Professional Documents

Culture Documents

16.20022018 Paul Bussey-CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI) (Rev A 170816) PDF

Uploaded by

Florina MihailaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

16.20022018 Paul Bussey-CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI) (Rev A 170816) PDF

Uploaded by

Florina MihailaCopyright:

Available Formats

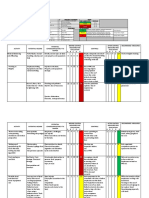

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

Significant Risk Index – SFARP

A Catastrophic risks – site specific and generic

B Significant risks – site specific

C Significant risks – site generic

D Existing services and utilities

E Contamination and buried objects

F Working space/working platforms

G Confined spaces

H Erecting structures-

J Materials/substances/components generally

K Cladding/glazing/roofing

L Fur niture, finishes and equipment

M Risks to building users, visitors and members of the public

N Maintenance/repairs

P Dismantling/demolition/future alteration/refurbishment

Guidance Note: The list set out below is not comprehensive but is provided to help identify design-relevant ‘significant issues’. It gives an indication of the sort of issues and information to identify

on projects. Identified risks to be entered into the Hazard Awareness and Risk Management Register (Template D4).

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 1

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

A – SFARP

Catastrophic risks – site specific and generic

Structural collapse • Existing and adjacent buildings, structures, party walls, retaining walls, etc. RR834 – Preventing catastrophic risks in

during construction, and permanent condition construction

• Underground voids such as tunnels, vaults, mines, old workings, wells, etc. CIRIA Publication C699 – Guidance on

• Existing fabric of buildings during refurbishments under temporary loadings of catastrophic events in construction

scaffold, materials or plant BS 5975:2008 – Code of practice for

• Construction cranes, scaffolding or trees in poor condition falling in high winds temporary works procedures and the

• Temporary works, including all types of scaffolding, shoring, propping. Ensure permissible stress design of falsework.

temporary works designer and coordinator appointed Identification of these works on the project

drawings or CDM Analysis is essential. Detailed

design to be by specialists.

Fire • Fire during construction – means of escape for operatives (e.g. stairs, routes) HSG168 – Fire safety in construction

and existing occupants (if in use). Access for fire-fighting appliances and UKTFA (STA) guidance on fire spread

personnel

• Temporary fire protection to prevent fire spread to adjacent properties in Ref: Mario Minchella prosecution 2014

construction phase, e.g. timber frame protection and unprotected area

calculations

Water • Rivers, canals, culverts, storm drains on site or adjacent Reference to HSE prosecution of the

• Temporary/permanent railing as an early activity Environment Agency, following a fatal accident

• Contractor to issue a safe system of work after seeking further advice, on the banks of the River Witham on 12

including consideration of lifejackets, throw-lines, torpedo floats and grab September 2001

rings, floatation devices, rescue and safety harnesses, rescue boats,

communications to raise alarm

• This should ensure that there is an adequate method of preventing falls on to

the mud or into the river and for retrieving persons

• Identify flooding risk – occupier may need to join the

• Environment Agency Flood Warning System and establish an evacuation

procedure

• Stagnant water from rivers, canals, culverts, drains. Risk of contamination to

watercourses by spills on site. Infection/Weil’s disease

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 2

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

Wind or extreme weather •– SFARP

Identify likelihood of extreme weather conditions on site in long and short term Eg. Cross laminated timber panels cannot be

which may influence the design and construction methodology installed in 8 mph winds or above.

B Significant risks – site specific

Noise, vibration and To occupied buildings and housing nearby, hospitals, churches, cemeteries,

disturbance to neighbours schools, care homes, etc.

• Piling operations – hammered/driven or augered? Noise disturbance or damage

to surrounding buildings

• Risk of disturbing those in vulnerable sectors of the community

• Limits on hours of site work

Health and respiratory To local environment, all neighbours, operatives, and site personnel L143 – Managing and working with asbestos

injuries from materials and • Identify asbestos materials and other contaminants in existing buildings, e.g. Control of Asbestos Regulations 2012

dust horsehair plaster

• Ensure adequate surveys and appropriate contractors used to identify Lead paint – www.lipsa.org

dangerous materials on site and/or their removal Control of lead at work Regulations 2002.

• Avoid or minimise chasing, cutting blocks and masonry etc., unless procedures

in place for dust suppression or vacuum extraction, or enclosure and

extraction

• Demolitions and concrete breaking – minimise works and use damping-down

processes

• Avoidance of screed removals where possible

• Lead paint in existing buildings – avoidance of dry sanding, drilling or cutting.

Surveys may be necessary

Site access and • Surrounding roads and access roads to be considered for safe access and HSG150 – Health and safety in construction

construction facilities egress of staff, materials and waste. Low or weak bridges, narrow roads,

overhanging trees or cables, etc. Site establishment design proposals to be

• Welfare facilities to be considered in terms of location, services, and provided in PCI as agreed with client and

convenience of contractors and existing users. Phasing of facilities as project design team. Contractor to review in tender &

progresses to be considered CPP.

