Professional Documents

Culture Documents

TAD1642GE: Volvo Penta Genset Engine

TAD1642GE: Volvo Penta Genset Engine

Uploaded by

Mahdi DehghankarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TAD1642GE: Volvo Penta Genset Engine

TAD1642GE: Volvo Penta Genset Engine

Uploaded by

Mahdi DehghankarCopyright:

Available Formats

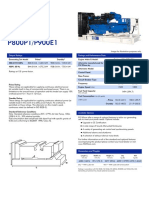

VOLVO PENTA GENSET ENGINE

TAD1642GE

536 kW (729 hp) at 1500 rpm, 585 kW (796 hp) at 1800 rpm, acc. ISO 3046

The TAD1642GE is a powerful, reliable

and economical Generating Set Diesel

Engine built on the dependable in-line six

design.

Durability & low noise

Designed for easiest, fastest and most

economical installation. Well-balanced

to produce smooth and vibration-free

operation with low noise level.

To maintain a controlled working tem-

perature in cylinders and combustion

chambers, the engine is equipped with

piston cooling. The engine is also fitted

with replaceable cylinder liners and valve

seats/guides to ensure maximum dura-

bility and service life of the engine.

Low exhaust emission

The state of the art, high-tech injection

and charging system with low internal

losses contributes to excellent combus-

tion and low fuel consumption.

The TAD1642GE complies with EU

Stage 2 exhaust emission regulations. Features

– Maintained performance, air temp 40°C

Easy service & maintenance – Tropical cooling system (55°C)

Easily accessible service and mainte- – Fully electronic with Volvo Penta EMS 2

nance points contribute to the ease of – Dual frequency switch (between 1500 rpm and 1800 rpm)

– High power density

service of the engine. – Emission compliant

– Low noise levels

Technical description – Gen Pac configuration

Engine and block

– Optimized cast iron cylinder block with – Full flow disposable spin-on oil filter, for ex-

optimum distribution of forces without the

Turbo charger

tra high filtration – Efficient and reliable turbo charger

block being unnessarily heavy. – The lubricating oil level can be measured – Extra oil filter for the turbo charger

– Wet, replaceable cylinder liners during operation

– Piston cooling for low piston temperature – Gear type lubricating oil pump, gear driven Electrical system

and reduced ring temperature by the transmission – Engine Management System 2 (EMS 2), an

– Tapered connecting rods for reduce risk of electronically controlled processing system

piston cracking Fuel system which optimizes engine performance. It also

– Crankshaft induction hardened bearing – Non-return fuel valve includes advanced facilities for diagnostics

surfaces and fillets with seven bearings for – Electronic unit injectors and fault tracing

moderate load on main and high-end bear- – Fuel prefilter with water separator and wa- – The instruments and controls connect to the

ings ter-in-fuel indicator / alarm engine via the CAN SAE J1939 interface,

– Case hardened and Nitrocarburized trans- – Gear driven low-pressure fuel pump either through the Control Interface Unit

mission gears for heavy duty operation – Fine fuel filter with manual feed pump and (CIU) or the Digital Control Unit (DCU). The

– Keystone top compression rings for long fuel pressure switch CIU converts the digital CAN bus signal to

service life – Fuel shut-off valve, electrically operated an anolog signal, making it possible to con-

– Viscous type crankshaft vibration dampers nect a variety of instruments. The DCU is a

Cooling system

to withstand single bearing alternator tor- control panel with display, engine control,

– Efficient cooling with accurate coolant con-

sional vibrations monitoring, alarm, parameter setting and di-

trol through a water distribution duct in the

– Replaceable valve guides and valve seats agnostic functions. The DCU also presents

cylinder block. Reliable sleeve thermostat

– Over head camshaft and four valves per cyl- error codes in clear text.

with minimum pressure drop

inder – Sensors for oil pressure, oil temp, boost

– Gear driven, maintenance-free coolant

pressure, boost temp, coolant temp, fuel

Lubrication system pump with high degree of efficiency

– Coolant filter as standard temp, water in fuel, fuel pressure and two

– Full flow oil cooler

speed sensors.

