Professional Documents

Culture Documents

MY. B-Nice - A Condition Survey

Uploaded by

Janko BacanovicOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MY. B-Nice - A Condition Survey

Uploaded by

Janko BacanovicCopyright:

Available Formats

35m Expedition yacht – a condition inspection.

MY. B-Nice – a condition survey.

By

Kim Skov-Nielsen, IRMS, IRMC, DipMarSur, MIIMS, SAMS AMS

Yacht Surveyor & Marine Consultant

UK-MCA Approved Examiner and ISM Auditor

New Build and Refit Project Manager

Maritime Expert Witness

Rigging Specialist

Apt Postal 330, 29680 Estepona, España.

Movíl : +34 609 891 650

email : kimskov@live.com

www.yachtmarinesurveyor.com

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Table of Contents

Cover page page 1.

Table of Contents page 2.

Introduction page 3.

Client page 3.

Special Conditions page 3.

Date & Location page 3.

Scope of survey page 3.

Abbreviations used page 3.

Vessel Details & History page 4.

Summary of Findings page 4.

Construction page 4.

Topsides page 45.

Underwater hull coating & condition page 5.

Props, Shafts & Rudders page 5.

Deck 0 pages 6-7.

Main deck 1 pages 7-8.

Deck 2. pages 8-10.

Flybridge Deck 3 pages 10-11.

Ground tackle page 11.

Interior hull & structure pages 11-12.

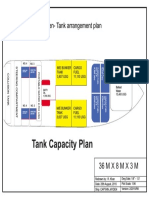

Plumbing & Tankage page 12.

Bilge pumping systems pages 12-13. 2

Galley page 13.

Main engines pages 13-14.

Generators pages 14-15.

Exhausts page 15.

Ancillary equipment page 16.

Steering gear pages 16-17.

Electrical installation including batteries page 17.

Electronics pages 17-18.

Life Saving Appliances pages 18-19.

Security page 19.

Tenders & Toys page 19.

Crane & passarelle page 19.

Canvas & covers page 19.

Findings & Recommendations pages 20-21.

Summary, Valuation & Signature page 22.

Appendix A

Signed Client Agreement.

Bilge system, Fire Fighting system & Ballast system plan.

Cooling water system plan.

Engine room ventilation plan.

Escape plan.

Exhaust system plan.

RINA 2018 statement.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Introduction

This document is the report on a pre-purchase condition inspection of the 35m custom-built steel

motor yacht from 2010 known as B-NICE carried out in accordance with the Limitations and

Exclusions agreed in the Order Acknowledgement and the Code of Practice for Small Craft Surveyors

published by the International Institute of Marine Surveying.

Client

The survey was carried out under the instructions of Mr. Howinda Singh of U.K.

Special Conditions

A snap-shot inspection only with no engineering surveyors, no electrical surveyors, no class surveyors

and no coatings surveyors in attendance. It was purely a visual condition inspection by one surveyor.

Date and location

The inspection was carried out by Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS, ashore and afloat

at YachtMarin in Marmaris, Turkey on Monday and Tuesday the 1st and 2nd of July, 2019.

Scope of survey

• No parts of the vessel were dismantled.

• No fastenings were removed for inspection.

• No woodwork or other parts of the structure, which are covered, unexposed or inaccessible,

have been inspected and therefore I am unable to report that any such part of the structure is free

from defect.

• Any parts of the vessel, equipment or fittings, which were inaccessible, were excluded from

the inspection. Any such part, therefore, is exempt from defect reporting. 3

• All areas covered within the survey have been examined.

• Any areas or items not specifically mentioned were not examined.

• The vessel and its equipment have not been checked for elements of design, suitability for

any particular purpose, or compliance with any rules, regulation, law, standard or code.

• This report does not constitute any form of warranty.

• Items on the inventory were not inspected.

• Machinery installations, auxiliary and ancillary equipment and other service systems,

electronic equipment, pumping and plumbing, sanitation systems, navigational aids and other

sundry items were visually inspected only. None of these items was dismantled or specific tests

applied except in the case of electrical systems where simple switch tests were used.

Abbreviations I may have used :

AF = Anti-Fouling Paint. LR = LifeRaft.

BP = Bathing Platform, or Bilge Pump LSA = LifeSavingAppliances.

OOD = Out of date. ME = Main Engines.

DZR = Dezincification Resistant O/B = Onboard, or Outboard.

ER = Engine Room. PT = Port.

FB = FlyBridge RM = RayMarine

FX = Fire Extinguisher. STBD = Starboard.

HE = HeatExchanger. SS = Stainless Steel

UW = UnderWater. U/S = Unserviceable/Broken

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Vessel Details & History

Name B-NICE

Builder : Saba Yachts, Antalya, Turkey.

Custom-built year 35m Twin screw tri-deck explorer-style yacht

First launched for sea trials in Oct 2010 giving her a 2010 Hull date. Delivered to client 03.01.11.

US Delaware Reg – 2010-072-86844

LOA 34.90m (114’6”)

BMAX 8.10m

Draft 2.10m

Tonnage 230 GRT

MAX SPEED 13 knots

Cruising speed 10 knots

RANGE : 4000 Nm

Documents seen : Builders Certificate, RINA Document list, tank plan, US Delaware reg. No HIN

number seen or offered.

