Professional Documents

Culture Documents

Microsoft Word - M001r3

Uploaded by

Thiago CurvoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microsoft Word - M001r3

Uploaded by

Thiago CurvoCopyright:

Available Formats

NORSOK standard M-001 Rev. 3, Nov.

2002

Even if the specification for the deaeration equipment gives more strict requirements, the above shall be

basis for the material selection. If the specified Oxygen Equivalent or temperature is above 50 ppb or 30°C

respectively for normal operation, the basis for material selection shall be subject to special evaluation.

Recommendation:

For carbon steel submarine injection flowlines the corrosion allowance should be minimum 3 mm.

In injection water systems where alternating deaerated seawater, produced water, aquifer water and/or gas

could flow through the systems, the material selection shall take this into account. All components which

may contact injection water or back-flowing fluids, shall be resistant against well treating chemicals or well

stimulating chemicals in case of back-flow situations. For carbon steel piping maximum flow velocity shall be

6 m/s.

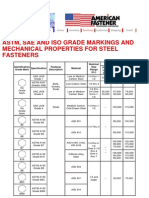

5.5.5 Bolting materials for piping, equipment, structural and subsea applications

The general bolting material for bolt diameters above 10 mm in piping systems and equipment shall be

carbon or low alloy steel selected in accordance with the ASTM Standards listed in table 3 below. Bolts with

a diameter < 10 mm shall be stainless steel Type 316 for metal temperatures below 60°C for topside

applications based upon maximum operating temperature.

Table 3 - Temperature range for bolting materials

Temperature BOLT4) NUT Size range,

range, (°C) (mm)

-100/+400 A 320 Grade L7 A 194 Grade 4/S3 or grade <65

7/S3

A 320 Grade L43 A 194 Grade 7/S3 or A194 <100

grade 4/S3

-46/+400 A 193 Grade B7 A 194 Grade 2H All

-29/+540 A 193 Grade B161) A 194 Grade 7 All

-196/+540 A 193 Grade B8M2) A 194 Grade 8M/8MA3) All

NOTES

1 This grade should not be used for permanent subsea equipment. Grade B16 is intended for high temperature service, outside

the temperature range for Grade B7.

2 Type 316 bolts and nuts shall not be used at maximum operating temperature above 60°C if exposed to wet marine

atmosphere.

3 Use 8MA with class 1 bolts.

4 Use of bolting for pressure equipment under PED shall be verified by a PMA.

Bolting materials for structural applications shall generally be carbon or low alloy steels.

The following limitations shall apply:

• For topside applications, the strength class shall not exceed ISO 898 class 10.9.

• For submerged bolts, the strength class shall not exceed ISO 898 class 8.8, ASTM A 320 Grade L7 or A

193 Grade B7.

• Bolts with a diameter above 25 mm shall be impact tested to the same requirements as for the steels to

be bolted.

If other bolting materials are required due to corrosion resistance or other reasons, the material shall be

selected in accordance with the general requirements of this document. For subsea applications, Alloy 625

shall be used when corrosion resistant bolts are required at ambient temperature, i.e. for conditions where

the bolts are exposed to aerated seawater and cathodic protection cannot be ensured. It shall be verified

that the materials have acceptable mechanical properties at the actual design temperatures.

Bolts screwed into component bodies shall be of a material that is compatible with the body with respect to

galling and ability to disassemble the component for maintenance, if relevant. Possibility for galvanic

corrosion, thermal coefficient if relevant, and for subsea applications the effect of cathodic protection, shall

be considered.