TAD1642GE

Technical Data Standard equipment Engine Gen Pac

General Engine

Engine designation......................................................................... TAD1642GE Automatic belt tensioner • •

No. of cylinders and configuration........................................................ in-line 6 Lift eyelets • •

Method of operation................................................................................ 4-stroke Flywheel

Bore, mm (in.)...................................................................................... 144 (5.67) Flywheel housing with conn. acc. to SAE 1 • •

Stroke, mm (in.)................................................................................... 165 (6.50) Flywheel for 14” flex. plate and flexible coupling • •

Displacement, l (in³)..................................................................... 16.12 (983.7) Vibration dampers • •

Compression ratio...................................................................................... 16.5:1 Engine suspension

Dry weight, kg (lb)........................................................................... 1480 (3263)

Dry weight with Gen Pac, kg (lb)................................................ 1910 (4211) Fixed front suspension • •

Wet weight, kg (lb)......................................................................... 1550 (3417) Lubrication system

Wet weight with Gen Pac, kg (lb)............................................... 2020 (4453) Oil dipstick • •

Full-flow oil filter of spin-on type • •

Performance 1500 rpm 1800 rpm By-pass oil filter of spin-on type • •

with fan, kW (hp) at: Oil cooler, side mounted • •

Prime Power 485 (660) 532 (724) Low noise oil sump • •

Max Standby Power 536 (729) 585 (796) Fuel system

Fuel filters of disposable type • •

Lubrication system 1500 rpm 1800 rpm Electronic unit injectors • •

Oil consumption, liter/h (US gal/h) at: Pre-filter with water separator • •

Prime Power 0.10 (0.026) 0.11 (0.029) Intake and exhaust system

Max Standby Power 0.11 (0.029) 0.12 (0.032) Air filter with replaceable paper insert • •

Oil system capacity incl filters, liter.................................................................42 Air restriction indicator • •

Air cooled exhaust manifold • •

Fuel system 1500 rpm 1800 rpm Connecting flange for exhaust pipe • •

Specific fuel consumption at: Exhaust flange with v-clamp • •

Prime Power, g/kWh (lb/hph) Turbo charger, low right side • •

25 % 218 (0.353) 229 (0.371) Cooling system

50 % 201 (0.326) 202 (0.327) Tropical radiator incl intercooler •¹) •

75 % 195 (0.316) 197 (0.319) Gear driven coolant pump • •

100 % 200 (0.324) 206 (0.334) Fan hub • •

Max Standby Power, g/kWh (lb/hph) Thrust fan •¹) •

25 % 213 (0.345) 222 (0.360) Fan guard − •

50 % 197 (0.319) 200 (0.324) Belt guard − •

75 % 195 (0.316) 198 (0.321) Control system

100 % 202 (0.327) 210 (0.340) Engine Management System (EMS) with

CAN-bus interface SAE J1939 • •

Intake and exhaust system 1500 rpm 1800 rpm CIU, Control Interface Unit – –

Air consumption, m³/min (cfm) at: Alternator

Prime Power 37 (1307) 44 (1554) Alternator 60A / 24 V • •

Max Standby Power 39 (1377) 46 (1624) Starting system

Max allowable air intake restriction, Starter motor, 7.0kW, 24 V • •

kPa (In wc) 5 (20.1) 5 (20.1) Connection facility for extra starter motor • •

Heat rejection to exhaust, kW (BTU/min) at: Instruments and senders

Prime Power 375 (21326) 439 (24965) Temp.- and oil pressure for automatic • •

Max Standby Power 426 (24226) 500 (28435) stop/alarm 103°C

Exhaust gas temperature after turbine, Other equipment

°C (°F) at: Expandable base frame − •

Prime Power 480 (896) 455 (851) Engine Packing

Max Standby Power 500 (932) 505 (941) Plastic warpping • •

Max allowable back-pressure in exhaust line, 1)must be ordered, se order specification

kPa (In wc) 10 (40.2) 10 (40.2)

− optional equipment or not applicable

Exhaust gas flow, m³/min (cfm) at:

• included in standard specification

Prime power 90.0 (3178) 105 (3708)

Max Standby Power 98.0 (3461) 115 (4061)

Cooling system 1500 rpm 1800 rpm

Heat rejection radiation from engine,

kW (BTU/min) at:

Prime Power 31 (1763) 33 (1877)

Max Standby Power 32 (1820) 34 (1934)

Heat rejection to coolant kW (BTU/min) at:

Prime Power 184 (10464) 199 (11317)

