Professional Documents

Culture Documents

Dealer Information SGI ECU, Type 2 - PDF

Uploaded by

Ivan PetrovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dealer Information SGI ECU, Type 2 - PDF

Uploaded by

Ivan PetrovCopyright:

Available Formats

Search...

Search for Log in Registration

Dealer Information SGI ECU, type 2

Laser Cutting Machine Price

3-2-1 warranty: 3 years for machine, 2 years for lPG, 1 year for labor.

Bodor Laser OPEN

Page: 2 of 41 Page Width

Свали сега

Започнете да изтегляте вашите файлове

To make this website work, we log user data and share it with processors. To use this website, you must agree to our Privacy Policy, including cookie policy. I agree.

WireWound

fusing alphacell.co ОТВАРЯНЕ

Resistors

setfuse.com

SETfuse

Imax above 1.5KA,

not damage under The SGI ECU, type 2

264VAC 1W/2W, UL/

VDE (UL1412, Table of contents.

IEC60065).

Introduction 3

1. Function SGI ECU 4

2. Connections SGI ECU, type 2 6

2.1. The inputs of the SGI ECU: 6

2.1.1. Opening time petrol injectors (TiB) 6

2.1.2. Engine Coolant Temperature (ECT) 7

2.1.3. Pressure in the intake manifold (MAP) 7

2.1.4. LPG vapour pressure (Pvap) 7

2.1.5. Power supplies 8

OPEN 2.1.6. Pulse (from the LPG switch) 8

2.2. The outputs of the SGI ECU: 9

2.2.1. The SGI injector drivers 9

2.2.2. The drivers of the LPG shut-off valves 9

2.2.3. Control of the Interface Unit (mode) 10

Similar documents

2.2.4. Control of the diagnosis LED

2.2.5. Control of the beeper

10

11

2.2.6. Ground connections 11

3. Wiring diagrams SGI 12 USER MANUAL OPERATION

3.1. Wiring diagram SGI ECU 12

3.2. Wiring diagram Interface Unit 15 AND USE OF CAR WITH. Diego

4 The SGI switch 17 G3 / NEVO SEQUENTIAL GAS

USER MANUAL OPERATION AND

USE OF CAR WITH Diego G3 /

NEVO SEQUENTIAL GAS

INJECTION SYSTEM Page 2 z 7

WireWound fusing Resistors Table of contents 1. STARTING

THE ENGINE... 3 2. CONTROL PANEL... 3 2.1

Indication of the current level

Imax above 1.5KA, not damage under 264VAC 1W/2W, UL/VDE

(UL1412, IEC60065). More information

PUSH BUTTON START

setfuse.com OPEN

INSTALLATION MANUAL

PUSH BUTTON START

INSTALLATION MANUAL

ALTHOUGH THIS PRODUCT HAS

SHARE HTML DOWNLOAD BEEN THOROUGHLY TESTED

KPIERSON TECHNOLOGIES

Save this PDF as: ASSUMES NO RESPONSIBILITY FOR ANY

DAMAGE THAT MAY RESULT BY THE

WORD PNG TXT JPG INSTALLATION OF THIS PRODUCT.

0 More information

Barry Sta ord 10 months ago Views: 48

Transcription

SPONSORED SEARCHES 1 Dealer Information SGI ECU, type 2 Galileïstraat 15 PO box CA Veenendaal The Netherlands Tel. +31 (0) Fax +31 (0)

Internet : tele exg .nl SGI ECU, type2 ENG*

Electrical Wiring Diagram

SGI ECU Power Supply Table of contents. Introduction 3 1. Function SGI ECU 4 2. Connections SGI ECU, type The inputs of the SGI ECU:

2

Opening time petrol injectors (TiB) Engine Coolant Temperature (ECT) Pressure in the intake manifold (MAP) LPG vapour

pressure (Pvap) Power supplies Pulse (from the LPG switch) The outputs of the SGI ECU: The SGI injector drivers The

drivers of the LPG shut-o valves Control of the Interface Unit (mode) Control of the diagnosis LED Control of the beeper Ground connections Wiring

diagrams SGI Wiring diagram SGI ECU Wiring diagram Interface Unit The SGI switch General information Working principle SGI switch Switch-over strategy

Electrical connections Diagnostic equipment User manual DiagnoseTool SGI (DTS) Installation DealerTool SGI Selection COM-port Adding a new data- le

Functions DiagnoseTool SGI (DTS) Identi cation menu Read in and outgoing signals (System Info) Diagnosis (Error codes) Software Update Modem

communication Trouble shooting 36 Annex 1. Error codes SGI ECU, type 2 37 Annex 2. Available Updates for the SGI ECU, type 2 39 Annex 3. Available

Modi cations for the SGI ECU, type 2 40 Annex 4. Available Calibrations for reprogramming the SGI ECU, type 2 41 SGI ECU, type 2 ENG*

3 Introduction. Like already pronounced in the rst version of the Dealer Information SGI, Tele exGFI Europe (formerly: AG Autogas Systems) has

introduced the second generation SGI ECU at the start of The second type of SGI ECU has more capabilities in terms of speed, capacity and diagnostics,

compared to the rst type of SGI ECU. The second type of SGI ECU is produced in almost the same housing as the SGI Interface Unit (as shown below),

because of which the installation of the unit itself has been facilitated. Because the introduction of such an ECU brings several changes about in the SGI

system, Tele exGFI Europe made this supplement to the Dealer Information SGI. In this supplement the changes of the unit itself as well as its connections

and diagnostic possibilities are described. The below mentioned matters have successively been described in the following paragraphs: q q q q q q Function

SGI ECU Connections SGI ECU (inputs and outputs) Wiring schematics SGI ECU and Interface Unit Connections SGI switch Direct communication with the SGI

ECU Indirect (modem-) communication with the SGI ECU SGI ECU, type 2 ENG*

4 1. Function SGI ECU. Just like the previous version of the SGI ECU, the way of controlling of the SGI injectors has been fully based on the translation of the

opening times of the petrol injectors, which are controlled by the Motor management computer (ECM). Thus it is still the ECM, which controls the opening

time of the SGI injectors, converted by the SGI ECU. The composition of the memory of the SGI ECU, type 2 has been shown below: RAM: EEPROM: PROM:

The RAM memory of the microprocessor is a kind of read and write memory, which read the incoming signals all the time. The measured values are used to PRODUCTIVITY THROUGH

execute calculations to be able to determine the correct opening time of the SGI injectors. In this way, possible errors will be detected and written into the INNOVATION 600 CONTROL

memory of the microprocessor. The RAM memory is maintained by the constant power supply of the SGI ECU. In contradiction to the rst type, the second

type of SGI ECU makes use of a separate EEPROM memory, in which engine speci c calibrations are being stored. Also the unique software and hardware DIRECT DRIVE

identi cation is stored in the EEPROM memory for the bene t of possible warranty issues. In case the RAM memory detects any errors, these will be saved in

Rev. D PRODUCTIVITY

the EEPROM memory after the ignition is switched o . Just like the RAM memory, the PROM memory has been integrated inside the microprocessor. The

THROUGH INNOVATION 600

basic SGI program is stored in this part of the memory, which is basically the same for each type of application. This program executes all calculations and

CONTROL DIRECT DRIVE

functions of the SGI translation system. SGI ECU, type 2 ENG*

TECHNICAL/OPERATION

MANUAL 10 BORIGHT AVENUE,

5 For a more detailed description of the translation strategy, please consult chapter 2.2. of the general Dealer Information SGI. The translation principle KENILWORTH NEW JERSEY 07033

has been depicted below: Petrol injector The disconnection of the petrol injectors is taken care of by the same Interface Unit as with the rst system set-up. TELEPHONE: 800-524-0273 FAX: 908-686-

This is mainly a disconnection unit, in which transistors are placed with integrated simulation resistors. Connection (32-pole) Vacuum The Interface Unit The 9317 TABLE OF CONTENTS Page

Interface Unit has been undergoing some internal changes before the introduction of the second type of SGI ECU. Because of these changes, the

partnumbers of the Interface Units have changed, as listed below. The rst and second type of Interface Unit are interchangeable. First type: Second type:

Characteristics: AG AG disconnections, simulation 120 Ω, including zener diodes AG AG disconnections, simulation 120 Ω, without zener diodes AG AG More information

disconnections, simulation 240 Ω, without zener diodes SGI ECU, type 2 ENG*

6 2. Connections SGI ECU, type 2. The in and outgoing signals of the SGI ECU, type 2 are shown below schematically: The in and outgoing signals of the SGI Automotive Sensor Simulator.

ECU have been explained in the next paragraphs The inputs of the SGI ECU: Opening time petrol injectors (TiB): Equally to the rst type of SGI ECU, the SGI Automotive sensor simulator.