NORSOK standard Page 19 of 30

You might also like

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- C 12 FastenersDocument5 pagesC 12 FastenersMithun Unni NairNo ratings yet

- Astm Bolt & NutsDocument24 pagesAstm Bolt & NutsDinesh Radhakrishnan100% (3)

- Bolts and Compatible Nuts InformationDocument11 pagesBolts and Compatible Nuts InformationBHARATHNo ratings yet

- 3.3 TestsDocument1 page3.3 TestsgullenariNo ratings yet

- Table 1B List of Bolting Specifications Applicable ASTM SpecificationsDocument1 pageTable 1B List of Bolting Specifications Applicable ASTM Specificationsbabis1980No ratings yet

- Astm A 563 2014Document9 pagesAstm A 563 2014Marlonnog100% (2)

- ASTM Bolting Specification Temperature MDocument2 pagesASTM Bolting Specification Temperature Mrazvan65100% (1)

- Table 1B List of Bolting Specifications Applicable ASTM SpecificationsDocument1 pageTable 1B List of Bolting Specifications Applicable ASTM SpecificationsPanchal ShaileshNo ratings yet

- A354 PDFDocument7 pagesA354 PDFnighat_fatima_12No ratings yet

- Bolting Material Specifications - PIPING HANDBOOKDocument1 pageBolting Material Specifications - PIPING HANDBOOK최승원No ratings yet

- How To Weld 254 SMODocument12 pagesHow To Weld 254 SMOsateesh chand100% (7)

- Bolt Grip Length PDFDocument1 pageBolt Grip Length PDFmatthewwalls4386100% (2)

- Materials Stud Bolts: ASTM A197 B7Document5 pagesMaterials Stud Bolts: ASTM A197 B7scribddisantoNo ratings yet

- Stainless Steel Pipe SpecsDocument3 pagesStainless Steel Pipe SpecsWahyuTantraFauziNo ratings yet

- Technical Data NRL 02301Document8 pagesTechnical Data NRL 02301Attiq Ahmad ChoudhryNo ratings yet

- M PL 033Document19 pagesM PL 033Ali ClubistNo ratings yet

- Astm Material Summary For BoltsDocument2 pagesAstm Material Summary For BoltsAkshay PoddarNo ratings yet

- SS333 1996 Fire DamperDocument18 pagesSS333 1996 Fire DamperAaron Ang100% (2)

- Astm A193 - Nuts and BoltsDocument5 pagesAstm A193 - Nuts and BoltsgarrybieberNo ratings yet

- 3 05 A Welding Specification of Carbon Steel Alloy SteelDocument40 pages3 05 A Welding Specification of Carbon Steel Alloy SteelvancongthanhNo ratings yet

- Juntas Flanchadas, Empaques y PernosDocument8 pagesJuntas Flanchadas, Empaques y Pernosjuancparra20No ratings yet

- Asme Section II A Sa-354Document8 pagesAsme Section II A Sa-354Anonymous GhPzn1xNo ratings yet

- Anchor Bolt Specification (Ksi 6.895 Mpa) : Astm F1554Document7 pagesAnchor Bolt Specification (Ksi 6.895 Mpa) : Astm F1554pbp2956No ratings yet

- Stainless Steel Pipe SpecificationDocument3 pagesStainless Steel Pipe SpecificationBhairu BaniNo ratings yet

- A 194 - A 194m - 03 Qte5nc9bmtk0ts1sruqDocument16 pagesA 194 - A 194m - 03 Qte5nc9bmtk0ts1sruqfadjarNo ratings yet

- Guidelines and Facilities Required For Fabrication Maintenance of Stainless Steel WagonsDocument14 pagesGuidelines and Facilities Required For Fabrication Maintenance of Stainless Steel WagonsSourav PaulNo ratings yet

- Sa 193Document18 pagesSa 193Haridev MoorthyNo ratings yet

- Marcação Parafusos PDFDocument5 pagesMarcação Parafusos PDFpank7210100% (1)

- Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and ShapesDocument6 pagesCold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapesalucard375No ratings yet

- ASTM Material SpecificationsDocument6 pagesASTM Material SpecificationsLim SenglinNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelDocument3 pagesPressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-Nickeljaskaran singhNo ratings yet

- Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and ShapesDocument6 pagesCold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and ShapesmameniqNo ratings yet

- Bayu Undan / Darwin LNG Facilities Technical Delivery TermsDocument6 pagesBayu Undan / Darwin LNG Facilities Technical Delivery TermsWidodo MuisNo ratings yet