Max Standby Power 190 (10805) 214 (12170)

Fan power consumption, kW (hp) 11 (15) 19 (26)

A* = 1587 mm / 62.5 in

B* = 1120 mm / 44.1 in

C* = 1976 mm / 77.8 in

English 12-2006. © 2006 AB Volvo Penta

Note! Not all models, standard equipment and accessories are available in all countries. D = 2296 mm / 90.5 in (During transport)

All specifications are subject to change without notice. D = Max 3311 mm / 130.5 in

The engine illustrated may not be entirely identical to production standard engines. * Including radiator and intercooler

Power Standards Rating Guidelines

The engine performance corresponds to ISO 3046, BS PRIME POWER rating corresponds to ISO Standard Power for

5514 and DIN 6271. The technical data applies to an engine continuous operation. It is applicable for supplying electrical power

without cooling fan and operating on a fuel with calorific at variable load for an unlimited number of hours instead of com-

value of 42.7 MJ /kg (18360 BTU/lb) and a density of 0.84 mercially purchased power. A10 % overload capability for govering

kg/liter (7.01 lb/US gal), also where this involves a deviation purpose is available for this rating.

from the standards. Power output guaranteed within 0 to MAXIMUM STANDBY POWER rating corresponds to ISO

+2% att rated ambient conditions at delivery. Ratings are Standard Fuel Stop Power. It is applicable for supplying standby

based on ISO 8528. Engine speed governing in accordance electrical power at variable load in areas with well established

with ISO 3046/IV, class A1 and ISO 8528-5 class G3 electrical networks in the event of normal utility power failure. No

Exhaust emissions overload capability is available for this rating.

The engine complies with EU stage 2 emission legislation 1 hp = 1 kW x 1.36

according to the Non Road Directive EU 97/68/EEC. The Information

engine also complies with TA-luft -50% exhaust emission For more technical data and information, please look in the Gener- AB Volvo Penta

regulations. ating Set Engines Sales Guide. SE-405 08 Göteborg, Sweden

www.volvopenta.com

You might also like

- Maxxforce 13 Manual de Servicio PDFDocument506 pagesMaxxforce 13 Manual de Servicio PDFDenia Isalia Santana Anguiano80% (5)

- Wiring DiagramDocument5 pagesWiring Diagramjesus silva89% (27)

- Volvo d12Document18 pagesVolvo d12ANH LÊ67% (6)

- Generac QTS ManualDocument166 pagesGenerac QTS ManualChris MaytumNo ratings yet

- Onan Accessories & Service Support Catalog PDFDocument46 pagesOnan Accessories & Service Support Catalog PDFBruce EgglestonNo ratings yet

- CAT Trouble Shooting C4.4Document236 pagesCAT Trouble Shooting C4.4Bradley Stewart100% (23)

- DSEWebNet PC Internet Browser Software ManualDocument131 pagesDSEWebNet PC Internet Browser Software ManualFernando MendozaNo ratings yet

- Volvo TWD1643GE BrochureDocument2 pagesVolvo TWD1643GE BrochureMTU650No ratings yet

- Diesel Generator Set N14 Series: Specification SheetDocument4 pagesDiesel Generator Set N14 Series: Specification Sheetsusmitamandali100% (1)

- Generator Automatic Voltage Regulator Operation ManualDocument6 pagesGenerator Automatic Voltage Regulator Operation ManualMahdi DehghankarNo ratings yet

- Manual EA20S CaterpillarDocument3 pagesManual EA20S CaterpillarHernán Peñafiel ReaNo ratings yet

- CPCB 1PC Ee483 Tci - 62.5kva TC-40 & 50 KvaDocument96 pagesCPCB 1PC Ee483 Tci - 62.5kva TC-40 & 50 Kvavikrant dalviNo ratings yet

- Farmall Super C ManualDocument101 pagesFarmall Super C ManualManual jockey75% (4)

- PERKÿNS SABRE 6TG2AM AYRDIMCI MOTORDocument2 pagesPERKÿNS SABRE 6TG2AM AYRDIMCI MOTORRiki Akbar100% (1)

- An Intro To Subaru TuningDocument46 pagesAn Intro To Subaru Tuningkai_isman100% (6)

- 1300 Edi Series 80 SplitDocument10 pages1300 Edi Series 80 Split何青No ratings yet

