Professional Documents

Culture Documents

Water in Oil-Filled High-Voltage Equipment Part II: Water Content As Physicochemical Tools For Insulation Condition Diagnostic

Uploaded by

Mohammed NouzalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water in Oil-Filled High-Voltage Equipment Part II: Water Content As Physicochemical Tools For Insulation Condition Diagnostic

Uploaded by

Mohammed NouzalCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/3259094

Water in oil-filled high-voltage equipment part II: Water content as

physicochemical tools for insulation condition diagnostic

Article in IEEE Electrical Insulation Magazine · October 2007

DOI: 10.1109/MEI.2007.4318270 · Source: IEEE Xplore

CITATIONS READS

19 503

2 authors, including:

Issouf Fofana

University of Québec in Chicoutimi

282 PUBLICATIONS 2,561 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Transformer oil reclamation by combining several strategies enhanced by the use of four adsorbents View project

CFD Modelling of power transformers View project

All content following this page was uploaded by Issouf Fofana on 29 November 2017.

The user has requested enhancement of the downloaded file.

F E A T U R E A R T I C L E

Water in Oil-Filled High-Voltage

Equipment Part II: Water Content as

Physicochemical Tools for Insulation

Condition Diagnostic

Key words: water content, water saturation limit, criteria of limiting state, diagnostics of electrical

equipment, residual life

Introduction V. G. Arakelian

I

n power equipment, such as transformers, switchgear, bush- The All-Russia Electrotechnical Institute, Moscow,

ings, cables, and their accessories, insulating liquid func-

tions as a heat-transfer fluid as well as a dielectric material. This

Russia

insulating fluid, commonly mineral oil, is used alone as electrical

insulation only in regions in which, by design, voltage stresses I. Fofana

are relatively low. A solid insulating material is used in regions in Université du Québec à Chicoutimi, Québec,

which voltage stresses are high, or in which a particular physical

configuration is needed. The solid insulation materials com-

Canada

monly used as wrapping and spacers are cellulose papers and

boards. In-service power equipment life/aging is mainly related

to the degradation of the insulation that is caused dominantly

by the thermal upgrading of the insulating paper, together with

the decomposition of the paper. The by-products are water and Our investigations show the advantage

other substances of partly polarizable and ionizable character.

Moisture, the number one enemy of power equipment, worsens of diverse methods for measuring

the dielectric properties and accelerates the aging of solid/liquid humidity in insulating liquids, and a

insulation. The Achilles heel of cellulose comes from its affinity

for water and oil degradation products. Therefore, it is important

variety of analytical expressions for

to know the condition, by means of suitable diagnostic tools, of calculating the condition of liquid/

the oil-impregnated paper used as primary insulation in power solid insulation systems.

equipment.

In the first part of our investigations [1], we examined the

current state of knowledge of the effect of water on paper and

liquid-insulating materials. We demonstrated that the scientific

representation of the states of water in insulating liquids has a

direct practical application as a diagnostic tool for electrical equip- materials, followed by a critical review of up-to-date water quan-

ment, at least for the dielectric properties of the insulation. tification methods. Based on the physicochemical criteria of the

The work presented in this second part of these investigations is limiting state discussed in the third section, this article proposes

divided into four sections. The first section deals with the influence some analytical expressions that can help electrical engineers

of water on the electrical characteristics of the oil/paper insulating monitor and/or diagnose oil-filled, high-voltage equipment.

September/October 2007 — Vol. 23, No. 5 0883-7554/07/$25/©2007IEEE 15

Influence of Water on the Electrical cally bound water occurring at equilibrium. This process of water

Characteristics of Insulating Materials removal takes place through a stage of dissolved water and is

Despite all its drawbacks, mineral insulating oil will continue accompanied not only by a decrease of dielectric losses, but also

to be used as an insulating liquid, as long as natural reserves of by an increase in the specific volumetric resistance.

petroleum are not depleted. Therefore, considerable attention is Generally, the substances having a low influence on the dielec-

still being given to this natural product. tric losses of oil exert a high influence on the dielectric losses of

oil-impregnated paper, and vice versa. Low-molecular peroxides,

A. Dielectric Losses and Electrical Conductivity acids, and other polar substances dissolved in oil, which practi-

cally do not influence the dielectric losses of oil, are adsorbed by

of Liquid Dielectrics paper and raise its dielectric losses. Substances forming colloids

Dielectric losses in insulating oil at power frequency are usu- in oil, which are the basic source of conductivity and dielectric

ally the result of the ionic and electrophoresis electrical conductiv- losses in oil, depict very low influence on the dielectric losses of

ity of the oil and its impurities. Hydrocarbons in oils (paraffins, paper. This is a confirmation of the above-mentioned water equi-

isoparaffins, naphthenes, cyclo-aromatics, and aromatics) are librium, in which the distribution of water in a paper-oil system

characterized by low dielectric losses. Thus, impurities (already goes through a state of intrinsic solution in oil.

present in unused oil or formed during its storage or operation)

are responsible for an increase in the dissipation factor.