• Materials unloading and waste storage areas to be considered

• Static and mobile crane sizes, locations, weights and access to be considered

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 3

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

– SFARP

in principle, away from possible vehicle impacts, and collapse on occupied

premises (where possible)

• Consider location, convenience and security of construction team vehicular

parking, materials and tools storage facilities

Project phasing and • Location of existing buildings, car parks and roads to be considered in relation Identify on drawings

occupancy to temporary and future site arrangements in terms of cost, convenience and

safety

• Occupancy of existing buildings and use of adjacent buildings or structures to

be identified, e.g. railways, gas holders, hospitals etc.

• Transient delivery or collection locations and times, such as school runs or

food deliveries during construction period

C Significant risks – site generic

Electrical interference to • Interference with neighbouring hospitals, ambulance stations, airport This is subject to site-specific risk assessment

radio equipment • Specify no site radios where safety is critical by PC

Injury to trespassers • Hoarding to/fencing-off of site and deep excavations Show site demarcation on ground floor, site

• Security measures to scaffolding, detectors, CCTV and or location plan

Animals, vegetation, • Aggressive seagulls or other birds, particularly during nesting season These environmental safety issues are included

poisonous bites • Consider bats, birds, newts and other fauna with regard to their breeding in BREEAM requirements but are part of an

seasons and relocations ethical and criminal requirement to protect

• Consider poisonous or aggressive vegetation such as Japanese knotweed that endangered and other species from harm. Some

can take considerable time to eradicate, or cause significant damage if ignored can also harm the building operatives and users.

• Consider tree roots and avoidance of killing trees during construction and Identification is the key.

causing structural damage to permanent structures

• Consider risk of adders, hornets and wasps’ nests from adjacent sites

Injury to pedestrians and • Rights of way adjacent to or across site, may need temporary closures Highlight on drawings and start liaison with

members of the public • Adjacent railways, roads and transport corridors local authorities, highway and transport

• Pavements – protecting the public from dropped materials and site works organisations.

Electric shock • Cables, street lighting, even if assumed disused BSI PAS 128

Specification for underground utility detection,

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 4

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

– SFARP verification and location

Falls on slopes • Identify steep falls, slopes and embankments which can increase site access Instability of mobile site plant and maintenance

costs and difficulties during construction and maintenance equipment

D Existing services and utilities

Stomach infection • Water supplies potable? Water quality tested? Site welfare needs drinkable water supply

Fire • Water supply/hydrants available for construction fire use Permanent supply may not be available

Electric shock • Overhead cables – barriers specified BSI PAS 128

• Underground cables – investigation to confirm position as survey drawing and Specification for underground utility detection,

utility company information. Identify possibility of unknown live services. verification and location

Further surveys and hand digging likely to be required

• Cables assumed disused, to be identified and checked Client to provide this information as early as

possible

Explosion • Gas pipes – investigation to confirm position as survey drawing and utility BSI PAS 128

company information. Identify possibility of unknown live services. Further Specification for underground utility detection,

surveys and hand digging may be necessary. verification and location

• Propane cylinders to be stored in a safe location

Uncertainty • Surveys of utilities are not totally reliable. On-site checks to be made BSI PAS 128

• Archaeological surveys can impinge upon underground services Specification for underground utility detection,

verification and location

Excavation • Encourage use of vacuum excavation equipment or hand digging in proximity

of dangerous or multiple utilities locations

E Contamination and buried objects

Contamination • Buried tanks/petrol interceptors Avoid further soil contamination by removal

• Purging or chemical cleaning of existing services

Explosion • Buried ordnance – check local authority records and bomb maps, or obtain a High consequence but low probability issue to

survey. Site detection/probing methods may be necessary prior to excavations be considered proportionately

• Methane and other ground gases risk

Musculoskeletal injuries • Identify particularly heavy objects or ones that are difficult to handle, remove Mechanisation methods preferred

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 5

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

– SFARP

or break up

F Working space/working platforms

Falls from height • Design to allow early installation of permanent floors, edge protection and Only unusual features to be highlighted rather

guarding to holes and penetrations. Fixing holes for edge protection than normal, routine work at height issues

• Allow for work to be carried out at ground level or from permanent floor levels

where possible

Manual handling/ • Avoid site layouts or dictating construction methods that limit space for Design team and client to consider in PCI and

musculoskeletal injuries access where reasonably practicable highlight in drawings or CDM analysis

• Consider type of access platforms, scaffolds and mechanical lifting aids that documents

are appropriate for the design to be constructed and maintained

Fire/ emergency evacuation • Design for early installation of stairs and fire compartments where possible. Temporary stairs or protection can be used as

Prefabrication can assist this process alternative

G Confined spaces

Entry into confined spaces • Silos, sewers, ductwork, unventilated rooms, storage tanks, basements, etc. If confined spaces are essential avoid the need

• Avoid creating confined spaces where possible for access or consider safe methods of use

• Minimise operations involving hazards in confined spaces, e.g. welding, cutting,

etc.

