Professional Documents

Culture Documents

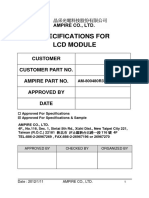

Specifications For LCD Module: Customer Customer Part No. Ampire Part No. Approved by Date

Uploaded by

Imran AshrafOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specifications For LCD Module: Customer Customer Part No. Ampire Part No. Approved by Date

Uploaded by

Imran AshrafCopyright:

Available Formats

SPECIFICATIONS FOR

LCD MODULE

CUSTOMER

CUSTOMER PART NO.

AMPIRE PART NO. AM-800480TTMQW-00H

APPROVED BY

DATE

Approved For Specifications

Approved For Specifications & Sample

AMPIRE CO., LTD.

2F., No.88, Sec. 1, Sintai 5th Rd., Sijhih City, Taipei County 221,

Taiwan (R.O.C.)台北縣汐止市新台五路一段 88 號 2 樓(東方科學園區 D 棟)

TEL:886-2-26967269 , FAX:886-2-26967196 or 26967270

APPROVED BY CHECKED BY ORGANIZED BY

Date : 2009/09/16 AMPIRE CO., LTD. 1

RECORD OF REVISION

Revision Date Page Contents Editor

2009/9/16 -- New Release Edward

Date : 2009/09/16 AMPIRE CO., LTD. 2

1. Features

6.2 inch module is a color active matrix thin film transistor (TFT) liquid crystal display

(LCD) that uses amorphous silicon TFT as a switching device. This model is

composed of a TFT LCD panel, a driving circuit and a backlight system. This TFT

LCD has a 6.2 (16:9) inch diagonally measured active display area with 800

horizontal by 480 vertical pixel resolutions.

(1) Construction: 6.2” a-Si TFT active matrix, White LED Backlight.

(2) Resolution (pixel): 800(R.G.B) X 480

(3) Number of the Colors : 262K colors ( R , G , B 6 bit digital each)

(4) LCD type : Transmissive , normally White

(5) Power Supply Voltage: 3.3V for logic voltage.

(7) Viewing Direction: 6 O’clock ( The direction it’s hard to be discolored )

(8) RoHS / Halogen Free Compliance.

2. PHYSICAL SPECIFICATIONS

Item Specifications unit

LCD size 6.2 inch (Diagonal)

Outline Dimension 155.2 x 88.2.0 x 5.0 (typ.) mm

Number of Pixel 800 RGB (H) x 480 (V) pixels

Pixel pitch 0.1719(H) x 0.1609(V) mm

Pixel arrangement RGB Vertical stripe

Display mode Normally white

Antiglare, Hard-Coating (3H) with

Surface treatment

EWV film

Weight 120 (typ.) g

Back-light Side-Light type

Power consumption (B/L system) 1.54 (max.) W

Date : 2009/09/16 AMPIRE CO., LTD. 3

3. ABSOLUTE MAX. RATINGS

3-1 Electrical Absolute Rating

3-1-1 TFT LCD Module

Values

Item Symbol UNIT Note

Min. Max.

VCC -0.3 6.0

VGH 0.3 40 GND=0

Power voltage VGL -20 0.3 V

AVDD 0.5 15 AGND=0

VCOM 0 6

Logic Signal Input Level VI -0.3 VCC+0.3 V

3-1-2 Back-Light Unit

Item Symbol Typ. Max. Unit Note

LED current IL 140 -- mA (1)(2)(3)

LED voltage VL 10.5 -- V (1)(2)(3)

Note

(1) Permanent damage may occur to the LCD module if beyond this specification.

Functional operation should be restricted to the conditions described under

normal operating conditions.

(2) Ta =25±2℃

(3) Test Condition: LED current 140mA. The LED lifetime could be decreased if

operating IL is larger than 140mA.