It has been shown experimentally that dissolved water, even at B. Electric Strength of Liquid Dielectrics

high concentrations and at higher temperatures, does not increase The electric strength of liquid dielectrics is not directly related

dielectric losses [2]. Dissolved water in unused oil is in a molecular to specific conductivity or dielectric losses; but it strongly depends

state, not dissociated into ions; consequently it does not influence on the presence of impurities. Dissolved gases and compounds,

dielectric losses. Water in emulsion, contrary to dissolved water, with a low boiling point, play an essential role during breakdown,

increases the dielectric losses at the expense of electrophoresis reducing the electric strength of dielectric liquids. Polar com-

conductivity. This is due to the movement of charged or polarized pounds at the impurity level, forming intrinsic solutions in oil, do

micelles as emulsion water can be dissociated into ions. In used not strongly influence the electric strength. However, if they are in

oils, some amount of bound water is added due to interactions the colloidal or emulsion state, the low-boiling substances greatly

with the resinous oxidation aging by-products, including salts of influence the electric strength of oil. This is probably related to

naphthenic acids among others. In the colloidal polar particles their boiling-off with the formation of gas cavities [2].

of oil, water connected to them is solubilized. Therefore, bound Water has a strong influence on electric strength. In a wide

water markedly increases dielectric losses. range of relative humidity, the electric strength of clean insulat-

Changes in the dielectric losses of oil have been monitored ing mineral oil, for temperatures higher than 0°C, falls practically

during vacuum drying [2] (Figure 1). The first zone is probably exponentially as relative humidity ϕ increases up to 1:

related to the removal of emulsion water. This leads to a sharp

decrease in dielectric losses. The second and third zones (this Ubr = 93 e –ϕ, for ϕ ≤ 1. (1)

division is given in [2]) are zones of low influence on dielectric

losses. These are caused by the removal of dissolved and physi- It remains at a constant level of 20–25 kV in a small range of

supersaturated states (Figure 2) [2], [3]. A similar relationship is

Figure 1. Dissipation factor of oil (at 90°C) versus duration of Figure 2. Electric strength of insulating liquids versus relative

vacuum drying process for various transformer oils. humidity.

16 IEEE Electrical Insulation Magazine

observed for more simple chemical analogs of hydrocarbons, the describe, for engineering use, the influence of this most important

alkylbenzene oils: general parameter of liquid dielectrics.

Ubr = 102 e –ϕ – 14.5 ϕ , for ϕ ≤ 1. (2) C. Electric Characteristics of Paper

The adsorption of polar components results in a change in the

However, this is only a rough approximation. It is difficult to electrophysical characteristics of paper, particularly, in the in-

rely on this relationship because the deviation in values of electric crease of its dielectric losses. The dependencies of the dissipation

strength is large [4]. This deviation depends highly on the nature factor at 80°C and the dielectric permittivity of oil-impregnated

of the insulating liquids and for mineral oil, on its structural-group paper εr with water content W, in dry weight percentage, are ex-

composition. Due to the possible formation of charged micelles pressed by these (generalized) equations [2]:

and conducting bridges, water has more influence on the break-

down of oil when it is in the colloidal state. At low-water contents tgδ = 0.0021 + 0.0083 W 2, (3)

in clean unused mineral oil, electric strength decreases slightly as

humidity increases. But, at a relative humidity of between 10 to εr = 3.8 + 0.41W. (4)

15%, it decreases more markedly as an exponential curve.

The influence of water on electric strength during vacuum dry- The presence of moisture in oil-impregnated paper also influ-

ing is illustrated in Figure 3 [2]. The first zone is caused by the ences the inception of partial discharges (PD): the resistance of

removal of emulsion water and characterized by a sharp increase paper to PD decreases with moisture uptake [5].

in electric strength. The second and third zones, zones of weak

dependence on the electric strength, close to 60 kV in a standard Water Quantification Methods and

discharge gap, are characterized by the removal of both physically

Their Potentialities

bound and dissolved water at equilibrium.