• Minimise work in basements and the need for deep trenches

Lack of oxygen/ poisonous • Avoid creating, and minimise operations involving, hazards in confined spaces L101 Safe work in confined spaces

gases (including from where possible Confined Spaces Regulations 2007

residues left) • Avoid entry to confined spaces where possible. If entry is unavoidable, follow a

safe system of work and put in place adequate emergency arrangements

before work starts

• Provision of ventilation and testing the air

• Provision of breathing apparatus

• Permit to work scheme

Drowning Due to liquids and solids that can suddenly fill the space Silos, water tanks, etc. to be identified on

• Rescue harnesses and lifelines drawings

• Communications to raise alarm

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 6

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

Fire and explosion •– SFARP

Check size of emergency exits

• Non-sparking tools and 25V max. equipment

Noxious fumes • Avoid specifying applied finishes in confined spaces where possible

• Avoid specifying hazardous materials/substances for application in confined

spaces

H Erecting structures

Steelwork, in-situ reinforced concrete, pre-cast reinforced concrete, pre-stressed concrete, timber, masonry, brickwork, blockwork, roof

structures, stairs

Collapse/ temporary • Avoid designs which involve temporary instability during construction or If unavoidable identify on structural drawings

instability specify erection sequence including details of temporary support measures or CDM analysis document

required

• Temporary props and bracing – high winds

Falls from height • Maximise pre-fabrication, pre-casting, use of simple intrinsically safe BS 8560 Code of practice for the design of

connection details, and allow for early installation of floors, roof decks, stairs, buildings incorporating safe work at height

edge protection, etc. to minimise risk from high-level working

• Detail to allow easy connection of safety lines, harnesses etc.

• Specify easily achievable tolerances where possible

Collapse – construction • Identify construction loadings on drawings together with any temporary Structural drawings to be clearly annotated

loadings support requirements, e.g. high walls, unbraced structures

• Provide adequate tender information

Manual handling/ • Heavy blocks/stone sections/windows components/lintels and window sills – Mechanical lifting aids to be used for blocks

musculoskeletal injuries lifting hooks/component size – over 20kg over 20kg

Handling major components • Consider access, storage, erection procedures and lifting details for large or Use of permanent or mobile cranes, hoisting

awkwardly shaped components methods of lifts. Size and capacity to be

• Consider composite roof panels for easier handling in high winds considered

Falling materials • Design temporary works to avoid falling materials Crash decks, fans etc.

• Tethering of tools to be recommended

J Materials/substances/components generally

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 7

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

Manual handling/ •– SFARP

Design to allow mechanical handling where possible (avoid blocks weighing Manual handling cannot always be avoided.

musculoskeletal injuries over 20kg, e.g. 190mm blocks) Tolerable methods to be agreed in site specific

• Ensure unit weights and sizes of materials are reduced to acceptable levels circumstances

where manual handling is unavoidable

• Specify easily achievable tolerances where possible

• Specify lifting hooks (e.g. coping stones, large masonry items)

Cuts and abrasions • Avoid specifying materials and components with sharp edges, corners, etc. This is more of a trade capability and training

where reasonably practicable issue, e.g. using brick ties

Carcinogenic diseases • Avoid specification of known carcinogenic materials and substances Certain paints and silica containing materials

• Where no alternative, ensure that adequate information is available at tender could be avoided

stage

Injury to eyes • Operations involving splashing, sparks, dust etc. Try to avoid before PPE is considered

Respiratory injuries • Avoid specifying materials and substances which are likely to cause respiratory Methods of minimalizing cutting of materials

problems where possible, e.g. epoxies and coordinating dimensions need to be

• Design to avoid cutting, chasing, scrabbling etc. considered

Deleterious materials • Check if allowed in your appointment terms PI Insurers to be consulted

• Check if acceptable to client’s building insurers

Skin diseases • Avoid specifying materials and substances which are likely to cause skin Protection against exposure to wet cement

diseases (e.g. dermatitis) where possible; protective clothing necessary for and mortar is a trade issue but unusual

cement and lime mortars. instances may need to be considered

K Cladding/glazing/roofing

Including flat roofwork, pitched roofwork, masonry, brickwork, blockwork, stonework, panels, windows, patent glazing, sheeting, tiling, slating,

curtain walling

Temporary instability • Avoid designs which involve temporary instability during construction, or This may be a specialist subcontractor

specify an erection sequence that avoids it. If unavoidable, detail temporary designer issue but some consideration may be

support measures required necessary.

• Temporary fixing of windows/curtain walling balustrades and guard rails to be

avoided

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 8

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

Falls from height •– SFARP

Maximise prefabrication, adopt simple details and allow for early installation of BS 8560:2012 Code of practice for the design

floors, roof decks, stairs, parapets, permanent edge protection etc. to minimise of buildings incorporating safe work at height

risk from high-level working

• Specify easily achievable tolerances where possible All methods of façade access are to be

• Detail to allow easy connection of safety lines, harnesses etc. where necessary considered in relation to the principals or

• Use large decking, cladding panels, domed roof lights prevention (sfarp). CDM analysis document to

• Consider future maintenance and cleaning, especially on and under balconies explain the other factors that have been

and difficult to access areas considered in the decision making process.

