Professional Documents

Culture Documents

19 Eti Psi 132 (8 89)

Uploaded by

pradeeepgarg0 ratings0% found this document useful (0 votes)

65 views45 pagesOHE Specs

Original Title

19-ETI-PSI-132-(8-89)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOHE Specs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

65 views45 pages19 Eti Psi 132 (8 89)

Uploaded by

pradeeepgargOHE Specs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 45

CARRIAGE DIRECTORATE

COMPUTER WING

COVERING LETTER

‘SUBJECT: SCANNINGIDIGITISATION/INDEXING OF OFFIGALDOCUMENTS OF DIFFERENT DIRECTORATES OF

DSO

NAME OF THE DIRECTORATE —

NAME OF THE SUB-

DIRECTORATE/SECTION

NAME & DESIGNATION OF THE SCANNING.

ORDINATION OFFICER/STAFF

ima

[CH

NAME OF THE RECORD/FILE/

“| DOCUMENT/SPECIFICATION etc. AND ITS

VOLUME/VERSION

| TOTAL NO OF PAGES/IMAGES:

Aina!

2A-

ce ETE LRG PD Go

bai 20 (e/as)= i

Total < Yoret 46 ~ BoNwhy,

NAME, SIGNATURE AND DESIGNATION OF

THE HANDING OVER RDSO OFFICIAL,

CAT

NAME, SIGNATURE AND DESIGNATION OF

THE TAKING OVER CMC OFFICIAL

Js ~ 2ilec\re

wall

uv

DATE OF HANDING OVER FILE/DOGUMENT

etc,

W]e} pe

FIELDS FOR INDEXING

7 | Type of Document (File?

DRAWING/TECHNICAL

CIRCULAR/MODIFICATION

2 | Document No.

SHEET/SPECIFICATIONINP) _

‘3 )SURIECT

4 | SUB-SUBJECT

5 | VOLUME -

[6 | St No.

7 | DATE OF CREATION OF FILE

i [8 -}Dealer

10 DATE OF RECEIVING BACK THE

DOCUMENT |

1

NAME, SIGNATURE AND DESIGNATICNOF

THE RISO OFFICAL RECEIVING BACK

THE DOCUMENT AFTER SCANNING

(No of papers to be checked by department)

2

REMARiS/FEEDBACK IF ANY

(Quality of documents. Jobe checked by

| departinant

A) COMPUTER GENERATED GOOD

QUALITY

8) COMPUTER GENERATED (DOT

MATRIX)

C) TYPE WRITTEN

D) HAND WRITTEN

| 20 qe"

ac igas cep an aaa NADIA SS

ea

ae

eng sateen

LER

GOVERNMENT OF INDIA

Sg

a

a

a

ag

ag

a

ag

PA

SC

MINISTRY CF RAILWAYS

meen tne 3

25 AC DOUBLE POLE, OUTDOOR;

VACUUM [NTERRUPTORS

FOR

RAILWAY-SWITCHING STATIONS

FOR

1x25 RY AT FEEDING SYSTEN

RGORR

—*

gy

rm

e:

ce

ee

©

g

ai

a

9

2

ra

ca

ies

bey

3

w

g

=

ioe)

MN

3

oo

S

AUGUSY 1989

126926

AAS

ISSUED BY

LLATIOM DIRECTORATE

ANDARDS ORGANISATION

LUCKNOW—226011

TRAC.

RESEARCH Di

Addendum & Corrigendum Slip N

(11/92) to Specificatian

, No. ETI/PS1/132 (8/89) for 2! ac double pole vacuum

he Interruptor far 2x25kV AT feeding system. .

Page 15 Replace Une clause by as under?

Clause 15.4

f “Only after, al) the design, and

drawings have been approved and

clearance given by RDSD to this effect,

Lhe manufacturer shall take up

manufacture of Prototype unit for

RUSO'S inspection/testing. it is to be

clearly understood that any change

required le be done on prokotype, as

required by RDSU shall be dene

expeditiously.

Prior to yiving call to the

Purchaser/Director Gernera, Traction

Installation, Research Designs and

Standards Organisation, Lucknow

(hereafter abbreviated as DG/TI/RDSO.

Lucknow) for inspection and testing af

the prototype, the successful

lenderer/wanufacturer shall submit a

detailed lest schedule consisting of

schematic circuil diagrams for each of

the tests and the number of days

required to complete all the tests at

ang stretch. The schedule shal), also

indicate the venue of each of the

tests. Once the schedule is Approved,

Whe test shall invariably be done

accordingly. However, during — the

process of type testing or even later,

the purchaser reserves the right to

nduct any additional test(s), besides

those specified herein, on any

equipment/item so as to test the

equipment/item le his satisfaction or

for gaining additional information and

knowledge. In case any dispute or

disaqrecment ari between successful

Loenderer/manutackurer and the

representalive af the purchase 7 DG 7

TE/RDSU, Lucknow durang the process of

testing as regards the procedure for

tyee tests and/or the interpretation and

acceplabilily of the results of type

tosis, Gb Shall be brought to lhe

notice of the purchaser /DG/TL/RDSO,

Lucknow as the case way be,

whose

126927

decision shall bé final and binding.

Gniy “ After the prototype of tie

equipment is manufactured and ready in

; all respects, shall the

| tenderer/manufacturer

call for the

successful

give the actual

inspection «and ~ testing

with wat’ least, 45.days notice for the

purposes °°

vin the event of the tests nol

beang’ carried through to completion at

one Stretch ~ for any reason

attributable vo

the

successful

enderer/manufacturer and it

required for the

representative of the

Pugchaser/DG/TI/RVSU, Lucknow Lo ao

again’ or more number of

times to the

works ““of" thes successful tenderer 7

manufacturer and

it is required for tne

representative of the purchaser/DG/TL/

RDSO, Lucknow to go again. or more

number” of times ta the Works of the

Successful | Lenderer/manufacturer op

other place(s) for continuing and/or

completing the tests on the

pratotype(s) of the equipment, the

Hecessful bonderer/manufacturer shat

reimburse tn the

purchaser /DG/T2/RDSO

the cost for the representative (#)

having to visit the works or other

Places(s) for the tests more than once.

the “zCost as claimed by the purchaser /

DO/TI/RUSO, Lucknow shall be paid

‘hrough a Demand Draft to the concerned

Accounts Officer of the Purchaser/DG/T11

RDSO, Lucknow as shall be advised to

the successful tenderer /manufacturer.

fhe following tests shall be

conducted on the

Prototype unit of the

equipment at works of the

manufacturer

or at a reputed testing laboratory in

Presence | of purchase/DG/TL, — RDSO,

Lucknow or his authorised

representative. The prototype af the

equipment shall be complete in ali

respects, asswould be supplied = if it

passes the tests.

Terminal connectors

include the part of the

bho equipment. “The bests

conducted as

shall ab

protalyye of

shali be

per relevant

Governing Specification and as modified

r"anplified. as under.

utdoor: vacuum eed

28 Bar Peak System.

Replace the existing clause by:

the centre "to centre distance of the

poles of the interrupters. shall be

1500 mn.

| Road the existing mbter as follows:

32(a),Minimum clearance between

live part and earth (in air) .. mm

(>) “Minimum electrical clearance

“* between two poles(in air) fe mm

(c) “Centre to centre distance

between the poles. Be mn

126928

fay

2 uy 99

Addendum & Corrigendum slip No.2 of August J9¥1 to

specification No-ENI/PS1/132(8/89) for 29 kV nec. double

pole; outdoor. vucuum Interruptors ror 2x25 kv AY Feeding

system.

Clause No-14 Galvanising : Add a sud-clause 14.

existing clause 14.1, as under.

alter

16.2 If the tenderer/menufacturer is uot able to

hot-dip gelvenise the steel operating mechanism cubicle

and steel supporting frame as per Clause 14, tne item

Shall beve tne following corrosion prevention System

applied over them with necessary. surface preparntiony

as unaer + 7

Surface preparation

a) Removal of all é11/grease froin the metal surface

using petroleum hydrocarton solvent to 1s L7Ab-78.

b) preparation of the surface by bot phospiating to

IS 318 Class - B.