Considering the dependencies presented in Figures 1 and 3, it

is possible to conclude that bound water can reduce the electric A. Physical Methods

strength of oil by approximately 40% and increase the dissipa- ASTM Method D 4056-01 [6] is the standard method for evalu-

tion factor by a factor of 2 or 3. Emulsion water can reduce the ating the solubility of water in hydrocarbons and aliphatic ester

electric strength approximately by a factor of 4, and increase the lubricants. Formulas given in the document, allow the calculation

dissipation factor by a factor of 1.5. of water concentration up to 1000 mg/kg in hydrocarbons and up

The influence of humidity on the dielectric strength of insulat- to 30,000 mg/kg in oxygen-containing compounds, as a function

ing liquids can be studied with the use of a more general parameter, of density, refraction, and molecular weight. ASTM Method D

i.e., relative humidity. It is standardized, as a rule, by the different 1315-63 (1973) describes the direct determination of water in

contents of water at a given temperature. However, the influence insulating oil by extraction.

of temperature is also very specific and depends on water content

[2]. Therefore, despite an abundance of experimental data, it has B. Chemical Methods

been impossible, until now, to generalize and to mathematically These methods involve the use of specific reagents such as so-

dium, hydrides, carbides, or azides of metals (Mg3N2). This group

of reagents interacts with water, forming gaseous components,

the volume of which can be measured.

2H2O + 2Na = 2NaOH + H2,

2H2O + CaH2 = Ca(OH)2 + 2H2,

2H2O + CaC2 = Ca(OH)2 + C2H2,

6H2O + Mg3N2 = 3Mg(OH)2 + 2NH3,

4H2O + LiAlD4 = Al(OH)3 + LiOH + 4HD.

All these methods (reactions) allow determining the dissolved

water. The use of calcium hydride gives the greatest effect: for

one mole of water, one mole of hydrogen is formed. This method

has been widely used for some time and standardized in Russia

(GOST 7822-75 [7]), but it is practically not used anymore. The

sensitivity is about 10 mg/kg, which is not acceptable for engi-

neering purposes. The use of the lithium-aluminum-deuterium

compound presents the advantage of using mass-spectrometer

detection [8].

Currently, the most widely used technique is the Karl Fischer

Figure 3. Electric strength of oil versus duration of vacuum (KF) method. This method is based on the chemical oxidation-

drying. I, II, and III zones. reduction reaction of iodine with sulfur dioxide in the presence

September/October 2007 — Vol. 23, No. 5 17

of water and in an excess of pyridine. The basic chemical reac- ity detector before hydrocarbons C4. In a two-channel recording,

tion is: the water peak appears as the fourth peak in the chromatogram of

the simple gases, after hydrogen, oxygen, and nitrogen. The water

H2O + I2 + SO2 = 2HI + SO3. peak is asymmetrical, and its asymmetry increases with the water

content of the oil. One of the reasons is the nonlinearity of the iso-

With volumetric titration, iodine is added as a titrant. The therms of adsorption of water on Porapack N. Another reason, and

method uses an automatic titrator [9]. With coulometric titration, probably the most important one, is the large amount of extracted

iodine is generated electrochemically by anodic oxidation on a water and the inadequate gas connections for the analysis of such

generating electrode. As long as there is water, generated iodine a polar compound. However, the integration system easily copes

will react chemically with it. Therefore the amount of electricity with the processing of asymmetrical peaks, and it is not a handicap

generated is a direct measure of the water content. The method for the quantitative calculation of water content. The advantage of

provides a determination from 2 to 100 mg/kg. Coulometric this method is that data on water content appear simultaneously

titration is performed with commercial instruments and is stan- with those of diagnostic gases. The detection limit is less than 1

dardized as IEC Standard 60814 [10] and ASTM Method D 1533 mg/kg; but, the upper limit is probably limited by the design of

[11]. IEC 814 (1985) is used for new and used insulating liquids. the extraction system. As the water content calculated in micro-

Most commercial instruments and chemicals are suitable for this liters of water vapor per liter of oil is very high, a water content

analysis. of 1 mg/kg corresponds approximately to 1000 µl/l.