• Consider window cleaning from inside where possible

• Consider permanent access or fastenings

• Consider appropriate type of temporary and permanent edge protection to

roofs

• Window restrictors, handle accessibility, cill heights and guarding

• Consider heights of balustrading where publicly accessible, or where seating is

provided adjacent (e.g. food courts)

Construction loadings • Identify construction loadings on drawings for mechanical installation plant and Roof, cradle, lifts, hoists to have loading

temporary works allowances and stacking of materials criteria described

Falls through fragile • Avoid specifying fragile materials (e.g. roof-light panels) Roof fragility criteria to be clarified. CWCT

materials • Consider installation, fragility and glazing of roof lights guidance 2012

• Provide guard rails around roof lights or raise up

Falling objects • Ensure adequate lifting provisions on components BS 8560- Design of Buildings incorporating

• Maximise prefabrication safe work at height

• Safe access for future maintenance and cleaning of facades

• Review specification for temporary fixing of windows/curtain walls to avoid

being blown out by gusts of wind before being permanently fixed (can cause PI

notifications)

• Design out complex fixing details of large elements at high level with small

components

• Ensure no gaps in balustrading where objects can pass through, above public

areas, e.g. atria, transport hubs, etc.

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 9

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

•– SFARP

Advise contractor of need to tether tools, elements and materials, where

working above others

Fire • Specify non- or low-flammable and non-combustible materials and products

where possible, especially for construction stage safety as well as end use

• Consider the end use of the building, e.g. kitchen areas, boiler rooms, and

check with the client’s building insurers for extra requirements

• Consider escape from roofs in a fire, during construction and use

L Fur niture, finishes and equipment

Stone, ceramics, coatings, paints, sealants, adhesives, wood, wood-based materials, synthetic materials

Hazardous materials/ • Avoid specifying finishes involving hazardous materials/substances where If not possible specify use of suitable PPE of

substances reasonably practicable specialist nature (e.g. breathing apparatus) in

• Substitute safer alternatives, where possible tender.

• Specify pre-finished components where reasonably practicable

Dust/fumes • Avoid specifying surface preparation, application methods and processes likely If not possible, specify dust extraction, water

to release hazardous dust or fumes where reasonably practicable, i.e. cutting, suppression and enclosure provisions in tender

drilling, abrading, polishing, etc. (e.g. with solvent paints, adhesives and spray documentation

paints)

• Avoid dust from creating site-mixed powder materials

Noise/vibration • Avoid specifying finishes requiring use of vibrator tools or noisy equipment for If not possible specify use of exposure

surface preparation or application methods where reasonably practicable limitation methods in tender documents

Fire • Avoid specifying materials using inflammable solvents If not possible specify ventilation expectations

Musculoskeletal injuries • Size of furniture and components such as glass screens, reception desks, Sizes of lifts, hoists etc. to be clarified for size

sliding folding partitions to be considered in terms of vertical access via goods of largest elements possible. Other methods to

lifts, hoists or at last resort stairs if of man-handleable size. Horizontal access be considered where necessary eg. Hoists,

also to be considered e.g. trolleys, skates, stillages, etc. BMU’s, cranes, etc. Protective coverings of

materials needs consideration

M Risks to building users, visitors and members of the public

Crushing • Escape routes from loading bays

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 10

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

•– SFARP

Protection of pedestrians from vehicular routes

• Boundary walls designed to fall away from railway tracks, roads, playgrounds

and pedestrian areas

• Vehicle barriers to prevent runaway cars falling from height in icy conditions or

where driver loses control

Drowning • Hazard warning signs to be provided, e.g. ‘Danger Sudden Drop’. Life buoys?

• Railings to be 1.1m high and difficult to climb. Designed to resist impact by

vehicles

• Whoever takes responsibility for the maintenance of river walks is to take the

decision as to the appropriate level of protection to meet the duty of care

requirement of health and safety legislation. They must also put into place a

management plan for the maintenance of such protection

Fire • Escape for deaf or hearing-impaired people, particularly in public buildings – These should be included in the Fire and

consider vibrating alerts or visual alarms Inclusive Design Strategies under parts B & M

• Consider evacuation as well as access and advise employers/ tenants of their of the Building Regulations

duty to provide a suitable evacuation strategy for a wide range of users and to

carry out fire risk assessments

Collision/trapping • Automatic doors – risk assessment to BS 7036 BS 7036 Code of practice for safety at

• Automatic gates – Gate Safe to be referenced powered doors for pedestrian use

Gate Safe

Falls from height • Operation of high-level blinds BS 8560 Code of practice for the design of

• Window controls as Part N, less than 1700/1900mm above floor level buildings incorporating safe work at height

• Fixing to be provided for ladders more than 6m long Building Regulations, Approved Document N &

• Horizontal force on balustrades specified as appropriate for use, e.g. public use AIF Information Building Regulations, Approved

– refer to AD K Document K

• No 100mm gaps between balustrades if children under 5 are likely to be

present

• Glass balustrades and full-height glazing at height – consider risk if toughened

glass shatters

• Safety glazing to Part N and BS 6262

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 11

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

•– SFARP

Restrictors and stays to opening windows to prevent accidental falls and

children climbing out

• Ability to attach safety harnesses to gantries and walkways, and anchor lines

• Guarding to level changes, riverbanks, ditches, stairs, under-stair soffits, ramps

Musculoskeletal injuries • Outward-opening doors and windows – walking into leading edges, especially

at head height

Burns/scalding • Low surface temperature radiators where toddlers, autistic and other These are Inclusive design and CDM issues to

vulnerable groups, or elderly may be present. Also avoid unprotected hot be considered

pipework.