Pain ting

a) ‘priser coat - Applying by brusn/airiess spray

\ txo coats of Epoxy zinc ,

phosphate primer to xDsO

Specification fo. & C/PCN-1

86, to 60 miceon minkmum vy

film thickness.

b). Findsaing coat = Applying by vrusi/airlecs spray

two coets of polyurethase

v aluminiua finishing to RDsO

Specific M & C/pen-LlO/

88, to 40 micron mininum dry

. filo thi BSS6

deuvuuua did Lorrigendum Slip No.1 to techniccd

specification Yo.8tl/PS1/132 (8/83) for 25 KY

double ‘pole, ot door, vacuun datermptors. t

as under:

Specifi

S91ia cx

cal po

o4,

5,.Page 8," clause S.2 (tiv)

: i

/ Gr Pages10,-clause 2.9

1S Page 1L,i clause 8.18

"Page 12, clause 2.21 7h Asn

clause 9.2 At the

flanges

grado BXsS

A00/12 to a

nine a

9. Page

i "Ihe waleriaL

nat] conform to

“yo. Page'13," elause 1 (rid)

11, Page 14, clause I ‘(xi4 )

12, Page 17, clause

exeuedh

423. Page 18, claus? 2nd

14, Page 18, claune

#15. Page 12

‘ Page 19

Qh ling rout

2use 2 reas "8909 4" a5 “zago9 AN

Page 19, claus

VOB

Annomre, page 1,

atom i.

20, Page 5, item 45

D Page 9, item 74

clause 79

In case of hotlow insulatogs

all the type tests and routine te

sonal) be conducted ag per 1S

in presence 01 RDEO's representatin

In adéition, tests for cantileye

gh and withstand’ p fs

1° also be ‘cw: ie

test only.

type

_ In case of solid

nis beén uszd as support i

sane shal) de tested as

RNSO Speckfication No. st

5" as "15.6"

C #

read Shyructe

ass hrote

GOVARNMENT OF INDIA

. ’

MINISTRY OF RALLWAYS 7

GWS AND STAMDARDS ORGANISATION

HAGAR, LUCKNOW 11

SPSCIFICATION NO, ETI/PSI/132(3/89)

25 Ki DOUBLE POLE, OUTDOOR, vACUU

te SOUP

1.1 This Speci fication covers design, nanufacture, test-

ing, supply and commissioning of 25 kV'single phase, double

pole vacuuin interruptor to be installed at unattended

traction sub-stations/switching stations for controlling

power supply to the 25 kV ac traction overhead equipuent,

on Indian Railways, ©

1.2 The interruptors offered shall be complete with all

parts and accessories necessary for their efficient

operation, All such parts and accessories shall be deaned

to be within the scope of this specification wiether

specifically mentioned or not. The interruptor ‘shall be

of proven design, 5

1.3 - The interruptors shall be installed by Indian Railways

under the supervision of the tenderer vho shall, however,

commission: the ‘equipment,

2... GOVERNING SPSCLRICATEON

2.1 The interruptor, shell conform to the latest version

of Indien Standard and RDSO's Specifications of mentioned

below, and to recommendations of IM documents and Indian

Blectricity Rules, sherever epplicable.

4) TB0:56 - 1987 High voltage alternating st

currat circuit breakers. a

wo.

2) 18:996-1979 Specification for single phase ay

ac and universal electric motor.

3) 1832516 (Pt.I/-Speci fication for circuit breakers

See.3)_1972 - \"Requirenent, Section 3,

voltages above-11 KV,

4) 18:25 16(Ft.IT/ Specification for circuit breaker

Sec. 2)_ 1980 ~ Ratings, Section 2 for

a above. 1000 Vac

~ 2

specification for circuit

breaker 5?

- Type tests and routine tésts,

ne ea . Sec. 2-for-voltages above

7000 V for'use in electrical

equi prent (arst Revision).

Iss 2516(Pt. see

Sec. 2) ~ 1980.

6.: 182 2944-1973 _. ‘Speci fication: for’ porcelain

red 4 0S ‘post insulators for. systens

. with nominal voltages greater

Sete: : * than “1000 V.

7... 1825331972. ‘Methods of testing unifor-

mity of coating on zinc

: coated articles.

g. 152555811970 ~- Specification for electric

pce, b z : “power connectors.

“9. :1825621- 960 . © Specification for Hollow

iasulator for use in electrical

equipment (First Revision).

4., TS:6875(PEE)-1973 Spedi fication for control,

suitcnes (switching device

for control and auxiliary’

cireaits intluding \contac—

tor relays); =: for. voltages

upto and including) 00 V

ac’ and 1200 de

~ cmeral Fequirévents, and

tests.

11. 1527906-1976 - Speci fication’ for Helical

. : compression spring.

42. .18+7907~1976 i speci fication for Helical

“ extension spring. .

13, RDSO''s Specn. i gbeci fication for not dip

tHe, BIT/OHE/ 73(4/84) zine galverli sation.

14. HOSO's Spex. Specification for steel and

Hos S21 /088/ 84/69 stainless steel bolts, nuts

and wasters.

6

= 3-

Ary deviation from this specification proposed

py the tenderer, calculated to improve ugon the perforzance,

utility and efficicicy of the equipaent will be given due

consideration, provided full particulars of the deviation

with justification thereof are furnished, In such a case,

the téiderer shall quote according to this speci fication

and deviations, if any, proposed by him shall be quoted

as an alternative/altematives. In case of any contradic

tion between the provisions of the Indian Standards

speci fication/Recomendations of the IM and this speci fi-

2.2

.cation, the latter shall prevail.

TAACTL 0 SUPPLZ SYSTEM (2x25 KV aT

Feeding System)

3.4 General scheme.

the electric power for railway traction is

supplied in ac 50. Hz, single phase through 2x 25 KV AT

feeding system, which has a feeding voltege fron the

sub-station two times as high (2x 25 WV) as cattenary

voltage (25 IW). Tais high voltage pover supplied from

the traction sub-station throug: catenary wre and feeder

yire-is stepped dom to the catenary voltage by use of

autotransformers installed about every 13 to 17. km along the

track, and ther fed to tne locomotives. In other words,

poth the catenary voltage and feeder voltage are 25 W

vagainst the rail, although the sub-station feeding voltage

between catenary end feeder is 50 KV. Therefore, the

eatenary voltege is the same as that of the conventional

25 KI systen. ’

Since the power is supplied in two times higher

voltage, the 2x 25 kV AT feeding systen is suitable for

a large power supply, and it has the following advantages,

conpared with conventional feeding systems:

(a) less voltage drop in feeder circuit.

(b) large spacing of traction sub-station

12693;

3 telecommmication interference by

(ce) les

of AY installed with edeuuate spacing.

w

The power is obtained from 22)/2 x 25 KV Scott.

connected traction transformer or 132/2 x 25 Hl single phase

transformers, The primary windings of tne single phase

transformers sanected to two or three phases of 152 bY

three-phase ansmission network of

the #lectricity & in case of a single phase

transformer or in case of the single phase transformers

coilnected in ¥, respectively. ne other hand, ‘the

primary windings of the Scott-connected transformers are

connected to the three phases of 220 IW three-phase,

effectively earthed transmission net-work of the Electricity

Board, Tne Scott-connected transformer and V-connected

single phase transformers are effective in reducing

voltage uibalance on the transmission net-work of the

Electricity Boerd. The spacing between adjacent sub-stations

is normally between 70 to 100 !ms.

One outer side terminel of the secondary winding

of traction transformer is connected to the catmary, the

other outer side tomminal being connected to the feeder.

Tyoimer side tersinals are, via series capacitors or

directly, connected to cach other, and their joint is

solidly earthed énd connected to the running rails.

The lo.d current from the sub-station flows through

the catenary end returns to the sub-station through the

feeder. Between tuo adjacent ATs, the load current fed from

the catenary to the locomotive flows in the rail and is

boosted up to the feeder through the neutral tap of

4Ts at left end right sides of the locomotive.

At the points of sub-stetion end sectioning post,

's dead zone !now es neutral section is provided in 0H3 to

avoid & wrong phase coupling. Th? power to the catenary

and feeder on one side of tne su b-station is fed by one

feeder circuit breaker, even if there exist tw breakers

for one side, and each track is controlled by an interruptor.