ECU, type 2 has 4 digital inputs to measure the opening time of the petrol injectors. These signals are coming from the Interface Unit and are still used to be

able to calculate the opening times of the petrol injectors. Compared to the rst version of the SGI ECU, no change has been made regarding these inputs. Operating manual. AutoSim

SGI ECU, type 2 ENG* Automotive sensor simulator

Operating manual AutoSim

7 Engine Coolant Temperature (ECT): The analogue input that monitors the Engine Coolant temperature has not changed as well compared to the previous Contents Introduction.. page 3

situation. As yet, the signal of the already present ECT sensor of the motor management system is branched o and measured by an analogue input of the Technical speci cations.... page

microprocessor. In case the original ECT sensor of the engine cannot be read, an external ECT sensor will be tted inside one of the coolant connections of 4 Typical application of AutoSim

the SGI vaporizer Pressure in the intake manifold (MAP): As described earlier, the internal map sensor of the Interface Unit measures the pressure in the simulator..... page 4 Device appearance...

intake manifold. The signal is measured through the wiring in between the Interface Unit and the SGI ECU. The map sensor signal of a turbo charged engine page 5

needs to be measured on a di erent (highpressure) map sensor LPG vapour pressure (Pvap): To be able to determine the di erential pressure over the SGI

injectors, next to MAP, the pressure of the vapour LPG is measured inside the vaporiser. This has remained the same because of using the LPG pressure More information

sensor, which is tted in the outlet of the SGI vaporiser. The SGI ECU supplies +5V and ground to the sensor. Its signal is read by an analogue input of the SGI

ECU. SGI ECU, type 2 ENG*

HANDBOOK on SEQUENT 24

HANDBOOK on SEQUENT 24

INDEX 0 - Introduction 0.1 -

What is SEQUENT 24? 0.2 - Main

WireWound fusing Resistors di erences with the previous

SEQUENT systems 1 -

Understanding the SEQUENT 24 system 1.1 -

Imax above 1.5KA, not damage under 264VAC 1W/2W, UL/VDE (UL1412, SEQUENT 24 ECU 1.2 - Changeover

IEC60065).

More information

setfuse.com OPEN PC SERIAL INTERFACE FOR

LAMBDA GAS CONTROL LGC-

8 Power supplies: In contrast to the rst type of SGI ECU, it is necessary to connect two power supplies, instead of one: +12 Volt, switched +12 Volt, 700

constant The switched power supply is in fact the main power supply of the SGI ECU. This power supply must be connected, either to the power supply of PC SERIAL INTERFACE FOR

the petrol pump or the petrol injectors for safety reasons. These are normally switched o automatically when the engine stalls. To prevent that the SGI LAMBDA GAS CONTROL LGC-

program does not shut-o properly, the switched power supply is kept internally for a maximum of 17 seconds. Regularly, the incoming +12 Volt power 700 INDEX 1- Introduction 2-

supply is connected to ground via an external resistor. Because of this, the SGI program will always be shut-o properly after the ignition has been switched AGI-PRO Program Set-up 3- AGI-

o . During 17 seconds, it is possible that the diagnosis led is on (after the ignition is turned o ). The constant power supply is necessary because of certain PRO Program Use 3.1- Interface

additional functions, which have been implemented in the program of the second type of SGI ECU. An example is that all detected errors will be written into Link 3.2- How Start AGI-PRO program 3.2-1.

the EEPROM memory after the ignition has been turned o Pulse (from the LPG switch): Just like the rst type of SGI ECU, the second type switches over Page MONITOR 3.2-2. Page

from petrol to LPG (and oppositely) when a digital input of the microprocessor is connected to +12 Volt momentarily. The +12 Volt pulse is switched by

pressing the button on the LPG switch. SGI ECU, type 2 ENG*

More information

9 2.2. The outputs of the SGI ECU: The SGI injector drivers: The SGI injectors are controlled open in the same manner as with the second type of SGI ECU.

The injectors are connected to a +12 Volt power supply (switched). The other side of each injector is connected to a low side driver inside the SGI ECU. The

time of switching the SGI injectors to ground (= opening time) determines the amount of fuel injected into the intake manifold. This opening time is

INSTRUMENT PANEL. 1995

calculated by translating the opening time of the petrol injectors, as described in chapter The drivers of the LPG shut-o valves: The rst type of SGI ECU Volvo 850 DESCRIPTION &

controls the opening of the LPG shut-o valves simultaneously by an internal high-side driver. Both solenoids (on the SGI vaporizer and on the tank) are both

opened by a +12 Volt power supply; the other side is connected to ground continuously. The second type of SGI ECU has two separate drivers to control the

OPERATION. 1995-96

shut-o solenoids: For the shut-o valve on the vaporizer For the shut-o valve on the tank The shut-o valves are opened in the same way as the SGI INSTRUMENT PANEL 1995 Volvo

injectors: one side is connected to +12 Volt, whilst the other side is controlled to ground (by two low-side drivers inside the SGI ECU). The shut-o solenoid 850 1995-96 ACCESSORIES &

on the tank is connected to the switched power supply of the SGI ECU; the other side is connected to ground when the SGI ECU is in LPG mode (also before EQUIPMENT Volvo Instrument

running on LPG). After switching o the engine or switching over to petrol operation, the shut-o valve will close directly. SGI ECU, type 2 ENG* Panels 850 WARNING: When

working around steering

10 The shut-o valve on the SGI vaporiser is connected to a constant power supply; the other side is connected to ground when the engine is running on column and before performing repairs,

LPG. After switching o the ignition, the shut-o valve on the vaporiser does not close directly with the shut-o valve on the tank. After switching o the disconnect and shield battery ground

ignition the shut-o valve on the vaporiser stays open for approximately two seconds. The reason for this is, that the di erential pressure over the SGI

injectors remains 800 millibar, because of which the injectors close o more e ectively. The result will be a better starting behaviour of the engine. This is

More information

the reason why the shut-o solenoid needs to have a constant power supply instead of a switched one. To be able to control this solenoid to ground, the SGI

ECU needs a constant power supply as well, which is di erent to the rst type of SGI ECU Control of the Interface Unit (mode): The moment of disconnecting

the petrol injectors is determined by the SGI ECU according to the measured ECT signal. Since the Interface Unit takes care of the injector breaks, the SGI

ECU controls the Interface Unit to connect or to disconnect the petrol injector wires. This is done by the so-called mode output of the SGI ECU. This is a low-

Signature and ISX CM870

side driver, which connects the input of the Interface Unit to ground to disconnect the petrol injectors. During running on petrol this mode signal will be +12 Electronics

Volt, because of which the petrol injectors are connected. The Interface Unit will disconnect the petrol injectors when the voltage on the mode input is lower

Signature and ISX CM870

than 1,2 Volt, which is the case when running on LPG Control of the Diagnosis LED: The SGI ECU controls the diagnosis LED on the switch on. The LED will be

Electronics Cummins West

on when a +12 Volt power is switched on (via a high-side driver inside the SGI ECU). When the LPG tank becomes empty during driving, the SGI ECU will take

Training Center System

care that the system switches back to petrol. I this situation, the diagnosis LED will be ashing, which is the same for the rst and for the second type of SGI

Description General

ECU. Compared to the rst type of SGI ECU, the second type has much more diagnostic capabilities. In case an error is detected by the ECU while running on

Information The Signature and

LPG, the diagnosis LED will be controlled on continuously by the output of the SGI ECU (in combination with the indication LEDS on). SGI ECU, type 2 ENG*

ISX CM870 engine control system is an

electronically operated fuel control system

11 In case the error is detected continuously, the diagnosis LED will be kept on after switching the ignition o and on; if the error is temporarily, the

diagnosis LED will be o again Control of the beeper: The beeper (behind the dashboard) is controlled by a low-side driver inside the SGI ECU when the

system has switched back to petrol because of an empty LPG tank. Also the diagnosis LED will be ashing in this situation. Both the beeper and the diagnosis More information

LED will be o when the switch is pressed once. This procedure is described in paragraph more in detail Ground connections: The ground connection of the

SGI ECU is considered as being an output, because the direction of the current is to the outside. The wiring harness of the rst type of SGI ECU had two

separate ground wires, one for the ECU and one for the Interface Unit. The wiring harness of the second type of SGI ECU only has one central ground wire CurveMaker v2.1 DYNAFS

for the whole SGI system. This wire is normally connected directly to the battery ground. SGI ECU, type 2 ENG* programmable ignition

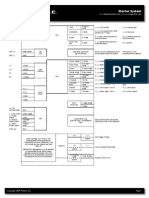

12 3.1. Wiring diagram SGI ECU. 3. Wiring diagrams SGI Just like the Interface Unit, the second type SGI ECU has a 32-pole Molex -connector. These are software

however not interchangeable because of the di erent mechanical blocking inside. Also the colour of both connectors is di erent: SGI ECU : Brown Interface CurveMaker v2.1 DYNAFS

Unit : Black The bottom view of the connector with all the pole numbers is shown below: Connector view SGI ECU, type 2 The numbers are numbered in the programmable ignition software

same way as for the Interface Unit: First the row number is mentioned and then the column letter. For example: the connection at the top left is row 4, Dynatek 164 S Valencia St.