Both the Karl Fischer and the hydride calcium methods give For the gas chromatographic determination of water content

results that are too high due to the reaction with hydroperoxides, as an independent task, it is necessary to achieve a symmetric

acids, and other impurities [12]. The authors in [12] consider peak of water first. For this purpose, it is necessary to use a

that the Karl Fisher and hydride calcium methods involve the column filled with Porapack Q and up to 10% of PEG, with an

determination of not only dissolved water but also of bound and average molecular weight of 1000 (PEG-1000), and to install all

emulsion waters. Authors in [13] consider that GOST 7822-75 gas connections as water vapor inlets in a thermostat at a higher

and IEC 60814 determine dissolved and emulsion waters, but not temperature. We are using the automatic analysis system for water

bound water. In our opinion, the Karl Fischer reagent is a pow- in insulating liquids shown in Figure 4.

erful means of destroying bound water. Consequently, it should The conditions for the analysis are: a column of 180 cm × 1/8

be considered as a method for the determination of total water in., filled with Porapack Q of 80 to 100 mesh and 10% of PEG-

content, with due regard for its reaction with peroxides and other 1000, argon carrier-gas at 20 ml/minute, a thermal conductivity

impurities. Borsi [14] shares the same opinion, specifying that detector, a detector temperature of 150°C, a temperature of the

the Karl Fischer method determines both dissolved and chemi- column and extraction system of 120°C. The extraction time of

cally bound water. water vapor is 60 to 80 seconds; contact time (intensive mass-

exchange in a thin layer) is 2 to 3 seconds. The retention time of

C. Chromatographic Methods the symmetric peak of water is 3 to 3.5 minutes. The cycle for the

It is likely that direct injection of an insulating oil sample into analysis is 6 minutes. The detection limit is 0.2 mg/kg. The repeat-

the injection port of a chromatograph at 250 to 300°C will detect ability of results is 4%. Figure 5 shows a chromatogram for the

all the water contained in this sample, regardless of its state. This

is generally achieved with a precolumn to separate the oil. A 2.5

cm × 3 mm precolumn, filled with a polymeric packing material,

allows the collection of up to 0.6 ml of insulating oil and the analy-

sis of up to 6 oil samples without forming asymmetrical peaks of

water on the chromatogram after 2 minutes. This is performed at a

helium flow rate of 25 ml/minute, in a 2 m × 3 mm column filled

with 15% of PEGA on “Polysorb-1”, at an injection temperature

of 180°C, with a column and thermoconductivity detector tem-

perature of 120°C, and for an injected sample volume of 100 µl.

It is possible to raise the injection temperature to be sure that all

the water in the oil sample is analyzed. However, it is impossible

to use sample syringes directly, and it is necessary to replace the

precolumn or purge it at high temperature.

Another way to determine water content in insulating oils is

based on its preliminary extraction in a gas phase and its determi-

nation by chromatography or coulometry. The amount of extracted

water will depend on the extraction conditions.

Extraction of water also takes place during the extraction of Figure 4. Automatic gas chromatographic analysis of insulating

gases from transformer oil for the purpose of their chromatograph- oils for water content: 1 - small three-way valve for installing

ic analysis. In the automatic device with dynamic thermovacuum the oil syringe; 2, filter; 3, measured vessel; 4, device for the

extraction of gases [15], water is detected in the thermal conductiv- thermovacuum extraction of gases and water.

18 IEEE Electrical Insulation Magazine

water content in insulating oil. Calibration is done using a solution the insulating liquid, only the thin-film transducers are suitable.

of water in mineral oil prepared with the help of ultrasound. Also, it is necessary to recognize that there is no reliable method

The method of calibration influences the results; the method for determining dissolved water.

determines the absolute water content. As measures for intensive

mass-exchange and linear isotherms of water content (as we shall F. Determination of Water in Layered Dielectrics

see later) are developed, the method provides correct results using IEC Standard 60733 [18] describes a method for the deter-

constant calibration factors in all ranges of concentrations. mination of humidity, not only in insulating oils but also in oil-

impregnated paper and cardboard. The method can determine

D. Sensor Controls water in oil-impregnated paper and cardboard in a range of 0.1

Nowadays, there is an increasing interest in using transformer to 20 % by weight. The basis for this method is the Karl Fischer

monitoring systems. One of the key variables to be monitored titration. The use of the Karl Fischer titration for the analysis of

is moisture content in the oil, as moisture is recognized to be water in paper shows the capacity of the method to determine

harmful to the insulation. Moisture in oil measurements using bound water in oil indirectly, but with accuracy.

thin film capacitance sensors have been available for some time

[16], [17]. The development of these sensor systems reacting to Physicochemical Criteria of the Limit State

moisture has reached such a level that it is now possible to use

them without endless checking and recalibration. The thin-film For diagnostic purposes, it is necessary to have a criterion for

transducers work over a wide range of relative humidity, and they the limiting state for decision-makings concerning the mainte-

are directly dependent on dissolved water or water partial pressure. nance and the residual life of power equipment. For the reliability