• Flue outlets located away from public areas or protected

Drowning • Full risk analysis required :-

• Particularly for unsupervised swimming pools or ponds where young children

have access alone eg. fencing or lockable areas

• River walkways, canalsides, etc.

Safe by • Consider personal safety and sense of safety Safe by Design, Local Crime Prevention

Design/rape/attack • Advice of crime prevention officer or guidance to be sought Officers, BREEAM advantages

• Good surveillance, lighting, minimisation of recesses

Slips/falls/and bruising • Slip resistance of floors specified to entrance, corridors, breaks swimming HSE Slips assessment tool www.hse.gov.uk/

pools and sanitary accommodation, especially in wet conditions. Entrance SLIPS/sat/index.htm

matwells and slip resistance research related to cleaning materials used

• Good extraction ventilation to kitchens, bathrooms and swimming pools to Specify slip resistance of finishes

minimize condensation

• Avoid undulations and paving trip hazards

• Guarding against falls in level, steep slopes

• Stair and step nosings in contrasting colour with good lighting, including to

external stairs and fire escapes

• Protection or deterrents to features that may attract children, e.g. skateboard

ramps, features to climb or sit on

N Maintenance/repairs

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 12

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

Falls from height •– SFARP

Consider ease of replacement of light bulbs, especially above stairs or in high Provide information regarding built-in safety

spaces, atria, etc. facilities, etc. in H&S file/ maintenance manual

• Design in adequate safe systems of access, edge protection, provision for the

attachment of safety equipment, eyebolts, rails etc. where necessary Ref: Oxford Architects Prosecution 2010

• Suitable base for ladders provided as in Approved Document N

• Position controls, valves and equipment requiring regular maintenance at low

level (or lowerable)

• Low-maintenance equipment/fittings where practicable, but infrequent access

to be considered

• Design process followed to select suitable mansafe/latchways system if no

suitable alternative. Harnesses and training for use included in specification,

including locked access doors, hatches

• Cat ladders and walkways designed to Building Regulations and relevant BS

8560

• Handrails to be specified around lift-up access hatches

Falls • Steep slopes, including landscape maintenance Identify on drawings, contours, levels, sections

Falls through fragile • Avoid specifying fragile materials where possible, but may be existing Provide information showing all fragile

materials • Design in adequate safe systems of access, edge protection, provisions for the materials and inbuilt facilities in H&S file/

attachment of safety equipment, etc. where necessary maintenance manual

Electrocution/scalds • Provide adequate isolation facilities for all plant and equipment Identify these on drawings

Manual handling/ • Design components for ease of handling and replacement Provide information regarding access and lifting

Musculoskeletal injuries • Provide adequate access facilities, working space and lifting facilities around all facilities in H&S file/maintenance manual

plant and equipment where necessary

• Large roof hatches with hydraulic or mechanical assistance to open and close

Hazardous • Avoid hazardous materials and substances Provide information in H&S file of extent and

materials/substances • Provide information on existing or unavoidable retention of hazardous location

materials or substances, e.g. asbestos, lead paint, etc

P Dismantling/demolition/future alteration/refurbishment

Uncontrolled collapse • Provide information regarding design parameters, design loadings, means of Designers do not need to tell demolition

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 13

Hazard-Awareness and Risk-Identification Checklist (HARI)

Project Number Status of CDM design RAG

Name

Location Risk tolerable

Building Type Risk to be further reviewed

Date of Review & Risk not tolerable

Stage RM/RR

RM – Risk mitigated and included in drawings or CDM Analysis document , for future management by contractor

RR – Residual risk identified for later resolution or inclusion in Health and Safety File.

Significant Risk Details Designers to consider the following significant risks and other factors Comments, Actions, References RAG

– SFARP

ensuring structural stability, construction details, specific alteration/demolition professionals how to demolish all buildings,

hazards (i.e. pre-stressing, suspension, cantilevers etc.) only identify significant risks.

CDM Template D2 - Hazard-Awareness and Risk-Identification Checklist (HARI)

Rev. 2017.08.16

Page 14

You might also like

- Waterman Principal Designer Training Day 2 - v10Document84 pagesWaterman Principal Designer Training Day 2 - v10eparvusNo ratings yet

- Risk Assessment-Regional Competition-Bricklaying PDFDocument6 pagesRisk Assessment-Regional Competition-Bricklaying PDFuknandiNo ratings yet

- Wilts & Berks Canal Trust Temporary Works ProcedureDocument21 pagesWilts & Berks Canal Trust Temporary Works ProcedureezzularabNo ratings yet

- 33.0 - Working On of Adjacent To A Road v3.0 EnglishDocument20 pages33.0 - Working On of Adjacent To A Road v3.0 EnglishjbdejhiuhwNo ratings yet

- RA - Risk Assessment - Surveying and Pegging - 2021Document4 pagesRA - Risk Assessment - Surveying and Pegging - 2021Asakundwi Mukhwa100% (1)

- 4-Final RA For Installation of Instalation Precast PDFDocument2 pages4-Final RA For Installation of Instalation Precast PDFeng mohamad husamNo ratings yet

- RiskAssessment For Precast Foundation and Road MarkingDocument13 pagesRiskAssessment For Precast Foundation and Road MarkingAneessh KumarNo ratings yet