The two breakers are used as a stend-by for eacn other, For

maintenance work: and keeping the voltage drop vithin limits,

one or more sudsectioning and paralleling posts (!mown es

$82) are introduced between traction sub-station and a sec-

tioning end paralleling post (Imow as 32). A SSP on 2

dowble track section normally has four sectioning

jnterrugtors for ech feeder circuit and one paralleling

jaterrugtor, In case of fault, tne feeder circuit breaker

of the sib-station isolates it.

A figure showing the principle of AT feeding system

and a typical power supply diagram shoving the general

feeding errangeuent at'a traction sub-station and sections

of the OHS are given in the sketch at the Appedix-Iand

Appendix-II. *

3.2

3.2.4

tion of traction tr

i rels

isformers?

are provided for the protec-

~5-

(a) Differential relzy.

(b) Over current relay on 22) KV or 152 kv side.

(c) Grounding overcurrest reley on 22 MV or

432 kW side.

(4) at

gh-speed overcurrent relay on 220 Ki or

2 Ki side,

(e) Phase-failure relay (to detect a malfunction

of a feeder circuit breaker).

12.8 The following relays are provided for the

otection of CHS:

28

(a) distance relay (with a parallelogram

progection characteristics). .

(>) Delte.I type faw

ctive relay.

B.S 25 kV 0:

Paramete

& and Traction Tren sformer-Blectric

3.3.1 The OnS is made up of 2 strended cadmium copper

catenary of 65 sq. mm ora stranded aluuinium alloy

eatenary of 115 sa.mm anc a grooved contact wire of ‘07 sa.

an, making up a total of 159 so.am or 149 sq.mn_ copper

equivaleit, respectively. As a feeder wire, a stranded

aluminium @lloy of 240 st.2i is used. The calculated OWE

impedance value of AT feeding circuit (OiB: Al 176-Cu

407 sqQ.nn, Feeder virex{ 41.249 sq.mwv) for a single track

line is 0.0601 + j0. 1419 olms/kn (at 25 KY system impedance)

Traction Transfomer

22x 25 NVA, 220/2x25 K Se nected transformer

anda Q UWA 132/2 x 25 IW dingle-phase transformer are

426 (at 27 HVA dase) and 12) (at 21.6 HVA base), pectively

ereentage impedance

3.4 Nature of

tsa

i

3.804 OHS (including 2 feder wire) is subjected to

frequent eart: facits causel by failure of insulation, or

by the OMB snapping and touciing the rai, th, or by @

plece of wire drcaued by birts connecting the OHE t

earthed overlying situctures, miscroant activities ete.

Taese faults 2re cLared by he Teeder circuit breaker wich

operates on any one or both 6

(a) Di stame

proke hor

(o) Delta & type fit s!

nN

3.

a

o

Nn

4

3.4.2 Short circuit level: The 22) kW and 2 KV source

impedance may be, based on a three’ph2se symmetrical short

circuit level, betieen 2000 end 10000 HV2, and between

1900 and 5000 HVA, respectively. The level of short circuit

on the 25 KV side for:a fault in the vicinity of a sub-

station could’be around 0 MVA or more. The exact short

circuit level on.25 kV side at each sub-station will be

indicated in the teider piers,

4.0

$e Toe vacuum interruptor shall be suitable for

outdoor use in moist tropibal climate and in erees subject

to heavy. rainfall, pollution due to industry and arine

atmosohere and severe lighining. The limiting weather

conditions wiich the interlustor has-to withstand in service

are indicated beloz: |

i. Mad tum anbi my air teperature - 45%

iiv Average ambient air temperature °

over a period of 24 tours = 35°C

iii. Maximum relativ) munias ty ~ 100%

iv. finqual rai: - Renging

from 175)

to 5 250mm.

v, Haximam nase tnuaecr storm

days ver annunl YS “= 85 days. ,

vi. Haximun numberlor daststorm days

/ per annua \ - 35 days.,

vii.dunbet of rein¢ day per annum - 120 days

vill. Basie wind erasure’! > 20 ke/sa.m ,

ix. #1titude i \ Not exceeding!

\ 1000 metres

, Tae interruptor puld also be subjected to

vibrations with the passagdof trains, me amplitude of these

vibrations lies in the rangi of 39 tov455 microns, wi i

instantaneous peaks g wito 350 microns, These vibrations |

occur with repidly varying ime i ge of |

Panes

i

|

5.

5.1

The interruptor s

oyS

rating and other particulars:

i)

ii)

iii)

iv) Squipwent voltage class

v)

vi)

vii)

viii)

ix)

h:

System

Nominal systea voltage

st systan voltage

wo. of poles

fated fr

eney

Rated normal current

Rated insulation level

a) One minute power

frequency withstand

voltage

») Standard impulse

withstand voltage

(4.2/50 miro.

second waveform

Rated short circuit

breaking current

(symmetrical)

Rated breaking

capacity (calculated

at @ recovery voltage

of 27.5 KV)

Reted short circuit

making carrent

Rated short time

current

Rated operating

sequence

er_particulars

hall be designed for the following

2x25 KV AT feeding

systen.

2x 25 kW

105 HY -(rms)

250 KV (peak)

12.5 ka

2 34.0 MVA

31.25 KA

12.5 KA for 3 seconds.

0-0.3 Sec.-C0-3) Sec.

-CO

126933

-8-

xiv) Out of phase rated

breaking current 23.125 KA

xv) Rating of Auxiliary

contacts:

a) Continuous current OA

10 A at 110 V de

b) Breaking currant

xvi) Total breaking time : Not more than 80

6.0

6.1 The vacuum interruptor shall be of the ae

type single bottle design, suitable for mounting on ste

single pole units operated through a coamon shaft by the

operating mechanism, The vacuum interruptor shall compri

of 2 sealed vessel with insulating side walls end metal

ends containing a fized and moving contact, The movenent

of the moving contact in the vacuum enclosure shall be

guided by means of metal bellows. Suitable shields a]

structures. It shall consist of two separate but “ty te]

sk

provided around the contacts te prevent the metal vapour

release during operation from condensing on insulating wa

of chamber Design and construction of the vacuum interrupi

shall such be that tae current chopzing level, is kept t

the minimum which does not prodce any appréciable swi tchi

over-voltages.

5.2 Te supporting structure of the interruptor sh@

be fixed on to a concrete foundation of approved design.

Details calculations for the foundation design shall b

suonitted by the tenderer. The interrupting chamber coil

sing fixed 2nd moving contacts shall be mounted on an

insulator,

é. The height of the supporting frame shall be sud

that in the erected condition of the interruptor, the

height of the lowest live part from ground or any point ™

yhere a person may stand, shall not be less than 3000 mie

The bottoa-nost portion of any insulator or bushing shall

be less than 2500 mm aoove the ground level, Also, the =

minimwa clearance betveen live parts and earth shall be

500’ iam.

5.4 The winiaum cistance between two poles shall be

1500 ma.

-9-

5 The vacuum interruptor shatl ve designed with

equate margin for the vacuun adopted.

terruptor offered shall be of proven design.

tenderer sial. produce dsounents in support of the same.

The main fixed and moving contacts of the interr-

uptor shall have ample cross-section and contact pressure

for carrying the rated current and short time current without

excessive teuperature rise, pitting 2nd welding. Arcing tips

shall b2 wade up of cupro-tungsten alioy or any other suitaole

material.

7-2

Apart from the auxiliary contacts used exclusively

}.for the functioning of the circuit breaker, at least 10 pairs

of auxiliary contacts shall be provided for the exclusive

“use of the Purchaser in conjunction with extemal circuits.

Five pairs shall be normally closed contccts and five pairs

normally opea contents, shen tie circuit breaker is in the

open position, The design of the auxiliary contact assenbly/

-shall be such tuat it shall be possible to add at least two

more addition pairs of axsiliary contacts.

SATING M SiANT Sd

‘8. o

8.4 The interruptor shall ve power operated by a motor

‘operated spring charging mechanism. The qotor shall be so

rated that the time required for fully charging the spring

does not exceed 15 seconds. Tne saring used shall be of

robust design using quality material. The closing section of

the interrustor shall actuate the opening spring so as

to be ready for instanteieous opening as and wnen required.

126934

8.2 The motor for spring charging shall be suitable for

Operation from a 110 Volt battery. The battery terainal

voltage is likely to vary between 119% and 85 of the normal

value end the voltage at the motor terminals is likely to

fall further due to drop in tne control cable.