3-2 Environment Absolute Rating

Item Symbol Min. Max. Unit Note

Operating Temperature Topa -20 70 ℃

Storage Temperature Tstg -30 80 ℃

Date : 2009/09/16 AMPIRE CO., LTD. 4

4. ELECTRICAL CHARACTERISTICS

4-1 TFT LCD Module

Values

Item Symbol Unit Remark

MIN TYP MAX

VCC 3.0 3.3 3.6 V

VGH 12 15 23 V

Supply Voltage

VGL -12 -7 -5 V

AVDD 9.9 10 10.1 V

VCOM VCOMin -- 3.4 -- V

Input signal VIH 0.7VCC -- VCC Note (1)

voltage VIL 0 -- 0.3VCC

IDD -- 12.37 -- mA VCC=3.3V

AVDD=10V

Current of power IADD -- 13.599 -- mA

(Black)

supply

IGH -- 0.099 -- mA VGH=15V

IGL -- 0.371 -- mA VGL=-7V

Input level of

Vx AVDD/2- AVDD-0.1- V

V1~V5

Input level of

Vx 0.1- AVDD/2- V

V6~V10

Note 1: HSYNC, VSYNC, DE, Digital Data

Note 2: Be sure to apply the power voltage as the power sequence spec.

Note 3: DGND=AGND=0V

4-2 Backlight Unit

The backlight system is an edge-lighting type with 21 LED

The characteristics of the LED are shown in the following tables.

Item Symbol Min. Typ. Max. Unit Note

LED current IL -- 140 -- mA (2)

LED voltage VL -- 10.5 -- V

Operating LED

Hr 20,000 -- -- Hour (1)(2)

life time

Date : 2009/09/16 AMPIRE CO., LTD. 5

Note (1) LED life time (Hr) can be defined as the time in which it continues to operate

under the condition: Ta=25±3℃, typical IL value indicated in the above table

until the brightness becomes less than 50%.

Note (2) The “LED life time” is defined as the module brightness decrease to 50%

original brightness at Ta=25℃ and IL=140mA. The LED lifetime could be

decreased if operating IL is larger than 140mA. The constant current driving

method is suggested.

LED Light Bar Circuit

Date : 2009/09/16 AMPIRE CO., LTD. 6

Note (3) Suggested Schematic of LED Back-Light Driver

Suggested Schematic of LED Back-Light Driver

Date : 2009/09/16 AMPIRE CO., LTD. 7

5. Optical Specifications

5-1 Optical specification

Item Symbol Condition Min. Typ. Max. Unit Note

Contrast CR 480 600 -- (1)(2)

Rising Tr -- 2 4

Response

msec (1)(3)

time θ=0

Falling Tf -- 6 12

Normal

White luminance viewing (1)(4)

Yl 320 400 -- Cd/m2

(Center) angle (IL=120mA)

Color Wx 0.260 0.310 0.360

chromaticity White

(CIE1931) Wy 0.280 0.330 0.380

θL 65 75 --

Hor. (1)(4)

θR 65 75 --

Viewing

CR>10

angle

θU 60 70 --

Ver.

θD 60 70 --

Brightness uniformity Buni θ=0 70 -- -- % (5)(7)

Optima View

6 o’clock (6)

Direction

5-2 Measuring Condition

(1) Measuring surrounding : dark room

(2) LED current IL : 140mA

(3) Ambient temperature : 25±2℃

(4) 15min. warm-up time.

5-3 Measuring Equipment

(1) FPM520 of Westar Display technologies, INC., which utilized SR-3 for

Chromaticity and BM-5A for other optical characteristics.

(2) Measuring spot size: 20 ~ 21 mm

Date : 2009/09/16 AMPIRE CO., LTD. 8

Note (1) Definition of Viewing Angle :

Note (2) Definition of Contrast Ratio (CR) :

Measured at the center point of panel

Luminance with all pixels white

CR =

Luminance with all pixels black

Note (3) Definition of Response Time : Sum of Tr and Tf

Date : 2009/09/16 AMPIRE CO., LTD. 9

Note (4) Definition of optical measurement setup

Note (5) Definition of brightness uniformity

(Min Luminance of 9 points)

Luminance uniformity = X 100%

(Max Luminance of 9 points)

Note (6) Rubbing Direction (The different Rubbing Direction will cause the

different optimal view direction.

