Professional Documents

Culture Documents

Watertreat Chrome Neutraliser (1150007) PDF

Watertreat Chrome Neutraliser (1150007) PDF

Uploaded by

Choice OrganoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Watertreat Chrome Neutraliser (1150007) PDF

Watertreat Chrome Neutraliser (1150007) PDF

Uploaded by

Choice OrganoCopyright:

Available Formats

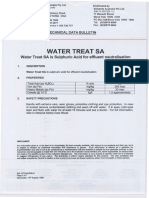

TECHNICAL INFORMATION

WATERTREAT CHROME NEUTRALISER

1. INTRODUCTION

Henkel Technologies supplies a number of chromium containing compounds for various metal

treatment procedures. From time-to-time, solutions or rinses containing these compounds

may require dumping. Stringent pollution control regulations in many areas prohibit the

disposal of hexavalent chromium compounds into sewage systems. This bulletin presents a

simple and economical treatment process, which will provide environmentally treated waste

water.

2. THE PROCESS

The process removes the chromium compounds via two steps. In the first step, the hexavalent

chromium is reduced with WATERTREAT CHROME NEUTRALISER. The second step

involves the formation of insoluble chromium hydroxides, which precipitate and settle to the

bottom portion of the solution. The upper, chromium-free water, is safe to dump as waste

water. The settled sludge is disposed of via a registered waste disposal company at regular

intervals.

3. EQUIPMENT

The whole treatment operation may be carried out in one tank, e.g. the solution tank or rinse

tank. However, sufficient time must be available for complete settling of the sludge. It is more

convenient to transfer the treated water to another tank for settling so as not to hold up the

use of the main solution tank. Adequate stirring must be available to dissolve the treatment

products. Alternatively, treatment may be carried out in a continuous system, consisting of a

pH adjustment and chrome reduction tank, a precipitation tank and a final settling tank.

4. TREATMENT PROCEDURE

a. Chromate waste water is pumped into the treatment tank.

b. The amount of hexavalent chromium in the solution is determined as outlined in

Section 5.

c. The amount of WATERTREAT CHROME NEUTRALISER required is then

calculated as in Section 6.

d. The solution is mixed thoroughly and the pH of the bath is maintained between 2.0

and 3.0 by the addition of the WATERTREAT CHROME NEUTRALISER. The

bath will turn a dark blue-green colour as the chromium is reduced to the trivalent

form. Allow at least 30 minutes for complete reduction. Complete reduction can

be checked colorimetrically using s-diphenylcarbazide reagent. Add several drops

of s-diphenylcarbazide reagent to a small sample of the solution If any

hexavalent chrome is present this solution will turn bright pink. If this occurs add

a further addition of Watertreat Chrome Neutraliser and mix.

Henkel Australia Pty Limited P. O. Box 63 135-141 Canterbury Road www.henkel.com

ABN 82 001 302 996 Kilsyth Victoria 3137 Kilsyth Victoria 3137 Tel: (+61) 1300 736 777

Australia Australia Fax: (+61) 3 9761 7179

Ref: WATERTREAT CHROME NEUTRALISER/IRR/WG

Page 1 of 2

th

Issue :28 May, 2008

WATERTREAT CHROME NEUTRALISER Page 2

4. TREATMENT PROCEDURE Cont…

e. The treated water may now be pumped over to the precipitation tank.

f. WATERTREAT M or CHROME PRECIPITATOR is now added in sufficient

quantity to raise the pH to between 7.0 and 8.0.

g. The mixer is stopped and solids are allowed to settle. The clear water can then be

pumped off into the regular sewage system. Settlement may take from hours to

several days.

h. The sludge can be scooped or shovelled into drums for pick up by a waste

disposal company. The longer the solution is allowed to settle, the more compact

the resulting sludge.

