Professional Documents

Culture Documents

22 Eti Psi 151 (1 96)

Uploaded by

pradeeepgarg0 ratings0% found this document useful (0 votes)

28 views54 pagesOHE Specs

Original Title

22-ETI-PSI-151-(1-96)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOHE Specs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views54 pages22 Eti Psi 151 (1 96)

Uploaded by

pradeeepgargOHE Specs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 54

CARRIAGE DIRECTORATE

COMPUTER WING

COVERING LETTER

SUBJECT: SCANNING/DIGITISATION/NDEXING OF OFFICIALDOCUMENTS OF DIFFERENT DIRECTORATES OF

“| DOCUMENT/SPECIFICATION etc. AND ITS

VOLUME/VERSION

Bow 8. ET/PSI/co(4h4) + 5

2-12

TOTAL NO OF PAGESIIMAGES:

_eri/esiAsi(s ~ 53 pring

TotroR= 18 Q Ne»

DSO

1 NAME OF THE DIRECTORATE. TT?

2 | NAME OF THE SUB- D

DIRECTORATE/SECTION | Doc ceFl __ i

"| NAME & DLSIGNATION OF THE SCANNING | _ Doan Frat

|__| CORDINATION OFFICER/STAFF Sivestera j Vs Hote,

4..._| NAME OF THE RECORD/FILE/ ~ Riwiren - 4: ETI/PR ida (Jaz) = Rger

NAME, SIGNATURE AND DESIGNATION OF

THE HANDING OVER RDSO OFFICIAL

CRxoro1

NAME;,SIGNATURE AND DESIGNATION OF

THE TAKING OVER CMC OFFICIAL

DATE OF HANDING OVER FILEIDOCUMENT

etc.

Sa

= recht e

15-06-10

FIELDS FOR INDEXING

Type of Document (File/

DRAWING/TECHNICAL

CIRCULAR/MODIFICATION

‘SHEET/SPECIFICATION/NP)

2 [Document No.

| B12

3° | SUBJECT spe e a

4 | SUB-SUBJECT S

3 | VOLUME —- |

€ | Sr.No 7 From, To 1@8 Ne

7 | DATE OF CREATION OF FILE — ’ S-01 aa

's” [Dealer cme

10 | DATE OF RECEIVING BACK THE

DOCUMENT _|

NAME, SIGNATURE AND DESIGNATIONOF

THE RDSO OFFICAL RECEIVING BACK

THE DOCUMENT AFTER SCANNING

(No of papers to:be checked by department)

Fry

need

REMARKS/FEEDI

‘RATED GOOD

QUALITY

B) COMPUTER GENERATED (DOT

MATRIX)

C) TYPE WRITTEN

D) HAND WRITTEN

)wesS2

197062

aEFRENcE copy -I

5-12

SPECIFICATION NO. ETI/PSI/151( 1/96)

GOVERNMENT OF INDIA

MINISTRY OF RAILWAYS

TECHNICAL SPECIFICATION

FOR

MICROPROCESSOR BASED COMPACT CONTROL, PROTECTION AND

METERING SYSTEM FOR 25 kV AC TRACTION SUBSTATIONS

ON INDIAN RAILUAYS

RESEARCH DESIGNS & STANDARDS ORGANISATION

MANAK NAGAR, LUCKNOW - 226 011

Government of India .

Ministry of Railways

Research Designs & Standards Organisation

Specification No.ETI/PS1/151(1/96)

MICROPROCESSOR BASED COMPACT CONTROL, PROTECTION AND METERING

SYSTEM FOR 25 KV AC TRACTION SUBSTATIONS ON INDIAN RAILWAYS

SCOPE

This specification applies to the design, manufacture, supply

and erection of micro procesgot based compact

control,protection and metering system complete with

microprocessor based protection modules for use in the

traction substation for control of 220/132/110/66 kV and 25

KV clreult breakera, 25 kV interruptore aud protection of 220

or 132 or 110 of 66/27 kV ngle phase Leangformers,

substation equipment, 25 kV over heac

and shunt capacitor bank.

equipment (OWE)

edera

The micro processor based compa conteol,protection and

metering ayutem offered shall be complete vith miccoproces#or

based protection modules, miniaturis meters & control

switches, wiring and all other accessories and materials which

are necessary for efficient control and protection of

equipment and feeders. Such accessories and materials shall be

deemed to be within the scope of this specification whether

specifically mentioned or not.

TRACTION POWER SUPPLY SYSTEM

GENERAL

SCHENE OF TRACTION POWER SUPPLY $y:

Power! is received from. the grid network of the State

Electricity Board at 220 kV/132 kV/110 kV/66 kV, at individual

traction substation (TSS). 25 kV power supply for traction ig

drawn through a gingle phage step own traction tranuformer

The ptinary winding of this transformer is connected to any

two nominated phages of the incoming three phase lines or to

the tvo incoming phase linea and on the secondary side, ei ther

of the two terminals of the 25 kV winding ix connects

the

traction overhead equipment, while the other is svlidly

eartled and connected to the running traction ails

Each transformer has its associated circuit breakers on the

primry and secondary sides, with a seporat

circuit breakers called " Feeder Circuit Breake

the traction OHE lines.

eet of 25 kV

4" for feeding

Adjazent TSS are fed from different pl of the Varese phase

syatem in rotation. Newtrai seetions in (rout of sectioning

and paralleling post (SP) are peovided in the 25 kW OWE for

segregating the different phases. [nh between the TSS and SP,

aub-sectioning and paralleling posis (SSP) ace provided toe

2.2.3

eub-sectioning and paralleling posts (SSP) are provided for

paralleling the UP and DN line OHE and alao for aectionaliaing

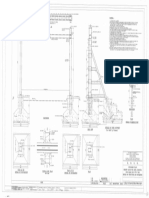

and fault localisation. The attached drawing No. ETI/PSI/702-1

at Annenxure-I shows the general acheme for traction power

supply ayatem,

The supply to the OHE can be awitched on/off through

interruptors which do not open automatically on fault, but can

be closed on to a fault. The fault is cleared by the feeder

circuit breaker provided at the traction substation.

Normally power supply from a TSS extends upto the SP on either

aide of the gubatation, but In case of an emergency

neceesitating total shut down of the substation, power supply

from adjacent TSS on either aide of the failed subatation can

be extended upto the failed substation by closing the bridging

interruptors at the tuo SPs.

NATURE OF TRACTION LOAD AND FAULTS ON THE OHE SYSTEM.

The traction load is a frequently and rapidly varying one

batween no-load and overload. The TSS equipment is subject to

a number of earth faults/short circuits. On an average the

number of faulte/short circuita per month Ie about 40 but in

exceptional cages the number could be as high as 120. The

magnitude of fault current may vary between 40% and 100% of

the dead short -circuit value. \

The ac electric rolling stock is fitted, for conversion of ac

to de, with aingle phase bridge-connected siliton rectifiers

with smoothing reactor for feeding the de traction motors. The

rectifiers Introduce harmonic currents in the, 25 kV power

supply. On few of the controlled asymmetrical thyrietor

bridge,in place of ailicon ‘rectifiers are |working which

introduces further harmonics in the system! The typical

percentages of harmonics present in the traction current with

electric rolling stock are as follows:

With diode eth

. rectifier thyristor

3rd harmonic (150 Hz) 15% 32%

Sth harmonic (250 Hz) 6x 18

7th harmonic (350 Hz) ae Be

9th harmonic (450 Hz) . ay

ith harmonic(550 Hz) 7 bk

the average power-factor of the electric 1dcomotive and

electric multiple units generally varies betwee 0.7 and 0.8

lagging, without compensation.

2.3

Pplor)

2.4

2.0.4

2.5

2.8.1

206)

2.6.2

SHORT -CIRCUI

APPARENT POUER OF THE SYSTEN

The short -.circuit apparent power for various system voltages

ja as undec:-

Highest System voltage | Short - circuit apparent power

kV NVA

52 200

72.5 3500

123 6000

145 10000

245

20000

POWER SUPPLIES AT TRACTION SUBSTATION

The following power supplies are available at a traction

substation:

1) 110 V de from a battery.

41) 240 V ac, 50 Hz, aingle phase from a 25/0.24 kV

auxiliairy tranaformer.