column A and is therefore called: 4A. TIP: NEVER measure the 32-pole plug connection of the SGI ECU by means of a metering pin or a paperclip as this may Glendora CA 91741 phone

immediately result in contact problems!! To be able to check the SGI ECU connections properly a special Breakout box has been developed, which can be (626)963-1669 fax (626)963-

connected in between the ECU and the 32-pole Molex connector. This box has also become available for dealers. SGI ECU, type 2 ENG* 7399 Contents 1) Installation...1 2)

Overview...1 3) Programming a Curve...4

More information

WireWound fusing Resistors Connection and Programming

Manual for

Imax above 1.5KA, not damage under 264VAC 1W/2W, UL/VDE (UL1412,

Connection and Programming

IEC60065). Manual for controller (also

available in the diagnostic

software and at www.ac.com.pl)

ver. 2.4 2010-02-23

setfuse.com OPEN

Manufacturer: AC Spółka Akcyjna. 15-182

Białystok, ul. 27 Lipca 64,

13 The wiring diagram, together with all the connections for the SGI ECU in the engine compartment, is shown below: SGI ECU, type 2 ENG* More information

14 As an addition to the wiring diagram of the SGI ECU, an overview of all connections is shown below: Pin nr: Wire colour: Function: 1A * CAN-L 1B Red

Input petrol injector signal 3 1C Brown Pulse signal (from LPG switch) 1D Orange Control diagnosis LED (LPG switch) 1E Purple Control beeper (near switch) Quick Start Guide Ski Doo

1F * Spare digital input 1G Black Ground (battery) 1H Black Ground (Interface Unit) 2A * CAN-H 2B Pink Input petrol injector signal 4 2C Red Switched power

+12 Volt (via Interface Unit) 2D Black/white Input Engine Coolant Temperature (ECT) sensor 2E * Input Ambient Temperature sensor Interface Unit 2F * Spare Snowmobiles

digital output 2G Black Control LPG shut0o solenoid on SGI vaporizer 2H Red Control SGI injector 3 3A Yellow/purple Power supply +5 Volt 3B Grey Sensor Thank you for purchasing

ground 3C * Spare analogue input 3D Green Input MAP sensor signal (Interface Unit) 3E * Spare analogue input 3F Brown Control Interface Unit (mode) 3G Candoopro! Please read the

Black Control SGI injector 1 3H Purple Control SGI injector 4 4A Yellow Input petrol injector signal 1 4B Blue Communication connection (K-line diagnosis following information before

plug) 4C Purple Input LPG pressure sensor signal (vaporiser) 4D White Input petrol injector signal 2 4E Black Control LPG shut-o solenoid on tank 4F > using the system for the rst

Resistor < Pull-down delay (connected to pin 2C) 4G Brown Control SGI injector 2 4H Black (> red) Constant power +12 Volt (battery) *: Optional connection time. If you have any questions

(no wire available in standard harness) SGI ECU, type 2 ENG* about the use of the system, please contact

us at Sales@candoopro.com,

15 3.2. Wiring diagram Interface Unit. The Interface Unit, which provides both interruption and simulation of the petrol injectors, is tted with a 32-pole

Molex plug connector. The bottom view of the plug with all the pole numbers is shown below: Connector view Interface Unit The connections are numbered More information

as follows: rst the row number is mentioned and then the column letter. For example: the connection at the top left is row 4, column A and is therefore

called: connection 4A. TIP: NEVER measure the 32-pole plug connection of the Interface Unit by means of a metering pin or a paperclip as this may

immediately result in contact problems!! To be able to check the Interface-Unit connections properly a special breakout box has been developed, which can

be connected between the Interface Unit and the 32-pole Molex plug. This box will also become available to dealers. The Interface-Unit wiring is integrated

MAKE OF AUTOMOBILE:

into the SGI-computer wiring. The connection diagram of the Interface Unit (in tabular form) is shown on the next page. Aside from a few exceptions, the NUMBER : 076/0800901 DATE

connections of the Interface Unit have not changed compared to the rst type of SGI ECU. SGI ECU, type 2 ENG*

: 2008-12-08 Copyright Prins

16 Pin nr. Colour: Function: Connection: 1A Red * Disconnection injector 5, input Injector side 1B Black * Disconnection injector 5, output ECM side 1C Red MAKE OF AUTOMOBILE: HONDA

Disconnection injector 4, input Injector side 1D Red Disconnection injector 3, input Injector side 1E Red Disconnection injector 2, input Injector side 1F Red TYPE: CIVIC PISTON

Disconnection injector 1, input Injector side 1G Yellow/purple Power supply + 5 Volt Pin nr. 3A (SGI ECU) 1H Black (> red) Power supply + 12 Volt (to SGI ECU) DISPLACEMENT: 1800 NUMBER

Pin nr. 2C (SGI ECU) 2A Red * Disconnection injector 6, input Injector side 2B Black * Disconnection injector 6, output ECM side 2C Black Disconnection OF VALVES: 16 ENGINE

injector 4, output ECM side 2D Black Disconnection injector 3, output ECM side 2E Black Disconnection injector 2, output ECM side 2F Black Disconnection NUMBER: R18A TYPE VSI

injector 1, output ECM side 2G H A Red * Disconnection injector 7, input Injector side 3B Black * Disconnection injector 7, output ECM side 3C Pink Output INJECTOR ( COLOR ) ORANGE MODEL YEAR:

petrol injector signal 4 Pin nr. 2B (SGI ECU) 3D Red Output petrol injector signal 3 Pin nr. 1B (SGI ECU) 3E White Output petrol injector signal 2 Pin nr. 4D (SGI 2008 ENGINE SET NUMBER 348/0250200.07

ECU) 3F Yellow Output petrol injector signal 1 Pin nr. 4A (SGI ECU) 3G H Red / White +12 V input Power petrol injectors 4A Red * Disconnection injector 8, NUMBER : 076/0800901

input Injector side 4B Black * Disconnection injector 8, output ECM side 4C Brown Mode / Switch wire (low-side) Pin nr. 3F (SGI ECU) 4D * 4E Grey Ground

(sensors) Pin nr. 3B (SGI ECU) 4F Green MAP signal Pin nr. 3D (SGI ECU) 4G Black Ground Pin nr. 1H (SGI ECU) 4H * : Optional connection (not present in

More information

standard wiring harness) SGI ECU, type 2 ENG*

17 4. The SGI switch General Information. Physically, the switch has not changed in combination with the SGI ECU, type 2. However, since the connections

E - THEORY/OPERATION

to the switch have changed, the di erences made are being explained in the coming paragraph. The photograph below shows that the functions of the SGI

switch on the dashboard have not changed. A: pulse-switch B: empty tank indication LED C: tank indication LEDs D: Photocell E: Diagnosis LED 4.2. Working E - THEORY/OPERATION 1995

principle SGI switch: For the sake of completeness, the working principle of the SGI switch is explained, together with its di erent functions. q Switch: A is the Volvo 850 1995 ENGINE

switch itself, with which it is possible to switch over from LPG to petrol and back. Since this is a pulse-switch, a short touch is su cient to switch between LPG PERFORMANCE Volvo - Theory &

and petrol. q Switch-over procedure: After the ignition is turned on, the ECU will use the fuel which has been used the latest. In petrol mode all LEDs are o , Operation 850 INTRODUCTION

as usual in combination with the rst type of SGI ECU. In LPG mode, the tankindication LEDs (B en C) will be on directly after starting the engine. At the same This article covers basic

time, the shut-o valve on the tank is opened directly. In LPG mode, the engine will rst run on petrol before switching over to LPG. The diagnosis LED (E) description and operation of engine

ashes during this situation until the engine is actually running on LPG. SGI ECU, type 2 ENG* performance-related systems and

components.

18 When the switchover temperature has been reached, the shut-o valve on the SGI vaporizer is rst opened, whilst the engine is still running on petrol (

ushing period ). It is not possible to recognise the ushing period on the indications of the SGI switch. With some engine types the SGI ECU will only switch More information

over above a certain opening time of the petrol injectors. Therefore, it is possible that in certain cases the system will not switch over to LPG when idling. q

Tank indication LEDs: B and C are the LEDs indicating the LPG tank level. When the LPG tank is full all four green LEDs (C) light up when driving on LPG. As

the LPG tank gets empty the LEDs will gradually go out from top to bottom. When the last green LED goes out the red LED (B) will light up, to indicate that Air conditioning, electrical

only a limited distance can be driven on LPG. D is not an indication but a photocell to regulate the light intensity of the indication LEDs B and C. This intensity

depends on the intensity of ambient light; in sunlight the LEDs will light up brighter than in the evening, when it is dark. q Automatic switch-over to petrol: testing