History

All information regarding the build and maintenance of the vessel comes from the owner/vendor and

his project manager.

Built in steel by SABA Yachts in the Antalya Free Trade Zone in Turkey from 2005 to 2010 for a

Turkish artist owner to live aboard. The vessel appears to be well-built, well-equipped and generally

well-maintained. With only 350 main engine hours she is really a “young” vessel ready to go.

The Turkish owner didn’t really use it after the first year; hence she has been stored ashore for ten 4

months of the year, and only launched and commissioned for a few weeks every summer.

Summary

I inspected this vessel over a three-day period in Marmaris in Turkey to establish her condition.

She needs to be repainted and she needs to be “inserted” into the RINA Class she was built to. Both

of these exercises have cost implications but will enhance her value when completed.

In fact, this vessel suffers only from lack of use rather than overuse or abuse – which means she has

enormous potential.

Construction

The vessel was built in steel with solid hull, frames, bulkheads and floors up to Deck 1 (main deck).

Built using Marine Grade Steel, from keelson and upwards, in 10mm, 8mm, and 6mm steel with wood

cladding of the upper deckhouses and bulwarks. In areas of greater stress extra thick steel has been

used – for example the stabilisers are set in 30mm steel plates. She has four (4) watertight

bulkheads. Above Main Deck 1 it is a “cage” construction also with solid structure, frames and

bulkheads; but clad in marine plywood.

She was built to RINA and MCA LY2 standard with RINA supervision; however she has not completed

her Class requirements. There remain, allegedly, issues with the inclining experiment which has not

been carried out, and the ER fans.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Topsides

The matt Pearl Grey topsides appear in awful condition until ones learns that the vessel was wet-

sanded and faired in preparation for painting last year.

The surface appears fair and is free of dents or dings, needing only surface prep for it to be ready for

painting.

Rubbing strake – none. Flotation line stripes – none. Trim stripes – none.

Underwater hull - Hull bottom coating & condition

Thin AF coverage.

Through-hulls and surrounding areas are generally good. No evident corrosion externally.

Damage or repairs – none evident.

Anodes must all be changed ASAP.

Thrusters & tunnels : there is no stern-thruster, just one big bow-thruster. Change the anodes asap.

A grille covers the opening.

Props, shafts & rudders

Propellers 2 x 1100mm diameter 4-bladed Magnesium Bronze props in good condition with no dings or 5

dents. Polished and greased for protection.

Shaft size : 100mm Ø Austenitic 316-grade SS in apparently good condition. They were removed for

renewal of cutlass bearings in 2018 (a year ago). They were tested with penetrating-dye for crevice

corrosion. RINA passed the shafts as being acceptable for further use.

Rudder condition good, no shaft movement, change the anodes asap.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Deck 0

From aft > lazarette and tiller flat, engine and machinery room, 3 x guest cabins en-suite where the

fourth cabin has been converted to a gym and is used for storage.

A staircase goes up to the Deck 1 salon. Going forward > this deck also houses the crew mess and two

crew bunk-bed cabins and a heads w/ shower, as well as a crew galley and a wine storage/cellar

currently used for storage.

The aft end, the area around the steering gear, is filled with tubes of ballast – lead shot set in

concrete poured into rectangular sections of PVC piping for ease of transport and stowage. These

should be fastened down.

The ER central bilge has some standing water causing corrosion. This area must be dried out and be 6

re-painted with red-lead primer to prevent further corrosion. In future all bilges must be kept dry so

as to be able to quickly identify the source of any water.

Forward of the ER, the central bilge in-between the fuel tanks is accessible and was found to also

have some corrosion issues where the bare metal must have the rust removed and be painted with

red-lead primer. See pictures on the next page here below:

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Main Deck 1

From aft > Aft deck seating with entertainment facilities, Salon with two seating areas and tables, a

bar wooden bar in the shape of a boat, a dining table area with seating for 8 to PT and the

professional SS galley to STBD w/ a prep room and storage plus captain’s cabin w/ ensuite

heads/shower forward of that.

The oak parquet flooring in fair condition with some gaps and some blemishes.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

The galley floor is tiled.

Teak deck covering on Bathing platform, main deck, owners and bridge deck, and flybridge deck

appears to be in good condition with about 8-10mm of teak remaining in most places.

Superstructure condition – the wood cladding is cracking along the join at the base of Deck 2 along

the exterior aft quarters of the superstructure.

Stairs – from BP to deck 1; from aft deck 1 to aft Deck 2; and from PT side-Deck 2 to FB Deck 3.

Aft Deck 1 (Main deck) seating – steel chairs around a steel coffee table with entertainment in the

FWD STBD corner behind a slide-down shutter. In the same style as FB dining table & chairs.

Deck 2, going forward > owners salon and owners suite, wheelhouse.

2 x side doors to/from owners suite to side-deck & aft deck. 2 x side doors to/from wheelhouse to

side deck and Portuguese (forward) bridge. 1 x door PT side to guest/day heads just abaft WH to PT.

Wood cladding drying out and cracking at the doors – new door seals required. See pictures on the

next page here below.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

The deck forward of the wheelhouse is given over to ground tackle with two windlass and twin

anchors – see picture on the next page here below.