- Examples CDM Toolkit (210427) R'DCT (v2)Document35 pagesExamples CDM Toolkit (210427) R'DCT (v2)Antonia D QuashieNo ratings yet

- Health and Safety Quarterly Audit ChecklistDocument73 pagesHealth and Safety Quarterly Audit ChecklistAnonymous sAApMNG9vw0% (1)

- ISO 45001: Example Audit PlanDocument3 pagesISO 45001: Example Audit PlanLikai ChinNo ratings yet

- NVQ 6 in Construction Site ManagementDocument43 pagesNVQ 6 in Construction Site ManagementAnne Andaca100% (2)

- Updated BREEAM Action List 24-3-08Document22 pagesUpdated BREEAM Action List 24-3-08c.blackburn100% (2)

- Standard Traffic Management PlanDocument11 pagesStandard Traffic Management PlanGLa DysNo ratings yet

- Risk AsseementDocument8 pagesRisk AsseementMajaga MabhenaNo ratings yet

- 4.5.5 Safety Management Internal AuditDocument10 pages4.5.5 Safety Management Internal AuditJim AlianNo ratings yet

- 2021 Year Ending HSE Performance ReviewDocument17 pages2021 Year Ending HSE Performance ReviewIfrekeNo ratings yet

- Use of Stepladders 05Document1 pageUse of Stepladders 05cardyNo ratings yet

- Workplace Safety and Health Guidelines: Tent-Related WorksDocument22 pagesWorkplace Safety and Health Guidelines: Tent-Related WorksAnton Indra SupriatnaNo ratings yet

- Risk Assessment - Pull Out TestDocument12 pagesRisk Assessment - Pull Out TestMohsin MohdNo ratings yet

- ISO-14001-2015 EA And-Procedure-SampleDocument7 pagesISO-14001-2015 EA And-Procedure-SampleFaisal0% (1)

- Fire Risk Assessment FormDocument19 pagesFire Risk Assessment FormGopinath SekarNo ratings yet

- Planned Task Observation ReportDocument6 pagesPlanned Task Observation Reportmerganser26100% (2)

- RA - Concrete PouringDocument1 pageRA - Concrete PouringعمروNo ratings yet

- Risk Register 001Document4 pagesRisk Register 001SreekumarNo ratings yet

- Safety in Design Risk RegisterDocument1 pageSafety in Design Risk Registerchayan83No ratings yet

- 4 Fleet Risk Assessment ProcessDocument4 pages4 Fleet Risk Assessment ProcessHaymanAHMEDNo ratings yet

- Risk Assessment 53 Light TowerDocument18 pagesRisk Assessment 53 Light TowerAchmad ChusnadiNo ratings yet

- Instructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsDocument21 pagesInstructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsWinstone AudiNo ratings yet

- Appointment Letter Temporary WorksDocument3 pagesAppointment Letter Temporary Worksjamie100% (2)

- 42.0 - Pre-Cast Construction v3.0 EnglishDocument20 pages42.0 - Pre-Cast Construction v3.0 EnglishchumairabbasNo ratings yet

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 pageNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiNo ratings yet

- Safe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201Document18 pagesSafe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201mkash028100% (1)

- SP-21 Dust ControlDocument2 pagesSP-21 Dust ControlYounis KhanNo ratings yet

- Ladders, Hop Ups Risk AssessmentDocument8 pagesLadders, Hop Ups Risk AssessmentRebecca Winter100% (1)

- Risk Management PolicyDocument1 pageRisk Management PolicyChauhan VineetNo ratings yet

- ESH Plan 50120CH JSW Jaigarh Drilling GroutingDocument167 pagesESH Plan 50120CH JSW Jaigarh Drilling Grouting123shripadNo ratings yet

- Construction Design and Management RegulDocument39 pagesConstruction Design and Management Regulkhx2No ratings yet

- Lead Crisis Manager 4pDocument4 pagesLead Crisis Manager 4pAsser El-FoulyNo ratings yet

- Nebosh Hse Award in Managing Risks and Risk Assessment at WorkDocument7 pagesNebosh Hse Award in Managing Risks and Risk Assessment at Workolaogun100% (1)

- Systematic Risk Assessment of High-Risk Structures Against Disproportionate CollapseDocument31 pagesSystematic Risk Assessment of High-Risk Structures Against Disproportionate CollapseHarikrishnan PNo ratings yet

- CIV510 - Management of Temporary WorksDocument14 pagesCIV510 - Management of Temporary Worksezzularab100% (1)

- QRC-RA-013-Removal of Existing Road StructureDocument10 pagesQRC-RA-013-Removal of Existing Road StructureKallem RajashekarNo ratings yet

- Logistic PlanDocument1 pageLogistic PlanAfif Azhar0% (1)

- ph1 App F Risk RegisterDocument3 pagesph1 App F Risk RegisterHugo HernandezNo ratings yet

- Health and Safety in ExcavationsDocument65 pagesHealth and Safety in Excavationsthirupathi9966No ratings yet

- Social Management PlanDocument46 pagesSocial Management PlanNilamSanjeev Kumar SinghNo ratings yet

