Professional Documents

Culture Documents

Purchase Inventory Model

Purchase Inventory Model

Uploaded by

Pragyan Kumar PradhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Purchase Inventory Model

Purchase Inventory Model

Uploaded by

Pragyan Kumar PradhanCopyright:

Available Formats

205

Materlals Managemont and Inventory Control

IMPLEMENTATION OF PURCHASE INVENTORY MODEL

9.7

of inventory

model be classified into Fixed Order Quantity

he nractical version of purchase

can

the

Period Quantity System (P System). Thesce are presented in

wstem (Q System) and kixed

following sections.

exist in each of the systems.

The following cases

Varying demand and constant lead time.

Constant demand and varying lead time.

Varying demand and varying lead time.

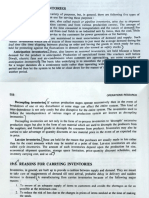

9.7.1

Fixed Order Quantity System (Q System)

an order is placed

of nventory, whenever the stock level touches the reorder level,

In this system in

of this model is shown

for a fixed quantity which is equal to EOQ. A schematic representation

the following Fig. 9.9.

Reorder level

Demard during leadtime

Reserve stock

Safety stock

Time

Fig. 9.9 Qsystem of inventory.

The average demand during the lead time (average lead time) is known as the demand during

lead time (DLT). The variation in demand during lead time (average lead time) is known as safety

stock. The average demand during delivery delays is called reserve stock. The Reorder level is

computed as the sum of the demand during lead time (DLT), the variation in demand during lead time

(Safety stock) and the average demand during delivery delays (reserve stock).

You might also like

- Investment Casting ProcessesDocument10 pagesInvestment Casting ProcessesPragyan Kumar PradhanNo ratings yet

- Economic Order Quantity in BriefDocument8 pagesEconomic Order Quantity in BriefEllur Anand100% (4)

- CH 12 HW Answs OmDocument15 pagesCH 12 HW Answs Omhammad06767% (6)

- Chapter Two Materials ManagementDocument40 pagesChapter Two Materials ManagementYeabsira WorkagegnehuNo ratings yet

- Chapter 12 11 Inventory Management Mcgraw Hillirwin Operations ManagementDocument33 pagesChapter 12 11 Inventory Management Mcgraw Hillirwin Operations ManagementmelakuNo ratings yet

- L&OM 07 MBA Pull Plan MakeDocument28 pagesL&OM 07 MBA Pull Plan Makeአንድ ለእናቱNo ratings yet

- Week 5 Lecture Material MOISDocument96 pagesWeek 5 Lecture Material MOISshashwat kushwahaNo ratings yet

- Model EOQ AnswerDocument7 pagesModel EOQ Answershafvan_786No ratings yet

- Class 03 InventoryDocument38 pagesClass 03 Inventoryzayed hossainNo ratings yet

- Figure Transcript - Chapter 9 (Inventory)Document8 pagesFigure Transcript - Chapter 9 (Inventory)Sakda SiriphattrasophonNo ratings yet

- Economic Order QuantityDocument9 pagesEconomic Order QuantityGwyneth Ü ElipanioNo ratings yet

- Inventory Models For Independent DemandDocument2 pagesInventory Models For Independent DemandAjmerNo ratings yet

- KEAB - S4A1 - MAPA CONCEPTUAL. LogisticaDocument4 pagesKEAB - S4A1 - MAPA CONCEPTUAL. LogisticaKeisy AispuroNo ratings yet

- Log (S20) - Inventory Models-1Document21 pagesLog (S20) - Inventory Models-1Aqib LatifNo ratings yet

- Inventory Systems For Independent Demand: This Section ExploresDocument28 pagesInventory Systems For Independent Demand: This Section ExploresShinjiNo ratings yet

- Chapter 9 Inventory ManagementDocument25 pagesChapter 9 Inventory ManagementJazz Kaur100% (1)