A hatch accesses the forepeak which is used for storage, and chain locker and bulbous bow.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Aft Deck 2 (Owners deck) seating = chairs around teak table w/ teak bar – see picture here below:

Deck 3 – Flybridge w/ dining table, Jacuzzi/Spa, wet-bar, plus tenders, toys and crane.

10

1 x wet bar area with coal and gas BBQ, refrigerator and cool box.

1 x TONGA Jacuzzi/Spa with hard cover.

There are cracks to the underside of the bar top lip, and to the setting for the jacuzzi.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

And a foot-pad of the FB guardrail is lifting – see picture here below:

Ground tackle

Windlass – 2 x HIDROMAR 2500-kgs-pull SS electro-hydraulic windlass each with a 220kg Navy-type

anchor and 220m of 22.5mm Ø galvanized steel chain in fair condition.

11

Both windlasses were tested by anchoring and were found to be in good working order.

2 x HIDROMAR electro-hydraulic SS mooring winches on the aft deck inside the aft fairlead – also in

working order.

There were no midships mooring cleats seen.

Interior hull and structure

I inspected every under-floor bilge space from the tiller flat to the inside of the bulbous bow. I found

some areas of surface rust where the rust must be cleaned away and the steel re-primed with “red

lead” paint to prevent further oxidation. See pictures on page 7 here above.

Standing water in the bilge only accelerates the corrosion so this must always be pumped out and

any residues sponged out at every opportunity so that the water source may be identified and the

fault corrected.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Bulkheads, ring frames, longitudinals – from visual inspection the structure appears to be sound with

no obvious bending, warping or twisting of frames or bulkheads.

Hull to deck join – there is no obvious join at hull and deck. I was given to understand from the

project manager that all hull shell plates below deck 0 (engine room, 4 x guest and crew mess) are

of minimum 10mm thickness. From there upwards plate thickness used reduces to 8mm for the main

superstructure while deck 2 and the flybridge is 6mm. I have no evidence as the superstructure

structure was not seen nor was it tested with Ultra-Sound equipment.

There are two (2) sea-chests for sea water entry into the machinery space with take-offs for all

cooling water uses – from main engines to generators and air-con. The main engines and generators

have underwater exhausts. See “Cooling water System plan” and “Exhaust System Plan2 attached to

the survey report in Appendix A.

The galley on Deck 1 drains overboard on the STBD side above waterline, while the crew mess galley

is pumped to the grey water tank.

Plumbing & tankage

Fuel tankage – 37,000 litres in two midships tanks.

Fresh Water – 9400 litres in two forward tanks.

Black Water – 1350 litres in one forward tank.

Grey Water – 4875 litres in three forward tanks. 12

Waste oils – 200 litres in one lazarette tank.

Fuel filtration – 2 x RACOR fuel filters per engine. Strongly recommend adding more fuel filtration –

right down to 30ma, especially as there is no centrifuge or fuel polishing plant.

Toilets, a.k.a. heads, are all sea-water flush and drain to a HEADHUNTER WASTE MANAGEMENT

SYSTEM sewage treatment plant before being stored in the black water tank.

All toilets were tested and found to flush properly although they had still to be properly cleaned

after winter. All showers were tested and seen to have good pressure. Shower sumps & sinks drain

through to a grey water tank.

There is a black-water smell in bilges – this means the bilges must be cleaned out and disinfected.

Water pressure system – 2 x water pressure pumps in ER PT side next to the watermaker.

YACHT MATE commercial water softener and STERILIGHT UV water sterilizer.

Bilge pumping systems

Only three electric bilge pumps of unknown capacity were seen, with high & low float switches. One

float switch in the ER STBD side bilge was clearly not working as evidenced by the standing water

there.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

I strongly recommend an emergency 20,000lit/hr 220v submersible pump. The fire pump of course

acts as an emergency pump but it may draw direct from overboard or from a different compartment.

Fire pump and hoses seen but not tested. No Breathing Apparatus (BA) were seen.

Galley & Utilities

Large professional SS galley forward on main deck 1 with captain’s cabin forward of that.

13

Electric 4 x plate electric hob plus a 2 x plate hob and grill, plus microwave and 2 x ovens and a

deep fryer.

2 x large upright Fridges and 2 x large upright Freezers.

No galley sink macerators.

Washer & Dryer in the crew mess below on Deck 0.

Main engines

2 x MTU Series-60 straight-six normally-aspirated 740HP (552KW) marine diesel engines with about

350 hours each driving ZF 3:1 transmission gearboxes.

PT Serial #06R1016652; STBD Serial #06R1015281.

Transmissions with HYDRAULIC Power-Take-Offs (PTO) for crane, passarelle and bow thruster.

The engines exhibit signs of corrosion in the heat exchanger (HE) circuits - see pictures on the next

page here below.

During the survey the PT engine HE had external corrosion removed and was painted over but this

doesn’t fix the problem. These circuits must be properly winterised when placing the boat ashore by

filling the circuit with anti-freeze which has anti-corrosive properties. The Heat Exchangers (HE’s)

must now be removed and flushed with acid and refitted with new internal anodes. See picture at

the top of the next page.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

14

The MTU computer system was indicating an injector alarm on the PT engine. The injectors were

changed a couple of years ago but the alarm can only be reset by MTU and they have not serviced

the engines since new.