When the SGI computer detects an empty tank, it will automatically switch back to petrol and a pulsating signal can be heard. The signal can be stopped by just a test. Air conditioning,

pressing the switch (the car will continue to run on petrol). q Diagnosis LED: E is the diagnosis LED. This red LED will be controlled on by the SGI ECU in the electrical testing 01-253 Wire

following situations: 1. The engine is running on petrol whilst LPG is the selected fuel (diagnosis LED ashes, in case of an empty LPG tank with the beeper and component test using

on) 2. An error is detected (diagnosis LED is on continuously) The above-mentioned situations are listed in order of priority. This means, that when an error VAG1598 A test box Special

is detected, together with the recognition of an empty LPG tank, the diagnosis LED will only be ashing. In case an error is detected while running on LPG, tools and equipment VAG 1598

the diagnosis LED will be on continuously (in combination with tankindication LEDs on) as a sign for the driver to contact the dealer to solve the problem A test box and VAG 1598/11 adapter cable

immediately. In this case, there are two di erent kinds of errors which can be detected; present errors and incidental errors: Present errors: This type of and VAG 1598/12 VAG1526

error is detected by the SGI ECU, and takes place at the moment of running; the diagnosis LED will be on continuously. The error code will be memorised by

the SGI ECU. Incidental errors: When the ignition is turned o , possible error codes are stored in the EEPROM memory of the microprocessor. If the error is

More information

not detected anymore after switching the ignition on, the present error will be recognised as an incidental error. SGI ECU, type 2 ENG*

The diagnosis LED will be o ; the error code can still be read from the memory of the microprocessor, using the diagnostic equipment Switchover

19

Unit 8. Conversion Systems

strategy: After starting, the engine will run on petrol rst. In this situation, the shut-o solenoid on the LPG tank will be activated directly after starting.

Shortly after, the LPG shut-o valve on the SGI vaporiser will be opened, after which the SGI injectors take over injecting fuel from the petrol injectors. The Unit 8. Conversion Systems

time until switching over to LPG is determined according to the Engine Coolant Temperature (ECT); at a lower temperature, it takes more time before the SGI Objectives: After completing this

ECU switches over to LPG. As described before, the opening time of the petrol injectors is measured to calculate the opening time of the SGI injectors. When unit the students should be able

the LPG tank becomes empty, the LPG vapour pressure to the injectors will decrease, which is compensated for by increasing the opening time of the SGI to: 1. Describe the Basic

injectors. Of course, there is a certain limit to this, when the pressure becomes too low. This could result in a lean mixture while driving on LPG. Considering conversion systems 2. Describe

the ECM is monitoring the mixture by reading the signal of the lambda sensor, it can happen that the ECM is going to learn away. This can be noticed after main conversion kit types. 3. Describe how

switching back to petrol; the engine will not run properly. It is conceivable that certain motor management systems (especially E- OBD), will store certain the CNG

error codes in its memory, whilst the engine check light on the dashboard will come on. To prevent this situation, the SGI ECU is able to recognise an empty

LPG tank; it will then switch back to petrol mode before any problem can occur. An empty LPG tank is recognised according to the measured vapour More information

pressure (under a certain value) in combination with the opening time of the SGI injectors (above a certain value). To notify the driver, the beeper will go on,

together with a ashing diagnosis LED (tank indication LEDs are o ). This will prevent the driver to unintentionally empty the petrol tank. on petrol Ø start

(LPG shut o valve on tank open) ushing period on LPG (on petrol) Ø Ø LPG shut-o valve petrol o on vaporiser open Temperature on petrol Ø LPG tank

empty SGI ECU, type 2 ENG*

Quick Start Guide RIVA/Athena

Sea-Doo ECU

20 4.4. Electrical connections. The electrical diagram of the switch connections is shown below. This diagram also shows that the SGI-system buzzer is Quick Start Guide RIVA/Athena

connected separately from the switch, behind the dashboard. The control wire for the beeper is no longer a separate wire in combination with the SGI ECU, Sea-Doo ECU PART# - RS11891-

type 2, but has now been joint in the 5-wire harness towards the switch. All connections of the SGI switch are listed below: Colour Pin nr. SGI ECU Function ECU-DC APPLICATION(S): Sea-

Signal Orange 1D Diagnosis LED +12 Volt (switched or intermittent) Brown 1C Pulse from switch +12 Volt (pulse, pressing the switch) Spare Red 2C Power +12 Doo 260/255/215hp icontrol

Volt +12 Volt (engine running) Black 4E Ground LPG shut-o v. Ground (running in LPG mode) Yellow Signal tank sensor Inductive Purple 1E Control beeper Models RIVA/Athena ECU

Ground (intermittent) Since all wires have already been accommodated with terminals, these only need to be connected into the 6-pin connector during Manager Web Site: www.rivaathena.com

installation. (It speaks for itself that all wires have to be facing equal colours.) SGI ECU, type 2 ENG* NOTE: YOU MUST PERFORM PHYSICAL

21 5. Diagnostic equipment. The diagnostic equipment for the SGI ECU, type 2 has not changed much compared to the rst type. Considering that the

More information

diagnostic possibilities have been extended considerably, its functions are being explained in the next paragraph (5.1.). The equipment has only changed

partly; instead of the Psion, a PC (or better: a laptop) is required to be able to read out the SGI ECU. The reason for this is that all data from the SGI ECU are

sent encoded. To be able to actually see the data of the SGI system, a special program is required which decodes all the data. This program is called

DiagnoseTool SGI (DTS) (partnumber ) and can be used with a PC or a laptop. The user manual for the DTS program is described on the following pages.

Via Ra aello,33/A - 42100

Next to the communication equipment a Breakout box has been developed for the second type of SGI ECU. This unit works in exactly the same way as Reggio Emilia Italia Tel +39

described in the manual Trouble shooting SGI regarding the Breakout box of the Interface Unit. This is an essential piece of equipment to be able to

measure all connections from and to the SGI ECU. TIP: NEVER measure the 32-pole plug connection of the SGI ECU by means of a metering pin or a paperclip

0522.514.461 Fax +39 0522

as this may immediately result in contact problems!! Because the motor management computer (ECM) is still in control of the fuelling strategy of the engine, Trouble Shooting Solving

the diagnostic possibilities of the SGI ECU, type 2 are limited. Thus it is still essential to perform a diagnostic check of the motor management system before problems with LSI-NSI software

a diagnosis is carried out of the SGI system The diagnostic possibilities are described in the following paragraphs User manual DiagnoseTool SGI (DTS): To be Update to version 2.1.0 1/14

able to perform a diagnosis by using a PC or laptop, a connection needs to be made with a diagnostic cable, which is connected to the 3-pole diagnosis plug Rev.0 2/14 Rev.0 CONTENTS 1.1.

of the SGI wiring harness in the engine compartment. The diagnostic cable is made in two parts: 1. Diagnostic cable to serial COM port 2. K-line converter Switching from petrol to gas

The K-line converter is taking care that the way of communication takes place in the correct way (in terms of transmission speed etc.) between the SGI ECU PAGE 4 1.2. Drop at medium-high speeds

and the PC or laptop. Both parts for communication are listed below: Description Part number AG diagnostic cable for PC AG AG K-line converter AG SGI PAGE 5 1.3. Functioning

ECU, type 2 ENG*

More information

22 It is only possible to communicate when the switched power supply to the SGI ECU is on. Since this is the case when running on LPG as well as on petrol,

it is possible to communicate when running on each fuel. In most cases it is only possible to communicate when the engine is running, because the switched

power is normally shut down when the engine stalls. The DiagnoseTool DTS has been developed to make it possible for dealers to communicate with the

second type of SGI ECU in case any after sales is required. First, the program needs to be installed on the hard disk of the PC with which the communication

Diagnosis manual SGI, type 1

is to be performed. It is necessary to have a Windows 95, 98, NT or 2000 operating system working on the PC Installation DiagnoseTool DTS: The Diagsis manual SGI, type 1

DiagnoseTool SGI can be installed on a PC easily by starting the setup.exe program by a simple mouse-click. This will start up the installation process. The Galileïstraat 15 Postbus 8002

DTS program is normally installed in the following directory: C:\Program Files\ AG \ DiagnoseTool SGI. It is however also possible to specify another location 3900 CA Veenendaal The

on the hard disk. After the installation is complete, you will nd a short cut to the DTS program on your desktop (SGI logo). When double-clicking on the Netherlands Tel. 0318 55 77 77

short cut, the DiagnoseTool SGI program is started like shown below. SGI ECU, type 2 ENG* Fax 0318 55 77 55 Internet :

www.tele exg .com E-mail:

23 Selection COM-port: The software has been developed to communicate via a serial COM 1 or COM 2 port with the SGI ECU. COM 1 is normally selected info@tele exg .nl Diagsis manual

after the installation of the DTS program, but it is also possible to select COM 2 instead for communication with the SGI ECU. The preferred COMport can be

selected by choosing the option Communication under Settings (see below) Adding a new data- le: In contrast with the rst type of SGI ECU, it is no longer More information

possible to use one program to communicate with all software versions of the SGI ECU, type 2. To be able to communicate with the second type of SGI ECU,

it is necessary to have a speci c data le which corresponds with the type of basic SGI software. The type of data le must have the same identi cation as

the basic software of the SGI ECU, like shown below: Software version Data le name dat When reading the data from the SGI ECU, the DTS program will