- EG 19-2-1.1 Strip Lining of Pressure Vessels: ScopeDocument6 pagesEG 19-2-1.1 Strip Lining of Pressure Vessels: ScopeaminNo ratings yet

- Specification For Auto LPG Dispensing StationDocument5 pagesSpecification For Auto LPG Dispensing StationShyBokxNo ratings yet

- Carbon and Alloy Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument12 pagesCarbon and Alloy Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothJaime Bernardo GonzálezNo ratings yet

- A 563 - 00 - Qtu2my1sruqDocument10 pagesA 563 - 00 - Qtu2my1sruqAnderson VelandiaNo ratings yet

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenershoannhuNo ratings yet

- A449-14 Standard Specification For Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120 - 105 - 90 Ksi Minimum Tensile Strength, General UseDocument7 pagesA449-14 Standard Specification For Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120 - 105 - 90 Ksi Minimum Tensile Strength, General UseislamakthamNo ratings yet

- A 354 - 03 - Qtm1nc1sruqDocument11 pagesA 354 - 03 - Qtm1nc1sruqJc DimayugaNo ratings yet

- Astm A618Document4 pagesAstm A618Mohamed Farouk100% (1)

- Sapa Alloy 6063Document2 pagesSapa Alloy 6063Sachith Praminda RupasingheNo ratings yet

- A4 80Document2 pagesA4 80alwezalokNo ratings yet

- A 414 - A 414M - 01 Qtqxnc9bnde0ts1sruq - PDFDocument5 pagesA 414 - A 414M - 01 Qtqxnc9bnde0ts1sruq - PDFTiến Lượng NguyễnNo ratings yet

- ASME Specification For Fastener MaterialsDocument11 pagesASME Specification For Fastener MaterialsAnonymous IwqK1Nl100% (1)

- Astm A36Document4 pagesAstm A36jemorpeNo ratings yet

- A 928 - A 928M - 04 Qtkyoc9boti4tqDocument6 pagesA 928 - A 928M - 04 Qtkyoc9boti4tqsachinguptachdNo ratings yet

- Bolting Selection Guide For Bolting MaterialDocument5 pagesBolting Selection Guide For Bolting Materialthuyenquyen_vtNo ratings yet

- Stainless Steel Pipe SpecificationDocument3 pagesStainless Steel Pipe Specification1trungson1No ratings yet

- Abstract of ASTM A563 2000Document10 pagesAbstract of ASTM A563 2000Jesse ChenNo ratings yet

- Astm A193/a 193MDocument13 pagesAstm A193/a 193MCLEMENTNo ratings yet

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현No ratings yet

- ASTM A500 2010 TubosDocument6 pagesASTM A500 2010 TubosRober Moises Chumbe SoveroNo ratings yet

- Saes L 130Document5 pagesSaes L 130Ahmed Kabel100% (1)

- Standard Specification For Corrugated Aluminum Pipe For Sewers and DrainsDocument15 pagesStandard Specification For Corrugated Aluminum Pipe For Sewers and Drainsjun floresNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Metric DIN 934 Hexagon Nuts: Visit Our For Product AvailabilityDocument4 pagesMetric DIN 934 Hexagon Nuts: Visit Our For Product AvailabilityThiago CurvoNo ratings yet

- BS-970-part3-Specification-for-Wrought-steels (Bright Bars) - For-Mechanical-And-Allied-Engineering-Purposes PDFDocument39 pagesBS-970-part3-Specification-for-Wrought-steels (Bright Bars) - For-Mechanical-And-Allied-Engineering-Purposes PDFvahab_shaikNo ratings yet

- Astm A 962 16aDocument12 pagesAstm A 962 16aDaryna KupriianovaNo ratings yet

- Norsok M-001Document34 pagesNorsok M-001Puskar Gupta100% (1)

- BS-970-part3-Specification-for-Wrought-steels (Bright Bars) - For-Mechanical-And-Allied-Engineering-Purposes PDFDocument39 pagesBS-970-part3-Specification-for-Wrought-steels (Bright Bars) - For-Mechanical-And-Allied-Engineering-Purposes PDFvahab_shaikNo ratings yet