Note (7) Measured at the brightness of the panel when all terminals of LCD

panel are electrically open.

Date : 2009/09/16 AMPIRE CO., LTD. 10

6. INTERFACE

6-1 TFT LCD Module

CN2 (Input signal): FPC Down Connector, (FH28-60S-0.5SH (HIROSE), 60pin,

PITCH = 0.5mm)

Pin No. Symbol I/O Function

1 AGND P Analog Ground

2 AVDD P Analog Power

3 VCC P Digital Power

4 R0 I Red Data Input (LSB)

5 R1 I Red Data Input

6 R2 I Red Data Input

7 R3 I Red Data Input

8 R4 I Red Data Input

9 R5 I Red Data Input

10 R6 I Red Data Input

11 R7 I Red Data Input (MSB)

12 G0 I Green Data Input (LSB)

13 G1 I Green Data Input

14 G2 I Green Data Input

15 G3 I Green Data Input

16 G4 I Green Data Input

17 G5 I Green Data Input

18 G6 I Green Data Input

19 G7 I Green Data Input (MSB)

20 B0 I Blue Data Input (LSB)

21 B1 I Blue Data Input

22 B2 I Blue Data Input

23 B3 I Blue Data Input

Date : 2009/09/16 AMPIRE CO., LTD. 11

24 B4 I Blue Data Input

25 B5 I Blue Data Input

26 B6 I Blue Data Input

27 B7 I Blue Data Input (MSB)

28 DCLK I Clock input

29 DE I Data Enable signal

30 HSD I Horizontal sync input. Negative polarity.

31 VSD I Vertical sync input. Negative polarity

DE/SYNC mode select. normally pull high

32 MODE3 I H : DE mode

L : HSD/VSD mode

global reset pin.

33 RSTB I Active low to enter reset state. suggest to connecting

with an RC reset circuit for stability. normally pull high.

standby mode, normally pull high

STBYB="1",normal operation

34 STBYB I

STBYB="0",timming control, source driver will turn off,

all output are high-Z

Source right or left sequence control.

SHLR="L", shift left: last data=S1<-S2…S1200=first

35 SHLR I data

SHLR="H", shift right: first data=S1->SS2…S1200=last

data

36 VCC P Digital Power

gate up or down scan control.

37 UPDN I UPDN="L" , DOWN shift : G1->G2…->G480 ;

UPDN="H", UP shift: G1<-G2…<-G480

38 GND P Digital Ground

39 AGND P Analog Ground

40 AVDD P Analog Ground

41 VCOMin I For external VCOM DC input(Optional)

Dithering setting:

DITH="H" 6bit resolution (last 2 bits of input data

42 DITH I

truncated) (default setting)