5. HEXAVALENT CHROMIUM TITRATION

The amount of hexavalent chromium present in the waste water is determined via the

following procedure:

a. Pipette a 5 mL sample of the waste water into a beaker or flask and dilute to

approximately 100 mL.

b. Add a few crystals or 5 mL of 20% Potassium Iodide solution.

c. Add about 15 mL of concentrated Hydrochloric Acid or Sulphuric Acid to the flask

and mix.

d. After approximately one minute, titrate the solution with 0.1N Sodium Thiosulphate

until a straw colour is obtained.

e. Add several mL of soluble Starch Solution and continue the titration with 0.1N

Sodium Thiosulphate until the blue-black colour disappears. (At the end point, a

light green colour due to trivalent chromium will be evident.)

f. Record the number of mL of 0.1N Sodium Thiosulphate used as hexavalent

chromium titration.

Note: Where solutions contain only small amounts of hexavalent chromium, larger sample

sizes are necessary, i.e. 25 mL or 100 mL. The titration obtained is then reduced

proportionately, to that of a 5 mL sample size. (For a 5 mL sample, number of mL x 350 =

ppm hexavalent chrome).

6. WATERTREAT CHROME NEUTRALISER REQUIRED

Add 6.0 mL of WATERTREAT CHROME NEUTRALISER per Litre of waste water for each

mL of hexavalent chromium titration.

Example: A 100 mL sample titrated 4 mL. Therefore, a 5mL sample would have titrated 1/20

of that value, or 0.20 mL. Theoretically, this solution would require about 1.2 mL of

WATERTREAT CHROME NEUTRALISER per Litre of waste solution.

DISCLAIMER

Any information given is, to the best of our knowledge, the best currently available, with respect to our products and their use, but

it is subject to revision as additional knowledge and experience is gained. Such information is offered as a guideline for

experimentation only and is not to be construed as a representation that the material is suitable for any particular purpose or use.

Customers are encouraged to make their own enquiries as to the material's characteristics and, where appropriate, to conduct

their own tests in the specific context of the material's intended use. This information is not a license to operate under nor is it

intended to suggest infringement of any patent. We guarantee a uniform quality standard for this product. The only conditions

and warranties accepted by Henkel in relation to this product or process are those implied by either Commonwealth or State

statutes.

Ref: WATERTREAT CHROME NEUTRALISER/IRR/WG

Page 2 of 2

th

Issue :30 January, 2008

You might also like

- Manual of Formulas - Recipes, Methods & Secret ProcessesFrom EverandManual of Formulas - Recipes, Methods & Secret ProcessesRating: 4.5 out of 5 stars4.5/5 (2)

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Are You Fully Charged - Tom RathDocument1 pageAre You Fully Charged - Tom RathHoratiu BahneanNo ratings yet

- Liquid Chrome Reductor (213016)Document3 pagesLiquid Chrome Reductor (213016)Choice OrganoNo ratings yet

- Separation Techniques Student Sheet: Intended Lesson OutcomesDocument19 pagesSeparation Techniques Student Sheet: Intended Lesson Outcomeslianchen251110No ratings yet

- 030-Zn EDTADocument7 pages030-Zn EDTArafiqqaisNo ratings yet

- SOP AMBL 104A HardnessDocument5 pagesSOP AMBL 104A HardnessRamiAdelNo ratings yet

- The Gravimetric Determination of NickelDocument7 pagesThe Gravimetric Determination of Nickelswathi_ravi_5No ratings yet

- Total Hardness DeterminationDocument2 pagesTotal Hardness DeterminationTal EshelNo ratings yet

- Kemp TR 375Document3 pagesKemp TR 375S SURESHNo ratings yet

- Water Content of Crude OilDocument9 pagesWater Content of Crude OilmhmdNo ratings yet

- Scope: CautionDocument7 pagesScope: CautionJavier Oswaldo Gonzalez AceroNo ratings yet

- Freshwater Aquaculture Test Kit Manual, Model FF-2, Kit 2430-01Document27 pagesFreshwater Aquaculture Test Kit Manual, Model FF-2, Kit 2430-01veme1No ratings yet

- Arsen.01 ImprimirDocument6 pagesArsen.01 ImprimirLautaro Valentin QuirogaNo ratings yet

- SurtecDocument7 pagesSurtecbrahymNo ratings yet

- Winkler Method Lab ReportDocument6 pagesWinkler Method Lab ReportYoonseo (Elin) ChaNo ratings yet