- Microsoft Word - M001r3Document1 pageMicrosoft Word - M001r3Thiago CurvoNo ratings yet

- Microsoft Word - M001r3Document1 pageMicrosoft Word - M001r3Thiago CurvoNo ratings yet

- BS-970-part3-Specification-for-Wrought-steels (Bright Bars) - For-Mechanical-And-Allied-Engineering-Purposes PDFDocument39 pagesBS-970-part3-Specification-for-Wrought-steels (Bright Bars) - For-Mechanical-And-Allied-Engineering-Purposes PDFvahab_shaikNo ratings yet

- Astm A194 18 PDFDocument12 pagesAstm A194 18 PDFThiago CurvoNo ratings yet

- ASTM A 962 - 16aDocument12 pagesASTM A 962 - 16aMarcos Verissimo Juca de Paula100% (2)

- Norsok M001 MaterialsDocument31 pagesNorsok M001 MaterialsbreeeeezzzzzeNo ratings yet

- DNV Os-H205Document45 pagesDNV Os-H205ndesigngmail100% (1)

- Din 975 PDFDocument1 pageDin 975 PDFThiago CurvoNo ratings yet

- A574Document7 pagesA574KAROLNo ratings yet

- Astm 194-2017 PDFDocument13 pagesAstm 194-2017 PDFThiago CurvoNo ratings yet

- Aws A 5.10Document38 pagesAws A 5.10বিপ্লব পালNo ratings yet

- High-Strength Low-Alloy Columbium-Vanadium Structural Steel: Standard Specification ForDocument4 pagesHigh-Strength Low-Alloy Columbium-Vanadium Structural Steel: Standard Specification Forcalidad campanaNo ratings yet

- A574Document7 pagesA574KAROLNo ratings yet

- BS-970-part3-Specification-for-Wrought-steels (Bright Bars) - For-Mechanical-And-Allied-Engineering-Purposes PDFDocument39 pagesBS-970-part3-Specification-for-Wrought-steels (Bright Bars) - For-Mechanical-And-Allied-Engineering-Purposes PDFvahab_shaikNo ratings yet

- A320 PDFDocument8 pagesA320 PDFThiago CurvoNo ratings yet

- Effects of Carbon Nanotube Content On The MechanicalDocument6 pagesEffects of Carbon Nanotube Content On The MechanicalThiago CurvoNo ratings yet

- ASTM A 962 - 16aDocument12 pagesASTM A 962 - 16aMarcos Verissimo Juca de Paula100% (2)

- Astm D3330Document6 pagesAstm D3330Thiago Curvo100% (2)

- Cálculo Solda FileteDocument3 pagesCálculo Solda FileteThiago CurvoNo ratings yet

- Iso 898-1 - 2013Document24 pagesIso 898-1 - 2013Thiago CurvoNo ratings yet

- Bolt Tightening HandbookDocument44 pagesBolt Tightening HandbookShekhar V Madhavi100% (1)

- Norma CMAA 70Document90 pagesNorma CMAA 70Marcelo Navarro100% (7)

- Nuts With Specified Property ClassesDocument2 pagesNuts With Specified Property Classesengrmech2009No ratings yet

- Aisc-Asd 89 PDFDocument15 pagesAisc-Asd 89 PDFKang Mas Wiralodra100% (4)

- MCQ Criminal Law 1Document18 pagesMCQ Criminal Law 1Clark Vincent Ponla0% (1)

- 010 Informed Search 2 - A StarDocument20 pages010 Informed Search 2 - A StarRashdeep SinghNo ratings yet

- The Dell Direct Model: What It Means For Customers (Users) : - ProsDocument12 pagesThe Dell Direct Model: What It Means For Customers (Users) : - ProsAbhinandan MattelaNo ratings yet

- CBD20LDocument1 pageCBD20LFelix StancioiuNo ratings yet

- Nil Queries Sheet: S. No. ProcessDocument24 pagesNil Queries Sheet: S. No. ProcessTarun BhardwajNo ratings yet