DITH="L" 8bit resolution

Date : 2009/09/16 AMPIRE CO., LTD. 12

43 NC - Not connect

44 NC - Not connect

45 V10 P Gamma correction voltage reference

46 V9 P Gamma correction voltage reference

47 V8 P Gamma correction voltage reference

48 V7 P Gamma correction voltage reference

49 V6 P Gamma correction voltage reference

50 V5 P Gamma correction voltage reference

51 V4 P Gamma correction voltage reference

52 V3 P Gamma correction voltage reference

53 V2 P Gamma correction voltage reference

54 V1 P Gamma correction voltage reference

55 NC - Not connect

56 VGH P Positive Power for TFT

57 VCC P Digital Power

58 VGL P Negative Power for TFT

59 GND P Digital Ground

60 NC - Not connect

6-2 Backlight Unit

CN1 : LED Power Source (BHSR-02VS-1) or equivalent

Mating Connector : (SBHT-002T-P0.5) or equivalent

Pin No. Symbol Function

1 VL LED power supply (high voltage)

2 GL LED power supply (low voltage)

Date : 2009/09/16 AMPIRE CO., LTD. 13

7. INPUT SIGNAL :

7-1 AC Electrical Characteristics

Date : 2009/09/16 AMPIRE CO., LTD. 14

7-2 Timing Diagram of Interface Signal

Sampling clock timing

Horizontal display timing range

Date : 2009/09/16 AMPIRE CO., LTD. 15

Vertical timing

7-3 Power Sequence

Power On Sequence: VCC-> AVDD -> VGL -> VGH -> Data -> B/L

Power Off Sequence: B/L-> Data -> VGH -> VGL -> AVDD -> VCC

Notes: Data include R0~R7, G0~G7, B0~B7, HSD, VSD, DCLK, SHLR, UPDN, DE

MODE, RSTB, STBYB, SHLR, UPDN, DITH

Date : 2009/09/16 AMPIRE CO., LTD. 16

7-4 Gamma circuit

Suggested Gamma Circuit

Date : 2009/09/16 AMPIRE CO., LTD. 17

8. RELIABILITY TEST CONDITIONS

8-1 RELIABILITY

Item Test Conditions Note

High Temperature Storage Ta = 80℃ 240 hrs

Low Temperature Storage Ta = -30℃ 240 hrs

High Temperature Operation Ts = 70℃ 240 hrs

Low Temperature Operation Ta = -20℃ 240 hrs

High Temperature and High

Ta = +60℃, 90%RH 240 hrs

Humidity (operation)

Thermal Cycling Test

-30℃(30min) Æ +80℃(30min), 200cycles

(non operation)

Electrostatic Discharge ±200V,200pF(0Ω) 1 time/each terminal

1.Random:

1.04Grms, 5~500Hz, X/Y/Z,

30min/each direction

2. Sine:

Vibration

Freq. Range: 8~33.3Hz

Stoke: 1.3mm

Sweep: 2.9G, 33.3~400Hz

X/Z: 2hr, Y: 4hr, cyc: 15min

JIS C7021,

100G, 6ms, ±X, ±Y, ±Z

Shock A-10

3 time for each direction

(Condition A)

Random: 0.015G^2/Hz, 5~200Hz

Vibration (with carton) -6dB/Octave, 200~400Hz

XYZ each direction: 2hr

Height: 60cm

Drop (with carton) JIS Z0202

1 corner, 3 edges, 6 surfaces

Note: There is no display function NG issue occurred, all the cosmetic specification is

judged before the reliability stress.

Date : 2009/09/16 AMPIRE CO., LTD. 18

9. General Precautions

9-1 Use Restriction

This product is not authorized for use in life supporting systems, aircraft

navigation control systems, military systems and any other application where

performance failure could be life threatening or otherwise catastrophic.

9-2 Disassembling or Modification

Do not disassemble or modify the module. It may damage sensitive parts

inside LCD module, and may cause scratches or dust on the display. Ampire

does not warrant the module, if customers disassemble or modify the

module.

9-3 Breakage of LCD Panel

9.3.1. If LCD panel is broken and liquid crystal spills out, do not ingest or

inhale liquid crystal, and do not contact liquid crystal with skin.

9.3.2. If liquid crystal contacts mouth or eyes, rinse out with water

immediately.

9.3.3. If liquid crystal contacts skin or cloths, wash it off immediately with

alcohol and rinse thoroughly with water.

9.3.4. Handle carefully with chips of glass that may cause injury, when the

glass is broken.

9-4 Electric Shock

9.4.1. Disconnect power supply before handling LCD module.

9.4.2. Do not pull or fold the LED cable.

9.4.3. Do not touch the parts inside LCD modules and the fluorescent LED’s

connector or cables in order to prevent electric shock.

9-5 Absolute Maximum Ratings and Power Protection Circuit

9.5.1. Do not exceed the absolute maximum rating values, such as the

supply voltage variation, input voltage variation, variation in parts’

parameters, environmental temperature, etc., otherwise LCD module

may be damaged.

9.5.2. Please do not leave LCD module in the environment of high humidity

and high temperature for a long time.

9.5.3. It’s recommended to employ protection circuit for power supply.

Date : 2009/09/16 AMPIRE CO., LTD. 19

9-6 Operation

9.6.1 Do not touch, push or rub the polarizer with anything harder than HB

pencil lead.