2002-2003 Kawasaki Vulcan

automatically search for the correct type of data le, which can normally be found in the directory: \ AG DiagnoseTool SGI \ Data \ Software In case a

communication is required with an SGI ECU, which has a new version of the basic software, it can happen that the corresponding data le has not been 1500 Mean Streak Installation

installed yet in the DTS program. In that case, the data le concerned will have to be added to the installation directory of the DTS program. Selecting the

Instructions

button File and subsequently Add data le, as shown in the image below can actualise this. The speci c data le can be found on the website SGI ECU, type 2

ENG* Parts List 1 Power Commander

1 CD-ROM 1 Installation Guide 1

24 5.2. Functions DiagnoseTool SGI (DTS): The DiagnoseTool SGI has the following menu structure: Identi cation System Info Error codes Updates Modem

Wire Tap Connector 2 Power

Commander Decals 2 Dynojet

communication The menu structure has been made in the same way as for the rst type of SGI ECU. Clicking on its tab can open each menu, of which an

Decals 1 Velcro Strip 1 Alcohol

explanation is given in the next paragraphs Identi cation menu: By clicking the tab Identi cation, the screen as shown below will become visible. The DTS

Swab 2002-2003 Kawasaki Vulcan 1500 Mean

program will start communicating when clicking on the Read button. The following data are shown in the Identi cation menu: ECU Software Information (see

Streak Installation

also chapter 1: Function SGI ECU): Calibration info : Information about the brand and type of vehicle with its engine code Calibration version : The speci c

EEPROM software used for this type of vehicle Software version : The version of the basic software of the SGI ECU (PROM) Calibration modi cations: Code :

Speci c identi cation code of the modi cations in the calibration Description : Description of the modi cations in the calibration > A Calibration Modi cation More information

is a general change of the engine speci c software that can be programmed in by a dealer or installer who has access to the DiagnoseTool SGI. How to

perform a modi cation of the calibration, is being described in paragraph The type of

modi cationisshownintheidenti cationmenutobeabletorecognisewhichspeci c changes have been made in the calibration. In the gure above, the Transmitter Interface Program

modi cation programmed in the ECU is that switching over from petrol to LPG will not take place below 1000 RPM. SGI ECU, type 2 ENG*

Transmitter Interface Program

Operational Manual Version

25 ECU Hardware Information: Serial Number : Unique serial number of the hardware of the SGI ECU Injector Information: Injector Number : Part number

3.0.4 1 Overview The

of the correct type of SGI injector; > This number can be: small capacity type SGI injector (4mm) medium capacity type SGI injector (5mm) large capacity type

transmitter interface software

SGI injector (6mm) The type of SGI injector tted can be recognised by its part number as mentioned on top: Injector number If the part number does not

allows you to adjust

correspond with the number mentioned in the Identi cation menu, the opening time of the petrol injectors will not be translated correctly by the SGI ECU,

con guration settings of your Max solid state

because of which the mixture will have to be corrected too much by the lambda correction of the motor management computer. This will result in problems

transmitters. The following

like hesitation, stalling and learning away (check engine) Read in and outgoing signals (System Info): When opening the tab System Info, the in and outgoing

signals of the SGI ECU will appear on the screen, as shown below: SGI ECU, type 2 ENG*

More information

26 Status: (also see en ) Actual Fuel : the actual situation in which the engine is running; possibilities: Status: Situation: Petrol Engine runs on petrol Petrol

heat up Engine runs on petrol; SGI injectors are controlled open Petrol ush Engine runs on petrol; LPG shut-o valve on vaporiser open LPG Engine runs on

LPG Selected Fuel : the fuel, which has been selected by the driver (petrol or LPG). Sensor signals: (measured signals of the sensors, as mentioned in 2.1.) All Introduction. Drenth

signals are shown in numeric values as well as graphically (vertical bar); the minimum and maximum values measured are shown behind min. and max., so it Motorsport Gearboxes

is possible to afterwards judge the values in an easier way. RPM : engine revolutions per minute (= injection frequency of INJ.1) The engine speed is

calculated from the injection frequency of the petrol injector, which has been disconnected by disconnection group 1 (INJ.1). Since no fuel is injected during Fleuweweg 10 7468 AG Enter

deceleration (fuel cut-o ), the engine speed as shown on the System Info screen will become 0000 in this situation. Using the wrong software, which can be

25.03.0023 Introduction The

checked in the Identi cation menu, normally causes wrong reading of the engine speed. Pvap : LPG vapour pressure in millibar (measure inside the outlet of

display comes with a software

the vaporiser) Pvap represents the pressure of the LPG, as supplied by the SGI vaporiser (in a vapour stage). This pressure is also displayed in millibar. Since

application. With the software

the vapour pressure is referenced to manifold pressure, its value varies with the value of MAP. The pressure of the LPG is measured by the LPG pressure

application information shown

sensor, which is tted onto the SGI vaporizer. Its characteristics are shown below: Idle Full load Voltage LPG Pressure (mbar) SGI ECU, type 2 ENG*

on the display can be adjusted.

There are di erent modes to adjust: the

27 MAP : pressure in the intake manifold in millibar (measured by the Interface Unit) The internal MAP sensor of the Interface Unit measures the pressure shape of

in the intake manifold of the engine. The pressure is displayed in millibar. The characteristics of the sensor are shown below. Idle Full load Voltage Manifold

Absolute Pressure When running at idle, the pressure is normally around 350 millibar; during full load, the pressure will become approximately 1000 millibar

with a normally aspirated engine; the manifold pressure will become higher than atmospheric with turbo charged engines. Since the maximum range of the More information

MAP sensor inside the Interface Unit in up to 1000 mbar, the signal needs to be read from an external MAP sensor (original or additionally supplied in the

SGI kit). DelP : di erential pressure over the SGI injectors (= Pvap Load) The di erential pressure over the SGI injectors is equal to the input LPG vapour

pressure minus the pressure in the intake manifold. Because the LPG pressure and the manifold pressure are both measured, it is possible to calculate the SELECTION, APPLICATION

di erential pressure of the SGI injectors (DelP = Pvap MAP). Just like Pvap and MAP, DelP is displayed in millibar. Tolerances are: 700 < DelP < 900 mbar AND MAINTENANCE

(measured statically). SGI ECU, type 2 ENG*

DIESEL PROTECTION SYSTEMS

Automatic Diesel Engine Shut

28 ECT : measured Engine Coolant Temperature (original sensor) The Engine Coolant Temperature is measured in degrees Celsius. Since this analogue

Down System for Safe Area

signal is normally branched of the signal wire of the original ECT sensor on the engine, the characteristics can vary per engine type. An example of the

Applications SELECTION,

characteristics of an ECT sensor is shown below: Temperature Nevertheless, in case the SGI ECU cannot use the original ECT sensor signal, the signal will be

APPLICATION AND

monitored from an auxiliary sensor, which is supplied with the SGI kit. Vbat : voltage of the power supply (measured by the SGI ECU) Considering that the

MAINTENANCE Series 300 Series 310 SYSTEM

voltage level of the power supply in uences the characteristics of both the petrol and SGI injectors, this is an important measurement for the translation

DESCRIPTION Suitable for attended engine

strategy of the SGI ECU. The voltage of the power supply to the petrol (and SGI) injectors is displayed on the screen. Ti Injectors: (Petrol and LPG; separated

into 4 groups) Also, the opening times of the are shown in numeric values as well as graphically (horizontal bar); the minimum and maximum values

measured are shown behind min. and max., so it is possible to afterwards judge the values in an easier way. Inj.1 Inj.2 Inj.3 Inj.4 : Injector group 1 (INJ.1): More information

Petrol: opening time petrol injector in milliseconds (measured via the Interface Unit) LPG : opening time SGI injector in milliseconds (calculated by the SGI

ECU) : Injector group 2 (INJ.2): Petrol: opening time petrol injector in milliseconds (measured via the Interface Unit) LPG : opening time SGI injector in

milliseconds (calculated by the SGI ECU) : Injector group 3 (INJ.3): Petrol: opening time petrol injector in milliseconds (measured via the Interface Unit) LPG : Technical Service BULLETIN

opening time SGI injector in milliseconds (calculated by the SGI ECU) : Injector group 4 (INJ.4): Petrol: opening time petrol injector in milliseconds (measured

Technical Service BULLETIN

via the Interface Unit) LPG : opening time SGI injector in milliseconds (calculated by the SGI ECU) Petrol: This is the opening time of the petrol injector (in

September 29, 2003 Title:

milliseconds), which is measured from the corresponding disconnection group of the Interface Unit. The basis of the translation strategy is to keep the

Models: 00 03 Avalon, Camry &

opening time of each petrol injector unchanged, either driving on petrol or on LPG. This only counts when the circumstances (i.e. RPM, MAP, etc.) remain

Solara, 0 03 Sienna EG03-03

equal, of course. SGI ECU, type 2 ENG*

ENGINE TSB REVISION NOTICE:

December 5, 2003: The Parts and Warranty

29 If this is not the case, the translation of the opening time of the SGI injectors will not take place properly. The reason for this to happen could be that

tables have been changed.

either the software is incorrect or that the wrong type of SGI injectors has been tted. TiB TiG Quantity (mg) SGI injector Petrol injector Amount of fuel

Opening time (ms) LPG: As described in chapter 1, the SGI ECU translates the opening time of the petrol injectors to the opening time of the SGI injectors.