- C633a GCM PDFDocument6 pagesC633a GCM PDFibrahemNo ratings yet

- 08 Main Engine Alignment PDFDocument24 pages08 Main Engine Alignment PDFarunNo ratings yet

- Kohler 14 20 RES OperationDocument48 pagesKohler 14 20 RES OperationQasim AliNo ratings yet

- Boost Check Via MFA - Volkswagen Corrado G60Document4 pagesBoost Check Via MFA - Volkswagen Corrado G60Joseph ScaramuzzoNo ratings yet

- User Manual: HMC6000A/E (HMC6000A/HMC6000EG/HMC6000ED) Diesel Engine ControllerDocument37 pagesUser Manual: HMC6000A/E (HMC6000A/HMC6000EG/HMC6000ED) Diesel Engine ControllerAli100% (1)

- ESG2001C1-W Controller PDFDocument12 pagesESG2001C1-W Controller PDFRenato Matičević100% (1)

- Sebp4321 20 00 AllDocument785 pagesSebp4321 20 00 AllNataly Mendoza100% (1)

- V2203 PDFDocument60 pagesV2203 PDFjust4mp3downloadNo ratings yet

- DI16077M 736kW PDFDocument2 pagesDI16077M 736kW PDFYasin GargıNo ratings yet

- Perkins 2806D-E18TA Operation and Maintenance ManualDocument3 pagesPerkins 2806D-E18TA Operation and Maintenance ManualMostafa ShannaNo ratings yet

- 7.6 Controller Application ProgramDocument2 pages7.6 Controller Application ProgramĐặng MinhNo ratings yet

- Project Report On Electric VehiclesDocument51 pagesProject Report On Electric VehiclesNaveen PrabhuNo ratings yet

- ID DCU Marine 3 0 0 Global Guide r1Document285 pagesID DCU Marine 3 0 0 Global Guide r1Mahdi DehghankarNo ratings yet

- Product Manual 02303 (Revision B, 9/2015) : 2301A Load Sharing and Speed ControlDocument46 pagesProduct Manual 02303 (Revision B, 9/2015) : 2301A Load Sharing and Speed ControlGaston MendozaNo ratings yet

- Tad1642ge PDFDocument16 pagesTad1642ge PDFWallace Ferreira100% (1)

- FY Operation Manual V200602Document48 pagesFY Operation Manual V200602Vicente ChinchillaNo ratings yet

- Sym Citycom 300i (En)Document271 pagesSym Citycom 300i (En)manualsym100% (1)

- 544D PDFDocument8 pages544D PDFNguyễn Tấn Trưởng100% (1)

- Perkins 4012 4012-46A DGNM Service IntervalsDocument1 pagePerkins 4012 4012-46A DGNM Service IntervalsmustafaNo ratings yet

- Cb2410ac D PDFDocument1 pageCb2410ac D PDFdinhvu100% (1)

- Datasheet Alternador Hci544e1 PDFDocument8 pagesDatasheet Alternador Hci544e1 PDFDilham BerrioNo ratings yet

- D7a Ta - Ucm274f - 3Document4 pagesD7a Ta - Ucm274f - 3ozakyus100% (1)

- Be-One OEM's Manual: Customer Support Bernini Design SRL Italy Mobile: ++39 335 7077148. Tel:++39 0386-31445 (Fax 31657)Document27 pagesBe-One OEM's Manual: Customer Support Bernini Design SRL Italy Mobile: ++39 335 7077148. Tel:++39 0386-31445 (Fax 31657)Gustavo Alonso Cappa SalasNo ratings yet

- DSE8003 MKII Operator ManualDocument74 pagesDSE8003 MKII Operator ManualEdgar GonzalezNo ratings yet

- Product Information: Reference OnlyDocument4 pagesProduct Information: Reference OnlyOmarColon100% (1)

- @perkins: 4000 Series 4016TAG2 4016TAG2ADocument2 pages@perkins: 4000 Series 4016TAG2 4016TAG2AIman AkbariNo ratings yet

- Davey Xp350p8cDocument2 pagesDavey Xp350p8cNum470% (1)

- Deep Sea Electronics: Complex Solutions Made SimpleDocument57 pagesDeep Sea Electronics: Complex Solutions Made SimpleRobertNo ratings yet