- Risk Assessment - Electrical - 2021Document9 pagesRisk Assessment - Electrical - 2021Asakundwi MukhwaNo ratings yet

- Safe Working Procedure ExcavationsDocument4 pagesSafe Working Procedure ExcavationsMunaku TafadzwaNo ratings yet

- Ge700 2020 Ga01Document1 pageGe700 2020 Ga01LucianNo ratings yet

- Project Safety ChecklistDocument4 pagesProject Safety ChecklistAejaz Mujawar100% (1)

- Security Risk Assessment Template Excel - QWGm7lwCTvk49HFDocument3 pagesSecurity Risk Assessment Template Excel - QWGm7lwCTvk49HFAjiWidyartaNo ratings yet

- Temporary Works Update Thursday, 21 November 2019Document25 pagesTemporary Works Update Thursday, 21 November 2019r_awadhiya100% (2)

- Risk Management PolicyDocument28 pagesRisk Management PolicyMamatha VNo ratings yet

- Risk Matrix: Project: ID: Start Date: End DateDocument2 pagesRisk Matrix: Project: ID: Start Date: End Dateketac100% (1)

- Hazardous Chemical RegisterDocument2 pagesHazardous Chemical RegistervictorNo ratings yet

- CDM 2015 CIBSE TalkDocument44 pagesCDM 2015 CIBSE TalkJeduardo Ch-mezaNo ratings yet

- Health, Safety AND Environmental PlanDocument63 pagesHealth, Safety AND Environmental Planm.umarNo ratings yet

- 14.20022018 Paul Bussey-RIBA CDM PD Documentation - Universities Short Couse (171107) v1Document68 pages14.20022018 Paul Bussey-RIBA CDM PD Documentation - Universities Short Couse (171107) v1Florina Mihaila100% (1)

- Risk Assessment: Construction Plan For Box Girder Joints, Wing Plates and Anti-Collision GuardrailsDocument3 pagesRisk Assessment: Construction Plan For Box Girder Joints, Wing Plates and Anti-Collision Guardrailssalauddin0mohammedNo ratings yet

- 1 - Construction SafetyDocument43 pages1 - Construction SafetyHawaiiChongNo ratings yet

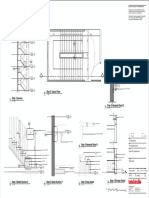

- A 27 001 - 01 PDFDocument1 pageA 27 001 - 01 PDFFlorina MihailaNo ratings yet

- Atrium Stair Ground Floor Plan 2: Do Not Scale This DrawingDocument1 pageAtrium Stair Ground Floor Plan 2: Do Not Scale This DrawingFlorina MihailaNo ratings yet

- A 27 003 - 01 PDFDocument1 pageA 27 003 - 01 PDFFlorina MihailaNo ratings yet

- Stair 2 Typical Plan 2: Do Not Scale This DrawingDocument1 pageStair 2 Typical Plan 2: Do Not Scale This DrawingFlorina MihailaNo ratings yet

- 14.20022018 Paul Bussey-RIBA CDM PD Documentation - Universities Short Couse (171107) v1Document68 pages14.20022018 Paul Bussey-RIBA CDM PD Documentation - Universities Short Couse (171107) v1Florina Mihaila100% (1)

- Course Assessment Cover Sheet: Example 3Document17 pagesCourse Assessment Cover Sheet: Example 3Florina MihailaNo ratings yet

- Basement Lift Lobby Waiting Area Render: Tatehindle 15Document1 pageBasement Lift Lobby Waiting Area Render: Tatehindle 15Florina MihailaNo ratings yet

- Pa enDocument36 pagesPa enFlorina MihailaNo ratings yet

- Transport Committee: Covid-19: Fair Refunds For Season Ticket HoldersDocument2 pagesTransport Committee: Covid-19: Fair Refunds For Season Ticket HoldersFlorina MihailaNo ratings yet

- Refund Subject To Airlines ConditionsDocument1 pageRefund Subject To Airlines ConditionsFlorina MihailaNo ratings yet

- 5 Real-Deal French Immersion Courses That Aren't Messing Around (France, Canada and Belgium)Document10 pages5 Real-Deal French Immersion Courses That Aren't Messing Around (France, Canada and Belgium)Florina MihailaNo ratings yet

- Nutrition Guide - Live Like Louise 1Document17 pagesNutrition Guide - Live Like Louise 1Florina MihailaNo ratings yet

- Bicycle Tours in Austria:: Selected Tour Start Date: Saturday, September 5th, 2020Document11 pagesBicycle Tours in Austria:: Selected Tour Start Date: Saturday, September 5th, 2020Florina MihailaNo ratings yet

- Institutul de Boli CardioVasculare Prof DR George IM Georgescu-2Document6 pagesInstitutul de Boli CardioVasculare Prof DR George IM Georgescu-2Florina MihailaNo ratings yet

- EcologieDocument1 pageEcologieFlorina MihailaNo ratings yet

- SectiuneDocument1 pageSectiuneFlorina MihailaNo ratings yet

- ReabilitareDocument1 pageReabilitareFlorina MihailaNo ratings yet

- Ubranism Ii RUNCON, England, UKDocument6 pagesUbranism Ii RUNCON, England, UKFlorina MihailaNo ratings yet