BOOSTER TRANSFORMERS (BTs)

In order to reduce inductive interference in adjacent

telecommunication ciccuits booster transformers on certain

aections of electrified track are installed in series with the

25 kV traction overhead equipment. The primary winding of the

booater transformer is connected to the 25 kv overhead

equipment and the secondary winding ie in series with the

return conductor (RC) which ia atrung close to the 25 kV

overhead equipment. Booster transformers with a rating of 150

or 100 kVA provide necessary voltage to force the traction

return current from the rail and earth to flow through the

return conductor. The Booster transformers have a leakage

Impedance of about 0.15 ohm each and are apaced about 2.66 km

apart.

PROTECTIVE RELAYS AT THE TRACTION SUB-STATIO

For protection of Transformer, aubstation equipments and the

feeders, the following relays are provided on control panels

housed in the masonry cubicle at the traction substation (TSS)

2.6.1.1 FOR THE TRANSFORMER PROTECTION

(1) Differential relay

CAL)IDMT overcurrent relays for the primary (IIV) as well as

for the secondary (LV) aide. The IDMT relay on the HV aide

ja also provided with an instantaneous overcurrent

element.

(iiL)Inetantaneous earth leakage relays on the primary. (HV)

aide as well aa on the secondary (LV) side.

iv) High speed intertripping relay.

v) Auxiliary relays for transformer faults i.e. Buchholz,

excessive winding and oil temperature trip and alarm and

low ofl level oil level alarm.

2.6.1.2 FOR THE OVERHEAD EQUIPMENT PROTECTION

(4) Admittance type directional distance protection relay.

(1i)Admittance type relay for protection against wrong phase

coupling.

(iii)Instantaneous overcurrent relay.

2.6.1.3 FOR SHUNT CAPACITOR BANK PROTECTION

4) IDMT over current protection relay With suitable settings.

ii) Over voltage protection relay.

11) Under voltage protection relay with timer to enable the

capacitors to discharge before recloaure.

iv) Current unbalance protection

v) Internal fuse for each capacitor element.

2.7 AUTO-RECLOSING OF FEEDER CIRCUIT BREAKERS

2.7.1 A single shot high apeed auto-reclosing scheme for 25 kV

feeder cireult breaker(#) at AC traction sub-station haa been

adopted to facilitate recloaing of the 25 kV feeder breaker

automatically once after a pre-set time delay after tripping

of the circuit breaker on OHE fault. This feature will help in

quick restoration of traction power supply to OHE if the fault

ie of a tranalent nature. It will alao help in?

checking/reetricting the continuance of arc in the event of

the pantograph of a moving locomotive passing the overlap

opposite. feeding post at such moments and thus protecting the

OHE, catenary in particular, from consequent damages.

\

\

2.8.1 In the event of failure of a traction substation 25 KV supply

le extended from the adjacent substations by clobing the

beidging interruptors at SPs. Under such emergency feed

conditions, wrong phase coupling may be caused at thei overlap

oppoaite the failed substation by the pantograph of a| passing

locomotive, reaulting in the tripping of 25 kV feeder | breaker

at any one of the two aubstations through wrong phase ‘coupling

(ho) relay. Thia may reault In the formation of an are at the

overlap due to which the OHE may be damaged. The damage due to

the arc can be minimiaed by tripping the feeder, circuit

2.8 INTERTRIPPING OF FEEDER CIRCUIT BREAKERS

2.9

2.10

2.at

eer

3.

3.1

breaker at the other substation also. This is achieved by an

intertripping arrangement through the remote control equipment.

For the purpose of calculation, the values of loop impedance

with earth return for the OHE are taken aa under:

1) One OHE without 0.41 £70 deg. Ohms/km

BT and RC

11) Two OHEs without 0.24 £70 deg. Ohms/km

BT and RC

ili) One OHE with BT and RC 0.70 £70 deg. Ohms/km

iv) Two OHEa with BT and RC 0.43 £70 deg. Ohms/km

TRACTION TRANSFORMER

The percentage impedance of a 21.6 MVA, 220 or 132 or 110 or

66/27 kV aingle phase transformer ia 12%. The traction

transformers are designed to carry ahort time overloads aa the

traction loada may exceed 21.6 MVA for short perioda. The

impedance angle for the loads at the traction substation le

nearly 37 deg.

Nature of faults on the over head equipment (OHE) system.

OHE le eubjected to frequent earth faulta caused by failure of

Inealation, or by the OHE snapping and touching the rail or

earth, or by a plece of wire dropped by birda connecting the

OHE to earthed overlying structures, miacreant activities etc.

These faults are cleared by the' feeder circult-breaker which

eperatea on any one or more of the following relays

1) Distance protection relay.

11) Instantaneous over-current relay.

(SERVICE CONDITIONS

|

‘The control and relay panels are intended for use in molat

tropical climate with the following atmoapheric conditions

i) Max. temperature of air 50 deg. C

iL) Min. temperature of air 0 dea. Cc

ili) Max. temperature attainable by 65 Dea Cc

an object exposed to Sun

iv) Max. relative humidity 100%

v) Max. wind pressure 200 kat/ag.m.

a.

4

4a.

vi) Altitude

less than 1000 m

vil) Average annual rain fall. 1750 Lo 6250 mm.

vill) Number of thunderstorm days 85 days.

per annum.

ix) No. of rainy days per annum 120 days (Max. )

x) Average No. of dust storm days 35 days.

per annum.

22 The control and relay panels shall be installed in masonry

control cubicales at the traction substations which are

normally unattended. The madonry control cublelen are eltuated

clowe to the Railway tracka and hence the control boards are

subjected to vibrations due to running trains

O EXISTING ARRANGEMENT OF CONTROL AND RELAY PANEL

The existing control and relay panel used on Indian

has following features. i

4.1 GOVERNING SPECIFICATIONS

:1.1 The main components covered by the specification con

the following standard specifications (latest version

Railvays

form to

) which

are applied in the manner altered, amended or supplemented by

the specification and Indian Electricity Rules where

applicable. \

(4) Electrical relays for power 1s.923)

ayatem protection.

(11) Static protective relaya 18:8686

(ili) Direct acting electrical indicating 18:1248

inatcuments. :

(iv) Control cable 1S: 694

(v) Conductors for insulated electrical 18:8130

cables and flexible cords

(vi) Protective current transformers 18:2705 cor-Wy

\

All other components such as awitches, contactor#, ind\cation

LEDs, push buttons and terminal blocks etc.’ contlem to

relevant 18 Specifications (latest version ) and\ euch

specifications are mentioned by the tenderers in their \eter

2 CONSTRUCTIONAL FEATURES

21 The panel ie of the vertical self- supporting los

ateel conatruction, low voltage, back to back duplex

\

\

type

cort\dor

&

4.2.5

type with central roofed-in acceas. The central acce

corridor is provided with lockable doora at either end. Th

control board is fabricated from sheet steel of thickness not

less than 3.25 mm ( 10 SWG ) for front and rear panels, base

frame, door frame, vermin- proof fitments and not lesa than

2.0 mm ( 14 SUG) for side panels, roof and doora. The bottom

portion of the panel is provided with detachable type sheet

steel covers (over trench portion) with suitable cable glands

to facilitate entries of control cable from trenches to

contcol board. The bottom of central accena corridor ta

provided with removable wooden planks of hard wood of adequate

thickness to facilitate free movement of working staff. The

board is suitable for erection flush with the concrete floor

by evenly spaced grouting bolts projecting throuph the base

channels of its frame. The board ia made in suitable sections

to facilitate eaay transport, handling and assembly at gite

The board as well ag inetrument and relay housings are dust

and vermin proof and are suitable for use in tropical humid

climate.

It normally compriaes four panela two on the front side for

mimic diagram, control switches, indication~ apparatus and

Instruments, known as control panel and the other two on the

eear aide for relays, known as relay panel. The equipment

provided on panele are indicated in clauge 4.19 and Annexure

“B', to this Specification. Each panel is about 2.3 m. (Max.)

high and about 2 m deep (between front and rear faces).

All control and supply cables are laid in a diatribution

trench running under the control panel. The cablea enter the

board from the trench through suitable glands. Detailed

dimensions of the trench work required ia furniehed by the

Contractors. Provision is made to seal the points of entry of

cables to prevent access of insects and lizards into the

board.