At 350 hours these engines are barely “run-in”. The first major service is normally at 500 hours

where the head is re-torqued, and these hours will only be reached this year.

I recommend a thorough “First” service by MTU including torquing down the heads, the HE service

and flush, oil change, oil & air filter change and revision of the CPU log.

In future I recommend oil changes at 100-150 hours and MTU service every 500 hours.

Generators

STBD Generator #1 ONAN CUMMINS 50kW – w/ 3398 hrs.

PT Generator #2 ONAN CUMMINS 50kW – 2091 hrs.

STBD “Night” Generator #3 ONAN CUMMINS 27.5kW w/ 3218 hrs.

The generators have quite a lot of hours. It is normal to change the oil every 100 hours but there

appears to be no engine service logbook. These have been serviced yearly but this is likely to have

been at more than 100 hours.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

All three generators need the full 5-year service including cleaning up the impellor housings and

surrounds. Flush the heat exchangers and refit with new internal anodes. Change oil and filters.

No oil change system was seen. However, on the plans there is a 200-lit waste oil tank.

Exhausts

All SS piping in the ER appears to have been custom-made and it shows along all the weld seams

where there is pitting and corrosion – some of it quite severe, leading to water running down the

upright exhaust piping the ER – see pictures here below:

15

This must be rectified as soon as possible as escaping water indicates Carbon Monoxide gases are also

escaping into the ER.

All rusty welds on steel, or SS, piping carrying sea water in the machinery space (ER) must be revised

and re-welded to seal what are clearly pinholes. Especially any carrying seawater.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Ancillary equipment

4 x TRAC 300/9X Digital Zero-Speed Stabilisers – 2 forward of midships and two abaft amidships.

Tested underway by switching them to Neutral and observing the vessel sway to leeward a few

degrees. Switching back to Active brought the vessel upright and made her steady again. In flat

water and F1 wind conditions.

Air-Conditioning throughout the vessel with fan-coil units in every space. A MARINECOOL custom-

made 440,000 BTU system with 3 x chillers units in the ER. Gas-free system using anti-freeze as the

coolant liquid.

As ever there is quite severe corrosion of the chiller pipe-work and connections due to the sea-water

used to cool the units. This will have to be monitored and replaced in due course.

16

Watermaker – HRO SC1500 235lit/hour – not seen working as it had been decommissioned, and the

vessel was in the polluted waters within the harbour at Marmaris.

Steering equipment, Autopilots & any emergency steering

Tiller flat access is good and there appears to be no leakage from the rudder heads. The steering

system appears substantial and solid.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

A/P connection arm and angle indicator appear in working order. Emergency tiller not seen.

The two rudder quadrants are connected by a long, solid alloy tube – as is normal. However it

appears to have been bent at some point: it is no longer straight but curved – see picture below.

Electrical installation including the batteries.

Service Voltage – 24v. Engine & Genny start voltage 12v.

25 x truck-size 200AH 24V GEL batteries on shelves in ER. Not strapped down.

17

7 x AGM 200AH 12v starter batteries. Not strapped down either.

Battery chargers – 3 x VICTRON 24/5000 Combi Charger/Invertor.

Shore power will accept 220V and 380V.

Panels w/ heat sensitive breakers in ER lazarette, in cupboard under the stairs from deck 0 to Deck

1, and in the wheelhouse where a separate VICTRON Phoenix 12v/50AH charger looks after the 2 x

car-size electronics batteries.

Electronics

RAYMARINE GPS & Plotter – there was a malfunction of the GPS, as well as the radar and the radar

interface with plotter. 3 x large CPU screens in front of helm.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

RM Autopilot not working as GPS not picking up a fix.

RM radar on radar arch on FB - closed RM scanner.

RM Depth Sounder– working.

Speedo – paddlewheel – not working.

Wind direction – RM ST60 – working.

VHF – 2 x RM DSC – working.

SatComs – 2 x domes on each end of the radar arch. However both are empty. No SatCom and no TV

dish or antenna. Today everything is WiFi and a WiFi signal enhancer may be a better solution.

LSA, or Life Saving Appliances

Life-Rafts – 2 x 12 person SOLAS-A satisfies 100% redundancy requirement. However, they were due

for service in 2011 and hence it may be cheaper to acquire new ones than to attempt to service

these.

Lifejacket’s – 12 x SOLAS-A-type foam LJ’s plus some water sports flotation devices seen.

ER FX – 3 x CO2 cylinders in dedicated locker in lazarette, as per RINA. FX serviced 2018 and valid

until 08.19

18

Cabin FX - no individual cabin FX seen.

Flares – not seen.

First Aid kit – not seen.

MOB kit – not seen.

NUC Stick – not seen.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

SOLAS tables – not seen.

Radio procedures cards – not seen.

I recommend 2 x 5kg ABC foam FX at the galley, plus 1 in the crew mess, plus 1 at FB BBQ area.

I further recommend a 2.5kg ABC FX in each sleeping area – from crew cabins to master suite.

Entertainment equipment – not tested.