- Redland Solarbgv June 2011Document16 pagesRedland Solarbgv June 2011Florina MihailaNo ratings yet

- 3LMGOO54 - Lean Start-Up: Course Description and ObjectivesDocument3 pages3LMGOO54 - Lean Start-Up: Course Description and Objectivespavan reddyNo ratings yet

- Lovely Professional University Mittal School of BusinessDocument2 pagesLovely Professional University Mittal School of BusinessPuru RajNo ratings yet

- Hot Consolidation and Mechanical Properties of Nanocrystalline Equiatomic Alfeticrzncu High Entropy Alloy After Mechanical AlloyingDocument6 pagesHot Consolidation and Mechanical Properties of Nanocrystalline Equiatomic Alfeticrzncu High Entropy Alloy After Mechanical AlloyingBuluc GheorgheNo ratings yet

- MKT 306 Final20Document13 pagesMKT 306 Final20lema messiNo ratings yet

- International Journal of Hospitality Management: Hyoung Ju Song, Jihwan Yeon, Seoki LeeDocument7 pagesInternational Journal of Hospitality Management: Hyoung Ju Song, Jihwan Yeon, Seoki LeeCarmenn LouNo ratings yet

- Intro To Computer ForensicsDocument38 pagesIntro To Computer Forensicssharath_rakkiNo ratings yet

- Reflective Essay MKWDocument1 pageReflective Essay MKWnicholas aprilieNo ratings yet

- Akhilesh ResumeDocument2 pagesAkhilesh ResumeAkhilesh TeluguntaNo ratings yet

- Tutorial Questions Pad214 Week 4Document16 pagesTutorial Questions Pad214 Week 4Afifah HananiNo ratings yet

- Con Solo Dated Financial Statement AsperUS GAAP 2009 10Document8 pagesCon Solo Dated Financial Statement AsperUS GAAP 2009 10Nitin VatsNo ratings yet

- The Consumer Decision JourneyDocument2 pagesThe Consumer Decision JourneyxxxNo ratings yet

- MKT101 NikeDocument31 pagesMKT101 NikeLinh DangNo ratings yet

- Live Report PathaoDocument28 pagesLive Report Pathaonalintimalsina1No ratings yet

- Maru Batting CentreDocument6 pagesMaru Batting CentreTanya GargNo ratings yet

- Network Competence Its Impact On Innovation Success and Its Antecedents - 2003Document10 pagesNetwork Competence Its Impact On Innovation Success and Its Antecedents - 2003Nima KhNo ratings yet

- Geotechnical Companies List: Human ResourceDocument14 pagesGeotechnical Companies List: Human ResourcePadala SaipavanNo ratings yet

- Apple Inc. Strategic Marketing Analysis and Evaluation: Xuanyi Chen Yiran Liu Hanzhen GongDocument9 pagesApple Inc. Strategic Marketing Analysis and Evaluation: Xuanyi Chen Yiran Liu Hanzhen GongAishwarya MishraNo ratings yet

- Relationship and Contact Details16042020143729628Document8 pagesRelationship and Contact Details16042020143729628Sourav KumarNo ratings yet

- KEY TO CONTROLLED WRITING Powerpoint. HCDHDocument21 pagesKEY TO CONTROLLED WRITING Powerpoint. HCDHTran LeNo ratings yet

- 2 MIDTERMS Election Law 1 of 3 IV Election Period PDFDocument17 pages2 MIDTERMS Election Law 1 of 3 IV Election Period PDFCha Ca100% (1)

- Unit 5: Company LawDocument4 pagesUnit 5: Company LawDiệp Quỳnh TrầnNo ratings yet

- A Comparative Study On Investment Policy of Nepalese Commercial BankDocument5 pagesA Comparative Study On Investment Policy of Nepalese Commercial Bankdevi ghimireNo ratings yet

- ASTM A395 - A 395M - 99 (Reapproved 2009)Document8 pagesASTM A395 - A 395M - 99 (Reapproved 2009)raulNo ratings yet

- BBA211 Vol5 Marginal&AbsortptionCostingDocument15 pagesBBA211 Vol5 Marginal&AbsortptionCostingAnisha SarahNo ratings yet

- Ramada Brand BookDocument9 pagesRamada Brand BookMX EARNNo ratings yet

- Date: 02/10/2022: Sale PriceDocument2 pagesDate: 02/10/2022: Sale PriceSiva PriyaNo ratings yet

- Master Thesis Search Engine OptimizationDocument7 pagesMaster Thesis Search Engine Optimizationf60pk9dc100% (2)

- AB InbevDocument13 pagesAB InbevNikhil Gautam100% (1)

- MA Economics PI A19Document7 pagesMA Economics PI A19Muhammad SajjadNo ratings yet

- Xtreme Fitness v. LA Boxing Case No. 30-2009-00293986-CU-FR-CJC - Doc 1 - (Geisler Misuse of Marketing Fund + Overcharging Franchisees)Document13 pagesXtreme Fitness v. LA Boxing Case No. 30-2009-00293986-CU-FR-CJC - Doc 1 - (Geisler Misuse of Marketing Fund + Overcharging Franchisees)Fuzzy PandaNo ratings yet