This strategy is mainly based on the mechanical di erences in between both injector types. The four values shown are the opening times of the SGI injectors, More information

which have been calculated by the SGI ECU. In case a connector of one of the SGI injectors is taken o , this will not make any di erence to the value as

displayed on the screen. The opening times of the petrol and SGI injectors can be displayed in two ways, standard and grouped (marked V by a mouse-click):

Standard : Opening time of petrol and SGI injector alternately (per INJ group); Grouped : Opening time of petrol injectors together and SGI injectors together Throttle Body Fuel Injection

(per fuel). Grouped Per INJ group SGI ECU, type 2 ENG* Throttle Body Fuel Injection

Initial Calibration of the TBI

30 Diagnosis (Error codes): The ECM determines the strategy in which the SGI injectors are controlled. In this way, the self-learning capabilities are utilised, Disclaimer The author of this

also when running on LPG, meaning that the SGI ECU does not have to be self-learning itself. Thus it is su cient to be able to read out possible error codes. presentation assumes NO

These error codes only concern the in and output signals, which are read by the SGI ECU while running on LPG. To check the memory of the SGI ECU for responsibility for information

possible error codes is a matter of clicking on the tab Error Codes, after which the screen below will be shown: No error codes detected Two errors provided causing the owner to modify or

memorised (code & description) Since the reading of diagnosis menu is a snapshot, the display will not change when the SGI ECU detects another error. The alter their motorhome

new error will be shown after clicking on the button Read, after which the screen will be reloaded. The error codes shown can be selected separately; by

clicking on the button Reset, the error codes, which have been selected in the screen, will be removed from the memory of the microprocessor of the SGI

More information

ECU. The error codes have been classi ed into two di erent types: Actual error : This error is present at the moment of reading (diagnosis LED is on

continuously); Memorised error : This error has been stored by the SGI ECU, but is not present at the moment of reading the error codes (in case no actual

error code is present). In annex 1 all possible error codes of the second type of SGI ECU are listed. In case any problem occurs, it remains essential to always

read out the error codes of the motor management computer FIRST (also with the SGI ECU, type 2)!! SGI ECU, type 2 ENG* NISSAN FIGARO FAULT CODES

AND DIAGNOSTICS

31 Software Update: With the second type of SGI ECU, the calibration possibility has been leaved out. Instead of this, three new features have been

NISSAN FIGARO FAULT CODES

implemented into the DealerTool SGI, behind the tab Update (see gure below). These features are: 1. Update 2. Modi cation 3. Reprogram 1. Update: With

AND DIAGNOSTICS The Nissan

this option it is possible to upgrade the calibration version to a newer version, which has been developed for a speci c type of engine (as long as the basic

Figaro uses an engine

software version is the same). 2. Modi cation: A modi cation is generally applicable for di erent types of engines, and can be used for all kinds of vehicles, if

management system with the

necessary (as long as the basic software version is the same). 3. Re-program ECU: It is possible with the DiagnoseTool SGI to completely reprogram the

acronym ECCS you ll see it in

calibration of an SGI ECU, type 2 (as long as the basic software version is the same). It is, for example possible to change to calibration for a di erent type of

large letters on the plenum box when you

engine. To be able to carry out any update, modi cation or to reprogram the engine speci c software of the SGI ECU, the basic software (= software version )

open the bonnet. It stands for

must be the same as the version mentioned in the le!! (In case the needed le is missing, this can be downloaded from the website > Procedures to change

the calibration of the SGI ECU: The procedure works mainly the same for an update, a modi cation or reprogramming the calibration of the ECU. The

descriptions of the procedures have been split vertically by a dotted line. For example, when carrying out a modi cation, the procedure can be followed More information

according to the middle column from the next page on. SGI ECU, type 2 ENG*

32 Update: Modi cation: Reprogram: 1) First make contact with the SGI ECU; the current identi cation of the ECU will be shown below ECU calibration (the RGK60 RGK50 RGAM10

same for all options; see below); 2) Choose the option wanted by a mouse click on the small round frame in front of the selection (update, modi cation or RGAM20 RGAM4 Generator

reprogram) as shown below; 3) Then click on the Select button to start looking for the necessary le to change the calibration of the ECU; 4) The available

update, modi cation or reprogram les will then be shown on the screen: 5) Choose the needed: Update- le (.ucl), Modi cation le or Calibration le (.pcl) set control units

Note: Check whether the software version is the same as the version the les are meant for! SGI ECU, type 2 ENG* I123 GB 1207 RGK60 RGK50

RGAM10 RGAM20 RGAM4

33 6) Con rm the selection and acknowledge changing the calibration of the ECU by clicking on the Start -button, which has been enabled by the program Generator set control units

(see below). 7) Follow the instructions underneath the Update screen (in the white message box); The instructions are successively: Please turn o ignition CUSTOMIZATION SOFTWARE

key and wait until Contact+ is o Please wait for the ECU to shut down Please start the engine Update / Modi cation / Reprogram successful! After this, the MANUAL List of contents

Update / Modi cation / Reprogram has been performed successfully. The notation of the change in the calibration software is as follows: q The Update can Introduction... 2 Main window... 3 Device

be recognised behind the identi cation Calibration version ; q The Modi cation can be recognised in the separate screen below the software identi cation ( model selection... 3 Transmission of data

Modi cations with a code and a description); q Reprogramming the calibration will result in a di erent identi cation of the engine type ( Calibration

description ). In Annex 2, 3 and 4, all available Updates, Modi cations and Reprograms have been respectively listed. SGI ECU, type 2 ENG*

More information

34 Modem communication: With this menu (see below) it is possible to make a modem connection with the second type of SGI ECU. In this way, a diagnosis

can be performed by the technical helpdesk of the representative of Tele exGFI Europe. The procedure for having a modem connection with the SGI ECU,

VS Commodore LPG

type 2 has changed. With the rst type of SGI ECU, a direct connection was made between the SGI ECU and an external modem via a special modem cable. In

the new situation, the modem communication is taking place via the PC (using the same diagnostic cable). Therefore, the modem communication can take installation utilising an LPG

place in mainly two ways: a. Via an external modem (from the existing AG test suitcase); b. Via an internal modem of the PC or Laptop. a. Via an external

Memcal and Apexus Quick-kit.

modem (from the existing AG test suitcase): The external modem is connected to the PC, which is used for having communication with the SGI ECU. The

modem will have to be installed properly in the operating system of the PC rst, of course, before any communication can take place. The modem of the AG VS Commodore LPG installation

test suitcase can be used for communication. b. Via an internal modem of the PC or Laptop: Considering that mot PC s are already equipped with an internal utilising an LPG Memcal and

modem, a feature has been developed in the DiagnoseTool SGI to be able to have a modem connection with this modem. With this possibility, the Apexus Quick-kit. Description of

connections for a modem have been simpli ed, and therefore, is has become more convenient for the dealers to prepare a modem communication. The the components and operation

principle of the modem communication remains the same as when using an external modem; the communication is taking place through the PC itself by LPG/Petrol changeover switch

using the Modem menu of the DiagnoseTool SGI. As mentioned before, in both cases the communication takes place using the same diagnostic cable The LPG change-over switch is mounted in

(together with the K-line converter). Because of this, the connections are being connected according to the picture on the next page. SGI ECU, type 2 ENG* the instrument

35 At present many dealers are only using digital phone lines (ISDN), which may complicate having a modem connection. In case only digital phone lines More information

are available, a special converter needs to be used to transform the transmitted signals into an analogue communication. In this way it is still possible to

communicate with the SGI ECU by modem. The operation for a modem communication is as follows: 1. Connect the PC (or laptop) to the SGI diagnostic

connector with the cable AG and the K-line converter AG ; 2. In case of using an external modem, connect the modem to the PC and to the power supply; 3. >> System CRD14-System

Connect the phone connection of the PC, and also connect the phone itself (with an external modem to the phone connection of the modem); 4. Start up the

DiagnoseTool SGI and make a connection with the SGI ECU (with the engine running); 5. Open the tab Modem and call the phonenumber of the modem JTD1 / 10556101

helpdesk; 6. When having the connection with the helpdesk, it is possible to explain the need for the modem communication; 7. After this, the technician at System CRD14-System JTD1 /

the helpdesk will ask to click on the button Connect ; 8. The modem communication will be started and a diagnosis is carried out; 9. It may happen that a 10556101 ENG40120 Table of

message appears on the screen from the helpdesk. In that case it is necessary to follow the instructions as mentioned. 10. After the helpdesk is ready Contents Scope of delivery /

communicating with the SGI ECU, the helpdesk will switch back to normal communication. This will also be noti ed on the screen of the PC. In this way the Preliminary 3 General

ndings during the modem communication will be explained, together with possible actions to be taken by the dealer. SGI ECU, type 2 ENG* instructions 4 Installation

principle 5 Changing Programs 6 Trouble

36 5.3. Trouble shooting In case it is not possible to communicate with the SGI ECU, a message box appears on the screen with the text No communication, shooting 7 Installation example

not connected (see gure below). Message Status information Below the screen, more detailed information is shown about the status of communication.