12 LCD TV screens with individual CD/DVD systems in each cabin and crew area. Wireless internet

throughout. 3 x Outdoor entertainment screens on FB, owners aft deck and main deck aft. 3 x home

cinema screens in owners salon, salon and crew mess. Onboard Video and Music library.

Security

500GB digital recorder w/ dome camera on radar arch w/ night vision, tilt/zoom and joystick

controller.

Plus 5 x indoor dome cameras and 6 x outdoor cameras.

Fire detection and alarms in all cabins and spaces including ER.

Tenders & Toys

1x 5.80m JOKER Rigid Bottom Inflatable tender w/ 115HP 4-stroke YAMAHA O/B engine. This tender 19

was launched and made to work although the bilge was full of rainwater and the battery submersed.

It is in need of a proper clean of bilges and inflation tubes. Check VHF radio and if necessary

replace. RIB’s must have working radio communications as a safety issue.

1 x 4.30m ORCA Rigid Bottom Inflatable tender w/ 40hp YAMAHA. The inflation tubes are in

“throwaway” condition. Rigid bottom may be salvageable. O/B may be serviced and kept as a spare.

1 x YAMAHA VX jet ski.

Crane and passarelle

1 x 1100 kg capacity electro-hydraulic crane on FB. Custom-made by a friend of the owner, this

crane contributes to the trim of the vessel. It appears massively overbuilt and I believe it could be

made lighter.

1 x 4.20m extension passarelle only goes straight out, it does not swing from side to side as is

sometimes necessary to avoid bollards and electric boxes on the quay. Custom-made by the same

people who made the FB crane, the hydraulic power system needs to be checked.

Canvas & Covers

No canvas or covers for the aft deck or bridge were seen. On the FB, two forward-leaning struts

appear to be for the Bimini canvas but the canvas does not appear to extend forward over the hot-

tub. Canvas seen stuffed in a locker.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Findings & Recommendations

1. Revise safety gear – life-rafts, flares, EPIRB, SART, cabin FX, BA’s & emergency Bilge Pumping.

2. Complete the requirements of RINA Classification, including an inclining experiment and upgrade

of the ER ventilation fans.

3. Paint the hull and superstructure – the surfaces have already been wet-sanded in preparation for

painting. The surface appears fair and is free of dents or dings. Needing only surface prep it is

ready to be painted.

4. ER extractor fans fitted were to RINA spec but the spec has changed. Consult with RINA.

5. MTU engine service with special attention to PT ME injector alarm. Also flush HE’s and fit new

internal anodes as well as changing oil and filters.

6. All three generators need the full 5-year service including cleaning up the impellor housings and

surrounds. Flush the heat exchangers and refit with new internal anodes. Change oil and filters.

7. Revise welds on ALL ER SS sea water piping, specifically exhausts & AC cooling.

8. Service the outboard engines and clean up the tenders ensuring they have full safety gear

onboard and working VHF’s.

9. All hull anodes must be replaced at the next opportunity.

10. Standing water and corrosion in some bilge sections – all water must be pumped out and the

corrosion must be cleaned away and the areas re-primed as an on-going project.

11. Dripping shaft seals – need only to be tightened up as they bed-in.

12. 1 x Float switch in ER bilge is not working properly. Check all BP’s & float switches.

13. The rudder connecting bar appears bent – check with engineers and, if necessary, straighten.

14. On the FB there is a lifting SS handrail footpad on PT side fwd.

15. Wheelhouse fabrics are deteriorating. Sliding hatches in wheelhouse

16. Sliding hatches over tv screens on aft Deck 1 and owners aft Deck 2.

17. Parquet floor defects throughout need to be attended to. 20

18. Paint the anchor chains at 5 or 10m intervals to let you know how much is laid out.

19. The elevator was not working during the survey and must be checked and commissioned by the

relevant engineers.

20. I recommend 2 x 5kg ABC foam FX at the galley & 1 in the crew mess plus 1 at FB BBQ area.

21. I further recommend 1x2.5kg ABC FX in each sleeping area – from crew cabins to master suite.

22. Revise the rolling shutters that cover the entertainment systems on aft decks 1 & 2.

Woodwork that needs attention

23. Superstructure wood cladding has cracks and wet-rot around the bulwark each side at Deck 2

level with water leaching to the outside and pushing-off the wood. Also above the aft seating

area on main deck 1 level - at the corners under the Deck 2. Rotten wood needs to be cut away,

have the water ingress points sealed with epoxy, be re-clad and repainted.

24. All door surrounds are in awful condition – they need to have the hinges and locks properly re-

fitted, sealed with epoxy and be painted properly; and then have new rubber seals fitted.

25. Deck head trim – the scales effect – is peeling and cracking in many places, especially edges,

corners and around windows. This was seen in all areas and cabins on lower Deck 0, salon &

dining on Deck 1, and in the owners’ suite on Deck 2.

26. The SS feet around aft deck seating on main deck 1 level.

27. Around mooring fairleads aft each side on main deck 1.

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Suggestions for future improvements

28. Add more fuel filtration and/or a fuel polisher/centrifuge.

29. Add a WiFi signal enhancer.

30. Replace FB crane with a much lighter and stronger model – improving stability.

31. Add a stern thruster.

32. Replace the passarelle with a unit that also swivels and is lighter.

33. Remodel the fly-bridge bimini so that it rolls away and covers the forward end of the FB. Possibly

use a sail furling system to roll it away.