The transducers cannot react with other states of water. of diagnostic actions, legal documents should be submitted; a

The main advantage of sensor systems is the possibility of report on the normative and criterion parameters [19]. The norma-

using them for monitoring. Sensors are calibrated with water tive parameters — the basic technical requirements of technical

vapor and attached directly onto operating equipment. Usually, and design documentation — are intended for the qualification of

the humidity transducer is combined with the temperature trans- the equipment condition as either serviceable or faulty.

ducer. Thus, the sensors will give information about the relative Criterion parameters [19] focus on the requirements describ-

humidity and temperature of the oil in a continuous mode that ing the equipment in terms of its ability to perform its functions,

provides a way of controlling humidity and, therefore, the electric as efficient, partly efficient or disabled. Criteria of the limiting

characteristics of the solid insulation. state are the quantitative characteristics of a limiting state, i.e.,

a condition in which further operation is not acceptable or not

E. Correlation Between Methods used to Quantify efficient.

Water in Dielectric Liquids The electric characteristics should be ensured during all ser-

Each of the above listed methods has specific features in rela- vice operation. They are the critical parameters. By comparison,

tion to the complex water/insulating oil system. Therefore, it is the physicochemical characteristics are not as critical in service

not surprising that the correlation between these methods is poor; [20]. The oil characteristics may vary widely. These variations

it should be so. It is necessary to define what is expected from are not a reason to remove the equipment from service. When

the analysis of water in oil. For the determination of total water switching the equipment off for other reasons, the differences in

content, probably only the method of direct injection of oil at high the physicochemical characteristics of the oil, as compared to the

temperature is reliable. The Karl Fischer method will determine normative parameters, will serve as justification for replacing or

all the water present in unused insulating liquids and will prob- regenerating the oil. Actually, from the long list of physicochemi-

ably overestimate it because of impurities. Gas chromatographic cal parameters, only two can be considered as critical parameters.

analysis with the dynamic thermovacuum extraction system will These are the partial pressure of the gases and water for sealed

provide correct determination of all water except chemically electrical equipment, and the humidity of the solid insulation. The

bound water. For the determination of relative humidity above latter is measured as paper moisture content, dissipation factor

or conductivity.

Normalized water contents in oil are meaningless because

equilibrium conditions change with temperature. The same value

of moisture in oil can correspond to either a satisfactory or an

unsatisfactory condition of paper. For example, critical values

for moisture in paper used in capacitors are related to critical PD

inception levels [21]. With the current technology of paper drying

(at 120°C, down to a residual pressure of 1 mbar), the residual

moisture of paper in the capacitor is one thousandth of a percent.

At W < 0.5 %, the critical level of PD appearance, Ecr, is reduced

by 10%, at W = 3% by a factor of 2. At W > 3% the moisture in

the solid insulation, as indicated in Table 1, corresponds to filling

Figure 5. Chromatogram for the analysis of water in mineral a monolayer, which should be considered as not acceptable.

oil. Acceptance criterion values are given in Table 1.

September/October 2007 — Vol. 23, No. 5 19

reached because time constants are very long. Moisture diffusion

Table 1. Criteria of limiting state for physicochemical diagnostics based on

time for 1 mm-thick oil-impregnated pressboard is 6 hours at 70°C

water content in solid insulation.

and 333 hours at 20°C [24].

Capacitors Other equipments Diagnostics based on water content consist of determining the

Paper humidity, %, maximum 3 4 moisture content of the solid insulation, which can be calculated

Dissipation factor, %, maximum 1.6

from the partial pressure of water (p) and temperature (t) (5) [1],

[2] or directly from the relative humidity (ϕ) above the insulating

Specific volumetric resistance, Ω.m, minimum 2⋅109 liquid (6) [1], [2]. The terms A, B, h, q, n, and m are defined in

(12) and (13) and Tables 6 and 7 in Part 1 [1]. These parameters

are directly related to dissolved water.