9.6.2 Use fingerstalls of soft gloves in order to keep clean display quality,

when persons handle the LCD module for incoming inspection or

assembly.

9.6.3 When the surface is dusty, please wipe gently with absorbent cotton or

other soft material.

9.6.4 Wipe off saliva or water drops as soon as possible. If saliva or water

drops contact with polarizer for a long time, they may causes

deformation or color fading.

9.6.5 When cleaning the adhesives, please use absorbent cotton wetted with

a little petroleum benzine or other adequate solvent.

9-7 Mechanism

Please mount LCD module by using mounting holes arranged in four corners

tightly.

9-8 Static Electricity

9.8.1 Protection film must remove very slowly from the surface of LCD

module to prevent from electrostatic occurrence.

9.8.2. Because LCD module use CMOS-IC on circuit board and TFT-LCD

panel, it is very weak to electrostatic discharge. Please be careful with

electrostatic discharge.

Persons who handle the module should be grounded through adequate

methods.

9-9 Strong Light Exposure

The module shall not be exposed under strong light such as direct sunlight.

Otherwise, display characteristics may be changed.

9-10 Disposal

When disposing LCD module, obey the local environmental regulations.

9-11 Others

AMIPRE will provide one year warrantee for all products and three months

warrantee for all repairing products.

Date : 2009/09/16 AMPIRE CO., LTD. 20

10. OUTLINE DIMENSION

Date : 2009/09/16 AMPIRE CO., LTD. 21

You might also like

- CPT TFT-LCD Technical SpecificationDocument17 pagesCPT TFT-LCD Technical SpecificationBhadreshkumar SharmaNo ratings yet

- LCD Module User Manual GuideDocument31 pagesLCD Module User Manual Guideyenninh86No ratings yet

- Specification: Product Type: 7" LCD Nunmber: Module NumberDocument16 pagesSpecification: Product Type: 7" LCD Nunmber: Module NumberGonzalo RiveraNo ratings yet

- 2134 091834 LCD Module TC1602D 02WA0 16x2 STNDocument18 pages2134 091834 LCD Module TC1602D 02WA0 16x2 STNInseparatioNo ratings yet

- LCD Module User Manual: Vatronix Holdings LimitedDocument18 pagesLCD Module User Manual: Vatronix Holdings LimitedPadmajan YesodharanNo ratings yet

- RXL104067-B DatasheetDocument23 pagesRXL104067-B DatasheetChetan DadhaniyaNo ratings yet

- CLAA089NA0ACWDocument18 pagesCLAA089NA0ACWczypigNo ratings yet

- Mikroe 3904Document17 pagesMikroe 3904kushliakNo ratings yet

- 8.0 Inch IPS MIPI 800x1280 AML08021016-31DDocument13 pages8.0 Inch IPS MIPI 800x1280 AML08021016-31DcalvinkleinwuNo ratings yet

- Customer acceptance specifications for TX31D203VM0EAB LCD moduleDocument33 pagesCustomer acceptance specifications for TX31D203VM0EAB LCD moduleMIGUELNo ratings yet

- Specification and Pinout of 20x4 Character LCD ModuleDocument25 pagesSpecification and Pinout of 20x4 Character LCD ModuleDomenicoNo ratings yet

- Igbt - 2sp0115t2a0-Cm600dx-24t-1093489Document9 pagesIgbt - 2sp0115t2a0-Cm600dx-24t-1093489Hector Zenteno RodriguezNo ratings yet

- AGM 1602W-818 SpecificationDocument23 pagesAGM 1602W-818 SpecificationDaniel BauerNo ratings yet

- 33/4 DIGITS LCD DISPLAY, 3260-COUNT A/D FOR DMMDocument17 pages33/4 DIGITS LCD DISPLAY, 3260-COUNT A/D FOR DMMDyogo MondegoNo ratings yet

- TX26D207VM0AAA DatasheetDocument28 pagesTX26D207VM0AAA DatasheetMIGUELNo ratings yet