34. Add an air-compressor and diving kit so as to be able to inspect the undership, and whenever

anchoring.

35. Add an oil change system such as a REVERSO in the ER so as to be able to change oil frequently.

21

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

35m Expedition yacht – a condition inspection.

Summary of Findings

I inspected this vessel over a three-day period in Marmaris in Turkey to establish her condition.

Built in the Antalya Free Trade Zone in Turkey from 2005 to the end of 2010 in steel for a Turkish

artist owner to live aboard, the vessel appears to be well-built, well-equipped and generally well-

maintained.

She needs to be repainted and she needs to be “inserted” into the RINA Class she was built to. Both

of these exercises have cost implications but will enhance her value when completed.

In fact, this vessel suffers only from lack of use rather than overuse or abuse – which means she has

enormous potential. With only 350 main engine hours she is in fact a “young” vessel.

Valuation

“FAIR MARKET VALUE” (FMV) is the most probable monetary value that a vessel should bring in a

competitive and open market under all conditions requisite to a fair sale, i.e. a sale without undue

stimulus.

Taking into account the condition for the vessel, the type and especially the age of the vessel, and

the state of the market - it is estimated that the Fair Market Value lies around 1,400,000 to

1,500,000 Pounds Sterling when she has been repainted, is in “In Class” and with VAT paid.

Please note that the above valuation is not an absolute - a sale at any price is dependent on a willing

seller and a willing buyer. 22

Please note that any reference made to the vessels condition must in all cases be considered in

relation to the vessels age, i.e. good condition should not be taken to mean as new.

Please note that this is not the replacement value of the vessel.

Signed without prejudice 16TH of August, 2019.

IIMS #831n & SAMS AMS #1128

Yacht Surveyor & Marine Consultant

UK-MCA Approved Examiner and ISM Auditor

New Build and Refit Project Manager

Maritime Expert Witness

Rigging Specialist

Apt Postal 330, 29680 Estepona, España.

Movíl : +34 609 891 650

email : kimskov@live.com

www.yachtmarinesurveyor.com

Kim Skov-Nielsen, DipMarSur, MIIMS, SAMS AMS

You might also like

- Sample Sailboat Marine Survey ReportDocument16 pagesSample Sailboat Marine Survey ReportTuswanNo ratings yet

- 1980 Alden Skye Ketch ReportDocument27 pages1980 Alden Skye Ketch ReportChetNo ratings yet

- 2006 40 Meridian 391 SampleDocument98 pages2006 40 Meridian 391 SampleChet Stephens100% (1)

- Part A - Summary ReportDocument21 pagesPart A - Summary ReportGreg AkisNo ratings yet

- 28 Sea Ray Sample SurveyDocument21 pages28 Sea Ray Sample SurveyBrad CroftNo ratings yet

- Yacht Appraisal ASA Part1Document5 pagesYacht Appraisal ASA Part1THawk100% (1)

- 1994 Catalina 36 SampleDocument76 pages1994 Catalina 36 SampleChet StephensNo ratings yet

- Foreign TK Vessel. Cg-840-1Document40 pagesForeign TK Vessel. Cg-840-1Adrian CretuNo ratings yet

- Westerly Centaur Survey 2015Document14 pagesWesterly Centaur Survey 2015api-1880728070% (1)

- Scarab 35Document21 pagesScarab 35ChetNo ratings yet

- Certificate of Bollard Pull - TRICAHUE IDocument2 pagesCertificate of Bollard Pull - TRICAHUE IRuben Rodriguez100% (1)

- Lagoon 44 ManualDocument31 pagesLagoon 44 ManualMattia TerenziNo ratings yet

- ManualDocument395 pagesManualrafael espinosa semperNo ratings yet

- Grady White SampleDocument77 pagesGrady White SampleChet StephensNo ratings yet

- 120 - Before Moving Boat ChecklistDocument1 page120 - Before Moving Boat ChecklistColin LeakeNo ratings yet

- Faircloth Skimmer®: 1 " Cut Sheet J. W. Faircloth & Son, IncDocument63 pagesFaircloth Skimmer®: 1 " Cut Sheet J. W. Faircloth & Son, IncpicottNo ratings yet

- Tayana 37 'Ayala' SurveyDocument41 pagesTayana 37 'Ayala' SurveyAntonio Garcia-MartinezNo ratings yet

- Sample Sundowner 30 Trawler SurveyDocument20 pagesSample Sundowner 30 Trawler SurveyTihomir MarkovicNo ratings yet

- Samplesurvey SailDocument14 pagesSamplesurvey SailSoldatos AthanasiosNo ratings yet

- Maintenance Repair and Production-OrientDocument36 pagesMaintenance Repair and Production-OrientasdfightNo ratings yet

- Cemfjord Cement CarrierDocument113 pagesCemfjord Cement CarriermuditNo ratings yet

- Charter Vessel Folder Version 2 4.1Document73 pagesCharter Vessel Folder Version 2 4.1BESHLYAGA DANYL100% (2)