- 12V - 200ah Agm-Vrla: Formerly Known As Global & Yuasa Co. LTDDocument2 pages12V - 200ah Agm-Vrla: Formerly Known As Global & Yuasa Co. LTDAnzad AzeezNo ratings yet

- 2Gr-Fe Engine: JdescriptionDocument2 pages2Gr-Fe Engine: JdescriptionMaiChiVuNo ratings yet

- EAOM-210 FD en MDocument118 pagesEAOM-210 FD en MAbdul Manan100% (1)

- DSE 157 ManualDocument2 pagesDSE 157 ManualTariqMaqsood100% (1)

- Dca 60eseiDocument10 pagesDca 60eseinelsonyNo ratings yet

- AVK Voltage Regulator COSIMAT C2Document1 pageAVK Voltage Regulator COSIMAT C2ibrahim salemNo ratings yet

- EAM Interface - Quick Reference: Interface Model Description GAC Product Information Bulletin Wiring DiagramDocument3 pagesEAM Interface - Quick Reference: Interface Model Description GAC Product Information Bulletin Wiring DiagramibrahemNo ratings yet

- Um0244 01 GBDocument84 pagesUm0244 01 GBnetharafernando1No ratings yet

- Aftercooler Condensate Drain Valve - Inspect/Clean: Shutdown SIS Previous ScreenDocument2 pagesAftercooler Condensate Drain Valve - Inspect/Clean: Shutdown SIS Previous ScreenTASHKEELNo ratings yet

- Panasonic FP PLC ManualDocument1,336 pagesPanasonic FP PLC ManualZu HainiNo ratings yet

- P800p1-P900e1 (4PP) GB (0313) PDFDocument4 pagesP800p1-P900e1 (4PP) GB (0313) PDFNom YusNo ratings yet

- CDocument620 pagesCHung Cuong PhamNo ratings yet

- Egcp1 (End User)Document160 pagesEgcp1 (End User)Dat Nguyen Cong100% (1)

- Be142 Genset Controller ManualDocument28 pagesBe142 Genset Controller ManualSousaFVNo ratings yet

- Standard Motors AustriaDocument24 pagesStandard Motors AustriaFlorinD2014No ratings yet

- QSB7-G5: EU Stage IIIA / EPA Tier 3Document3 pagesQSB7-G5: EU Stage IIIA / EPA Tier 3V.ganese MoorthyNo ratings yet

- DSE Link 5000 Software ManualDocument61 pagesDSE Link 5000 Software ManualAnonymous vqsuRyNo ratings yet

- 6M21 10403e Pk.s.308.en .06.22Document4 pages6M21 10403e Pk.s.308.en .06.22Edwin MoralesNo ratings yet

- LXC701 V1.1 enDocument8 pagesLXC701 V1.1 enAnonymous vqsuRy100% (1)

- V222TIDocument2 pagesV222TIcmendezNo ratings yet

- Danfoss MBC 5000 5100 Pressure ControlDocument4 pagesDanfoss MBC 5000 5100 Pressure ControlAnom HarimurtiNo ratings yet

- Operator'S Manual: For Models: M673L2 and M673LD2Document40 pagesOperator'S Manual: For Models: M673L2 and M673LD2CarlosNo ratings yet

- User Manual: FPC915 Diesel Engine Fire Pump ControllerDocument48 pagesUser Manual: FPC915 Diesel Engine Fire Pump Controlleramin aliNo ratings yet

- LXC706 V1.0 en User ManualDocument16 pagesLXC706 V1.0 en User ManualAnonymous vqsuRyNo ratings yet

- KDGC Control Panel Manual PDFDocument92 pagesKDGC Control Panel Manual PDFÁngel aguilarNo ratings yet

- Technical PG620 (Rev)Document7 pagesTechnical PG620 (Rev)W Winarto100% (1)

- Safety: Operation and Maintenance Manual ExcerptDocument30 pagesSafety: Operation and Maintenance Manual ExcerptIuri BragaNo ratings yet

- 501eng Deep SeaDocument2 pages501eng Deep Seajadi purwonoNo ratings yet

- TAD1640GE: Volvo Penta Genset EngineDocument2 pagesTAD1640GE: Volvo Penta Genset EngineRenzo zuñiga ahon100% (1)

- TWD1643GE: Volvo Penta Genset EngineDocument2 pagesTWD1643GE: Volvo Penta Genset Enginemohsen_cumminsNo ratings yet