- A 4558 AmplifierDocument4 pagesA 4558 AmplifiercostelcnNo ratings yet

- Akira LCT-17HT LCDDocument186 pagesAkira LCT-17HT LCDRajaNo ratings yet

- CLAA170ES01Document21 pagesCLAA170ES01A.b. JethavaNo ratings yet

- 3001B-DIP8: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDocument4 pages3001B-DIP8: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersManuel MartinezNo ratings yet

- 13.3-inch LCD Panel SpecsDocument9 pages13.3-inch LCD Panel SpecsMarco KersulNo ratings yet

- Technical Data Sheet: Everlight Electronics Co., LTDDocument12 pagesTechnical Data Sheet: Everlight Electronics Co., LTDNhân Hồ ChíNo ratings yet

- 16 X 1 LCD DisplayDocument19 pages16 X 1 LCD DisplayKIYASHA CHANNELNo ratings yet

- Am 640480GTMQW T00HDocument18 pagesAm 640480GTMQW T00HHelderDosSantosNo ratings yet

- Rk055ahd091 CTGDocument17 pagesRk055ahd091 CTGEhab Anwar ElnagdyNo ratings yet

- TYBT1 ModuleDocument7 pagesTYBT1 ModuleRaya SadhukhanNo ratings yet

- AGM 24064A-801 LCD Module SpecificationDocument24 pagesAGM 24064A-801 LCD Module SpecificationrogeriocorreaNo ratings yet

- Electronic Tuning-Use FM Front End For Car Radio, Home StereosDocument8 pagesElectronic Tuning-Use FM Front End For Car Radio, Home StereosVeronicaGonzalezNo ratings yet

- Ambient Light SensorDocument16 pagesAmbient Light SensorashamanukondaNo ratings yet

- S1d15200doa or EquivalentDocument10 pagesS1d15200doa or EquivalentArduinoBeto RojasNo ratings yet

- Data Sheet 1SD536F2-5SNA0800N330100: Single-Channel SCALE Plug-and-Play IGBT DriverDocument6 pagesData Sheet 1SD536F2-5SNA0800N330100: Single-Channel SCALE Plug-and-Play IGBT Driverashkan emamiNo ratings yet

- 2scr502u3 HZG: V 30V I 0.5aDocument9 pages2scr502u3 HZG: V 30V I 0.5aprofe321No ratings yet

- Technical Specification for CPT TFT-LCD ModuleDocument20 pagesTechnical Specification for CPT TFT-LCD ModuleHoson AkNo ratings yet

- ITR8307-S17-TR8Document10 pagesITR8307-S17-TR8cointoinNo ratings yet

- Specifications for LCD ModuleDocument26 pagesSpecifications for LCD ModuleDaniel Martinez CollazoNo ratings yet

- 162E Series Displaytech SpecDocument23 pages162E Series Displaytech SpecrochaseletronicaNo ratings yet

- Mitsubishi - AA101TA12 - DatasheetDocument25 pagesMitsubishi - AA101TA12 - DatasheetaylinaykanNo ratings yet

- 74HCT32 Quad 2-Input OR GateDocument7 pages74HCT32 Quad 2-Input OR Gateholej18237No ratings yet

- Chunghwa Picture Tubes, Ltd. Technical Specification: Model: CLAA170EA07PDocument27 pagesChunghwa Picture Tubes, Ltd. Technical Specification: Model: CLAA170EA07PandymustopaNo ratings yet

- T370HW02 Ve - 20081113Document29 pagesT370HW02 Ve - 20081113Tran Van Thien0% (1)

- Remote Control Receiver Module SpecificationDocument7 pagesRemote Control Receiver Module SpecificationrNo ratings yet

- FM62429 Serial Data Control Dual Electronic Volume: SpecificationDocument10 pagesFM62429 Serial Data Control Dual Electronic Volume: Specificationfabio_sgNo ratings yet

- Agm 240128a 801Document17 pagesAgm 240128a 801MarceloVictorinoNo ratings yet

- MBT3904L NPN Transistor DatasheetDocument9 pagesMBT3904L NPN Transistor DatasheetJakub PilarskiNo ratings yet