The sheet steel ae well as other steel works ie properly

treated and then an under coat suitable to serve as base and

binder ‘for the finishing coat applied. The exterior and

interior gurfacea and the base frame of the panels are epoxy

coated In a shade mutually decided by manufacturer and

Rallways

If any painted surface gets damaged during transit, the

surface finish is restored at site after erection.

INDICATING INSTRUMENTS

Ammeters and Voltmeters as indicated in the particular

sp:cification at Annexure-B are provided on the control panel

Tre Voltmeter provided for OHE voltage indication is connected

t either the UP or DN OHE PT which ever ia live, by an

automatic changeover device, provided in the control and relay

ranel

4.3.3

4.4

Add

The inatruments are of the switch-board type, back connected,

suitable for aemi-fluah or (lush mounting, provided with dust

tight cases and finished in dull black enamel. Scale markinga

are in black on white background. The acale length is 200 mm (

8 in). The ammeter is of dual range type and has linear acale.

The instruments conform to accuracy class 2. Inetrumente

which are spring controlled are provided with zero adjusters

on the front aide so that adjustment ia made when the

instruments are in service.

The instruments are of moving coil type and provided with

suitable means of adjusting the accuracy in the laboratory.

Standard 5A current coils are used in the instruments. All

¢ircuita including the current coile of instruments are

capable of withstanding at least 20% overload for 8 hours. The

instruments are capable to withstand a high voltage teat of

2,000V rma to earth for one minute.

RELAYS

The relays are of the draw-out (Plug-in), switch board type,

back - connected and suitable for eemi-flush or flush

mounting, provided with dust-tight covere in dull black enamel

finish. i

The relays are provided with test plugs or separate test

blocke for secondary injection teata. The relay parta are

eagily acceasible with the relays mounted on the panela. The

terminal connectiona inaide the relay housing are auch that

when the relay la drawn-out the cureeit teemingla of the CT

secondaries get shorted automatically. Since the aubstationa

are normally unattended, the relays ard of aelf'- reset type,

except ‘for the following which: are of hand - reset type

(1) Low oil level alarm.

(il)Uinding temperature Indicator alarm‘and telp.

(il) 011 temperature indicator alarm and trip.

(iv) Buchholz alarm and trip.

(v) Auxillary unit in differential relay)

(vl)Presaure rellef device with alarm and trip.'

In addition, wherever necessary for proper fuactioning of the

scheme, hand-reset contacta in auxiliary'relays\are alao be

provided. All the protective relaya dnd thd aesoclated

auxiliary relays in the ciecuite of alarsa and \annunelation

etc. including inter-trip relays have LED operation indicatora

with manual reset avitchea eultable for operation from the

front of relay cauea.

The protective relay current coils are rated for a ‘continuous

current of 5 A and the voltage colls for 110 V. THY current

colle are capable of withstanding 20% overload for 8 houra.

a

The protective relays are static/Electromechanical type

relays. The relays are of teat voltage Class -IIIl aa per

clause 3.2 of 18:8686 ~ 1977.

The auxiliary relays are designed for continuous service

voltage of 110 V dc and are capable of satisfactory operation

upto atleast +/- 20% fluctuation in voltage

The contacts of the relays are of silver or gold plated. The

rating of output contacts of the protective relays are

adequate to operate the aasoclated auxiliary relays

The relays have name platea with rating data, serial number

and manufacturer's name marked on them. The matal case is

provided with separate earthing terminals.

The bagle acheme of protection ig indicated in Clauses 4.16 to

4.18. 7

The Indian Railways are using the following static relays

manufactured by M/a ALIND, TRIVANDRUM for 25 kV traction sub

atationa:

Description Type Rating/setting Remarks

dealgnation range.

(A) Teaneformer Protection

Teansformer percentage — TNADT Current setting

blaged differential 40-100% of SA,

relays. Blag setting 20%

30% or 40% of 5A.

IDNT overcurrent relay TMAS 111-2A 80 -320% of SA.

combined with 400-1600% of 5 A

Inatantaneous high set

overcurrent (132 kV aide).

Restricted earth fault TMAR-10 10 - 40% of SA.

relay (132 kV and 25 kV

aide).

IDMT overcurrent relay TMAS-101 80 - 320% of 5A.

(25 kV aide).

Aux. relaye for Buchholz, TAR 3E -

excessive winding and oil

temp.tripping.

(B) QHE PROTECTION.

1. Mho type directional YCG -14 0.33 to 12 Ohm

distance protection (E.E.make ) extended zone

relay(DPR). reach upto 60 Ohm

of 5A with MTA 75

deg.

2. Mho type relays for YCG - 14 0.33 to 12 Ohm

protection againat (EB. make ) extended zone

wrong phase coupling. reach upto 60

Ohm of 5A with .

MTA 125 dee with

forward offset of

11k.

3. Instantaneous high TMA -110 200 - 800% of SA.

get over current relay on

25 kv side.

(C) SHUNT CAPACITOR BANK PROTECTION

1. Overcurrent relay TMAS 101A aa

with inverge difinite

minimum time (IDMT) element.

2. Over voltage relay Tv 4110 =

3. Under voltage relay _ THV 110 -

with timer.

4, Current unbalance TMAH -

protection relay

5. Internal fuse for -- eo

each element.

(D) AUXILIARY RELAYS

D.C. SUPERVISION

i) Transformer HV CB Trip TAR 5S

Supervision.

41) Teansformer LV CB trip TAR 5S

auperviaion

iii) 25 kV Feeder control. TAR 5S

iv) 25 kV interruptor control.TAR 4S

10

v) DC fail alarm cancel. TAR 4S

vi)Alarm annunciation control.TAR 4S

2. Auxiliary Relay for contact TAR 4S

multiplication of directional

distance protection relay

(¥CG -14).

3. Alarm Bell Relay. TAR 1S

4. Flasher Relay. TAR 1S

5. High Speed Master THST

Trip Relay.

6. High Speed Inter THSTS

Trip Relay.

7. Single shot TRRLX

auto-recloaing relay.

8. Timer relays for eingle TDR - 2P

ahot auto-recloaing acheme.

9. Auxiliary relay for Buchholz/ TAR 4 E

oil temp. /winding temp./low

oil alarm.

1

10. Alarm annunciation relay. TAR - 4S

4.5 | MIMIC DIAGRAM

4.5.1

The a¢heme of' connections at the traction aub-station

(including feeding poet ') showing the circuit breakers,

tranafofmers, isolators and intercuptora are represented by a

aingle line mimic diagram on the control panel. The colour of

the biabar ja aignal rad to shade S37 of 18:5 for

220/132/110/66 kV, golden yellow to shade 356 of IS:5 for 25

KV and black for 240V. The mimic diagram ia apray painted on

the parel with the width of mimic atrip of 8 mm,

Suitable epring loaded push-button switches are on the control

panela in conjunction with red and green indication LED'a for

control and indication of circuit breakers and interruptors.

Autométic aemaphore relays are also incorporated in the mimic

diagram to indicate the position of circuit breakers and

intertuptora. The semaphore relay have the feature of diee

coming to the neutral position in the event of failure of

supply,

A locd /remote change-over switch is provided for each remote

contedled apparatus viz. circuit breaker/interruptor for

changije over the control from local to remote and vice verea,

The agar trip eiveult operated by the protective relays trips

yy

the circuit breakera directly irreapective of the position of

the change-over switch.

4.5.4 Ammeters provided are of dual range. Manually operated

selector awitchea are provided below each ammeter to indicate

the range of ammeter to be read.

4.5.5 The position of 220/132/110/66 kV and 25 kV isolators is

represented on the mimic diagram by manually operated

semaphore avitchea.

4.6 ANNUNCIATION

4.6.1 Red LEDs and a bell, both LEDs and bell operated off 110 V

d.c.aupply, are provided on the control panel for giving

Individual vieual and audible alarm whenever any of the

protective or other relaya operates. The vieual alarm ia of

flasher type which continue to flicker and become stable till,

the alarm ie accepted. The annunciation LEDs is provided on

the control panel at the top in suitable number of rows and

concerned tranaformer/circuit-breaker/PT etc. symbol on the

mimic diageam, as approved by the purchaser. The alarm

accepting, visual resetting and annunciation testing buttons

are mounted on the control panel at a convenient place &

height. The alarm bell ia mounted inside the control board.