- Unit 10 Inventory Systems and Modelling: ObjectivesDocument17 pagesUnit 10 Inventory Systems and Modelling: ObjectivesTanmay JagetiaNo ratings yet

- Inventory MCS Lec NotesDocument12 pagesInventory MCS Lec NotesMohamed HamedNo ratings yet

- Inventory Management: Iscussion UestionsDocument17 pagesInventory Management: Iscussion UestionssebastianNo ratings yet

- CH - 2 Inventory MGMTDocument23 pagesCH - 2 Inventory MGMTVartika AgarwalNo ratings yet

- Solve The Activity - Docx12Document3 pagesSolve The Activity - Docx12omar.chatti34No ratings yet

- Inventory Management, Supply Contracts and Risk PoolingDocument81 pagesInventory Management, Supply Contracts and Risk PoolingnaniagricoNo ratings yet

- Inventory ControlDocument12 pagesInventory ControlVikasNo ratings yet

- Scan Apr 29, 2019 PDFDocument17 pagesScan Apr 29, 2019 PDFVivek SinghNo ratings yet

- Chap 17Document35 pagesChap 17Binh DoNo ratings yet

- Inventory ManagementDocument8 pagesInventory ManagementMike Padilla IINo ratings yet

- Week 7-8 Inventory PlanningDocument68 pagesWeek 7-8 Inventory PlanningAbhinav GuptaNo ratings yet

- Inv NewDocument56 pagesInv NewPrasad GharatNo ratings yet

- Prof. (DR.) Sandeep Nemlekar: Phone # Email More Details On Youtube &Document30 pagesProf. (DR.) Sandeep Nemlekar: Phone # Email More Details On Youtube &smith awesomeNo ratings yet

- Inventory Theory.S1 Inventory Models: Flow, Inventory and TimeDocument4 pagesInventory Theory.S1 Inventory Models: Flow, Inventory and TimeJuvenal Espirito SantoNo ratings yet

- Title: Inventory Management Simulation Game For Services IndustryDocument1 pageTitle: Inventory Management Simulation Game For Services IndustrySohini DeyNo ratings yet

- Independent Demand SYSTEMS: Deterministic Model: by AnastasiaDocument40 pagesIndependent Demand SYSTEMS: Deterministic Model: by AnastasiaAraNo ratings yet

- Agarwal 2014Document5 pagesAgarwal 2014Yusuf Ali DanışNo ratings yet

- Erpetual vs. Eriodic Ystem: Feature Perpetual System Periodic SystemDocument1 pageErpetual vs. Eriodic Ystem: Feature Perpetual System Periodic SystemIris DescentNo ratings yet

- Inventory Management PPT Handout 76 SlidesDocument38 pagesInventory Management PPT Handout 76 Slidessnehashish gaurNo ratings yet

- Chap 12 SolnDocument13 pagesChap 12 SolnggleichgesinntenNo ratings yet

- Unit 3 Inventory Control '23Document11 pagesUnit 3 Inventory Control '23Karan DhiverNo ratings yet

- Dokumen - Tips Hansen MowenDocument31 pagesDokumen - Tips Hansen MowenImran Riaz MalikNo ratings yet

- AEC 4204-Agribusiness Management: Lecture 8: Agricultural Enterprise Selection and ManagementDocument26 pagesAEC 4204-Agribusiness Management: Lecture 8: Agricultural Enterprise Selection and ManagementRogers Soyekwo KingNo ratings yet

- Management of Inventory SystemsDocument14 pagesManagement of Inventory SystemsBiswanathMudiNo ratings yet

- IS Unit-1Document6 pagesIS Unit-1Kumuthaa IlangovanNo ratings yet

- (Revised) Inventory ManagementDocument54 pages(Revised) Inventory Managementjomarybrequillo20No ratings yet

- CH 12 - Managing Inventories in Supply ChainsDocument20 pagesCH 12 - Managing Inventories in Supply Chainsgeyb awayNo ratings yet