- AM2837 V0.3 EngDocument9 pagesAM2837 V0.3 Engjuanito35731057No ratings yet

- Reference For IR1 IR2 SFP-OC48-IR2-GT Spec SheetDocument7 pagesReference For IR1 IR2 SFP-OC48-IR2-GT Spec SheetSai Krishna SNo ratings yet

- Disea Electronics 5Document23 pagesDisea Electronics 5RophildNo ratings yet

- QF132V1 00Document10 pagesQF132V1 00JlavieraNo ratings yet

- Ir2175 (S) & (PBF) : Linear Current Sensing IcDocument7 pagesIr2175 (S) & (PBF) : Linear Current Sensing IcDavid CoronadoNo ratings yet

- Agm 1602W-803Document18 pagesAgm 1602W-803Sebastian Rojas LepeNo ratings yet

- Dta123Yua Fra: OutlineDocument8 pagesDta123Yua Fra: Outlineedicruz10hotmailcomNo ratings yet

- Auo t370hw02 v1 Lcdpanel DatasheetDocument28 pagesAuo t370hw02 v1 Lcdpanel DatasheetIonescu CristinaNo ratings yet

- MMRF1016HDocument19 pagesMMRF1016HandreasmonNo ratings yet

- Iramx16up60b 2Document18 pagesIramx16up60b 2Odair SilvaNo ratings yet

- MBT3906LDocument8 pagesMBT3906Lby767ronNo ratings yet

- Transistor 2sc5866-208975Document8 pagesTransistor 2sc5866-208975Teguh Setio WawNo ratings yet

- Datasheet - CPDQC3V3C-HF RevD050204 - Esd ProtectionDocument5 pagesDatasheet - CPDQC3V3C-HF RevD050204 - Esd ProtectionAnhtuan HoangNo ratings yet

- HDM3224L-G: Dimensional Drawing 320 X240 Monochrome Graphics, White LED BacklightDocument1 pageHDM3224L-G: Dimensional Drawing 320 X240 Monochrome Graphics, White LED BacklightVallerynNo ratings yet

- US5881Document11 pagesUS5881Gustavo Iván VázquezNo ratings yet

- Stp130N6F7: N-Channel 60 V, 4.2 Mω Typ., 80 A Stripfet™ F7 Power Mosfet In A To-220 PackageDocument12 pagesStp130N6F7: N-Channel 60 V, 4.2 Mω Typ., 80 A Stripfet™ F7 Power Mosfet In A To-220 PackageOsmir MonteiroNo ratings yet

- Amplificatoare Audio PhilipsDocument55 pagesAmplificatoare Audio Philipsalex061989100% (3)

- Product Specification: Customer Date Approved by DateDocument30 pagesProduct Specification: Customer Date Approved by Datesluz2000No ratings yet

- Honors and Awards SID 2017Document6 pagesHonors and Awards SID 2017Imran AshrafNo ratings yet

- LCD Technology: - LCD Technology - Back Light Module System - Clean Room - Main BoardDocument75 pagesLCD Technology: - LCD Technology - Back Light Module System - Clean Room - Main BoardImran AshrafNo ratings yet

- CH 21Document19 pagesCH 21dilhanNo ratings yet

- LED TV Randomly Can't Power On, Randomly Power Shutdown and Randomly No DisplayDocument4 pagesLED TV Randomly Can't Power On, Randomly Power Shutdown and Randomly No Displayluiz carlos de souzaNo ratings yet

- G-IC-LEDDR-351-HSOP28-BD9261FP BD9261FP A 1 1 Rohm BD9261FP P1-P25 1 以下空白 1 1Document27 pagesG-IC-LEDDR-351-HSOP28-BD9261FP BD9261FP A 1 1 Rohm BD9261FP P1-P25 1 以下空白 1 1Imran AshrafNo ratings yet

- How An Smps Works: Rectifier StageDocument7 pagesHow An Smps Works: Rectifier StageImran AshrafNo ratings yet