W = A e –B t p h + q t, (5)

W = (4.61 + lnϕ)/(n – mϕ). (6)

Diagnostics Based on Water Analysis

There are two ways of obtaining data about moisture in the

A. Calculation of the Humidity Content liquid insulation of operating equipment: by monitoring the

of Solid Insulation relative humidity1 and temperature, or by laboratory analysis of

Time domain spectroscopy or frequency domain spectroscopy oil samples. The laboratory analysis can be performed by gas

techniques are used by power utilities for assessment of power chromatography, the Karl Fischer method, or with a humidity

transformer insulation wetness [22], [23]. For accurate results, transducer.

the transformer has first to be held at a constant temperature for

several days [22]. Otherwise, the most effective use of these

techniques is for trending purposes only and not for an indication B. Use of Transducers on the Equipment

of absolute insulation wetness. The humidity of insulating oil in operating equipment can

Moisture equilibrium characteristics between oil and paper be measured with a permanently installed, thin-film transducer,

insulation are well established and often used [24], [25]. Moisture providing relative humidity values calibrated with water vapor

in paper can be determined from the moisture measured in oil [16], [17]. The values of ϕ and t thus obtained can be directly used

in those periods when the moisture in oil has attained its steady for the calculation of the characteristics of paper as the humidity

state [25], [26]. Thermodynamically, equilibrium is reached when transducer provides only the relative humidity responsible for the

macroscopic observables parameters (pressure, temperature, etc.) humidity in the solid insulation (6). Using (5), the partial pres-

have ceased changing with time [26]. Water migration/dynamics sure of water vapor at saturation above pure water is described

between the paper and oil are well-known to be a slow process. by the equation:

So even with a constant temperature, a moisture steady state/

equilibrium requires a long time to be attained. In addition, trans- ln(ps) = 8.0589 – 1729.9875/(t + 233.856), (7)

former load usually varies, and ambient temperature describes

daily cycles, so steady state (thermodynamic equilibrium) is where ps (in mmHg at temperatures higher than 0°C ) is calculated

never completely attained. This is particularly true in transform- from the reading of the temperature transducer. The water partial

ers that have load profiles which are cyclical and have periods pressure (in mmHg) is calculated from the combined reading of

of rapid change. the transducer:

Nevertheless, a local thermodynamic equilibrium (LTE) can

occur. This happens when the macroscopic observables are vary- p = ϕ10 (8.0589 – 1729.9875)/(t + 233.856). (8)

ing in space and time, but so slowly that, for any point, one can

assume thermodynamic equilibrium in some neighborhood about It is necessary to install the transducer in the upper, hotter layers

that point [27]. Therefore, LTE can take place when a transformer of the oil; but the temperature of paper is always higher. If this

operates at a constant load for a sufficient time. Equilibrium dia- difference is known as a function of loading and oil temperature,

grams, therefore, can be used provided their validity is limited to it should be used for recalculating the relative humidity and partial

areas with LTE. However, at low temperatures, LTE are hardly pressure. A local temperature rise will raise the local partial pres-

sure of water, the solubility of oil, and the relative humidity. As

shown previously, this will increase the concentration of dissolved

water due to the dissolution of a part of the dispersed and bound

water. As there is no direct communication between the transducer

and paper through a gas space, equilibrium of partial pressures is

A transducer placed in oil, but calibrated from vapor water in

1

impossible. In a stationary mode at constant temperature, a static

air, provides values of relative humidity of a gas phase at equi- equilibrium will take place and the concentration of dissolved

librium, even though the gas phase is not present. water will become identical in different temperature zones, despite

20 IEEE Electrical Insulation Magazine

the complicated moisture dynamics in oil-impregnated paper. For C ϕ A/B

oil around the transducer (9): H/H* = –––––––––––– (14)

1+ (C–1) ϕ ABϕ

p = K cH2O for an isotherm t = toil, (9)

which, with a certain combination of coefficients, allows the de-

and for oil around paper: scription of all the variations of water content isotherms: direct,

convex, concave, and S-shaped. Coefficient C varies from 0 to 1.

Coefficients A and B should be positive and less than the estab-

p’ = K’ cH2O for an isotherm t = tpaper (10)

lished limit. Their ratio determines the slope of an S-shaped curve.

When C = 1 and A = B, the relationship becomes linear. The values

thus: for coefficients A, B, and C shown in Table 2 are calculated from

the relative humidity values found in Table 4 Part 1 [1].

p’/K’ = p/K

(11) The 60°C isotherm from (14) with the above chosen coeffi-

cients correlates well with experimental results. The isotherm at

Taking into account that Henry’s factor (K) is equal to the ratio 20°C does not, and for the coefficients we have preferred the data

of saturation pressure to solubility (1[a]) in Part 1 [1], it yields: obtained at relative humidities of 0.2 and 0.5. As with temperature

rise, the isotherm should be straightened, the coefficient C should

be close to 1, and coefficients A and B should become closer.