- Quick Guide: Making Modern Living PossibleDocument36 pagesQuick Guide: Making Modern Living PossibleMahdi DehghankarNo ratings yet

- Data Sheet 3WL1116-2CB32-1AA2: ModelDocument7 pagesData Sheet 3WL1116-2CB32-1AA2: ModelMahdi DehghankarNo ratings yet

- Tachimetro Di Gps Velocímetro de Puesto Global 1. Install Installation Verkabelung Installi InstaleDocument2 pagesTachimetro Di Gps Velocímetro de Puesto Global 1. Install Installation Verkabelung Installi InstaleMahdi DehghankarNo ratings yet

- Innio BR t6 Update A4 en 2019 Screen Ijb-119006-EnDocument2 pagesInnio BR t6 Update A4 en 2019 Screen Ijb-119006-EnMahdi DehghankarNo ratings yet

- O P E R A T O R G U I G E يرﻮﺗاﺮﭘا يﺎﻤﻨﻫار A M F 2 5Document10 pagesO P E R A T O R G U I G E يرﻮﺗاﺮﭘا يﺎﻤﻨﻫار A M F 2 5Mahdi DehghankarNo ratings yet

- ID-Operator Guide r2 PDFDocument21 pagesID-Operator Guide r2 PDFMahdi DehghankarNo ratings yet

- Umkc1 CamshaftDocument3 pagesUmkc1 CamshaftBurik8No ratings yet

- Kp420 Kp420E Kp460 Kp460E KP420 KP: Chongqing Lifan Industry (Group) Imp.&Exp - Co., LTDDocument33 pagesKp420 Kp420E Kp460 Kp460E KP420 KP: Chongqing Lifan Industry (Group) Imp.&Exp - Co., LTDЛещенко СергейNo ratings yet

- Bajaj - Chetak & Legend Passive Emissions Control Hookup SchematicDocument1 pageBajaj - Chetak & Legend Passive Emissions Control Hookup SchematicJeovannyAlexanderMatamorosSanchezNo ratings yet

- Cylinder Liner and Cylinder LubricationDocument2 pagesCylinder Liner and Cylinder LubricationRM HaroonNo ratings yet

- MH 6030 4WD AnzDocument132 pagesMH 6030 4WD AnzHendra Syalala100% (2)

- Leveling Limits For Stationary Reciprocating Compressors: Engineering ReferenceDocument2 pagesLeveling Limits For Stationary Reciprocating Compressors: Engineering ReferencealtruismNo ratings yet

- Engine Parts For Zetor Tractors 1005 Euro 3, 4001, 7501 and 8001 SeriesDocument1 pageEngine Parts For Zetor Tractors 1005 Euro 3, 4001, 7501 and 8001 SeriesJanos HallaNo ratings yet

- Unit I: Design Against Static and Fatigue LoadsDocument10 pagesUnit I: Design Against Static and Fatigue LoadsG.G. PRABHATH CHINTHAKANo ratings yet

- t210-34p Multifuel EngineDocument175 pagest210-34p Multifuel EngineTorqueNo ratings yet

- Code EngineDocument33 pagesCode EngineRôpíp PhanNo ratings yet

- Sym 3. Lubrication System: Mechanism DiagramDocument7 pagesSym 3. Lubrication System: Mechanism DiagramLuis Carlos Barrera IdarragaNo ratings yet

- Power Curve of Cummins ISLe290 30FR92142 Diesel EngineDocument4 pagesPower Curve of Cummins ISLe290 30FR92142 Diesel EngineAntonio UgartecheaNo ratings yet

- VW Passat B5 Secondary Air Injection, Engine Aug AwmDocument14 pagesVW Passat B5 Secondary Air Injection, Engine Aug AwmNPNo ratings yet

- Sauer Compressors Commercial Shipping Global en 2022 PDFDocument24 pagesSauer Compressors Commercial Shipping Global en 2022 PDFVarun RautelaNo ratings yet

- ZH40Document5 pagesZH40Игорь КулешNo ratings yet

- Cam Less EngineDocument18 pagesCam Less EnginePushkar VermaNo ratings yet

- Mitsubishi 4G63 & 4G64 EngineDocument4 pagesMitsubishi 4G63 & 4G64 Engineptt0010% (1)