0% found this document useful (0 votes)

239 views6 pagesElectrical Engineering Qualifications

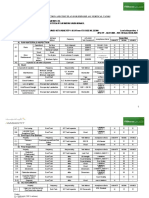

The document provides details about Wakeel Ahmed's qualifications and experience as an electrical engineer and inspection engineer. It outlines his educational background with a Master's in electrical engineering and Bachelor's in electronics engineering. It also lists his work experience as an inspection engineer from 2014 to present at AMO & Partners Engineering Co., where he is responsible for quality assurance inspections of various electrical and instrumentation systems, equipment, and components. The document provides examples of systems he has inspected, including low and medium voltage cables, instrument and telephone cables, fiber optic cables, cable tray systems, and switchgears.

Uploaded by

gayas416Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

239 views6 pagesElectrical Engineering Qualifications

The document provides details about Wakeel Ahmed's qualifications and experience as an electrical engineer and inspection engineer. It outlines his educational background with a Master's in electrical engineering and Bachelor's in electronics engineering. It also lists his work experience as an inspection engineer from 2014 to present at AMO & Partners Engineering Co., where he is responsible for quality assurance inspections of various electrical and instrumentation systems, equipment, and components. The document provides examples of systems he has inspected, including low and medium voltage cables, instrument and telephone cables, fiber optic cables, cable tray systems, and switchgears.

Uploaded by

gayas416Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd