Professional Documents

Culture Documents

Transformers Notes - 6 PDF

Uploaded by

Eng Ogada KelvinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transformers Notes - 6 PDF

Uploaded by

Eng Ogada KelvinCopyright:

Available Formats

3.

OPERATING CONDITIONS

The transformer faults which can occur in service may be due

to a variety of possible causes including:

1) Lightning and switching surges producing flashover

(and or puncture) of internal insulation, including the

tap changer. Also significant surges can be transferred

r

to lower voltage windings by inductive and capacitive

la

coupling. At high frequencies its is by capacitive

coupling as shown in Figure 26.

2) Short circuits which distort the windings usually with

resultant failure due to sudden insulation breakdown

te

between turns and sections. Note: an internal insulation

failure can develop into a short circuit. (see Figure 27).

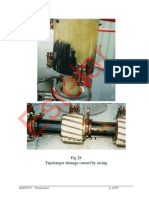

3) Tap changer failure perhaps causing out of balance of

Es

the tapping windings and internal surges. The cause

may be due to the effects of arcing (see Figure 28)

4) Overload currents resulting in gradual degradation of

the conductor insulation due to overheating, leading to

accelerated insulation deterioration and premature

failure.

5) Bad joints in winding conductors, leads and earth

connections. Also in core clamping and earthing

systems. Little insulation involved.

6) Isolated metal (e.g. shields) with capacitive coupling

may causing sparking or high energy PDs.

ELEC9712: Transformers p. 36/79

7) Circulating currents in metal tanks, clamps etc.,

producing high temperatures. Only for large MVA

power transformer units.

8) Insulation deterioration (solid and oil) caused by

moisture ingress, partial discharging, and/or long-term

ageing, possibly giving chemical by-products e.g.

acidity, gas and furans.

r

9) Bushing failure due to moisture ingress from corroded

seals or oil draining from the bushing housing.

la

Capacitor-graded bushings may have failure due to

discharging in and short circuiting between layers.

te

The above failure modes will be discussed in relation to

possible detection methods, e.g.

Dissolved gas in oil analysis.

Partial discharge measurements (and location).

Es

Insulation resistance and DDF.

High precision liquid chromatography for furan analysis.

Oil quality measurements (Breakdown level and DDF).

Frequency response analysis

and protective devices, e.g

Buchholz relays.

Temperature monitoring.

Differential protection

ELEC9712: Transformers p. 37/79

r

la

te

Es

Figure 26: Surge transference through transformers.

ELEC9712: Transformers p. 38/79

r

la

te

Es

Figure 26: Surge transference through transformers.

ELEC9712: Transformers p. 39/79

r

la

te

Es

Figure 26: Surge transference through transformers.

ELEC9712: Transformers p. 40/79

r

la

te

Es

Figure 26: Surge transference through transformers.

ELEC9712: Transformers p. 41/79

r

la

te

Es

Figure 27: Short circuit forces on windings.

ELEC9712: Transformers p. 42/79

You might also like

- 24 PsuDocument14 pages24 PsuSándor SzabóNo ratings yet

- Leakage Reactance - PaperDocument24 pagesLeakage Reactance - PaperRodrigo Javier RomayNo ratings yet

- Transformers Notes - 1 PDFDocument7 pagesTransformers Notes - 1 PDFEng Ogada KelvinNo ratings yet

- Experimental Validation of A New Methodology To Reduce Hot Spots On The Screws of Power Transformer TanksDocument5 pagesExperimental Validation of A New Methodology To Reduce Hot Spots On The Screws of Power Transformer TanksDante FilhoNo ratings yet

- Transformers Notes - 5 PDFDocument7 pagesTransformers Notes - 5 PDFEng Ogada KelvinNo ratings yet

- GL in Kowski 1997Document8 pagesGL in Kowski 1997alvarofranciscooliveiraNo ratings yet

- Reverse Bias BehaviorDocument25 pagesReverse Bias Behaviormolie moliutzaNo ratings yet

- Transformers Notes - 3 PDFDocument7 pagesTransformers Notes - 3 PDFEng Ogada KelvinNo ratings yet

- Electrical and Instrumentation Technology: Faculty of Chemical Engineering Universiti Teknologi MARA, Shah AlamDocument52 pagesElectrical and Instrumentation Technology: Faculty of Chemical Engineering Universiti Teknologi MARA, Shah AlamMy EverythingNo ratings yet

- How To Demagnitization in PTDocument8 pagesHow To Demagnitization in PTbcqbaoNo ratings yet

- Kawooya Charles 20 - U - 1298 Ele3114Document12 pagesKawooya Charles 20 - U - 1298 Ele3114Kawooya CharlesNo ratings yet

- Abb, Sweden AbbincDocument20 pagesAbb, Sweden AbbincMuhammad Asghar KhanNo ratings yet

- Demagnetization of Power Transformers Following A DC Resistance TestingDocument7 pagesDemagnetization of Power Transformers Following A DC Resistance Testingdfrs chhNo ratings yet

- Introduction of Transformers: 2.1 What Is Transformer?Document17 pagesIntroduction of Transformers: 2.1 What Is Transformer?Anshika SinghNo ratings yet

- Generator Breaker Equipped With Vacuum InterruptersDocument4 pagesGenerator Breaker Equipped With Vacuum InterruptersVenna Karthik ReddyNo ratings yet

- Impact of Generator and Power Grid On Unit Transformer ReliabilityDocument5 pagesImpact of Generator and Power Grid On Unit Transformer ReliabilityEd ArenasNo ratings yet

- PDF Generaltechnicalinformation PDFDocument21 pagesPDF Generaltechnicalinformation PDFsudershan rawatNo ratings yet

- Chapter-3Document13 pagesChapter-3Bts ArmyNo ratings yet

- Alstom Grid France Alstom Grid UK: 21, Rue D'artois, F-75008 PARISDocument11 pagesAlstom Grid France Alstom Grid UK: 21, Rue D'artois, F-75008 PARISTaylor MartinezNo ratings yet

- New QBhve3yearDocument29 pagesNew QBhve3yearArun SelvarajNo ratings yet

- Design of Twelve Pulse Rectifier Used in HVDC System 1398Document6 pagesDesign of Twelve Pulse Rectifier Used in HVDC System 1398Berihun EngdaNo ratings yet

- Alternador ReguladorDocument32 pagesAlternador ReguladorcaldasferreirasoutoNo ratings yet

- Loss Reduction in Distribution TransformersDocument37 pagesLoss Reduction in Distribution Transformerstapas_kbNo ratings yet

- Varistor Calculations (ID 16263)Document8 pagesVaristor Calculations (ID 16263)bspassov6No ratings yet

- Index: Web Space - Website Hosting - Business Hosting - Free Website Submission - Shopping Cart - PHP HostingDocument12 pagesIndex: Web Space - Website Hosting - Business Hosting - Free Website Submission - Shopping Cart - PHP Hostingcelo81No ratings yet

- Distribution TransformersDocument4 pagesDistribution Transformersbsee40% (1)

- Sir NotesDocument600 pagesSir Notessiddharth mohantyNo ratings yet

- Geiger Counter (Practical-Electronics-1975)Document4 pagesGeiger Counter (Practical-Electronics-1975)Peeters GuyNo ratings yet

- EE1402 HVE NotesDocument96 pagesEE1402 HVE NotesKarthikeyanKarunNo ratings yet

- Trans Diff ProtectDocument3 pagesTrans Diff ProtectShazmaniaNo ratings yet

- XMFR Impedance FactorsDocument13 pagesXMFR Impedance Factorssalemg82No ratings yet

- 489Document52 pages489jovce.doneski215No ratings yet

- Topic Assignment15Document8 pagesTopic Assignment15cuongakamarineNo ratings yet

- EE35T - Transformer Differential ProtectionDocument4 pagesEE35T - Transformer Differential ProtectionTanveer Ul HaqNo ratings yet

- Investigation of Transformer Winding Architectures For High Voltage Capacitor Charging ApplicationsDocument8 pagesInvestigation of Transformer Winding Architectures For High Voltage Capacitor Charging ApplicationskrystonNo ratings yet

- Stray Losses in Power Transformer Tank Walls and Construction PartsDocument5 pagesStray Losses in Power Transformer Tank Walls and Construction PartsGregurius DaniswaraNo ratings yet

- Lab Week 3 EE462L Diode Bridge Rectifier PDFDocument18 pagesLab Week 3 EE462L Diode Bridge Rectifier PDFFrew FrewNo ratings yet

- Importance of Transformer Demagnetization-OffcialDocument7 pagesImportance of Transformer Demagnetization-OffcialoedisNo ratings yet

- What Are Partial Discharges On Cast Resin Transformers - EEPDocument3 pagesWhat Are Partial Discharges On Cast Resin Transformers - EEPa_mohid17No ratings yet

- EP09 2003-FailureAnalysisofTransformersDocument13 pagesEP09 2003-FailureAnalysisofTransformersKhashane Willy MohaleNo ratings yet

- Testing of Tap Changers - Practical Experiences in Using The CPC 100Document6 pagesTesting of Tap Changers - Practical Experiences in Using The CPC 100bcqbaoNo ratings yet

- Engineering-Handbook Cable PDFDocument65 pagesEngineering-Handbook Cable PDFabhi_26tNo ratings yet

- ACS Switch Application Note PDFDocument18 pagesACS Switch Application Note PDFnassimNo ratings yet

- Bypass Capacitors IntersilDocument10 pagesBypass Capacitors IntersilBlykerNo ratings yet

- Impulse Voltage Calculation of TransformerDocument11 pagesImpulse Voltage Calculation of TransformerAnonymous sAmJfcV100% (1)

- Capacitors. Description and FunctionDocument12 pagesCapacitors. Description and FunctionscufigNo ratings yet

- Dielectric Material Impact On Capacitive RF MEMS ReliabilityDocument4 pagesDielectric Material Impact On Capacitive RF MEMS ReliabilityTeweldebrhan KifleNo ratings yet

- Current Limiting Reactor PDFDocument11 pagesCurrent Limiting Reactor PDFraj sekharNo ratings yet

- Tecnica 100-140Document12 pagesTecnica 100-140Georgel PalNo ratings yet

- Transformer EfficiencyDocument12 pagesTransformer EfficiencyhaysomaNo ratings yet

- Transformers Notes - 7 PDFDocument7 pagesTransformers Notes - 7 PDFEng Ogada KelvinNo ratings yet

- ESO 210 Lecture-22 - 2014Document40 pagesESO 210 Lecture-22 - 2014Amit MondalNo ratings yet

- DC Transformers 77Document15 pagesDC Transformers 77Keshavamurthy MurthyNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- Modern Devices: The Simple Physics of Sophisticated TechnologyFrom EverandModern Devices: The Simple Physics of Sophisticated TechnologyNo ratings yet

- Electrical and Electronic Principles: Volume 2From EverandElectrical and Electronic Principles: Volume 2Rating: 4 out of 5 stars4/5 (5)

- Transformers Notes - 8 PDFDocument7 pagesTransformers Notes - 8 PDFEng Ogada KelvinNo ratings yet

- Transformers Notes - 7 PDFDocument7 pagesTransformers Notes - 7 PDFEng Ogada KelvinNo ratings yet

- Transformers Notes - 2 PDFDocument7 pagesTransformers Notes - 2 PDFEng Ogada KelvinNo ratings yet

- Transformers Notes - 3 PDFDocument7 pagesTransformers Notes - 3 PDFEng Ogada KelvinNo ratings yet

- PDFDocument31 pagesPDFJesus SalazarNo ratings yet

- State-Of-The-Art Review On Asset Management Methodologies For Oil-Immersed Power TransformersDocument18 pagesState-Of-The-Art Review On Asset Management Methodologies For Oil-Immersed Power TransformersAdrian SieNo ratings yet

- Evaluating Dielectric Conditionin SF6 Gas BreakersDocument18 pagesEvaluating Dielectric Conditionin SF6 Gas BreakersGabriel Zenarosa Lacsamana100% (1)

- Basic Principal of Electrical CircuitryDocument19 pagesBasic Principal of Electrical CircuitryAreeba ParvezNo ratings yet

- Testing Power TransformersDocument65 pagesTesting Power TransformersAbdul Kadhir83% (6)

- CE Physics 1985 Paper 2 Page 1 of 13Document13 pagesCE Physics 1985 Paper 2 Page 1 of 13jshfjksNo ratings yet

- Wireless World 1950 12Document41 pagesWireless World 1950 12Jan PranNo ratings yet

- 2722 0-Emri - 2492-V1 38 PDFDocument28 pages2722 0-Emri - 2492-V1 38 PDFsssfsfsNo ratings yet

- Test Templates: Application NoteDocument24 pagesTest Templates: Application Notemoon111222100% (1)

- Preview NECA+410 2013Document8 pagesPreview NECA+410 2013GILBERTO ALTUNARNo ratings yet

- BH023332 HNCD Engineering UnitsDocument375 pagesBH023332 HNCD Engineering UnitsYashveer100% (1)

- IHT Installation Manual Ignition System EDocument16 pagesIHT Installation Manual Ignition System EraiNo ratings yet

- McagDocument12 pagesMcagragingwildfireNo ratings yet

- GIS RC Voltage DividerDocument6 pagesGIS RC Voltage DividerEldin EnggNo ratings yet

- AC Voltmeters and AmmetersDocument8 pagesAC Voltmeters and AmmetersrajivNo ratings yet

- All-Test Pro At5 Brochure r092414Document6 pagesAll-Test Pro At5 Brochure r092414cbernabeNo ratings yet

- Design and Construction of An Electric Arc Welding Machine's TransformerDocument6 pagesDesign and Construction of An Electric Arc Welding Machine's TransformerEditor IJTSRDNo ratings yet

- Capacitor Voltage TransformerDocument10 pagesCapacitor Voltage TransformerGurwndrSandhu100% (1)

- 4thSemesterNSQFQBCTS PDFDocument46 pages4thSemesterNSQFQBCTS PDFKiran AithalNo ratings yet

- Insulation Coordination Studies For 400 KV Gis in A Hydroelectric Project in IndiaDocument6 pagesInsulation Coordination Studies For 400 KV Gis in A Hydroelectric Project in IndiaAchint KumarNo ratings yet

- Section 17.3 TransformerDocument30 pagesSection 17.3 Transformertwy113No ratings yet

- Ansi C57.12&iec 76 PDFDocument8 pagesAnsi C57.12&iec 76 PDFfreddy vargas100% (1)

- Catalogo Sm6 2012Document124 pagesCatalogo Sm6 2012Gilberto Mejía50% (2)

- Induction Furnace HandbookDocument163 pagesInduction Furnace HandbookRaja Bharath Donthi0% (1)

- 12 Std. IMPORTANT QUESTIONS & PROBLEMS - 2022 - 2023 PDFDocument16 pages12 Std. IMPORTANT QUESTIONS & PROBLEMS - 2022 - 2023 PDFUdhayaNo ratings yet

- Catalogue of RC140-50 Toroidal Core Winding MachineDocument8 pagesCatalogue of RC140-50 Toroidal Core Winding MachineSoham ShahNo ratings yet

- Catalog For Transformer Explosion Prevention and Fire Extinguishing SystemDocument16 pagesCatalog For Transformer Explosion Prevention and Fire Extinguishing Systemtholgasenel100% (1)

- ABB TRF ProtectionDocument181 pagesABB TRF ProtectionModisa TsamaaseNo ratings yet

- BE Mechanical 2019 Scheme With Syllabus PDFDocument181 pagesBE Mechanical 2019 Scheme With Syllabus PDFAkhilesh Kumar SinghNo ratings yet

- Electricity TheoryDocument30 pagesElectricity TheoryTito Lebelo IllNo ratings yet