8.5 = The mecnanisn shall normally bs for renote electrical

operation i.e, fron the control and relay panel'in the

“ sub-station and from the Remote Control Centre. Provision

shall, however, b2 aade for local electrical control aad

for this purpose 2) !Rui0TS /LOSKL' 2way selector switch

shall b? provided in the operating mechanisa cubicle. Far

-10-

jocal electrical closing and opening 2 push buttons or

mob shall also be provided on the ope ‘ating mechanism

cubicle. Operationof these imobs/push bottons shall be

possivle without opening the switcn cubicle door.

8.4 The interraptor shall also be provided with

manuelly operated local mechanical opming device for use in

emergency, i.2, in the event of failure of my sart of tie

d.c, control circuit including interruptor opening coil,

8.5 The interruptor shall also be provided vith mzaual:

operated local mechanical closing device. (

8.6 In addition to the manually operated local

mechanical opening and closing devices as indicated in

Clauses 8.3, 8.4 and 8.5 above, srovision shall also be

made by means of a suitable crank or handle for slow closing

and opening of the interruptor for meintenance purposes,

8.7 The closing device shall be suitable for operation

from 170 Volts bettery supply subject to 2 voltage variation

of + 1 to -15%. The opening device shall however be pie

for operation with voltage variation of + 1) to - 30%

8.8 in operation counter, having five digit recording

mochanisn for the n er of opening operations shall be

sO provided as to be conveniently read by the operator

standing on the ground, without opening the door of the

cubicle.

8.9 Mechanical indicators for ‘ON’ and ‘OFF! condi tion |

of the interruptor shall be provided, so that same is visible

from a distance,

8.10 Working parts of the mechanism shell be of

corrosion resisting material. It would be preferable to

have bearings, if any, that. do not require greasing ete.

If the beari: require grease they shall be equipped yita 4

pressure type grease fittings, bearing pins, bolts, nuts and

other parts shall be adewately pinned or locked tg prevent

jooseiing or the need for adjustments after repeated opera.

tion of the interruptor

"1 The operation of the power operated closing device

he interraptor is elready closed shall not cause

teoe to eny part of tne interrutor or eidanger the operztor,

® average power requirenent during, closing operation

Cludiag ssring charging motor saall not exceea 75) vatts,

waxiaum input to the opening coil for the opaing

operation shall not exceed 2) watts.

-11-

8.12 The operating mechenism and associated acc:

shell be enciosed ina weather, dust and vermin proof

cabinet or cubical using 2 mn thick shcet stecl (of teste

A provision for pad locking. Suitable hvater(

alongwith thermostat control shall be provided, to oserate

off 240 ¥ ac 50 Hz single phase supply, to prevent condensztior

of moisture during monsoon/winter. A 240 volts, 5a, 3-pin

socket outlet for en inspection lamp shali also be provides.

8.13 The entry of all cables inte the operating

mechenism cabinet shall be through suitable glands

shall not alloy ingress of water into the cabinet,

gable gle~ds shall be supplied by the successful tendcrers.

Pive cable glands shall be provided, 3 of che glends shall

be suitable for cable of 16,5 ua outside dia, and th

valance 2 glands for cable of 14 ag outside diameter,

8.14 The wiring inside tne operating mechenism cabinet

shell be with 1103 Volt grade PVC insulated single core c.

as per 18:1534(Pt.1)-1976, with stranded copper con

of adequate cross-section so proportioned as to red

volteg. drop and I°R losses to the berest minimus. Phe

ends of wires shell be terminated with crimped eye tyce

luge. The wiring for 110 V de control circuits and 240V,

ac 50 Hz simple phase circuit shall oe kept segregatec And

properly identified

8.15 . ‘the terminal end of 211 wires shall be provided

with numbered interlock type ferrules which shell be o:

PVC or other durable material with ma! gs either engraved

or punched so as to the indelible. Ths ferrules shall .

“ preferably be of white colour with block le ‘tering thereon,

8.15 Fuses shall be provided

shall be of the cartridge type

ir the heater circuit

C) with suitable fitcing.

8.17 Termina: block provided in the operating mechenism

' cebinet shall be of approved desigr insulating barriers

Shell be provided between adjacent terainels. The

ae Of terainals shall {stud type with spring weshers. Suiteti

wibr. GUSt proof shrouds of /exxzr’ trans nt material shali be

Wappbie Provided on cach terminal block.

¥ and ac circuits shell be clearly distingl

Separated from each other .

8.18 the materiel used for plunger

¢ block ete.,

the closis

and tripping coils shall b: corrosion resis

nee,

8.19 Houlded case circuit breakers of approved quality

shall be in the motor circuit,

126935

42-

8-20 The contsctor, if any, used in the motor circuit

shell be suitable for operation from 110 Volt do batter

supply subject to a voltage variation of +10 % to - 45%,

8.21 For earthing of the operating‘machanism cabinet,

two earthing terainals of adequate capacity to carry the

rated short circuit current shall:be provided, The

terminal connector shall be suitable for connecting to

50 x 8 ma H.S.flats. The earthing terminal shell be

provided with 17.5 +0.5 mm... s 5

= 9:3 aia,

hole. for fixing the

earthing falt. n lee

3. LLON INSULATOR, AND TERHINAL COUNECTOR.

9.1 Outdoor type porcelain hollow insulator shall

conform to 18:5621, It shall be capable of withstanding

all electrical and mechanical stresses that might be

produced during the operation of the interruptor under nog

mal and short circuit conditions, The insulator shall

be of a Single picce construction with plain sheds i.e.,

without rios.

9.2 Both the porcelain hollow insulator (interrupting

chamber) and support insulator: shall have: a minimum

creepage distance of 1300 mm. t ;

9.3 The porcelain hollow insulator terminals shall be

provided with Rigid type terminal connector to suit

23.25 mm overall dia; all aluminium conductor (butter

fly), size 19/4,65 mm shall be as per RDSO's approved

ng. The connector shall conform to 18:5561 and its

design shall be such es to be connected to the equipment

terminal pad with 2 winiaum of four 12 ma diameter

bolts, nuts and lock nuts which shall be of stainless stee

conforming to 18:1570(Pt.V) Grede 04 cr. 17 N i 12 No, 2

Each of these bolts shall also have a flat washer

-spring washer. a0

3.4 ‘The connectors shell be prociréd only from

approved manufacturers.

10, INTERLOCKING ARRANGE

40.1. The interruptor shall have provision for suitanie |

electrical end mechenical interloéking with its associated

isolator such th: operetion of isolator is possible

only when the interruptor is locked ia the ‘open! position

and to prevent operation of the interruptor cither

manually or electrically by local/remote control unless the

isolator is locked in the ‘closed’ or ‘open! position.

13-

40.2 The interlocking device shall therefore consist

of pzir of locks having < common interlock key. One of the

locks snell be supplied es duly mounted on the operating

mechenisa of the interruptor and the other lock shell

supplied loose for mounting by the Purchaser on the

associated isolator, The supply shall also cover one spere

‘duplicate key alohg witn the common interlock key.

“10.3 The lock meant for mounting on the associated

isolator shall-oe of the bolt type end of approved desig

and shall be suiteble for fixing directly on the isolater.

The internal mechanism of bolt type locs shell be made

of non-i rrous metal end the outer housing shell b2 of

mild stcel not-dip gelvarised, & copy of the drawing,

roved by RDSO, showing “ both caste! end bolt type

inverlocas is etteched with this specizication.

“40.4 - Since et a-switc' station, a number of interr-

uptors are provided, it is essential that the inte

interruptors are non-Laterc'! ble. Intverlo

eys with different key codus shal) therefore be supplied

ifor interruptors being instelled et cre switching station

The successful tenderer shell thereyore advise the deta

sof key’ codes offered by him and shall ascertain the

requirements of differeat key codes.

10.5 The interlocks shell bs procured only from

menufecturers approved by RDSO.

116

D ACCES

kpert from the parts, fitti end eccessorics

specificaily detailed in the foregoing cleusos, the

following parts, fittings and eccussories shell v2

provided for each interruptor

iechenically cpereted closi:

device,

end tripping

ii, Locel/kemote control switch.

iii. Locel elvctrica? tripping aed closiag push

buttons or hencles.

v, Interiocking device,

Vi, Teruinel connectors,

vil, Supporting from end foundetion bolt.