Possible errors have been listed below, together with the possible cause and solution: Message status information Cause / solution

More information

ConnectiontoCOM1/2failed Has the correct COM port been selected? Select the correct COM port acc. to , COM port selection Does the engine run? Check

the power supply to the SGI ECU. Check the connection PC SGI ECU Error init COM 1/2 The COM port selected is already in used by another application; close

the other application. COM port not present; use another COM port Error reading data le Missing data- le; add this le according to , Add Data- le. SGI

ECU, type 2 ENG*

INSTALLATION INSTRUCTIONS

BOOST CONTROLLER. Pro

View more Control Input (Optional) Tach.

2650-1706-00 INSTALLATION

INSTRUCTIONS BOOST

CONTROLLER WARNING! The

installation of the Auto Meter

Evaporative emissions system Connection and Programming well as pulses from a magnetic Boost Controller is

just a test. Evaporative Manual for driveshaft sensor or a recommended only for experienced

emissions system 20-48 technicians. This product may damage your

Function description of EVAP

Connection and Programming magnetic speedometer cable engine

Manual for controller (also

canister system Depending 1. Overview The Maximizer 4

available in the diagnostic

upon the air pressure and progressive nitrous controller

software and at www.ac.com.pl) More information

ambient temperature, fuel vapor will form operates one or two separate

ver. 2.8.9 2013-07-09

above the level of fuel in the stages of nitrous based on

Manufacturer: AC Spółka Akcyjna. 15-181

Białystok, ul. 42 Pułku Piechoty either time, RPM, MPH, throttle ECU MS 3 Sport GT3 Cup.

More information percentage or boost pressure. Whether your

engine is naturally Quick Start Manual

More information

ECU MS 3 Sport GT3 Cup Quick

PROCEDURES FOR SELF More information Start Manual V1.0 11/6/2015

Table of Contents Table of

DIAGNOSTICS Fault codes DM1. Industrial Contents 1 Welcome... 3 1.1

PROCEDURES FOR SELF engines DC09, DC13, DC16. Introduction. In this Self-study Hardware Checklist... 3 1.2

DIAGNOSTICS Baum Tools Hardware Installation... 3 1.3 Software

Unlimited Inc. March 31, 1999

Marine engines DI09, DI13, Programme we will explain to Installation... 3 2 Tools:

TAU 2.1 READING ACTUAL Fault codes DM1 Industrial you the design and function of

VALUES 1. Remove the engines DC09, DC13, DC16 More information

operating console from the TAU 2. At the Marine engines DI09, DI13, DI16 Introduction The requirements

upper side of the operating consol there is 03:10 Issue 5.0 en-gb 1 DM1...3 relating to driving safety, driving

comfort, exhaust emissions and

Abbreviations...3 Fault type

fuel economy are are becoming

Before installation it is

More information identi er...3...4 03:10 Issue 5.0 en-gb 2 DM1

DM1 Fault ever more stringent. This entails important to know what parts

more intensive information exchange

between

you have and what the

ILISC515-A Shift Interlock More information

INSTALLATION GUIDE Before

(Manual Lift Door) 2015 Ford More information installation it is important to

know what parts you have and

Transit, 3.7L and 3.5L Electronic Diesel Control EDC what the capabilities of these

An ISO 9001:2008 Registered 16 LT1 Tune Kit Quick Start Guide parts are. The Recon XZT is the

Company ILISC515-A Shift smallest and most powerful gauge of its kind.

Interlock (Manual Lift Door) Service. Self-Study Programme LT1 Tune Kit Quick Start Guide With

2015 Ford Transit, 3.7L and 3.5L 304 Electronic Diesel Control Revision D Page 1 Table of

Introduction The ILISC515-A is a EDC 16 Design and Function Contents Introduction... 3

The new EDC 16 engine Minimum PC Requirements... 3 More information

microprocessor driven system for controlling

wheelchair management system from Program Installation... 3

Bosch has its debut in the V10-TDI- and R5- Registering the Program... 4 Installing the

TDI-engines. Increasing demands USB/ALDL Interface INSTALLATION MANUAL OF

More information

THE LPG/CNG SEQUENTIAL

More information More information

FUEL SYSTEM

Electronic Power Control

INSTALLATION MANUAL OF THE

Service. Self-Study Programme Service Manager Dealer QUICK START GUIDE LPG/CNG SEQUENTIAL FUEL

210 Electronic Power Control SYSTEM May 2005 Tartarini

Design and Function With the Principal, North American 199R10546 Auto S.p.a Via Bonazzi 43 40013

Electronic Power Control Ducati Dealer Network. QUICK START GUIDE 199R10546 Castel Maggiore (Bo) Italy

system, the throttle valve is Tel.:+39 051 632 24 11 Fax: 051 632 24 00 E-

1.0 Overview This contains

actuated only by an electric motor. This . 10443 Bandley Drive mail: info@tartariniauto.it

detailed information on how to

eliminates the need Corporate Headquarters

use Holley EFI software and

Cupertino, CA 95014 Tel: 408-

perform tuning that is included More information

253-0499 Fax: 408-253-4099

More information within the software itself. Once you load the

www.ducatiusa.com Recall

software,

Bulletin RCL-08-001 DNA Date: February 13,

2008 To: Subject: Service Manager How to connect your Victron

Renewable Energy Monitor More information

to a computer with VE Bus

User Manual And Software More information

Quick Con gure

Reference Guide. G-100/200 Operation & How to connect your Victron to

Renewable Energy Monitor User Left Hand Limit Switch. Installation a computer with VE Bus Quick

Manual And Software Reference Con gure Before connecting

Guide sales@fuelcellstore.com Housing. Left Hand. G-100/200 Operation & your Victron to a computer the

Installation 2 Contents 7

(979) 703-1925 1 Introducing Connections. Motor Installation 15 Getting Started

following is important: - Only

the Horizon Renewable Energy identical models with VE Bus software (see

Monitor The Renewable Energy Monitor is an LIGHT BLUE GRAY PURPLE 16 GPS Mode Setup 18 Wheel sticker

educational Circuit Breaker Intput Circuit Sensor Mode Setup 20 Fuel

Breaker Output #1 Relay Left Calibration 23 Basic Operation 24 Telemetery

Screen 27 Entering a Distance More information

Hand Limit Switch Housing Left

More information

Hand Motor Connector Right

Hand Limit Switch on Radiator Support Right More information

Hand Limit Switch

www.sebury.com.cn Digital

AMS-1000 Multi-Channel Air Keypad Use s Manual

Management System for More information Diesel: Troubleshooting K3 K4 www.sebury.com.cn

Boost Control Diesel: Troubleshooting Digital Keypad Use s Manual

Probable Cause Engine not Contents Introduction

AMS-000 Multi-Channel Air

Management System for Boost

i ChatterBox! Motorcycle starting Hard to start engine Introduction Speci cations

Intramural Interface Circuit 3

Control The terminal pin Security Runs rough at lower RPM Lack

Mounting 3 Wiring 5 Power UP 7 Engineer

descriptions may also be viewed of power Diesel knock / pinking

i Before you Start the Black White Blue Low compression X X X Low Programming Mode 7 The K3/K4

on screen. See Page 4 of

Installation * Please read this fuel pressure X X

manual for details. Clutch Input Shift Input

manual to become familiar with

Scramble Boost Input More information

the requirements necessary to

complete the installation. * Use More information

More information a high quality multi-meter to test all wires

before

Meritor WABCO Pneumatic

PCM REPROGRAMMING FOR Antilock Braking System (ABS)

WIRING HARNESS FOR More information DTC P0300/P0303, P0116, 42.22

AS635P4. BLUE PLUG RED, P0131/P0151, P0133/P0153, (ABS) 2.22 Troubleshooting

BLUE, BLACK, WHITE - Plug in VEHICLE DIAGNOSTICS THE Page 1 of 6 SUBJECT : PCM

WARNING Before testing a

vehicle equipped with

REPROGRAMMING FOR DTC

WIRING HARNESS FOR AS635P4 AUTOCOM WAY P0300/P0303, P0116,

Automatic Traction Control

ANTENNA NOT USED 5 PIN (ATC) on a dynamometer, the

WHITE PLUG 2 PIN WHITE PLUG VEHICLE DIAGNOSTICS THE P0131/P0151, P0133/P0153,

ATC system must be disabled. See Subject

GREEN - PARKING BRAKE INPUT AUTOCOM WAY CARS TRUCKS AND P2100 No: DATE: October,

160 for instructions. Activation

(-) BLUE - NOT USED 3 PIN BLUE GENERIC A COMPLETE 2005 MODEL: See below CIRCULATE TO: [ ]

PLUG RED, BLUE, BLACK, WHITE - Plug in dual DIAGNOSTIC SOLUTION CDP+ is GENERAL MANAGER [X] PARTS MANAGER [X]

stage sensor harness a quick and reliable diagnostic More information

tool serving as a link between vehicle and

More information

computer. It works on both old

More information

Advanced Scooter Workshop

More information DTC P1271/78 FUEL V2.82

POINTS POSITION INDICATOR PRESSURE REGULATOR Advanced Scooter Workshop

PPI4 GB Software handbook CIRCUIT MALFUNCTION

V2.82 User manual April 2013 1.

