Petroleum Corporation Limited Project: Vizag Refinery Modernization Project (VRMP)jaganNo ratings yet

- OSHJ-CoP-07 Management of Hot Work Version 1 EnglishDocument11 pagesOSHJ-CoP-07 Management of Hot Work Version 1 EnglishsajinNo ratings yet

- Catalogo Proteccciones PVC Antibacterial 2023 Arfen Sercion GuatemalaDocument14 pagesCatalogo Proteccciones PVC Antibacterial 2023 Arfen Sercion Guatemalaalvaradolu85No ratings yet

- Series: C80/C89 C70/C74Document12 pagesSeries: C80/C89 C70/C74Anupam MehraNo ratings yet

- RACK Industrial Rack Storage Solutions by RFLDocument12 pagesRACK Industrial Rack Storage Solutions by RFLbelal545No ratings yet

- Astm B 316 Acero InoxidableDocument9 pagesAstm B 316 Acero InoxidableMajo BárcenasNo ratings yet

- Casting Notes MechanicalDocument21 pagesCasting Notes MechanicalKharbal AkashNo ratings yet

- HCW June 2020Document52 pagesHCW June 2020Anoop G PillaiNo ratings yet

- Diamond EssentialsDocument260 pagesDiamond EssentialsBergen100% (1)

- Capstan LatheDocument18 pagesCapstan LatheAditya SatopeNo ratings yet

- BST Gen Cns Mos Aip 10003 10002 00 Pin BrazingDocument67 pagesBST Gen Cns Mos Aip 10003 10002 00 Pin BrazingRao DharmaNo ratings yet

- Final VD 2015Document138 pagesFinal VD 2015VinayAgrawalNo ratings yet

- Purge Gas vs Backing Flux for Stainless Steel Pipe WeldsDocument3 pagesPurge Gas vs Backing Flux for Stainless Steel Pipe Weldshareesh13hNo ratings yet

- 606 Universal Shelving System Price ListDocument4 pages606 Universal Shelving System Price ListArtemis PapachristouNo ratings yet

- 1.2.4 HDG - Painting Issues PDFDocument2 pages1.2.4 HDG - Painting Issues PDFAnonymous 1AAjd0No ratings yet

- MIL-F-5509D - Fittings, Flared Tube, Fluid ConnectionDocument18 pagesMIL-F-5509D - Fittings, Flared Tube, Fluid ConnectionthomasNo ratings yet

- Htpro: Low-Temperature Surface Hardening of Stainless Steel: Christiansen, Thomas Lundin Somers, Marcel A. JDocument3 pagesHtpro: Low-Temperature Surface Hardening of Stainless Steel: Christiansen, Thomas Lundin Somers, Marcel A. Jsabounchimarzieh1995No ratings yet

- Pressure Gauge: Aschroft or EqualDocument1 pagePressure Gauge: Aschroft or EqualRendy AlfasyahNo ratings yet

- High-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)Document4 pagesHigh-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)indityoNo ratings yet

- Radiographic Examination Report of Pipeline WeldsDocument1 pageRadiographic Examination Report of Pipeline WeldsMd Ashikur RahmanNo ratings yet

- Switch de Presion BARKSDALEDocument2 pagesSwitch de Presion BARKSDALEEduardoMiullerNo ratings yet

- Post Head Damage Repair ProcedureDocument12 pagesPost Head Damage Repair Procedureddfp enerlandNo ratings yet

- Microvia: Microvias Are Used As The Interconnects Between Layers in High Density Interconnect (HDI) Substrates andDocument3 pagesMicrovia: Microvias Are Used As The Interconnects Between Layers in High Density Interconnect (HDI) Substrates andMadhusudanan AshokNo ratings yet

- Die-Materials classEDITDocument45 pagesDie-Materials classEDITSatya AsatyaNo ratings yet

- Konsport... (Broșură) - IndustrialDocument30 pagesKonsport... (Broșură) - IndustrialVieru DumitruNo ratings yet

- ASHLOKDocument4 pagesASHLOKevolve energyNo ratings yet

- TN28B Brick Veneer Steel Stud WallsDocument15 pagesTN28B Brick Veneer Steel Stud WallsKen SuNo ratings yet

- Hexalobular Metric Thread Forming ScrewsDocument3 pagesHexalobular Metric Thread Forming ScrewsRodrigo AugustoNo ratings yet

- Mcqs FitterDocument64 pagesMcqs FitterdaasapNo ratings yet