126933

=1h-

Earthing terminals.

Name plate/rating plate.

Mechanical 'ON' end 'OFF' indicators.

xi, Handle crank for charging the closing spring

__. manually.

xii) Foundation bottom.

name/reting plate shall contein the following

niormetion:

i) Make and type designation.

Rated voltege.

) Equipment voltage class.

iv) Reted frequency.

v) Rated normal current.

vi) Reted short circuit bre

current (syimmetrical).

vii) Kated short time current and duration.

viii) Rated insuletion level,

ix) Rated operating sequence.

x) Control circuit voltage.

xi) Conforming specification I $/xD80 Speen,

‘ xii) Total weight of interruptor.

xiii) Year of manufactare,

xiv) Order reference,

xv) Vacuua level in Torr.

SLPPORTING FRAMES

13.4. The steel supporting freme for interruptor should

be “designed with e factor uf safety of not less then

2.5 with respect to the yicld point under conditions of

maximum loeding, ellowing for a besic wind pressure of

200 ke/som on 1.5 times the projected arca of cach

meaber of one face and taking into account the deed end

‘shock loeds of circuit breeker. Cnly tested quelity

stevl sheil be used end proof of having used Such Steel

shell be produced by the successful tenderer,

43.2 For equipaent earthing, each leg of steel

supporting frem: shall be provided with tvo eertning

terminals of adequate capacity to carry the rated short

circuit current safely, The eartning terainal shell be

connected to 50x 8 ma 4S, flat, The earthing shall be

provided with 17.5 + 0.5 mm diameter hole for fixing

- 0.0

the earthing flat.

qa. y

The steel supporting frame end operating mechanisa

cubicle shali be hot dip galveniscd as Research

Design Standards Organisation's specificetion No. ETI/CHE/

.13( 4/84; and the wesght of zinc coating shell not be

“less thea 1000 ga/m*.

All fasteners of 12 aa diameter end

posed to atmpsphere shall be of steinless steel enc

above 12 mm diameter shall proferesly be of stainie

or of aild stecl hot dip galvanised to RDSU's

tion No. SYT/oHit/18(4/84) .

‘TESTING

(2) Only efter all the design and drawings

and clearance’ givea dy aDSO to this

e"menufacturer shall take up manufacture of the

ion, It is to o& clearly

understood that any changes required to be done in the

Prototype - as required by RDSO shail te done expeditious!

126937

y (b) Before giving the call to RDSC/the Chief

‘Slectricei kngincer for inspection and testing of the

Prototype of the system, the menufacturer 11 subinit

a@ detailed test schedule consisting of schematic circuit

Giagrems for cach of the tests and nature of the test,

-Venue of the test and the duretion of cach test and the

total nunber of days required to comp the test at one

stretch, Once the schedule is approved, the test shall

invariadly be done eccordingly, However, during the process

of type testing or even later, RDSO representative

reserves the right to conduct any additional test(s}

besides tho: pecified herein, on any equipment/sub

system or system so as to test the systeq to his

setisfecticn or for gaining additional informetion and

knowledge, case any dispute or disegreemunt arises

~16-

between the manufacturer end RDSO/the Chicf Slectrical

Engineer during the process of testing as regards the

type teste and/or the interpretation end acceptapility

of the type test results, it shall be brought to the

notice of the Director General (Traction Installations),

8DS0/the Chicf dlectrical Engineer es the case may be,

whose decisions hall be final and binding.

(c) The following tests shall be carried out at

she works of the manufacturer or at e reputed testing

lacoratory in the presence of the Indian Reilwey's

fepresentetive,s) on the prototype unit of the interrup-

sor as per relevant governing specification and es modified

or amplified és under:

15.1.1 Mechanical test: The test shall be conducted in

2ccordence ‘987. but the number of operations

shall be 10,000 instead of 2,000 specified there

: following checks/tests shall, however, be done before

comaznceinent of the mechanical test:

i) Generel visual inspection of the equipment

to check its conformity with the approved drewin,

ii) Checking of operation of verious circuits and

device

iii) Meesurement of dimcasions of components lizdle

to weer, operating springs and clearances of

operating coil armatures,

iv) Measureacnt of insulation resistance of main,

euxiliary and motor circuits,

Vv) Hvasureaent of resistence of main circuit

and closing end opening coils.

vi) Measurement of closing and opening times at”

the specified normal, minimum and maximum

controi voltages,

vi.) Mecnanical test comprising 5 closing and

5 opening operations at thu specified normal,

minimum and maximum control voltages.

viii) Closing and opening speed of the moving

contacts of the interruptor at the specifica

normal, minimum and maximum control voltages.

-17-

The measureaents ageinst items (iv) to (

above shell be repeated efter every 2000 operati

value obtained shall bo compared with the previo

15.1.1.1 | after completion of 10,000 operations end

before di. ing the interruptor for internel inspection,

the following tests shall be surformed:

i) Dielectric

(110 V de) é

2 kV for 1

sts on auxiliary circuit

‘d motor circuit by applying

ate,

il) Power frequency dry withstend voltage

test on couplets pole by epplying 105 kv (rms)

for one minute,

Hit) Temperature rise test opening end closing coils,

15.1.2 temperature rise test:

test on main circuit end auxil

closing and opening coils, auxiiia cts, shell be

carried out as per IS:2516(Ft. IV/: c.2), fhe resistance

of the wain circuit shall also oe measured and recorded.

fhe tennereture rise whcn the interruptor is carrying

its rated normal current continuously shall not exceed

the values given hereunder

The temperature rise

y circuit comprising

a} Mein contacts 35° ¢

). Terainals of interruptor

to be connected to external

conductors by bolts 40° ¢

c) Metal parts in contact with

insulators 45° ¢

dj Auxiliary contacts’ 30° Cc

Ay case the temp.

eed the limits. give

of 45°C.

ise should nov

ambient temperature

15.1.5,

eetric

te These tests shall be carried out es per 15:2516

gitstV/Sec.2). Tho following tests shall constitute the

dielectric tusts:—

126933

unpuise withste

The interruptor withstend 250 V(peek) impulse

voltage of 1.2/50 micro-second wave shape.

15.1.3.2 Reted one-minute power frequency wet

1d voltage test,

The interruptor shall withstand 105 kV(rms)

power frequency voltege for one minute.

15.1.3.3 Tests on euxiliary end control circuits

Auxiliery end control circuits of the interrup-

ing spring charging motor) shall withstend

equeney voltage for one minute.

tor (ine

2 «VY (rms) power 1

15.1.4 Rated short circuit making and breaking

ts shell be cerried out es per IS

2 recovery voltage of not less than

Thuse te

(Pt, IV/Sec.2) 2

27.5 KV

15.165 Que

ruptors shell be able of breaking 25%

sof the rated symmetrical short circuit breaking current

voltage (55 kV) under out of phese

condition as per 1$:2516 (Part. IV/Sec.2), Clause No.2,13.

15.1.6 Rate rt time withstend current test

This test shall be carrivd out as per IS +2516

(ft.IV Sec.2), The short time current shall be not less

then @ kA for 3 seconds.

lectrical

15.1.7 Sp

11 successfully carry out the

y appreciable

ect on the contacts of vacuum oottle.

11 be carried out at a recovery

The

rations

© operations

volte,

Test (2) ebov.

operetions if

cool down to &

For t.st db) 2 the open

be done with tho supply disc

tusts (2) and () need not

interrupter.

rruptor shall

ovo surics of

carried out on the seme

s the

wctricel &

provision of

At the ond of spucial <

interruptor shal} comply with ¢

2.6 of 18:2516 (2t.IV/sec.2

15.2 All o

r tests except specie! electrical

test shell be czrried out on the seme interruptor

whien may be ruconditioned aftur vach test as per

* 1822516 (rt.IV/Sec.2).

15.3 The tenderer may qucte seperately his charges

for tne short circuit meking ead breeking cepecity

tests described in Cleuse 15.1.4 hercof. No cherges

shell be payable for any other type end routine /aceeptence

tests.

15-4 If che prototype of interruptor conforming

to this specification has been epproved for verlier

supglies to Indiza Railways, testing of prototype again

ay be waived provided thet no changes in the design

or meterial(s) us.¢ have been made.