Introduction Advanced Scooter

POINTS POSITION INDICATOR SOFTWARE 05 596 DIAGNOSTICS ECD Workshop is a K-line tool that

PPI4 Advanced PPI with incorporates ignition control

GB Software handbook SYSTEM (1KD FTV)(From August,

Adjustable Brightness & unit (CDI) internal memory modi cation

SOFTWARE Table of Contents 2004) DTC P1271/78 FUEL

Simpli ed Wiring Monitors the functions without

CHAPTER 1 CHAPTER 2 PRESSURE REGULATOR CIRCUIT

brief positive operating voltage

LANDIRENZO OMEGAS MALFUNCTION (OPEN/SHORT)

across points motors when they are switched

SOFTWARE MAIN SCREEN 2.1 05NJ6 01 DTC P1272/78 FUEL PRESSURE More information

Lights a corresponding

Main screen 5 2.2 Main menu 5 2.3 Function REGULATOR SYSTEM MALFUNCTION For

buttons 6 2.4 Multilanguage panel 6 2.5 more

More information Status INSTALLATION MANUAL 3RP /

More information

5RP 4-BUTTON SERIES

More information

GEARBOX MONITOR MODEL VEHICLE SECURITY SYSTEMS

NR. 1.1203 USER MANUAL Introduction to Electronic 3RP / 5RP 4-BUTTON SERIES

GEARBOX MONITOR MODEL CONTOIL DFM 8EDM. Table of Signals VEHICLE SECURITY SYSTEMS

INSTALLATION MANUAL Before

NR. 1.1203 USER MANUAL USER contents. Mounting and Introduction to Electronic you begin the installation Read

SAFETY Before starting to drive

with a mounted gearbox operating instructions Signals Oscilloscope An the INSTRUCTIONS! Always use

oscilloscope displays voltage a multi-meter when verifying vehicle wiring.

monitor you need to make sure Mounting and operating changes over time. Use an Before mounting the

that: the monitor does not limit eld of vision instructions CONTOIL DFM oscilloscope to view analog and

of the driver; monitor 8EDM Table of contents Safety digital signals when required during circuit

instructions 2 - Designed use - diagnosis. Fig. 6-01 More information

More information Installation, commissioning and

operation - Operational safety - Return of the

More information

instruments WAMLocal. Wireless Asset

K9 Heat Alarm Owners Manual Monitoring - Local Food Safety

More information

HA-1520 CHAPTER 11: Flip Flops Software. Software Installation

K9 Heat Alarm Owners Manual CHAPTER 11: Flip Flops In this

Wireless Asset Monitoring -

HA-1520 Your K9 Heat Alarm is Wiring diagrams 14 1. chapter, you will be building the

Local Food Safety Software

a state of the art product part of the circuit that controls

designed and developed by Component key for wiring the command sequencing. The

BA/WAM-L-F Software

Installation and User Guide

ACEK9.COM a division of diagrams 1 to 29 Note: Not all required circuit must operate

System Overview The BAPI

Radiotronics, Inc. It is a unique blend of the counter and the memory chip. When the

Wireless Asset Monitoring Local (WAM Local)

positive features taken Wiring diagrams 14 1 teach

Software receives temperature

Component key for wiring

diagrams 1 to 29 Note: Not all

More information More information

the items listed will be tted to More information

all models No Description

00200 Alternator with built-in regulator

Module 21 Fuel Injectors - 00500 Battery 01001 Starter

Service Manual Trucks USB Floppy USB Floppy Disk

Dual Point Injection (DPI) Service Manual Trucks Group 36

Emulator

Vehicle Electronic Control Unit

Module 21 Fuel Injectors - Dual More information

(MID 144), Diagnostic Trouble USB Floppy USB Floppy Disk

Point Injection (DPI) Author:

Code (DTC), Guide From build Emulator Manual ipcas GmbH

Grant Swaim E-mail:

date 1.2007 PV776-88951780 Phone: +49 (0)9131/ 7677-0

sureseal@nr.in .net URL: TOYOTA ELECTRONIC Foreword The descriptions and service Gundstraße 15 Fax: +49

www.tech2tech.net Phone: (336)

632-9882 Fax: (336) 632-9688 Postal Address:

CONTROL TRANSMISSION procedures contained (0)9131/ 7677-78 D-91056

Erlangen Internet: http://www.ipcas.de

Tech-2-Tech Website Electronic Control Transmission

Germany Email: info@ipcas.de Contents

(ECT) The Electronic Control More information

Transmission is an automatic

More information

transmission which uses More information

modern electronic control INTRODUCTION. 3 PARTS

technologies to control the transmission. The

Contents Installing the ucal transmission itself,

SUPPLIED. 3 BEFORE YOU e-ask electronic Access

Software on your PC/Laptop BEGIN. 3 CONNECTING THE Security Keyless-entry

ucal Programmer Version More information Table of Contents e-ask electronic Access Security

INTRODUCTION... 3 PARTS Keyless-entry e-fob Keyless-

Contents Installing the ucal

SUPPLIED... 3 BEFORE YOU entry entry System Full-Function

Software on your PC/Laptop 1 Speedlink software will run on BEGIN... 3 CONNECTING THE Function Installation Manual

ucal Programmer Version 1

Connecting the ucal Windows NT, Windows 7, and ECU INTERFACE TO OTHER FCC ID: TV2EFOB1 (UM20 ~

EQUIPMENT... 4 CONFIGURING A DATA 22793-02) Table of Contents Introduction... 1

Programmer to your PC/Laptop Windows 8; it will run on both LOGGER TO WORK WITH THE ECU e-fob Operation

1 Optional USB Adapter Kit (for ucal) 1

INTERFACE... 11 DATA OUTPUT

Installing the USB Driver for Guide to the Speedlink software

and drivers. Status Instruments More information

has a range of process control More information

More information

equipment that can be

con gured using the Speedlink

INSTALLATION & SERVICE

LG Air Conditioning Multi F(DX)

software. Some equipment will connect Programming Logic controllers

directly to a Windows MANUAL. Display Panel

Programming Logic controllers

Fault Codes Sheet. Multi Split Programmable Logic Controller INSTALLATION & SERVICE

Units More information (PLC) is a microprocessor based MANUAL Display Panel The

system that uses programmable PowerLine EMS TM is a

Multi Split Units If there is a specialized power distribution

memory to store instructions

fault on any LG Multi unit, an

Error mark is indicated on the

Diagnosing and and implement functions such as logic, and energy management

sequencing, system intended to be used in recreational

display window of the indoor Understanding Starting vehicles. The Control Module is housed

unit, wired-remote controller,

and LED s of outdoor unit control board. A

Problems on the ZR-1 Marc More information

two More information

Diagnosing and Understanding

Starting Problems on the ZR-1

More information Marc Haibeck 28-Sep-13 There 1955-1956 Chevy Bel-Era

are three basic failure 02-04 GSX1300R Hayabusa

Classic Instruments 1955-1956

conditions: - A VATS security Chevy Bel-Era Installation PCIII/PCIIIr

system lockout - A click from the starter

OWNERS MANUAL. Status Manual Revised January 2, 2014 Floppy Disc Request Form If you

solenoid but no engine Page 1 Table of Contents Table

Monitor. for Windows 95, 98, of Contents 2 Welcome to the

do not have a CD-Rom drive

and would like to receive the

ME, NT 4, 2000 & XP. More information Team of Classic Instruments! 3 55-56 Chevy program and the alternate

Part Identi cation maps for your model on a 3 1/2

OWNERS MANUAL Status

oppy disc, please fax this form to Dynojet at

Monitor for Windows 95, 98,

ME, NT 4, 2000 & XP

iloq P10S.10/20 Programming More information 1-702-399-1431

SIGNALCRAFTERS TECH, INC. device User's Guide

www.signalcrafters.com 57 More information

Eagle Rock Avenue, East Hanover, NJ 07936

iloq P10S.10/20 Programming

Mobile Satellite Solutions. A

device User's Guide CONTENTS

Tel: 973-781-0880 or 800-523-5815 Fax:

CONTENTS... 2 GENERAL... 3 WiWorld Partner SATELLITE TV

Multi-Touch Ring Encoder

USING THE PROGRAMMING

ANTENNA CONTROLLER RFM-

More information DEVICE... 5 Starting the Software Development Kit

programming device... 5 Programming of Mobile Satellite Solutions A