4.6.2 Annunciation is arranged for the following conditions as are

applicable for each circuit.

4) 220/132/110/66 kV transformer breaker auto-trip.

il) 25 kV tranaformer breaker auto - trip. i

il) 25 kV feeder breaker auto-trip

iv) Teandformer Buchholz trip.

v) Traneformer o11 temperature trip.

vi) Transformer winding temperature trip. |

vil) Tranéformec preaaure relief device trip.

vill) Tranaformer Buchholz alarm.

ix) Tranaformer o1l] temperature alarm.

x) Transformer winding temperature alarm. | \

xi) Transformer low oi] level alarm. , 4

xil) 25 kV OHE supply /PT fuse fall. in

xlil) 240 V, aingle phage aupply fall (onlyione\No.).

For monitoring the ONE aupply or 240 V supply, suitable Call

or nothing) relays operated off the ONE PT or 240 V aupply

reapectively is provided. in the control janel by the

guccesaful tenderer. A push ~ button, in seried with each of

these, supply monitoring circuits, is provided ly the side of

the corresponding eupply fail indication LED]/to teat the

healthinesa of the monitoring and annunciation drcuit.

4.7 DC SUPPLY SUPERVISION i

4.7.1 Provision is made for annunciation and supervilion of 110 Vv

d.c. supply to various control and alarm fd indication

i

12

4.7.3

circulta, 110 Vd.c. supply to control and relay panol ia

normally made available from 110V battery chargers/batteriea

through distribution panel provided in the control room, in

five separate circuite as under:

i)Control circuit for H.V. and L.V. breakers of traction

transformer - 1.

ii)Control citewit for H.V and L.V. breakers of traction

tranaformer ~ 2.

411) Control circuit for 25 kV feeder breakers.

iv) Control circuit for interruptors

v) A common circuit for alarm and indication purposes.

Necesgary proviaion for auperviaion of d.c. aupply to each of

the above clrcuita le made. On failure of d.c. wupply to any

elecult, a yellow LED (provided individually for each of the

elrcuite) and horn, both operated off 240 V, single phase

supply, come up. A push button, in series vith

each

Gupervision circuit, is provided by the side of the

corresponding d.c. fail indication LED in order to teat the

healthiness of the supervision and annunciation circuit. In

addition, a common miniature type push button for the

cancellation of horn is alao provided.

The control/common circuits mentioned in Clause-4.7.1 above,

being conmon for all the panels, are segeregated guitably at

the control panel for each panel through linke ete. #0 that

d.c. aupply ia available to other panels when any one is taken

out of service for maintenance purpose.

TRIP CIRCUIT SUPERVISION a

The continuity and the availability of d.c. eupply to the trip

circuit of each circuit breaker are monitored independently by

an auxiliary relay connected in series with the trip coll of

the breaker. The current taken by the auxiliary relay doee not

exceed 10 mA. Whenever the auxiliary relay de-energises

(while the breaker ia in the closed position) either due to

discontinuity in the trip circuit or d.c. eupply failure, a

yellov LED (provided individually to the trip circuit of each

breaker) \and horn, both operated off 240 V , «ingle phase

supply, Come up. A puah button, in series with each of these

auxiliary belaya, 1s provided by the aide of the corresponding

teip-circult fail indication LED to teat the healthiness of

the supervision and annunication circuit.

Since the substation is un-attended, necessary cut-off

witches are provided on each control panel for disconnection

of the ajdio-visual alarm and annunciation and indication

circuits te avoid-un-necessary drainage of the battery.

13

INDICATION AND ANNUNCIATION LEDs

Low consumption, extra bright, 5 mm dia, light emitting diodes

(LEDs) are used. The LEDs are suitably wired to glow ‘off at

110 V d.c. or 240 V a.c. supply, as required.

LEDs are housed in suitable metallic holders with

glazed/polished surface to act aa reflector. The holdere are

screwed to the panel from inside.

The following colour scheme is adopted for LEDs

Signal for Colour of Light.

Circuit breaker/interruptor closed Red

Circuit breaker/interruptor open Green

Trip circuit of CB fail Yellow

Control or alarma Indication circuit] Yellow

d.c. aupply fall |

TEST AND TERMINAL BLOCKS 4

Suitable test blocks are mounted conveniently inside the

control panel a0 aa to be easily accesjible. The current

rating of the contact la 10 A continuousland 150 A for at

least one second at 240 V a.c. or dic.

The current terminals are provided with shott circuiting links

or other aultable devicea : \

1) To ghort ciecult the current teanaformer leade before

interrupting the normal circuit for | injection from

external source for teating (applicable for secondary

injection testa of relays ).

11) To complete the current tranaformer cilcult through a

testing inatrument in which case the teatile instrument ia

connected to the current terminals and the intermediate

link opened out (applicable for checking indicating

inatruments with aub-standard metera at site).

The poteritial teating terminals are preferably housed in

narrow recesses of the moulded insulation tlotk to prevent

accidental short circuits. \

The arrangement of the terminale ie made ‘ouch \that either

portable type energy and maximum demand metera, or trivector

metera with peinto-maxigraph for recording kU, kVA, and kVAr

can be connected when required.

Vertical or horizéntal pillar stack terminal blocks

suitable fer 1100 V service and not less ¢ fan 30 A rating are

provided for terminating outgoing enda of ae panel wiring

and the corresponding incoming tail enis of the control

cables. Provision is made on each piney for holding 20%

14

4.10.2)

4.10.3

extra connections. The terminal blocks have individual

identification markings which are be either engraved or made

indelible by any other means. Pillars of terminal blocks

meant for connections of incoming control and indication

cables are specially provided with identitication lables

indicating function(s) of each terminal block.

The terminals on the terminal blocks are of stud type suitable

for terminating the ends of control wiring and outgoing cable

ends through crimped terminal spade/lugs, which are securely

tightened with nuts and spring washers. Suitable shrouds of

\ unbreakable transparent material are also be provided on each

terminal block.

Terminal blocks connected to potential circuits and current

cireulte are not placed adjacent to each other in a pillar.

Where auch segregation is not convenient due Lo any reagon, a

dummy spacer of ingulating material of adequate thickness op a

yotwo euch cleeulta.

gpace terminal block ig provided in betwe

Al) panel wiring is done with switch board type 1100 V grade

PVC insulated single core, tinned annealed stranded copper

conductor for service in extremely tropical climate. The PVC

wires conform to latest version/revision of 18:694 and ave

flame proof. The wiring ie also not prone to attack by vermin,

i.e. mice, white ants, cockroaches etc.

The size of wires in the meter and relay circuits connected to

the curcent transformers is not less than 4 aq.mm copper and

in potential and other circuits not less than 2.5 sq.mm

copper. The wires are stranded,’ composed of strands conforming

to clags 2, table 2 of 18:8130 - 1984.

The nutbering and scheme of wiring for various circuits in the

control and relay panel are in accordance with latest version

of 18:375. The following colour scheme is “adopted for the

wiring in order to facilitate identification of circuits

Colour . Cireuit

of wire

Red 220 kV or 132 kV or 110 KV or 66) kV

curvent trangformer elreult

Yellow 25 kV potential transformer circuit.

Green 25 kV current transformer circuit

Uhite (live) 240 V a.c-auxiliary

Black (neuteal) Supply circuits

4.10.4

4.10.5

4.10.6

Grey d.c. control circuits PVC sleeves of

colours, red for

trip circuit, blue

for indication

circuit, yellow for

alacm circuit,

green for relay and

other inter

connect iong

A suitable plaque of durable material and indelible

description giving the colour scheme of wiring is provided

inside the control board to facilitate quick identification of

circuits for maintenance purposes.