15.5 Only afcer cluer written epprovel of the i

rusults of the tists on the prototype is coamunicated by

RDSC/Purchaser to the menufecturer, shell be taken up

bulk menufecture of the interruptor - which shall be

ctly with th. same aetcriel end process es edopted

for the prototyse. In mc circumstences shall the

material other oved in the designs/drewings

and/or the 2 on

2 approve

protot:

126939

15.6 feczurers type test

tests carried out on spring charging

nsuletor, support

Hisit switches end oy ry insulators

€ rucommendations/- ication

tte ad by the successful tenderer for

springs,

ulators,

ing/ro

as per rel.ve

shell be subm

approval.

~20-

16, ROUTINE TESTS

16.1 Every interruptor s be subjected to the

following routine tests at the aenufecturers' Works

as per Clause 3.1, 3.2, 3.3 & 3.4 of 15:2516(Ft.IV/ Sec.2)

16.1.1 Rated one-minute power frequency dry

witastand voltege. t

The interruptor shell successfuliy withstand

105 kV(rms) power frequency, voltage for one minute.

16.1.2 Dielectric tests on control end euxiliery

circuits including spring cherging motor.

16.1.3 Me

ement of the resistance of the main circuit,

16.1.4 Mechanical operetion test - Comprising five

opening and five closing operations at the rated,

meximum and minimum supply volteges i.e,, at 110 V de,

+ 10% and - 15% for closing operétions end 110V dc —

30% for opening operations.

16.1.5 Menual clo:

1g end opening operations

Manual closing and opening operation shall be

carried out to ensure satisfactory operation, The

operation of interlock device shall also be checked for

its proper operation,

7. 2

TICAL DATs

5 DAY

1704 The informetion furnis:

teed performance, technical end

(Ansexure A} shell be complete

is any entry like “shall be furnished later" or blenks are

left ageinst any item, che tender is not likely to be

considered as such omissions causes deley in finalising

the tender. Evidence in the forn of type test reports

for besic insuletion level i.e., rated impulse withstand

voltage test, separate source voltage withstand test,

short circuit test and temperature rise test on the

transformer sn2ll also be furnisned.

in schedule of gueran-

er perticulers

in all respects. If there

17.2 The tenderer shal} specizically indicate in a

statement attached with his offer, his compliance with

each clause and sub-clause of this specificetion, &

seperate statewent shall be atte

indicating reference to the cleu:

devietes therefrom together with

9

ned with the offer

3 where the tenderer

@ remarks/

t of compliance

tached with the

justificetion, If either the st

or statement of devistions is n

'

~21-

offer, it is not likely to be considered. If there are

no deviations, a 'WIL' stetedent shall be attached.

17.3 The successful tenderer shall submit for

approval the foilowing detailed dimensioned drewings es

per Indian Railveys' standard ia sizes of 210 am x 297 am

or aay integral sultiples thereof:

a) General asseai showing mounting arrengenent

and overaii dimensions,

b) Supporting frame with details of fixing

arrangesent end foundation giongwith calculati

for their designs,

c) Porcelain hollow insulator end support

insulator.

4) Cross-section of arcing chanber indicating

the arcing/imain contacts.

e) Details of control devices, if used.

i) Operating end coupling mechanism of complete

interruptor,

8) Schematic and wiring diagrea,

h) Details of fixed end moving contacts and

arcing contact, if any.

iy) Terminal block.

°

+

a

oO

n“

4

3) Nene / Rating plete.

kj Interlocking errange

ent.

1) Limit end ausiliery tehes with technical data.

m) Details of springs.

n) Operating motor with technical specificetion,

0) Terminal connectors,

225

17.4 & epprovel, six copies of apyroved dre

along with two sets of reproducible prints shall b

supplied to each consignes(s). Besides, two copi

Grewings alongwith one sez of reproducible prints

shall de supplied to Director General (Traction Instelle~

tion), Research, Designs & Stenderds Organisation,

Lucknow (India;.

of

17.5 The succes.

ref shall supply ten copies

of the instruction/me

rence menuel gor the interrup-

tor to 22 i two copies to Director

General (Traction Ir on), aesearch, Desicns

& Stendards Orgenisetion, Lucknow (Indiaj.

ints

ch consignee(s,

17.6 The menufeccurer shell supply a graph showing

number of peraissiole loz switching operations at

gerious current besLore cheage of vacua bottle.

18, Ensen

» T3Pit

ABD, CO:MIISS IONING.

18.1 The interrupvor sa@ll be erected by the Purcheser

under the supervision of 2 competent Engineer of the

successiul tenderer/menuzecturer/supplier, The interruptor

shell be subjected to th ecified proving/pre-

i Railvay's Engineer at site

ul tenderer/supplier/

menufecturer shall eso bs fully associated. For this

purpose, prior intimetior. regarding the date end

location of tests shell be given by the Purchaser to

tac supplier/menufacturer/successful tenderer,

Tenderer/supplier/menufecturer shall elso be! fully

essociated. For this purzose, prior intimation regerding

tne date end location of tests shall be given by the

Furcheser to the licr/aenufecturer/successful tenderer,

oF) TECHNICAL Co) BION & INDICED

TION

sation of SF-6 gas circuit

brecker covered by this sivcificetion is contempleted,

Design calculations, detailed menufecturing processes

and all relevent intormetion pertaining to transfer of

technical know-how i. regerd will be carried out in

such a manner betwee over-seas menufecturer end the

Indien menufecturer to ensure that the indigenous

content of the SF-6 reuit breekers made in India

incpeese progressive 2 repidly without secrificing

quality end reliebil searcn Designs & Stenderds

Orgenisetion of tie Reilweys ere to be associa-

ted at the verious s nndigenisetion so 2s to tak

into account servic: nee de. attempting

progrussive indigeaisat:

19.4 Progressive ind.

~ 23-

19.2 ‘The information ex

seas manufacturer and the Indien menufecturer is not

ordinarily "required to be passed oa to the Indien

Railweys. However, the euthorised representative of the

Indien Railways shell have access to the es0ve information

at the menugecturer's Works overseas or the menufecturer's

Works/Design office in Indie whenever it becomes

necessery for the purpose of inspection end acceptance

of the preduct at the uenufecturer's vorks or for the

purpose of enalysis/investigation for over-coming

difficulties end prooless ead for improving the perfor-

mance reli vice.

hanged betwee the over

20. 2

20.1 The tenderer shell furnish elong with his offer,

a list of spares (wita cost) recommended by him for

maintenence of interruptor.for a period of five yeers.

2. LLWAY'S ENGINEE

ne The offer shall include the training of two

engineers of the Indien Reilways free of cost at the

manufecturer's Works in India or abroad end at the

maintenence depots/workshops on a railway systum or

other public utility where interruptors of similer/

identical design are in operation. ‘The tovel duration

of training for ezch engineer hall be 12 weeks of which

approximately § weeks will be et manufacturer's Works

and S weeks on a reilwey system or other puolic utility.

The cost of travel te the country of manufacture and

back will be borne by the Indian Railways. Other details

shall be settled at the time of finalising the contract

or Purchese order, =

o

22, ON

4

22.4 Eech interrwtor supplied nst a purchase

order/eontract in vhish this ion is quoted,

irrespective or origi: (inported/indigenous), shel! be

guerenteed for troubl.—free and satis:ectory perforaance

for 2 period of 18 maths from the date of Supply or

12 months from the de: comiissioning at the sub-

station or switching :tetio. Reilweys, which~

ever period is shorte:, Details of werranty clause,

the extent of respons:bility and other relevant aspects

shall be as included nm

The tenderer shell fu!

in this retard in his 9:

© purchase order or contract.

re

2h

successful tenderer sh.

errengenents for closuly monitoring

the imcerruptor through periodical a

two months during the werrenty period)v

sub-stecion switching station for on thi

observetions. ‘Srrangénments shell also be mede

spere parts to be kept reedily evaileble with the

uehufecturer/supplier/successful tenderer to meet

exig: werrenting repleceaent so es to put beck

the interruptor in survice wichout unduly long interr-

uption of trection power sugply.