p’ c*H2O’ / pH’ = p c*H2O / pH,

For synchronizing coefficients A and B, their ratio is used. The

A/B ratio should not exceed 1. To provide the specified bound-

ϕ’ = ϕ c*H2O / c*H2O’, (12)

ary values of the coefficients, it is necessary to use the following

functions varying linearly with temperature t in °C, using values

where values related to paper temperature are indicated by a prime. given in Table 2:

Water solubility values in mineral oil at different temperatures

(permanent characteristic for a given grade of oil, against water ln(B / (20 – B)) = – 2.0904 + 0.03808 t,

saturation limit) are obtained from Figure 7 of Part 1 [1], (with ln(C / (1 – C)) = – 0.97097 + 0.02622 t, (15)

the tolerance which will be leveled due to ratio) as: ln(A/B / (1 – A/B)) = – 0.85458 + 0.02742 t.

ln(c*H2O ) = 7.33 – 1521.3 /(t + 233.856). (13) Expression (14) significantly deforms the initial area up to ϕ

= 0.2 between 10 and 35°C and overestimates it. For this range,

Water vapor pressure at a given paper temperature is obtained we shall take advantage of the Langmuir equation:

from (8) for ϕ’ and t = tpaper, then inserted into (5) and (6).

H/H* = N ϕ/( M + ϕ). (16)

C. Use of Transducer in the Laboratory Using data from (14) for relative air humidities of 0.2 and 0.3,

Data necessary to calculate paper humidity can be obtained the relationship of factors N and M with temperature t in °C is:

by directly measuring the relative humidity of an oil sample

with a transducer, at the temperature corresponding to the paper N = 1.147 – 0.025 t. (17)

temperature in the equipment, with the subsequent calculation M = 0.032 + 0.003 t.

of partial pressure from (8), and paper humidity W from (5) and

(6). In this case, it is not necessary to use otherwise unreliable Expressions (14) and (15) (for ϕ ≥ 0.2) and equations (16) and

solubility data. In this way, the task of calculating W can be solved (17) (for ϕ < 0.2 and t < 35°C) allow us to calculate the relative

without approximation. humidity of oils between 10 and 120°C (Figure 6), and to select

values of relative humidities ϕ corresponding to the values H

D. Use of Other Humidity-in-Oil Data determined by analysis, taking into account the water saturation

from Laboratory Investigations limit H* [1]:

Humidity (H) can be obtained from the laboratory analysis of

oil by chromatography or by the Karl Fischer method. For diag- ln H* = 6.41 – 1217 / (t + 233.856) (17a)

nostic purposes, it is necessary to determine the relative humidity

of air at equilibrium ϕ. Converting H into ϕ is possible only with

water content isotherms (similar to those in Figure 8 of Part 1 [1]) Table 2. Parameters A, B, and C depicted in (14) for mineral oil.

at all operating temperatures. A B C A/B

The values available at 23 and 60°C, shown in Table 4 of Part 1

23°C 0.43 1.15 0.3 0.3739

[1], can be used for the analytical representation of isotherms. By

analogy with the adsorption isotherms of Lengmure and Brunauer- 60°C 10.5 12.2 0.8 0.8607

Emmett-Teller [28], the correlation can be expressed as:

September/October 2007 — Vol. 23, No. 5 21

Table 3. Empirical factors for calculating the dissipation factor and specific

resistance of paper using (18) and (19).

Cellulose material

Cable Paper Capacitor paper

Coefficients “K-120” “K-2-10”

p 2.68 3.8

q 6 7

r 1.85 2.3

s 2.7.105 1.4.106

h 5800 5600

n 2.8 2.3

m 0.1 0.03

d 0.8 1

Figure 6. Relative water content isotherms of mineral oil,

computed from (14)–(17).

A humidity/temperature transducer permanently installed on

the equipment will give direct information on a developing situa-

tion. In its absence, the task can be solved by using the laboratory

The partial pressure of water is calculated from (8) and the

analysis of oil-water content.

paper humidity from (5) and (6).