- Alex FordDocument4 pagesAlex FordElectroventica ElectroventicaNo ratings yet

- Insular Bank of Asia vs. InciongDocument11 pagesInsular Bank of Asia vs. InciongChristiane Marie BajadaNo ratings yet

- Vibroscreen BrochureDocument12 pagesVibroscreen BrochureVarun MalhotraNo ratings yet

- Merenstein Gardners Handbook of Neonatal Intensive Care 8Th Edition Sandra Lee Gardner Brian S Carter Mary I Enzman Hines Jacinto A Hernandez Download PDF ChapterDocument52 pagesMerenstein Gardners Handbook of Neonatal Intensive Care 8Th Edition Sandra Lee Gardner Brian S Carter Mary I Enzman Hines Jacinto A Hernandez Download PDF Chapterrichard.martin380100% (16)

- Ch03 Kinetics of Particles - Energy&Momentum Methods - Part 1Document48 pagesCh03 Kinetics of Particles - Energy&Momentum Methods - Part 1Mehmet Fatih SunçaNo ratings yet

- Psar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0Document183 pagesPsar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0PhatNo ratings yet

- Kompresi MobilDocument58 pagesKompresi Mobilfatah hamid100% (1)

- Appendix 24 - QUARTERLY REPORT OF REVENUE AND OTHER RECEIPTSDocument1 pageAppendix 24 - QUARTERLY REPORT OF REVENUE AND OTHER RECEIPTSPau PerezNo ratings yet

- Glass V Oral Surgeons of Virginia PLLC Vaedce-23-01246 0001.0Document80 pagesGlass V Oral Surgeons of Virginia PLLC Vaedce-23-01246 0001.0Sam OrlandoNo ratings yet

- Account Statement 060922 051222Document51 pagesAccount Statement 060922 051222allison squad xXNo ratings yet

- Lolcat - Linux Cat Command Make Rainbows & Unicorns - LinuxsecretsDocument1 pageLolcat - Linux Cat Command Make Rainbows & Unicorns - LinuxsecretsAli BadNo ratings yet

- 14.symmetrix Toolings LLPDocument1 page14.symmetrix Toolings LLPAditiNo ratings yet

- Law EssayDocument7 pagesLaw EssayNahula AliNo ratings yet

- How To Write The Introduction of An Action Research PaperDocument8 pagesHow To Write The Introduction of An Action Research Papergw1qjewwNo ratings yet

- Designing A 3D Jewelry ModelDocument4 pagesDesigning A 3D Jewelry ModelAbdulrahman JradiNo ratings yet

- Losses in Valves and FittingsDocument17 pagesLosses in Valves and FittingsMintesnot AberaNo ratings yet

- 1st Activity in EthicsDocument2 pages1st Activity in EthicsAleiah Jane Valencia AlverioNo ratings yet

- Beer Distribution Game - Wikipedia, The Free EncyclopediaDocument3 pagesBeer Distribution Game - Wikipedia, The Free EncyclopediaSana BhittaniNo ratings yet

- Conventional and Computed TomographyDocument29 pagesConventional and Computed TomographyJerome D FlorentinoNo ratings yet

- Pre-Interview Fresh Graduate Programs PDFDocument5 pagesPre-Interview Fresh Graduate Programs PDFDimas Kusuma AndanuNo ratings yet

- ACI 533.5R-20 Guide For Precast Concrete Tunnel SegmentsDocument84 pagesACI 533.5R-20 Guide For Precast Concrete Tunnel SegmentsJULIE100% (3)

- 27 HestiaDocument24 pages27 HestiaAlberto AdameNo ratings yet

- 147380-1 Motoman XRC Controller Fieldbus (XFB01) Instruction ManualDocument102 pages147380-1 Motoman XRC Controller Fieldbus (XFB01) Instruction Manualrubi monNo ratings yet

- Kathrein 739624Document2 pagesKathrein 739624anna.bNo ratings yet

- Sick - Photoelectric 4-180 MM v2Document7 pagesSick - Photoelectric 4-180 MM v2Muhammad SumeetNo ratings yet