0

: th. verious comporents of vech

shall be securely pecked in woodea cre

General peciting togy with

dimensions of pe ceses shell be furnished for

cech incerruptor indiceting the following:

Crate/ deseription Approx. gross 2 te

Box No. of icem com- weight in ourside

ponent in the Kg. dimensions

craty/vox

23.2 As fer eS possible, the gross

weilht of the crete shell be

{80 lept thet it snould be

wposiible to do menual handling

‘by Wwo/three persons.

3.3 In dese of oversees supplies,

pecting shell be sce-worthy.

'

23.4 + Necdssary instructions for

hen/ling end storege shell

zls{ be furnished for use et

reoliving end,

23.5 Portelein housing/support

ins{lztor shell oe supplied

sucirely packed in wooden cretus,

Not!more tnan two insuletors/

por{elein housings shall be

peciud in @ crate as to

fecllitace manuel loading

andlunloed Be

n

ANHLXUTE

ERC UIUIAN!

Unit meesure-

ment/informazion

ii Kaker!s neme

Eb Country of manufecture.

3. Wenufecturer's type designetion:

i) Interruptor pole

ii) Operating mechanism.

4, Type of interruptor indoor/outdoor

Ri

= tated voltage

6. Volcage rating class as per IS:

7 Raced norael current

a Rated frequency

Rated insulation Level of the

interruptor

i} one-winute dry end wet power

frequency Withstend voltage

ii) Lightening impulse withstand

voltege (1.2/50 icro second

wave form)

10. Hated short circuit breaking

current:

i) Symmetrical at a recovery

voltage of not less than 2

kv

kV

‘Hz

kV(rms)

kV (pez)

126942

-2- Annexure(contd,2)

ii) Asyametricel at 2 recover

voltage of not less than 27,5 kV KA

iii) Asyumetricel et a recovery voltege

of 55 kV kA :

iv) 2reaking cepacity (Syametricel) HVA

WW. Rated making current ka(?)

12, Rated short tine wit. and current

for 3 secs, ka

13. Reted operating secuence -

14, ing current on out of

condition kA(ras)

Constructionel features

15. Wuaver of brzaks per pole No.

16. Totei lengta of breek per pole nun

17. Length of contect trevel run

18, Rete of conzect travel at tripping a/sec.

19. Rate of contact travel at closing a/sec.

20, Type of sein contacts.

21, Type of arcing contacts.

22, ileterial of écatacts (including

chemicel composition):

i) Hein concects,

ii} arcing contects.

23. Distance’ between pole centres mm

24, Hinigun cleerance between poles san

25. Shelf life of vacuum vottle + years

28. Weight of vecuua bottle :

27, rressure reiief devices if provided Yes/No

-3- Annexure(conid.3}

28. Level of vecuun adopzed oe els or=

23. \het is the Jevel of current oe AADS.

chopping

30. Net weight of interruptor

complete with opereting mechanism etc. Kg.

a Impact loed for foundation design

(including deed load plus inpect

load on opening end closing et

maximum interrugting rati

32. siiniauk clearence between

live part end eerth (ia air) om

33. Niainun cleerence between lowest

unscreened live part ead any

péint where a person aay stend mm

34, sfinimum height of bottsii-nost

pert of say insuletor irom ground = am

35. Overell dimensions of the incerrup-

tor complete with insulators,

mechenism box etc. moutited on

support structure:

Length mm

Width mm

Height ion

ce Operating parti

36. Closing time from the instant of

closing coil energisetion ms

37. Opening time from the instant

of opening coil energisetion,

38. Arcing time:

t ms

i) gt rated normel cur

1i) Av 1004 short circuit erecting, ns

126943

-4&- Annexure (contd.4)

iii) At 50} short circuit brezking

current ms

iv) &% 25% * * aes ms

v) At 10% ‘ “ ow ms

vi) Criticel current (current giving

longest ercing time):

2) current kA

b) sreing time ms 4

Totel break time from the moment

of trip coil energisation to the

final extinction of arc:

i) At rated normel current. ms

ii) at short circuit sreak:

current ms.

Totel Length of arc ay

Miniawa tine intervel permissible

between successive closing opera~

tions (Co-t-Co} Sec.

Kumber of operations the interrup-

tor can perform with the evailable

stored energ; (spring) los.

whet is the mechanicel life of

the interruptor (operstions}

ber of operations periissible

without replecesent of vacuum

bottle (Electrical life) Nog.

a) At 50% reted current.

b} At 100% rated current.

ce) AS 905

King curreat,

d) At 100 cresking current.

(A graph for sex

tions verous c

should be enc.

nugver of opera.

interrupted

45.

46,

Annexure (contd.5)

D- Other technical per

Meximua ris

ambient of 45°C when carrying

rated normal current continuous]

i) Nein contacts

ii) Terminals when connected with

terainal connectors

iii) Auxiliary contacts

Spring cherging motor:

i) Nake end type designation,

ii) Ratings

ili) Voltege (with permissible

veriation)

iv) Power frequency withstand voltage

v) Class of insuletion

vi) Time required by the motor to

charge the spring fully

vii) Power required at normal control

voltage to charge

Speciticetion epplicadle for

design end testing

ix) Hode of protection recomsended by

the motor menugecturer with their

ratings.

Averege power required for tripping/

closing

- closing/opening:

Bo. of springs

ion/spiral)

ii) Type (compression/t

Ww

jlos.

126944

50.

iii} Ho. of turns

iv) Gauge

v) Sxternel

vi) Stiffness

vii) Nateri

©

ea

position,

ix) Speci

Annexure{ contd.6)

Force developed in fully charged

fuxiliery control supply voltege

with permissible volte

a) Closing coil

b) frippans coil

c) Contectors (if any)

a) other item (for waich

tenderer feels that

voltage is to be

mainteined withia certain

mits)

Coil data:

Closing coil/tripping coil/

contector coil

a) Wire section

b) No.of turns

c, Resistence at 20°C

d) Cless of insulation

Vides $e

Vidor w

Vides %

V.de/ac

ication for designs & testing IS

veriation for

variation

permissible.

variation

permissible,

varietion

peraissible,

a

+ varia-

tion

peraissible,

53.

Shy

55.

Annexure (contd.7)

Type of tripping/closing

mechanism (sprinz)

Manuel ciosing/trigping mechanisa

(Lever/Fush mechanism or any other

device).

Porcelain hollow insulator/support

insuletor

ation,

i) Meker's neme end type des

Governing specizicetion Is

ili) Nininum creepage distence

a; Support insulator mn

b, Interrupting cheaber

insulator mm

iv) Test certificate (to be atteched)

Deteils of operation counter:

i) Meke & type

ii) ho. of digits No.

Auxiliery switch (contacts)

i) Meke end type

di) Normally open contects --Totel--Sgare

iii) ifermally closed contects -~Total--Spere

iv) Continuous reting of contects. A

v) Bree capacity of contacts

at 110V dc with inductive Load A

vi) Lite {iso.0f 0; erations) Nos.

viij

Yes/No

126945

-6- (Annexure contd, 8)

. 2. 3.

56. ait switch (for motor):

: i) Make end type

ii) Concinuous current rating A

iti) Breaking capacity et ii0Vv

de with inductive load £

iv} Life (Ho.or operetions) No.

57. Whet is the type & designation of

the vecuua dottle,

58. whet is the contact cleerance

when the interruptor is open

ration

59. vecuun tube eesily replacecble, Yes/ilo

50. ct weer indicetor for

. physical checking cf contect condition

Provided or not, Yes/No

61. If provision of trip circuit

supervision exists ' Yes/No

62, If mechanical tripping device provided Yes/No

63, If mechenical closing device provided Yes/No

Su, (2) Ef locel electrics closing

end tripping device provided Yes/No

(9) Is it possible to operate these

pusa bottons/knobs without

opening the switch cubicle door Yes/No

65. If the operation counter is visible

without opening the mechanism door Yes/No

66. echanical Glose/opea indicator

provided Yes/tio

‘

67. If three-way treaote', 'locel', off!

switca provided Yes/No.