All potential bus wiring, audible alarm bus wiring, de

control supply bus wiring, and such other wiring which

from panel to panel within the control board are suitably

supported and clipped to the frame work. The wiring for

interconnections between control and relay panele is Cixed

under the roof of the corridor. All wiring ie neatly bunched

with PVC tape or laced by thread. Uhere a bunch of wires is

clamped by meta) clips, the wires are taped together by one or

two layers of PVC tape to protect them! against mechanical

injury. Wiring connected to the space heaters in the panels is

provided with porcelain beaded ineulation\for a short distan

from the heater terminals and heat resistant bushes of

insulating materiale are provided at the terminal housing

outlets. No joints are permitted in, the wiking.

rung

The terminal ends of all wires are provitled with numbered

interlock type ferrules which are of PVC lor other durable

material with marking either engraved or pinched go as to be

indelible. The ferrules are of white colour with black

lettering thereon. However, for trip circuite ferrules of red

‘colour are used. At a point of inter-section where a change of

number is necessary, duplicate ferrule! are provided and

marked with proper numbers. ios

Ende of all wires are provided with termisial spades (tinned)

which are erimped. into the wires. At tetminal connection

washers are interposed between wire tersinala and holding

nuts. The connection studs project at least 3 ma from the

lock-nut surface. Wice ends go connected at the terminal studa

that no terminal ferrule gets mavked due lo the succending

connections. The wire anda are suitably bent to meet the

terminal ‘stud at right) angles with thel etud axis; uk

connections are not permitted. \

FUSES AND LINKS

|

HRC fuses of adequate current rating are/ provided in all

potential circuits. Fuse'bases and carriersjace mounted in the

16

4.11.2

4.12

4.42.1

4.12.2,

4.12.3

aetna)

fats 3)

interior of the control board and at easily acceasible places.

The fuse rating and the identification number, as assigned in

the schematic diagram, are indicated on the fuge carriera.

Suitable lables with engraved markings indicating the rating,

identification number and the circuit in which used, are also

provided below the fuee baaea.

The links provided in the circuits either on negative/neutral

aide or for branching purposes, are alao eimilar to fusea

mentioned above, except that these are provided with tinned

copper strip of suitable size in place of IRC fuse. The link

identification number as aasigned in the echematic diagram is

indicated on the link carrier. The link base is also

identified in the similar manner as the fuse base mentioned in

Clause 4.11.1.

SPACE HEATERS AND CONTROL PANEL LIGHTING

Suitable space heatera to operate off 240 V single phase ac

supply with*ON’ awitches are provided inaide the control board

to prevent condensation of moisture in humid veather.

The interior of control board enclosure is adequately lighted

by incandescent lamps connected to 240 V single phase ac

aupply. {The central corridor is illuminated by a lamp

controlled by the door switches provided on the doors on

either side of the corridor. Each section of the control and

relay panel is also illuminated, controlled by separate

avitches.

Two ete, one each for relay panela and control panels, of §

Ampa, single phase, 3 pin plug aocketa with avitchea are

provided inaide the control board at convenient polnta for uae

of portable lampa.

EARTHING

All current free metallic bodies of equipments/relays etc. on

the control board are earthed properly. Main earth circuit is

of 25x 3 mm tinned copper strip and individual connections of

equipment/relays with main earth circuit are by means of 2.64

mm (12 SUG) tinned annealed copper bare conductor/atripa,

using |tinned copper apade terminala/lugs. Some timea aa an

alternite, PVC ingulated stranded tinned copper wire of aize

equivalent to 2.64 mm ( 12 SUG) ia aleo provided. Jointa are

avoided aa far aa possible.

In order to facilitate the earthing of secondaries of CTa and

PTs inside the control board, suitable earth links of adequate

size made of tinned copper/braes are provided inside the

_ control board at the appropriate points.

Huftiple earthing of current /potential tranoformer circuits is

avjidad. Main earth connection for each panel brought out to

tu} terminals for connection to the general earthing system

17

4.14.2

4.14.3

4.14.4

4.14.5

4.14.6

4.14.7

AIA. 8,

NAME PLATES/IDENTIFICATION LABLES

All relays, instruments and other electrical devices mounted

on the board have name plates with rating data, aerial number

and manufacturer's name.

Identification lables of size 65 x 13 mm bearing

identification marka indicating funetlona of reapective

equipments are provided on the exterior of control and relay

panels under all the relays, instrumenta and teat blocks ete.

Similar lables are also provided under the switchea where

necessary.

Identification lables of size 25 x 25 mm bearing

identification marks indicating numbering of reapective

equipments are provided beside the semaphores, pouer

transformer and auxiliary transformer positions on’ control

panels. The control and local/remote selector toggle switches

are provided with suitable lables duly Inserted in their

pockets available for the purpose. The echene of numbering of

various equipmenta in traction sybstationa are supplied by the

purchaser. ‘

All push buttons on the control board} have guitable

inscription on the collars indicating the functions of each

puah button, and where auch collara are\ not available,

separate indicating labela of PVC sheet of sultable width and

vlength not more than the overall outside dimensions of the

puah buttona are provided. Similarly, the fuhetion of each

indication and annunciation LED is Indicated\by a label of

elegant and appropriate aize provided alongeidé/alongwith the

concerned LED holder.

Plastic plates about 50 mm wide, bearing suitable captions to

identify the transformer bay and corresponding dutgoing 25 kV

feeder, are provided on the top of each relay, and control

panel. ‘

All the identification labels on the exterior sf control and

relay panels are secured with the help of chromium plated

metallic screve. 1

Identification labels are also provided in tle interior of

the control panel. For auch of the equipments, and fittinga

which are exélusively mounted inaide the contrdl. panel, the

labele of auitable size indicating function ‘of teapective

equipment aré provided. Whereas the labele inai\e the control

board for the equipments mounted flugh/semi-flush outalde the

conteol and relay panels, bear reference \index code

corresponding to the achematie diagrama.

The labeld inside the panels are secured with the help of

adhesive of good quality (wherever necessary). Th\ labela in

the interior of the board under the equipments/relays are 90

'

18

4.44.9

Labe

provided that they are not obscured due to bunches of wire

rung and any other obstructions. Painting of inacriptiona is

not permitted.

All ingcriptiona on the labels to be fixed on the control and

relay panela are made on the PVC aheet atrip of black

background with white engraved lettera/figurea. However, the

labels to be fixed inside the panela are either of engraved

letterings or of aluminium anodized screen printed type.

The lettering for inscriptions on the labels are generally of

the following sizes:.

1 description Size of label Height of

Lettera/figurea

1) Main labels to be 50 mm x length 15 mm (two rows)

provided on the to ault

top panels.

1i) Circuit labels to 13 mm x 65 mm 5 mm (single row)

be provided at the

bottom of the panels

4i1)Funetion label under 13 mm x 65 mm 4 mm

the equipments

dv) Push button and 4 mm(single row)

indication LED labela 3mm(double row)

v) Equipment numbering 25mm x 25 mm 7 som

label.

vi) Control & selector toggle 7 mm

awiteh labela.

vil)Labels under fuses and 25mm x 25 mm 3 mm

Links.

vili)Reference labels 25mm x 15 mm 5 mm

(Interior of panel)

ix) Terminal block pillar 10mm x 15mm 5 mm

numbering labels.

x) Terminal numbers 3 mm

on terminal blocks.

xi) Function inscriptions 3 mm

on terminal blocks.

Any, other label not covered above are of matching eize

19

4.15.1

4.15.4.1

4.15.1.2

4.15.1.3

4.15.2

3

ESTS

GENERAL

Only after all the designs and drawings are approved and

clearance given by RDSO to thia effect, the manufacturer takea

up manufacture of the prototype for RDSO inspection. It is

clearly understood that any changes required to be done in the

prototype - as required by RDSO is done expeditiously.

Before giving the call to RDSO/The Chief Electrical Engineer

for inspection and testing of the prototype of the system, the

manufacturer submits a detailed teat achedule consisting of

schematic circult diagrams for each of the tests and nature of

the test, venue of the test and the duration of each test and

the total number of days required to complete the test at one

atretch. Once the achedule ia approved, the test are

invariably done accordingly. However, during the process of

type testing or even later, RDSO representative reserves the

right to conduct any additional test(s) besides those

specified herein, on any équipment/sub-system or system so as

to teat the ayatem to hie satiefaction or for gaining

additional information and knowledge. In case any dispete or

disagreement arises between the manufacturer and RDSO/The

Chief Electrical Engineer during the process of testing as

regards the type tests and /or the interpretation and

acceptability of the type test results, it is brought to the

notice of the Director General(Traction Installation),

RDSO/The Chief Electrical Engineer aa the cage may be whose

decigion is final and binding.