- Yacht and Small Craft Surveying: Diploma inDocument46 pagesYacht and Small Craft Surveying: Diploma inAdele Murray100% (1)

- Table of Shipboard Working ArrangementsDocument2 pagesTable of Shipboard Working ArrangementsKunal SinghNo ratings yet

- MNC Shipboard Manual - Container Vessels PDFDocument631 pagesMNC Shipboard Manual - Container Vessels PDFЮрий КлимкинNo ratings yet

- 1996 33' Jupiter 31 Open Center Console - Sample Survey ReportDocument46 pages1996 33' Jupiter 31 Open Center Console - Sample Survey ReportSuenos AzulesNo ratings yet

- ICL CIRMAR 002 Guideline For Condition Surveys and Pre Purchase InspectionsDocument7 pagesICL CIRMAR 002 Guideline For Condition Surveys and Pre Purchase InspectionsEmre AlgülNo ratings yet

- Oosoul Tarahi KeshtiDocument252 pagesOosoul Tarahi Keshtifajee_faridNo ratings yet

- TheShipMastersBusinessCompanion Part CDocument26 pagesTheShipMastersBusinessCompanion Part CMuhammadNo ratings yet

- Survey Report East of EnglandDocument55 pagesSurvey Report East of EnglandThan Htet100% (1)

- Marine Survey Report Sample 1987 Ta Chiao CT 35Document33 pagesMarine Survey Report Sample 1987 Ta Chiao CT 35ChetNo ratings yet

- XXX Marine Survey Report - YelkenokuluDocument36 pagesXXX Marine Survey Report - YelkenokuluTeknoloji HaritasıNo ratings yet

- Drydocking Coast Guard 8634 - STDDocument62 pagesDrydocking Coast Guard 8634 - STDzeek77No ratings yet

- Captura 2021-09-05 A Las 0.44.58Document122 pagesCaptura 2021-09-05 A Las 0.44.58Jose DopicoNo ratings yet

- Precision Checklist PDFDocument4 pagesPrecision Checklist PDFResianing MaritaNo ratings yet

- 053 (C) Tong An Cheng - MokpoDocument82 pages053 (C) Tong An Cheng - MokpoAdriano FernandesNo ratings yet

- Havila Favour PDFDocument4 pagesHavila Favour PDFGabriel JardimNo ratings yet

- Occasional Survey ReportDocument9 pagesOccasional Survey ReportManish SoodNo ratings yet

- Seakeeping LectureDocument30 pagesSeakeeping Lectureknowme73100% (1)

- Ship Lay Up Guidelines Mar10Document24 pagesShip Lay Up Guidelines Mar10Hamada GadNo ratings yet

- Class Annual Survey/ Intermediate Survey/ Special Survey/ General Examination Checklist For Bulk CarrierDocument12 pagesClass Annual Survey/ Intermediate Survey/ Special Survey/ General Examination Checklist For Bulk Carrieralex bencyNo ratings yet

- ASTM TablesDocument44 pagesASTM Tablessamar jeetNo ratings yet

- Tank Capacity PlanDocument1 pageTank Capacity PlanAnonymous ycFeyuLAtNo ratings yet

- West of England P&i GuidelinesDocument48 pagesWest of England P&i GuidelinesParthiban Nagarajan100% (1)

- Sample J108 Survey ReportDocument40 pagesSample J108 Survey ReportChet100% (1)

- Blank Vessel Safety Inspection Report - NPO FunctionDocument13 pagesBlank Vessel Safety Inspection Report - NPO FunctioncaptafuentesNo ratings yet

- Standard P&a ManualDocument16 pagesStandard P&a ManualVasant Kumar VarmaNo ratings yet

- Marine Survey Practice - Failure and DamageDocument10 pagesMarine Survey Practice - Failure and DamageJym GensonNo ratings yet

- Pre Purchase Condition Survey Report On M V XINHEDocument22 pagesPre Purchase Condition Survey Report On M V XINHEMoe LattNo ratings yet

- Report Part A Container Sample 1 - CompressedDocument22 pagesReport Part A Container Sample 1 - CompressedMohamed OmarNo ratings yet

- Loading Survey Report N19HZZSQ1012 002Document33 pagesLoading Survey Report N19HZZSQ1012 002Paulo DiasNo ratings yet

- Short Condition Survey Report-2012-1Document7 pagesShort Condition Survey Report-2012-1alive2flirtNo ratings yet

- DKT0/2020/J5110: Ships in Service Survey ReportDocument26 pagesDKT0/2020/J5110: Ships in Service Survey ReportLeonidas Galanis100% (1)

- Functions of Cargo Surveying NewDocument13 pagesFunctions of Cargo Surveying NewAchala Dharmasiri100% (1)

- Final Report FM Prosperity Voy 02095 Dicharge CristobaDocument30 pagesFinal Report FM Prosperity Voy 02095 Dicharge CristobaCESAR VIECNTENo ratings yet

- Dry DockingDocument46 pagesDry DockingVinod KumarNo ratings yet

- Stability HandbookDocument60 pagesStability HandbookNoom' NoppasinNo ratings yet

- Register of Materials Handling Equipment-AMSA357Document10 pagesRegister of Materials Handling Equipment-AMSA357SudheerRawatNo ratings yet