$8. - approximate height of the switches

fron gound level mm

nexure (cont

If electrical & mechanical inter-

hock with lock & key. provided

If the operating mechanism is

housed in a dust, weether and

verain proof cabinet of sheet

steel construction

If a space heater is provided for

prevention of condensation of moisture

in the operating mechenism box

If inspection lamp/socket is provided

If cable glands provided, indicate

their sizes and nuaber °

If insulation grede of PVC control

wiring ceble

If ac and de wiring completely

segregated

Are the comnectors as per «2S80's

cation

Name of the supplier of the connectors

If terminals of wiring ends ere

provided with crinped lugs

If terminel blocks for wi ing are

dust proof end provided with

unbreakable transparent shroude

lf earthing terminals provided

if hendle/crank for manual cherging of

the closing spring provided

Device for slow closing and opening

Provided or not

esteners of 12 mm dia end less

re of stainless steel?

psy

Festenwrs of more then 12 mm dia

are of stainless steel or steel hot

Sip galvenised?

+9)

Yes/xo

Yes,

Yes,

Yes/io

Yes/tio

Yes/Xo

Yes/iio

Yes/lio

Yes/xo

Yes/No

ves/lio

oO

12694

Annexure (contd. 10)

-10-

qe oo

84, (a) Is supporting freme hot

dip calvenised Yes/ic

ight of zinc costing (g/n°) g/m?

85. Is the offered interrupter of

proven design? Yes/iio

BS. fest certificetes, for ¢

sts as per the specif:

are etteched or not

a7. ervision fecilivies for

er on, testing ead commissioning

provided or not

as. Z of imported components

used in the offered breeker %

82. Are tne working components of .

mecnerisn ere of corrosion resistance !

maverial

90. Is the materiel for plunger of

closing end tripping coi}

corrosion resistance Yes/io

a. Is the firm have indigeaisation be

procremme Oo Yes/No i

o

32. If training of 2 It engineers ay

erranged for a tote] period of

412 weeks or not a Yes/No

33. Warranty provided as per Cleuse No,21 Yes/No

3h. 4 list of spares has beea furnished ? Yes/No

93. Is the offered interruptor of s °

bottle design Yes/No

2. iary/contrel supply voltage with

sible voltage verisvions for

2) Closing coil V de + % variatio:

permissib2

Annexure

{contd.11)

tripping coil

Concractors

Any other item (for

which the tenderer

feels that the voltage

s to be maintained

within certein limits)

ay deviation from this

on asked

+ % verietion

peraissiole.

+ jo ver ion

permissiole,

it

# varietion

permissible,

Yes/ito

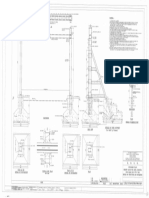

LEGEND

"D cikewtt preacer

; moe ° i as = TWTERRUE TOR

. OD ISOLATOR

TY - ee . =

io

Pre AISTRACTION TRAISTORMER

a xT 7 : : a

ey ee MY. AUTO TRANSFORMER,

-bao Saab: "se CAPACI ion

Appendix-1!

Principte of AT Feeding Systen

Traction

Substation |

126949

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Signal Engineering Manual Part 1Document171 pagesSignal Engineering Manual Part 1pradeeepgarg67% (3)

- UGC06 - Part2 - Section VII - (ODS) - R2 - 20141127Document408 pagesUGC06 - Part2 - Section VII - (ODS) - R2 - 20141127pradeeepgargNo ratings yet

- ACTMDocument823 pagesACTMdc12dc86% (7)

- Scada SPC For Mumbai-AreaDocument50 pagesScada SPC For Mumbai-AreapradeeepgargNo ratings yet

- UGC06 - Part2 - Section VIII - (OCS) - R2 - 20141127Document392 pagesUGC06 - Part2 - Section VIII - (OCS) - R2 - 20141127pradeeepgargNo ratings yet

- Metro Rail Design Criteria Section 07 Rev 1 100611 PDFDocument55 pagesMetro Rail Design Criteria Section 07 Rev 1 100611 PDFamitvaishnav10% (1)

- 25 KV Traction SCADA SPECIFICATION No. TISPCRCCSCADA0130 (Rev-1) 1Document70 pages25 KV Traction SCADA SPECIFICATION No. TISPCRCCSCADA0130 (Rev-1) 1pradeeepgarg100% (1)

- A Case Study On Laying of 132 KV Underground Cables in LMRC. by - Mahendra Kumar Director - Rolling Stock and SystemsDocument48 pagesA Case Study On Laying of 132 KV Underground Cables in LMRC. by - Mahendra Kumar Director - Rolling Stock and Systemspradeeepgarg100% (2)

- The Direc':Ofu:Re: Tl/SPCIOH&ITO LF L'l1-UDocument13 pagesThe Direc':Ofu:Re: Tl/SPCIOH&ITO LF L'l1-UpradeeepgargNo ratings yet

- 79 Ti SPC Ohe Lwtsi 0060 1 21Document22 pages79 Ti SPC Ohe Lwtsi 0060 1 21pradeeepgargNo ratings yet

- 82 Ti SPC One Toolpl 0990 (Tirfox) 1 2Document3 pages82 Ti SPC One Toolpl 0990 (Tirfox) 1 2pradeeepgargNo ratings yet

- 80 Ti SPC Ohn SNS 0000 1 20Document24 pages80 Ti SPC Ohn SNS 0000 1 20pradeeepgargNo ratings yet

- 22 Eti Psi 151 (1 96)Document54 pages22 Eti Psi 151 (1 96)pradeeepgargNo ratings yet

- 23 Eti Psi 159 (10 94) PDFDocument41 pages23 Eti Psi 159 (10 94) PDFpradeeepgargNo ratings yet

- Ti SPC Ohe Atd 0060Document16 pagesTi SPC Ohe Atd 0060pradeeepgarg100% (1)

- TI-DRG-CIV-HGAUGE-RDSO-00002-05-0 (Standard Plan Height Gauge For Level Crossing (For Clear Span Above7.3m Upto 12.2m) Details of Structure and Foundation)Document1 pageTI-DRG-CIV-HGAUGE-RDSO-00002-05-0 (Standard Plan Height Gauge For Level Crossing (For Clear Span Above7.3m Upto 12.2m) Details of Structure and Foundation)pradeeepgarg80% (10)

- 21 Eti Psi 139 (12 89)Document47 pages21 Eti Psi 139 (12 89)pradeeepgargNo ratings yet

- 21 Eti Psi 147 (03 92)Document28 pages21 Eti Psi 147 (03 92)pradeeepgargNo ratings yet

- 22 Eti Psi 150 (4 94)Document52 pages22 Eti Psi 150 (4 94)pradeeepgargNo ratings yet

- Ingress Protection Reference Chart RM TechnicalDocument2 pagesIngress Protection Reference Chart RM TechnicalMayank Kumar GuptaNo ratings yet

- Psi FinalDocument162 pagesPsi FinalsselmtpdrNo ratings yet

- TI-DRG-CIV-HGAUGE-RDSO-00001-05-0 (Standard Plan Height Gauge For Level Crossing (For Clear Span Upto 7.3m) Details of Structure and Foundation)Document1 pageTI-DRG-CIV-HGAUGE-RDSO-00001-05-0 (Standard Plan Height Gauge For Level Crossing (For Clear Span Upto 7.3m) Details of Structure and Foundation)pradeeepgarg63% (8)

- TI-DRG-OHE-FTGFE-RDSO-00001-00-1 (18mm Single Clevis Assembly Modifiesd)Document1 pageTI-DRG-OHE-FTGFE-RDSO-00001-00-1 (18mm Single Clevis Assembly Modifiesd)pradeeepgargNo ratings yet

- Genset Installation RecommendationDocument30 pagesGenset Installation RecommendationAnonymous MDkp0hnb3l100% (8)

- Psi FinalDocument162 pagesPsi FinalsselmtpdrNo ratings yet

- Eti Ohe 13 - 4 - 84Document8 pagesEti Ohe 13 - 4 - 84pradeeepgargNo ratings yet

- Elsewedy ControlDocument62 pagesElsewedy ControlpradeeepgargNo ratings yet

- HANDBOOK ON ARTISANS TOOLS FOR TRACTION DISTRIBUTION DEPOTS (By RDSO)Document79 pagesHANDBOOK ON ARTISANS TOOLS FOR TRACTION DISTRIBUTION DEPOTS (By RDSO)pradeeepgargNo ratings yet

- Three Phase LocomotiveDocument138 pagesThree Phase LocomotiveManas Moharana67% (3)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)