In the event of the tests not being cartied through to

completion at one stretch for any reason attributable to the

auccesaful tenderer/manufacturer and it ie required for the

representative of the Purchaser/Director General (Traction

Installation),Research Designe & Standards: Organiaation,

Lucknow to go again or more number of times to the works of

the successful tenderer/manufactucer or other| place(a) for

continuing and/or completing the teats on the piototype(s) of

the equipment, the aucceaaful tenderer /manufacturer reimburses

to the purchaser/Director General (TI),Researth Deslgna &

Standards’ Organisation,Lucknow, 1a paid through a demand draft

to the concerned accounta officer of the Purchager/Director

General (TI), Research Designa & Standards drganiaation,

Lucknow, as is advised to the \ succeasful

tenderer/manufacturer.

TYPE TESTS

The relays are type tested as per 15:3231,1S:8636 and IEC

relevant standard for microprocessor based relays (if any)

or/and any other relevant standarde. All jnstrumenta,

interpoaing CTa and any other equipmenta ae thi purchaser

desires are type tested as per the latest version of

respective standard IS/BS Specificationa applicable.

20

aease2 el

4.15.2.2

4.15.35

"alag.3.4

asd

TEMPERATURE RISE TEST

The temperature rise of the coil of the relay does not exceed

the limite of 55 deg C and 80 deg C for Claga- A and Clasa-B

ingulation respectively.

If the prototype of the relays and other equipments conforming

to this specification has already been approved in connection

with previous supplies to Indian Railways, fresh prototype

testing is waived if it had passed the prototype tests earlier

and no changes in the design or material used are made.

ROUTINE TESTS

All relayd, inakeumanta interpading CTa and other equipmente

are subjected to routine tests at the manufacturer’s works aa

per the relevant Standards.

The following checks and tests are carried out on the complete

control and relay panel:

1) VISUAL CHECKS;

General check of the control board in respect of construction,

wiring, provision of various equipments/relays etc.

1i) OPERATION TESTS:

Operation tests on all equipments, switches and tests to prove

correctness of wiring of various circuits including

indications, alarms, operation of relays and annunciation etc.

4{1) POWER FREQUENCY HIGH VOLTAGE WITHSTAND TESTS

Vpltage test on the panels with all equipmente and wiring for

gwithatand voltage of 2 kV (rma) to earth for one minute.

{v) INSULATION RESISTANCE TESTS:

Measurement of ingulation resistance of the complete panel

viring, ahd circuit by circuit, with all equipmente mounted on

the panel, by uaing 1000 V meger.

Only after clear written approval of the results of the testa

on the prototype 1s communicated by RDSO/Purchaser to the

manufacturer, he takes up bulk manufacture of the equipment-

which ia strictly with the same material and process as

adopted for the prototype. In no circumstances, material other

than those approved in the designs/dravings and/or the

prototype is used for bulk manufacture on the plea that they

had been obtained prior to the approval of the prototype

2a

4.16

4.16.1

4.16.1.1

SCHEME OF PROTECTION

The scheme of protection provided at each of the traction

substations comprises of the following:

Gi) Protection of the 220/27 kV or 132/27 kV or 110/27 kV or

66/27 KV transformer inatalled at the traction aubatation.

il) Protection of the 25 kV traction overhead equipment.

iii) Protection of shunt capacitor bank equipment.

SCHEME OF PROTECTION FOR 220/27 KV OR 132/27 KV OR 110/27 KV

OR 66/27 KV TRANSFORMER

DIFFERENTIAL PROTECTION

Protection against internal faulte is provided by means of a

sensitive single-pole differential relay. The relay is of the

high speed type and operates in less than two cycles. The

following features.are incrporated in the relay:

\

1) There 1a no necessity for changing the getting of the relay

when the trangformer tap is changed. The trinaformer is

provided with tapa from -15% to +10%.

ii) Necessary harmonic restraining features is incorporated to

prevent operation due to in-rush. of magnetisatiin. current

when the transformer ie charged either from thedlV or the

LV side. }

iil) The relay does not operate for maximum through fault

current. 1

iv) The current setting of the relay is adjustable, j}referably

between the range of 20% and 80%. The minimus current

setting is as low as possible to obtain better eersitivity.

v) Adjustable bias setting is aleo provided. The Mias at

minimum operating current getting le 20%,30% & 40%'th auit

the tapping range of the traction tranaformer and \other

design consideratione.

The relay 1s connected to bushing type current tranafothera

provided in the bushing of 220/27 kV,132/27 «V,110/27 kV, 6\/27

kV tranaformera; see clause 4.18. However, interpoaing curtint

transformers of suitable ratio and rating with matcling

characteristica of knee point voltage, excitation current lte.

are provided with the differential relay in order to boost: up

the bushing CTs secondary current, at full load, to a vaue

equal to relay rated current.Magnetisation and catio etor

curves for the current transformers are supplied to he

auccesaful tenderer to enable him to match the characteriat la

of the relay and interpoging CTs with those of ‘the currér

transformers.

22

4.16.1.2

4.16.1.3

4.16.1.4

EARTH - LEAKAGE PROTECTION

Back-up protection for internal earth faults within the

transformer is provided by means of a sensitive, high speed,

earth-leakage instantaneous relay of very low pick up current.

Such relays are provided separately of both the primary and

secondary aides of the transformer, Both on the primary and

the secondary sides the relays are connected to separately

mounted current transformers. The current setting for the

relay is adjustable between 10% and 40% of 5 Amps in equal

step at 5%. The relay is of T 10 class with operating time not

exceeding 10 ma.

OVER-CURRENT PROTECTION

Protection against over-current in the transformer provided by

meana of aingle-pole, non-directional over-current relay with

inveree definite minimum time lag characteriatics both on the

primary and the secondary sides of the transformer. Further,

an additional ingtantaneous over-current relay ia provided on

the primary side. On the primary side the over-current relay

is connected to separately mounted current transformers. On

the aecondary aide the over-current relay is provided only on

the live (unearthed) leg of the eecondary terminals and la

connected to a separately mounted current transformer. The

over-current relay on the eecondary side serves as back-up

protection againat faulta in the 25 kv overhead equipment and

algo Against bus faults, etc. The over-current relays on the

primary side shall serve as back up to the over-current relay

on the eecondary aide ag well as back-up to differential and

earth leakage relays against heavy faults. Proper

diecrimination is maintained in the operation of these two

aete of overcurrent relays. The setting on these relays are

adjustable as under:

i Current Time multiplier

setting setting

1. IDMT overcurrent 80% to 320% 0 to 3 secs.

on primary aide.

2. Instantaneous 400% to 1600% -

overcurrent on

primary side.

3. IDMT overcurrent 80% to 320% 0 to 3 secs.

on secondary aide. a

The instantaneous relays are of T 10 class with operating time

not exceeding 10 milli-seconda at 5 times the current setting.

The differential relay and earth leakage relays both on the

primary and secondary sides as alao the over~current relays on

primary side cause inter-tripping of the 220/132/110/66 kV and

25 kVcircult breakers associated with the transformer. The

23

4.16.1.5

4.16.1.6

4.16.1.7

4.16.2

4.16.21

inter-tripping of the associated transformer circuit breakers

on HV and LV sides is also effected due to other faults in the

transformer, namely Buchholz trip, excessive winding

temperature and excessive oil temperature trip. The IDMT over-

current relay on the secondary ide le, however, trip the

reapective circuit breaker on 25 kV aide only. The inter-

tripping of aasoclated transformer circuit breakera enviaaged

above is effected through a high speed tripping relay with

hand reset contacts. Such inter-tripping relay locks out the

closing of circuit breakera from all modea of closing commanda

viz. remote control, local control at the panel and also at

the circuit breaker mechaniam, until the inter-trip relay or

the lock out relay (if provided separately), is reset

manually.

OTHER PROTECTIVE DEVICES

The traneformers as supplied by the purchaser ia fitted with

the following warning and protective devicea:

i) Low oil level alarm.

ii)Buchholz relay with alarm and trip contacts. “

411) 011 temperature indicator with alarm and trip contacts.

iv)Uinding temperature indicator with alarm and teip contacts.

v) Peesaure relief device with alarm and trip contacte

These contacts are wired up to a weather-proof, terminal box

mounted on the tranaformer by the transformer: manufacturer.

The connections are extended to the alarm and trip circuits as

well as to annunclation acheme provided on the control panel.

CO-ORDINATION UITH EQUIPMENT MANUFACTURERS. .