- MCP MethodDocument9 pagesMCP MethodRobert SuiNo ratings yet

- Wall Wash Test ProceduresDocument5 pagesWall Wash Test Proceduresrabi4457No ratings yet

- Wall-Wash Tests On Chemical TankersDocument6 pagesWall-Wash Tests On Chemical TankersMoe Win AungNo ratings yet

- New ChrysotypeDocument15 pagesNew ChrysotypeTeresa WieNo ratings yet

- DAK Revised SOPDocument10 pagesDAK Revised SOPazlinkadirNo ratings yet

- CM-1 24957-00 CorrosionManagement PDFDocument28 pagesCM-1 24957-00 CorrosionManagement PDFSamirNo ratings yet

- Lieberman NDocument3 pagesLieberman NTitis Adisti HapsariNo ratings yet

- Stereo ChemistryDocument4 pagesStereo ChemistryDORINA MANTUNo ratings yet

- Method For The Determination of StigmastadienesDocument12 pagesMethod For The Determination of StigmastadienesSlaw Ben AissaNo ratings yet

- PDF Dioctahedral MOADocument3 pagesPDF Dioctahedral MOAHoover PharmaNo ratings yet

- Chemistry Practicals First YearsDocument65 pagesChemistry Practicals First Yearskokimesh0% (1)

- Boiler Water TestDocument8 pagesBoiler Water TestMohammad Jahid AlamNo ratings yet

- Surface Preparation Guide For Adhesives, Sealants, and CoatingsDocument3 pagesSurface Preparation Guide For Adhesives, Sealants, and CoatingsJohnJaimezNo ratings yet

- Mud TestDocument8 pagesMud TestNakkolopNo ratings yet

- PAG 02 - Acid-Base TitrationDocument3 pagesPAG 02 - Acid-Base TitrationHailey WongNo ratings yet

- Additive 384Document2 pagesAdditive 384Enrico WibowoNo ratings yet

- Surtec 680: Protection UpgradedDocument7 pagesSurtec 680: Protection Upgradedyudhien4443No ratings yet

- Santa Monica College Chem 22 Lab ManualDocument59 pagesSanta Monica College Chem 22 Lab ManualMide Ogundipe100% (1)

- Rhenium in Catalysts by SpectrophotometryDocument7 pagesRhenium in Catalysts by SpectrophotometryDavinNo ratings yet

- Experiment 12 Preparation of Adipic Acid From CyclohexeneDocument6 pagesExperiment 12 Preparation of Adipic Acid From Cyclohexenesaransh1994No ratings yet

- Cyano Type Blue PrintingDocument11 pagesCyano Type Blue PrintingShubham MauryaNo ratings yet

- Chemistry Practicals First YearsDocument65 pagesChemistry Practicals First YearsWaleed EmaraNo ratings yet

- 1983 Roberts The Analysis of Dextran in Sugar ProductionDocument10 pages1983 Roberts The Analysis of Dextran in Sugar ProductionGustavo CardonaNo ratings yet

- CFNS Experiment 16 - Titrating Sodium Hydroxide With Hydrochloric AcidDocument4 pagesCFNS Experiment 16 - Titrating Sodium Hydroxide With Hydrochloric AcidMark 00vvNo ratings yet

- TrimyristinDocument3 pagesTrimyristindinna_dinunNo ratings yet

- Determination of Calcium by ComplexometryDocument3 pagesDetermination of Calcium by ComplexometryAnonymous NxpnI6jCNo ratings yet

- Synthesis of Lidocaine: Chemistry 212 LaboratoryDocument4 pagesSynthesis of Lidocaine: Chemistry 212 LaboratoryNuteLLa Gaming (EFL)No ratings yet

- RS DextranDocument8 pagesRS DextranelgaNo ratings yet

- MT 158 Determination of Mercury On Treated Seeds: Miscellaneous Techniques and ImpuritiesDocument18 pagesMT 158 Determination of Mercury On Treated Seeds: Miscellaneous Techniques and ImpuritiesFelipe Navarrete100% (1)