- PNGRB - Electrical Safety Audit ChecklistDocument4 pagesPNGRB - Electrical Safety Audit ChecklistKritarth SrivastavNo ratings yet

- Micon Ic Check SheetDocument3 pagesMicon Ic Check SheetVenkatesh Subramanya0% (1)

- Fundamentals of Computers: Reema TharejaDocument39 pagesFundamentals of Computers: Reema TharejaYash SharmaNo ratings yet

- Standard Operating Procedure Operation of Power Plant: Punyam Manufacturing INCDocument2 pagesStandard Operating Procedure Operation of Power Plant: Punyam Manufacturing INCMAYMODERN STEEL0% (1)

- Jadwal Kuliah Semester Genap Tahun Akademik 2020/2021Document2 pagesJadwal Kuliah Semester Genap Tahun Akademik 2020/2021Andri YansyahNo ratings yet

- LogcatDocument39 pagesLogcatazarane38No ratings yet

- Dell dd9400Document5 pagesDell dd9400frpinaNo ratings yet

- Page 44Document1 pagePage 44Abhishek ShatagopachariNo ratings yet

- Throttle Linkage CheckDocument4 pagesThrottle Linkage Checkjbert55No ratings yet

- Flujometro SierraDocument52 pagesFlujometro SierraCapacitacion TodocatNo ratings yet

- Fee Structure Btech CseDocument1 pageFee Structure Btech Cseankit panwarNo ratings yet

- ABB RMU Tech SpecificationDocument4 pagesABB RMU Tech SpecificationJuned HamzaviNo ratings yet

- Protect Your Home From Thermal ExpansionDocument2 pagesProtect Your Home From Thermal ExpansionDenis HidayatullahNo ratings yet

- UniFi - Getting StartedDocument6 pagesUniFi - Getting StartedRachwandiNo ratings yet

- Detailed-Lesson-Plan Empowerment TechnologyDocument3 pagesDetailed-Lesson-Plan Empowerment TechnologykaryawarxNo ratings yet

- DGCA Form 107-01 UAS Operator Certificate Application Rev - 2 - 2Document2 pagesDGCA Form 107-01 UAS Operator Certificate Application Rev - 2 - 2BOsquad OfficialNo ratings yet

- Ingles Rainier 11Document14 pagesIngles Rainier 11Evelin RojasNo ratings yet

- Dana TE13/17 transmission maintenance manualDocument16 pagesDana TE13/17 transmission maintenance manualMohamed El Gamal100% (1)

- AirScale RNC Product DescriptionDocument46 pagesAirScale RNC Product Descriptionsamir YOUSIF100% (1)

- PythonToolkit User GuideDocument190 pagesPythonToolkit User GuideWilmer Arcos100% (9)

- Predicting Bottom-Hole Pressure For Gas and GasDocument2 pagesPredicting Bottom-Hole Pressure For Gas and GasLibya TripoliNo ratings yet

- 01fe19bme175 InternshipDocument28 pages01fe19bme175 InternshipVenugopal kulkarniNo ratings yet

- Unit V Processes and Operating SystemsDocument37 pagesUnit V Processes and Operating SystemsManikandan Annamalai100% (1)

- LogDocument2 pagesLogBormeyNo ratings yet

- Promoting Digital InclusivityDocument12 pagesPromoting Digital InclusivityFrench Mariee P. EdangNo ratings yet

- Cylinder Head - Install: Shutdown SISDocument4 pagesCylinder Head - Install: Shutdown SISReymundo Enrique Dominguez HernandezNo ratings yet

- Period Start Time Mrbts/Sbts Namelnbts Type Lnbts NameDocument24 pagesPeriod Start Time Mrbts/Sbts Namelnbts Type Lnbts NamedanielNo ratings yet

- Engl-112 Week 1-20Document34 pagesEngl-112 Week 1-20Sheena85% (52)

- Brochure2-Mobil Greases PDFDocument2 pagesBrochure2-Mobil Greases PDFPedro PerezNo ratings yet

- Kevin Chou ResumeDocument1 pageKevin Chou Resumeapi-472210762No ratings yet