The aucceaaful tenderer ensures necessary co-ofdihatioin with

the manufacturers of transformers, circuit’ breakers and

interruptors with regard to terminal markings ,wiring,scheme of

protection, etc. He obtains the namea of thefe manufacturers

from the purchaser. ; .

Particulars of separately mounted current tranaformera are

given in clause 4.18.

SCHEME OF PROTECTION FOR 25 KV OVERHEAD EQuirnenr

The substation equipment as well as the overhtaa equipment is

protected against short circuite and over-lodda by meanz of

feeder circuit breakers. Normally the tracks\on one side of

the substation are fed through one feeder, tle other feeder

circuit breaker is arranged to feed tracka oi both sides of

the gub-etation. the protection acheme fulfills the following

functions

2a

4.16.2/2

4.16.2.'3

1) To detect all short circuits over the zone of overhead

equipment fed by the feeder circuit breaker.

11)To operate with minimum delay in opening the circuit

breaker.

iil) To refrain from operation at the maximum working

current,i.e. to discriminate between the maximum load

currente and short circuit currents even though the

magnitude of the former is at times more than the latter

especially when the faults are remote from the substation.

iv)To detect and isolate faults on the ONE caused by

accidental coupling of two different phases from adjacent

substationa.

v) To provide single shot high apeed auto-reclosing of the

feeder circuit breaker.

vi)To reclose the 25 kV feeder circuit breaker through single

shot high epeed automatic reclosing acheme in the event of

feeder circuit breakers tripping on fault through any of

the three relays viz. admittance (Mho) relay for distance

protection , admittance (Mho) relay for wrong phase

coupling and instantaneous over current relay.

The normal zone of feed of a substation to a neutral section

variea from 25 to 40 Km under emergency feed conditiona,

however, the zone extends up to the next substation by closing

the bridging interruptors at the neutral aection and is about

double the zone of normal feed.It is apparent from the

impedance values given in para’2.9 that the fault current

under euch conditions could be well below the traction load

current. Over current or plain impedance relays which operate

below a certain impedance level and which function

independently of the phase angle between voltage and current,

ia unable to discriminate such faults. Therefore, a relay with

maximum torque angle for an impedance of given argument ia

required.

The protective system, therefore, comprise the following

relays:

4) An admittance (Mho) relay to cover the entire zone of

protection, i.e. from the substation to adjacent substation

and! to operate for any earth fault on the over head

equipment in the zone. In order to allow for the additional

impidance of booster tranaformera and return conductora,

the realys have a reach of at least 125 Km of single track

OHEwith an impedance of 0.41 Km / 70 deg. Ohms/Km.

ii) An admittance ( Mho) relay for protection againnt wrong

phace coupling due to phase to phase faulta with 120 deg.

or 60 deg. phase difference between two phages, with a

25

4.16.2.4

4.16.2.5

4.16.2.6

4.16.2.7

4.16.2.8

maximum torque angle of 125 deg. to 145 deg. The relay is

provided with a forvard "Off Set” to prevent it from

operating it from phage to earth faulte.

iii) An over current relay of instantaneous type which clears

faulta between the aubstation and the neutral aection, vith

an adjustable current aetting ranging from 200% to B00 &.

The inetantaneous relaya ig of T 10 claas -with operating

time not exceeding 10 ms.

iv) A gingle shot high speed Auto-reclosing scheme to work in

conjunction with the Master Trip relay is provided. The

auto reclosing scheme designed for a dead time adjustable

between 0.1 and 1 second (normally set at 0.5 second ) and

a reclaim time adjustable between 6 and “60 seconds

(normally set at 30 seconds , the operating duty of feeder

circuit breaker being 0-0.3 ¢ - CO - 30 8 - Co). A typical

single shot high speed Auto reclosing scheme is enclosed at

Annexure "A".

The relays (i),(ii) and (iii) in eub-para 4.16.2.3 above trip

the corresponding feeder circuit breaker in case of fault,

through a high speed gelf-cesot type tripping relay designated

ae Master Trip relay. i

Whenever a feeder circuit breaker ia tripped ‘due to operation

of any of the feeder protective relays, namely distance, urong

phage and inatantaneous over-current relayd, the concerned

auto recloging acheme clogea the breaker after a pre-set dead

time of 0.5 second. If the breaker trips again due to

presistence of fault during the reclaim tike of the auto

reclosing scheme, the acheme geta locked out! It is possible

to reset the locked out state either locally cr through remote

control. Necessary contacts for telesignalling the locked-out

state and for resetting the same are provided for interfacing

with the remote control equipment. Irrespective of whether the

auto reclosing scheme is in the normal condition or in the

locked out condition, it is possible to operate the circuit

breaker locally as well as through remote contiol.

Suitable operation countere are also be providid individually

for distance protection admittance (Mho) rela}, wrong phage

coupling admittance (Mho) relay, instantaneous |current relays

and also for the auto- reclosing scheme.

In addition to the above protection, an instantaneous acting

under voltage relay is provided by the purchager to teip the

bridgning interruptor at the neutral sectich in case of

undervoltage during emergency feed conditions.

The relaya are suitable for operation from the 25 kv current

teanaformer and 25 kv potential tranaformer tdthe following

particulara:

cr PT

1, Rated system voltage 25 kV risingupto 30 kV

26

4.16.2.9

4.16.2.10

4.16.2.11

1

2. Rated transformation ratio. 1000-500/5A —25000/110V

1500-750/5A

3. Rated burden 60 VA 100VA

4. Rated accuracy limit factor 15 =

8. Accuracy class SP as per 1.0/3p as

1S:2705 per 18:3156

(pt. 1IT)- (pt. 11a1I1)

1981 1978

The relays conform to accuracy class 15 as per IS:3231-1965.

The operating time for the Mho relays ia as small as possible

and does not exceed 20 milliseconda for a source to line

Impedance ratio of 1:1 in cawe of earth fault relays. The

operating times for minimum and maximum settinas of the relays

in terms of distance are furnished by the tenderer together

with the variation in operating time for various fault

positions expressed as a percentage of relay setting.

The polarizing input for relays have a tuned memory

circuit, so that it is poesible to maintain a polarizing

signal even after a fault occurs, for a aufficiently long time

for the operation of relay to operate in cave of a fault close

to the substation, when the restraining voltage disappears.

The celaya are Ingenaitive to power ewings, heavy overload and

transient condition including magnetizing inrush current of

locomotive transformers and are euitably designed to

comipengate the effect of fault arc resistance.

SCHEME OF PROTECTION FOR SHUNT CAPACITOR BANK EQUIPMENT:-

The protection system for shunt capacitor bank include

protection againat overcurrent, overload,

overvoltage,undervoltage and unbalanced current protection,

41) Overcurrent relay with inverse definite minimum time (IDMT)

element with suitable settings.

ii) Overvoltage relay - Overvoltage protection against system

evervoltagea is provided with an inverse time

characteriatica with aultable settings. The overvoltage

relay is energised from a potential transformer connected

to the main bue bar on the incoming side of the circuit

breaker controlling the capacitor bank. Ifrequired an

interposing voltage tranaformer (IVT) of euitable ratio is

used for matching the capacitor overvoltage withstand

characteriatice.

11) Undervoltage relay - In conjunction with the timer to

enable the capacitore to diacharge before reclowure. The

felay provided for thie purpoee is connected to the bue

potential transformer and have high resaeting ratio. Also

A time delay relay ia included with adjustable setting of 0

27

4.18

4.18.1

iv) The capacitor bank is protected by means

to 5 minutes to provide a time lag before the breaker can

be reclosed. However, thia relay la not required if a timer

la included in the cloging circult of ite aasoclated

breaker to prevent ite reclosing within 5 minutes.

£ unbalance

current protection. The capacitor bank is coniiected as a

bridge and an unbalance sensing current transformer

provided. The current tranaformer ratio is chosen so that

even one capacitor element failure can be detected. The

realy used is a harmonic insensitive overcurrent relay with

fixed time delay characteristic. The time delay is set at

approximate 0.1 aec.

v) Each capacitor element is protected by means of internal

fuae. The fuse is connected in series with each capacitor

element ingide the capacitor unit to limit the effects of

dielectric failures. If a puncture of dielectric occurs,

only one element is disconnected and the capacitor unit

continue to operate. While selecting the fuse rating, it is

neceseary to choose proper time- current characteristics

which in turn significantly depends upon the cross section

and circumatance of the fuse. Fuses chosen’ have adequate

thermal capability and comply with | relevant = 1S/IEC

Specification.