- METHOD 14:1: Calcium - Volumetric Method 1: Scope and Field of ApplicationDocument2 pagesMETHOD 14:1: Calcium - Volumetric Method 1: Scope and Field of ApplicationAshok KumarNo ratings yet

- MN Phospating PDFDocument4 pagesMN Phospating PDFarshia123No ratings yet

- ChemisttryDocument16 pagesChemisttryAayush AmitNo ratings yet

- En Data SheetDocument5 pagesEn Data SheetPhanuwit ThavalNo ratings yet

- Acm Ino 04 PARABEN Version 2005 PDFDocument10 pagesAcm Ino 04 PARABEN Version 2005 PDFminh trang huỳnh lêNo ratings yet

- Surtec 832: Protection UpgradedDocument5 pagesSurtec 832: Protection Upgradedtân hoàngNo ratings yet

- Chapter 2Document8 pagesChapter 2Christian EduardoNo ratings yet

- Practicum AZG Makro 5 - Moisture DistilationDocument5 pagesPracticum AZG Makro 5 - Moisture DistilationUlis SalsabilaNo ratings yet

- TitrationDocument4 pagesTitrationangelmhandeNo ratings yet

- Lipase ActivityDocument10 pagesLipase ActivityNathalie QuezadaNo ratings yet

- Tds Tss in WaterDocument48 pagesTds Tss in Water2K19/CE/137 VISHAL JEPHNo ratings yet

- Wall Wash TestDocument5 pagesWall Wash TestutkarshgahtoriNo ratings yet

- Nickel Experiment XWDocument4 pagesNickel Experiment XWKhairul Anwar Abd HamidNo ratings yet

- Titrimetric AnalysisDocument7 pagesTitrimetric AnalysisLisa DentonNo ratings yet

- Watertreat LCS (1334880)Document1 pageWatertreat LCS (1334880)Reply choiceNo ratings yet

- Watertreat HCL (170096)Document1 pageWatertreat HCL (170096)Reply choiceNo ratings yet

- Dowcal 10 Tech Data Sheet PDFDocument2 pagesDowcal 10 Tech Data Sheet PDFReply choiceNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument11 pagesSafety Data Sheet: 1. IdentificationReply choiceNo ratings yet

- Dowtherm and Dowfrost Heat Transfer Fluids: Quick Reference GuideDocument2 pagesDowtherm and Dowfrost Heat Transfer Fluids: Quick Reference GuideReply choiceNo ratings yet

- Water Treat Sa (1334891)Document1 pageWater Treat Sa (1334891)Reply choiceNo ratings yet

- Company ProfileDocument24 pagesCompany ProfileReply choice100% (1)

- INDIONFiltration ChemicalsDocument6 pagesINDIONFiltration ChemicalsReply choiceNo ratings yet

- And Heat Transfer Fluids: Dowtherm, Syltherm, Dowfrost, DowcalDocument20 pagesAnd Heat Transfer Fluids: Dowtherm, Syltherm, Dowfrost, DowcalReply choiceNo ratings yet

- How To Select The Right Heat Transfer FluidDocument5 pagesHow To Select The Right Heat Transfer FluidReply choiceNo ratings yet

- Rocare A11Document1 pageRocare A11Reply choiceNo ratings yet

- The Merk IndexDocument182 pagesThe Merk IndexReply choice100% (1)

- Product Line CardDocument1 pageProduct Line CardReply choiceNo ratings yet

- Industrial Water Treatment Product Name Indion Ffip Indion Ffip (MB) Indion NipDocument5 pagesIndustrial Water Treatment Product Name Indion Ffip Indion Ffip (MB) Indion NipReply choiceNo ratings yet

- Roto Gard 2401: ROTOGARD2401Document1 pageRoto Gard 2401: ROTOGARD2401Reply choiceNo ratings yet

- Super Absorbent PolymerDocument10 pagesSuper Absorbent PolymerReply choiceNo ratings yet

- True Hydro GelDocument8 pagesTrue Hydro GelReply choiceNo ratings yet

- Thesis On Accounting and Finance PDFDocument5 pagesThesis On Accounting and Finance PDFNicole Heredia100% (2)