- How to Abandon Ship: The World War II Classic That Can Save Your LifeFrom EverandHow to Abandon Ship: The World War II Classic That Can Save Your LifeNo ratings yet

- Generator End-Winding Retaining Rings - A Literature Survey and Care GuidelineDocument28 pagesGenerator End-Winding Retaining Rings - A Literature Survey and Care Guidelinemeisam davoodabadiNo ratings yet

- 13 Critical Steps: To Ensure Metal Stamping SuccessDocument17 pages13 Critical Steps: To Ensure Metal Stamping SuccessluisNo ratings yet

- Metal Based PackagingDocument21 pagesMetal Based PackagingSheraz KarimNo ratings yet

- Petronas Technical Standards: Passive Fire and Cryogenic Protection For Structural SteelDocument27 pagesPetronas Technical Standards: Passive Fire and Cryogenic Protection For Structural SteelvinothNo ratings yet

- PD 8010-2 Presentation April 2005 NewDocument40 pagesPD 8010-2 Presentation April 2005 NewrahulranjanNo ratings yet

- Buildex Self Drilling ScrewDocument40 pagesBuildex Self Drilling ScrewKhader Abu-dagga100% (1)

- Ripstar 109: SpecificationDocument3 pagesRipstar 109: SpecificationAnkita Baban GavadeNo ratings yet

- Thor-Coat - Corrosion Protection For Rotating Marine ApplicationsDocument4 pagesThor-Coat - Corrosion Protection For Rotating Marine ApplicationsErick AmadeuNo ratings yet

- Chemtex Speciality Limited West Bengal IndiaDocument10 pagesChemtex Speciality Limited West Bengal IndiaChemtex Speciality LimitedNo ratings yet

- Epocoat 111 PDFDocument3 pagesEpocoat 111 PDFjunaid112No ratings yet

- Catalogo Tecnico ENGDocument52 pagesCatalogo Tecnico ENGAdvokat HadziTonicNo ratings yet

- Stress Corrosion CrackingDocument50 pagesStress Corrosion CrackingssjunedNo ratings yet

- SSPC SP16 Brush-Off Blast CleaningDocument5 pagesSSPC SP16 Brush-Off Blast Cleaninglonglong300394% (16)

- Defect SheeetDocument44 pagesDefect SheeetAfiq FuadNo ratings yet

- Coupons For Cathodic Protection Evaluation of Mixed-Metal Piping SystemsDocument8 pagesCoupons For Cathodic Protection Evaluation of Mixed-Metal Piping SystemsRobert J MayNo ratings yet

- Fosroc Guncrete E: High Strength, Low Shrinkage, High Build Dry-Spray Applied Repair Mortar Uses Application InstructionsDocument3 pagesFosroc Guncrete E: High Strength, Low Shrinkage, High Build Dry-Spray Applied Repair Mortar Uses Application InstructionsJohnNo ratings yet

- Final Alt 2Document44 pagesFinal Alt 2Abdul LahNo ratings yet

- Environmentally Assisted Cracking - Corrsion CourseDocument39 pagesEnvironmentally Assisted Cracking - Corrsion CourseMd. Saimon IslamNo ratings yet

- Fastener Material SelectionDocument3 pagesFastener Material SelectionIzzah AmalinaNo ratings yet

- Chemical Resistance Applications Note For Object 3d PrinterDocument2 pagesChemical Resistance Applications Note For Object 3d PrinteruimtiazNo ratings yet

- Development of A Dissimilar Temper Bead Welding Procedure For An Amine Tower RepairDocument0 pagesDevelopment of A Dissimilar Temper Bead Welding Procedure For An Amine Tower RepairNaveen KurupNo ratings yet

- LNG - Growing Challenges of Heat Exchanger's Operation & Maintenance in LNG PlantsDocument16 pagesLNG - Growing Challenges of Heat Exchanger's Operation & Maintenance in LNG PlantsR P SinghNo ratings yet

- T1 Orbital Welding of DuplexSSDocument9 pagesT1 Orbital Welding of DuplexSSssmith2007No ratings yet

- SEE4121 (2023) - Basic Gas Engineering & Energy Market - Lecture 2 - 16 Jan 2023Document85 pagesSEE4121 (2023) - Basic Gas Engineering & Energy Market - Lecture 2 - 16 Jan 2023MelodyNo ratings yet

- Chapter 1 - Introduction To CorrosionDocument36 pagesChapter 1 - Introduction To Corrosionmotasem100% (2)

- 205 PV LPGDocument211 pages205 PV LPGf166No ratings yet

- Mil DTL 15024GDocument15 pagesMil DTL 15024GLogo SkyNo ratings yet

- N-CR-001 1st 1996 Common Requirements - Structural Design PDFDocument19 pagesN-CR-001 1st 1996 Common Requirements - Structural Design PDFhadiNo ratings yet

- C-86 An Acceleration-Cyclic Corrosion Test of Coating Systems For Steel BridgesDocument6 pagesC-86 An Acceleration-Cyclic Corrosion Test of Coating Systems For Steel BridgesDhananjay ShimpiNo ratings yet

- 2021 Inspection ReportDocument58 pages2021 Inspection ReportDaniel MillerNo ratings yet