PARTICULARS OF POTENTIAL AND CURRENT TRANSFORMERS

The relays for transformer protection are suitable for

operation from current transformers to the following

particulars.

Particular '

Current Class of Rated accuracy

Transformer Ratio Burden accuracy as limit factor.

per IS:2705 \

1.Bushing CTs

1) 220/27°kV Transformer

HV. 200/5 7 PS -

Lv 1600/5 a PBS 7

41)132/27 kV Transformer

HV 330/5 - PS a

Lv 1600/5 - PS -

iii) 110/27 kV Traneformer

Hv 400/5 - PS -

Lv 1600/5 - PS 5

iv) 66/27 kV Transformer

HV 660/5 = PBS -

Lv 1600/5 - Ps -

28

4.18.2

4.18.3}

4.19.1

2.Separately mounted CTs on HV side.

220 kV CT 200 - 100/5 30 VA SP 15

132 kV CT 400 - 200/5 30 VA SP 15

110 kV CT 400 - 200/5 30 VA SP 15

66 kV CT 800 ~ 400/5 30 VA 5P 15

3.Separately mounted CT@ on LV side.

25 kV CT 1000 -500/5 60 VA 5P 15

1500-750/5 60 VA 5P 15

For details of the bushing current transformers purchaser's

Specification No. ETI/PSI/118 (10/93) (clause 5.1.20) for

reapective power transformers is referred.

The particulars of these current and potential traneformere

are given in the following apecificationa of the purchaser:

ETI/PS1/117 (7/88) for 220/132/110/66 kV current

transformer.

ETI/PS1/90(9/87) for 25 kv current transformer.

ETI/PS1/8 (10/92) for 25 kV potential transformer.

for a.c. traction substation and

avitching station.

The drawing No. ETI/PS1/024-1 and ETI/PSI/0226-1 showing - the

proposed achemes of connections at the exclusively atep down

single/double transformer gubstations for the location of

various and current transformers, inatruments and protective

relays are listed in the Annexure-II and III respectively.

The normal load current of a 25 kV circuit is 800 A with 21.6

NVA transformer. The circuits including the transformers are,

however, designed to take 50% overload for 15 minutes and 100%

overload for 5 minutes. Normally, 500/5 or 750/5, CT ratio is

used in the instrument and relay circuits for 25 kv current

transformers.

NOTE: The two transformers in a substation are operated in

parallel if required due to increase in load. To enable

this, dual ratio 25 kV current transformer (1000-500/5

and 1500-750/5) are specified.

LAY OUT OF EQUIPMENT ON THE CONTROL PANEL

The inatruments, control toggle switches and the mimic diagram

are arranged on the front panela of the control board

dealgnated as ‘control Panels’. The protective relaya ar

provided on the rear panela designated as ‘relay panel’.

29

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Signal Engineering Manual Part 1Document171 pagesSignal Engineering Manual Part 1pradeeepgarg67% (3)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- UGC06 - Part2 - Section VII - (ODS) - R2 - 20141127Document408 pagesUGC06 - Part2 - Section VII - (ODS) - R2 - 20141127pradeeepgargNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- ACTMDocument823 pagesACTMdc12dc86% (7)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Scada SPC For Mumbai-AreaDocument50 pagesScada SPC For Mumbai-AreapradeeepgargNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- UGC06 - Part2 - Section VIII - (OCS) - R2 - 20141127Document392 pagesUGC06 - Part2 - Section VIII - (OCS) - R2 - 20141127pradeeepgargNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Metro Rail Design Criteria Section 07 Rev 1 100611 PDFDocument55 pagesMetro Rail Design Criteria Section 07 Rev 1 100611 PDFamitvaishnav10% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 25 KV Traction SCADA SPECIFICATION No. TISPCRCCSCADA0130 (Rev-1) 1Document70 pages25 KV Traction SCADA SPECIFICATION No. TISPCRCCSCADA0130 (Rev-1) 1pradeeepgarg100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Case Study On Laying of 132 KV Underground Cables in LMRC. by - Mahendra Kumar Director - Rolling Stock and SystemsDocument48 pagesA Case Study On Laying of 132 KV Underground Cables in LMRC. by - Mahendra Kumar Director - Rolling Stock and Systemspradeeepgarg100% (2)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Direc':Ofu:Re: Tl/SPCIOH&ITO LF L'l1-UDocument13 pagesThe Direc':Ofu:Re: Tl/SPCIOH&ITO LF L'l1-UpradeeepgargNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 79 Ti SPC Ohe Lwtsi 0060 1 21Document22 pages79 Ti SPC Ohe Lwtsi 0060 1 21pradeeepgargNo ratings yet

- 82 Ti SPC One Toolpl 0990 (Tirfox) 1 2Document3 pages82 Ti SPC One Toolpl 0990 (Tirfox) 1 2pradeeepgargNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 80 Ti SPC Ohn SNS 0000 1 20Document24 pages80 Ti SPC Ohn SNS 0000 1 20pradeeepgargNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 21 Eti Psi 147 (03 92)Document28 pages21 Eti Psi 147 (03 92)pradeeepgargNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 23 Eti Psi 159 (10 94) PDFDocument41 pages23 Eti Psi 159 (10 94) PDFpradeeepgargNo ratings yet

- Ti SPC Ohe Atd 0060Document16 pagesTi SPC Ohe Atd 0060pradeeepgarg100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- TI-DRG-CIV-HGAUGE-RDSO-00002-05-0 (Standard Plan Height Gauge For Level Crossing (For Clear Span Above7.3m Upto 12.2m) Details of Structure and Foundation)Document1 pageTI-DRG-CIV-HGAUGE-RDSO-00002-05-0 (Standard Plan Height Gauge For Level Crossing (For Clear Span Above7.3m Upto 12.2m) Details of Structure and Foundation)pradeeepgarg80% (10)

- 21 Eti Psi 139 (12 89)Document47 pages21 Eti Psi 139 (12 89)pradeeepgargNo ratings yet

- 22 Eti Psi 150 (4 94)Document52 pages22 Eti Psi 150 (4 94)pradeeepgargNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 19 Eti Psi 132 (8 89)Document45 pages19 Eti Psi 132 (8 89)pradeeepgargNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Ingress Protection Reference Chart RM TechnicalDocument2 pagesIngress Protection Reference Chart RM TechnicalMayank Kumar GuptaNo ratings yet

- Psi FinalDocument162 pagesPsi FinalsselmtpdrNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- TI-DRG-CIV-HGAUGE-RDSO-00001-05-0 (Standard Plan Height Gauge For Level Crossing (For Clear Span Upto 7.3m) Details of Structure and Foundation)Document1 pageTI-DRG-CIV-HGAUGE-RDSO-00001-05-0 (Standard Plan Height Gauge For Level Crossing (For Clear Span Upto 7.3m) Details of Structure and Foundation)pradeeepgarg63% (8)

- TI-DRG-OHE-FTGFE-RDSO-00001-00-1 (18mm Single Clevis Assembly Modifiesd)Document1 pageTI-DRG-OHE-FTGFE-RDSO-00001-00-1 (18mm Single Clevis Assembly Modifiesd)pradeeepgargNo ratings yet

- Genset Installation RecommendationDocument30 pagesGenset Installation RecommendationAnonymous MDkp0hnb3l100% (8)

- Psi FinalDocument162 pagesPsi FinalsselmtpdrNo ratings yet

- Eti Ohe 13 - 4 - 84Document8 pagesEti Ohe 13 - 4 - 84pradeeepgargNo ratings yet

- Elsewedy ControlDocument62 pagesElsewedy ControlpradeeepgargNo ratings yet

- HANDBOOK ON ARTISANS TOOLS FOR TRACTION DISTRIBUTION DEPOTS (By RDSO)Document79 pagesHANDBOOK ON ARTISANS TOOLS FOR TRACTION DISTRIBUTION DEPOTS (By RDSO)pradeeepgargNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Three Phase LocomotiveDocument138 pagesThree Phase LocomotiveManas Moharana67% (3)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)