- Kennedy Teaching PhilosophyDocument2 pagesKennedy Teaching PhilosophyAngela KennedyNo ratings yet

- Raon, Glishel P. Bs-Entrep 2-4Document5 pagesRaon, Glishel P. Bs-Entrep 2-4Glishel Raon100% (1)

- Cri Nozzle2016Document40 pagesCri Nozzle2016Екатерина КалашниковаNo ratings yet

- Basic Geography: SUMMER - A.Y. 2019-2020Document117 pagesBasic Geography: SUMMER - A.Y. 2019-2020Freshie PascoNo ratings yet

- CSS International Relations Past Papers 2000-2021 (Free Download)Document50 pagesCSS International Relations Past Papers 2000-2021 (Free Download)AyshahNo ratings yet

- Society For Research in Child Development, Wiley Child DevelopmentDocument8 pagesSociety For Research in Child Development, Wiley Child DevelopmentYannu JiménezNo ratings yet

- User Manual: For AI Alarm Wireless NVR KitDocument33 pagesUser Manual: For AI Alarm Wireless NVR KitCarl SwickNo ratings yet

- Bard 3 Entertainer Bobby Lee Human CG: StrengthDocument1 pageBard 3 Entertainer Bobby Lee Human CG: StrengthClyde McFreeNo ratings yet

- Dengue 1Document1 pageDengue 1Sure NavyasriNo ratings yet

- Lisa Mullen MSA Seminar PaperDocument6 pagesLisa Mullen MSA Seminar PaperRaluca BibiriNo ratings yet

- Lombok Daily TourDocument9 pagesLombok Daily Tourazmi LombokNo ratings yet

- MFJHamRadioCatalog 2020 PDFDocument133 pagesMFJHamRadioCatalog 2020 PDFLeslie Citrome100% (1)

- Operating and Installation Instructions WasherDocument80 pagesOperating and Installation Instructions WasherSorin Ionut MoldoveanuNo ratings yet

- Resume Training 1Document2 pagesResume Training 1api-231079644No ratings yet

- Country Project PPT GuidelinesDocument2 pagesCountry Project PPT GuidelinesLaia Moreno FerranNo ratings yet

- The Mind's Ear-CovingtonDocument15 pagesThe Mind's Ear-CovingtonAna Mx100% (2)

- Prepositional PhrasesDocument13 pagesPrepositional PhrasesBerlianova Cahya CantikaNo ratings yet

- Rum Price in Chandigarh Bottle 750 ML HALF 375 ML Quarter 180 MLDocument7 pagesRum Price in Chandigarh Bottle 750 ML HALF 375 ML Quarter 180 MLNikhil MahajanNo ratings yet

- Advanced Rune Shamanism by Michael William DenneyDocument102 pagesAdvanced Rune Shamanism by Michael William DenneyPicaso DavidNo ratings yet

- Understanding of HPC Cluster and Its ComponentDocument29 pagesUnderstanding of HPC Cluster and Its Componentmadhursen99No ratings yet

- DrRacket GuideDocument351 pagesDrRacket GuideWhite DragonNo ratings yet

- WQT Visual Inspection Report ASTRON-22Document1 pageWQT Visual Inspection Report ASTRON-22sasikumarNo ratings yet

- Communication English IDocument10 pagesCommunication English Isenthil kumaran mNo ratings yet

- Plan Approval Application .Document2 pagesPlan Approval Application .Tariro DziruniNo ratings yet

- College Admission - University of Makati 2Document3 pagesCollege Admission - University of Makati 2Ella Bajande SarteNo ratings yet

- The Architect and The ModelDocument9 pagesThe Architect and The ModeldudiNo ratings yet

- G9-ICT-CSS-Q1-Week2-3 Hardware and SoftwareDocument11 pagesG9-ICT-CSS-Q1-Week2-3 Hardware and SoftwareRizaldo C. LeonardoNo ratings yet

- Rewrite The Following Sentences Using Conditional SentencesDocument6 pagesRewrite The Following Sentences Using Conditional SentencesRomeo ConguitoNo ratings yet