- Mds3 Ch23 Inventorymgmt Mar2012Document24 pagesMds3 Ch23 Inventorymgmt Mar2012Berchi TímeaNo ratings yet

- Inventory Management-IIDocument17 pagesInventory Management-IIShahrukh AzizNo ratings yet

- Economic Order Quantity Model: A Review: December 2014Document5 pagesEconomic Order Quantity Model: A Review: December 2014yovirolandNo ratings yet

- L5 InventoryDocument52 pagesL5 InventoryYến Hải ĐoànNo ratings yet

- Yale Top 10 Warehouse Operational MetricsDocument1 pageYale Top 10 Warehouse Operational MetricsHoseaNo ratings yet

- Chapter 15 - InventoryDocument7 pagesChapter 15 - InventoryKhairul Bashar Bhuiyan 1635167090No ratings yet

- Chap 014Document34 pagesChap 014Agung TriNo ratings yet

- Inventory Models: Provide Uninterrupted Service To Customers Without Any Delay in DeliveryDocument5 pagesInventory Models: Provide Uninterrupted Service To Customers Without Any Delay in DeliveryChelsea VisperasNo ratings yet

- Inventory Management: Answers To QuestionsDocument9 pagesInventory Management: Answers To Questionsjinu220No ratings yet

- Periodic VS Perpetual Inventory SystemDocument3 pagesPeriodic VS Perpetual Inventory SystemBea chuaNo ratings yet

- OM-Inv-session 29 & 30Document12 pagesOM-Inv-session 29 & 30Alok PandeyNo ratings yet

- Economic Cost OrderDocument28 pagesEconomic Cost OrderPiyam RazaNo ratings yet

- Unit 8 Inventory Models: StructureDocument19 pagesUnit 8 Inventory Models: StructureShah UzmaNo ratings yet

- ©the Mcgraw-Hill Companies, Inc., 2004Document35 pages©the Mcgraw-Hill Companies, Inc., 2004kate sultanNo ratings yet

- Chapter 7 - INVENTORY MANAGEMENTDocument11 pagesChapter 7 - INVENTORY MANAGEMENTLong Đoàn PhiNo ratings yet

- Inventory System PDFDocument27 pagesInventory System PDFthegreatNo ratings yet

- Chapter Map 5 Gigin Nopandra (20134033)Document1 pageChapter Map 5 Gigin Nopandra (20134033)Gigin NopandraNo ratings yet

- Hydraulic MachinesDocument9 pagesHydraulic MachinesPragyan Kumar PradhanNo ratings yet

- Vapor Absorption Refrigeration SystemDocument15 pagesVapor Absorption Refrigeration SystemPragyan Kumar PradhanNo ratings yet

- Study On EnzymesDocument21 pagesStudy On EnzymesPragyan Kumar PradhanNo ratings yet

- Expansion DeviceDocument9 pagesExpansion DevicePragyan Kumar PradhanNo ratings yet

- EvaporaterDocument9 pagesEvaporaterPragyan Kumar PradhanNo ratings yet

- Network Connection GuidelinesDocument1 pageNetwork Connection GuidelinesPragyan Kumar PradhanNo ratings yet

- Metal CastingsDocument24 pagesMetal CastingsPragyan Kumar PradhanNo ratings yet

- Lec 1Document10 pagesLec 1Pragyan Kumar PradhanNo ratings yet

- Independent: Le-Machine e The MinimizingDocument1 pageIndependent: Le-Machine e The MinimizingPragyan Kumar PradhanNo ratings yet

- Operation Management SemDocument1 pageOperation Management SemPragyan Kumar PradhanNo ratings yet

- Electron Beam Machining: Principle of EBMDocument4 pagesElectron Beam Machining: Principle of EBMPragyan Kumar PradhanNo ratings yet

- Assignment 4 Answer IEDocument6 pagesAssignment 4 Answer IEPragyan Kumar PradhanNo ratings yet