The total amount of water G (in kg) in a sealed apparatus is the

amount of water in the solid insulation (paper) Gp, the transformer

E. Calculation of the Electric Characteristics oil, Goil, and the gas space Gg:

of Paper

The dissipation factor and specific volumetric resistance of G = Goil + Gp + Gg = 10–3HQoil + 10WQp + 10–3αVg, (20)

paper at a given level of paper humidity W (5) and (6) are calcu-

lated [2] using equations: where the value of the oil water content H (in mg/kg) is obtained

by analysis (GC, KF), or calculated from the relative humidity

tg δ = ( p + q W r ) exp (− 2700 / T ), (18) (obtained from a transducer and (14) or (16) and water saturation

limit (17a), [1], at the temperature of measurement. Humidity

ρv = s exp [ h / T − n ( W − m )d], (19) of the solid insulation W (in %) is calculated from (5) or (6),

the weight of transformer oil Qoil and paper Qp, in tons, and the

where tg δ is in absolute units, ρv in Ω × m, W in %, T is the volume of the gas space Vg, in m3. The humidity of the gas above

temperature of paper, in K; p, q, r, s, h, n, m, d are the tabulated the transformer oil α (in g/m3) is derived from the partial pressure

data from Table 3. [in mm Hg, (8)], as:

F. Oil Temperature Acceptable Limits Computation α = 0.98529 pH2O, (21)

From the obtained value of oil humidity, it is possible not only

to calculate the values of paper humidity, dissipation factor and or from the relative humidity and temperature, using hygrometric

specific conductivity, but also to determine the lower acceptable tables.

limit of oil temperature. The notion of an acceptable temperature From the calculated total amount of water in the equipment,

of oil arises in relation with the redistribution of gases and water one can determine the paper humidity, the humidity of the oil and

under the action of temperature between two or three phases of of the gas space at equilibrium at all operating temperatures in an

the electrical equipment insulating system: gas, liquid, and solid. iterative way. Other parameters related to humidity are determined

The change of temperature of the oil because of changes of load using (18) and (19).

or ambient temperature can result in the adverse redistribution of

water regarding the achievement of the limiting state for the solid G. Residual Life Prediction

insulation humidity. The estimation of an acceptable lower limit Expression (20) for the equilibrium of water is the basis for the

of oil temperature based on the analysis of humidity is especially determination of residual life. Assuming that the total amount of

important after repeated operation start-ups of cold equipment. water in electrotechnical equipment increases continuously and

Before being energized, the equipment should be warmed-up to linearly, neither paper humidity nor dissipation factor, nor specific

the allowable lower limit of temperature calculated above. resistance will have a linear relationship with temperature, which

22 IEEE Electrical Insulation Magazine

makes the calculation of residual life directly from these param-

eters impossible. Therefore, at operation start-up, it is necessary

to calculate the total amount of water in the equipment from the [3] F. Ishi and M. Ueba. Trans. IEE Pap. no. 3, part A, pp. 154–158,

results of the analysis of humidity in oil, and to use it as a starting 1972.

reading point: ΣGbeg. Then, it is necessary to calculate the limiting [4] I. Fofana, H. Borsi, E. Gochenbach. “Fundamental investigation on

values of humidity, dissipation factor, and specific resistance at all some transformer liquids under various outdoor conditions,” IEEE

operating temperatures and the total amount of water in the equip- Trans. Dielec. Elect. Insul., , vol..8, no.6, pp. 1040–1047, 2001.

[5] S. Okabe, M. Koto, Y. Fukuda, Y. Hayashi, T. Nara, and K. Taka-

ment in the limiting state. Then, from the values obtained in the

hashi, “A study on the deterioration characteristics of power capaci-

limiting state, the most efficient and proven final value has been tors with oil-impregnated paper,” Elect. Eng. Jpn., vol. 115, no. 8,

chosen: ΣGend. From the water content (Gτ) accumulated during pp. 1–11, 1995.

time τ between present time and the beginning of operation in [6] ASTM D4056-01, Replaced by ASTM D4056-01(2006), Standard

years, calculated from the analysis of oil humidity in service, the Test Method for Estimation of Solubility of Water in Hydrocarbon

residual life rres, expressed in material (accumulation of water), and Aliphatic Ester Lubricants, Aug 2001.

in percentage, is: [7] GOST 7822-75 Oils petroleum: A method of determination of the

content of dissolved water (in Russian), 1975.

rres = 100 (ΣGend – ΣGτ)/(ΣGend – ΣGbeg), (22) [8] L. Szepes, K. Torkos, R. Dobo and A.Szekely, “A new analytical

method for the determination of the water content of transformer

oils,” IEEE Trans. Elect. Insul., vol. E1-17, no. 4, pp. 345–349,

or expressed in time, in years: 1982.

[9] K. Fischer, „Neues Verfahren zur Vassanalitischen Bestimmung

rres = τ(ΣGend – ΣGbeg)/(ΣGτ –ΣGbeg) – τ. (23) des Wassergehaltes von Flussigkeiten und festen korpern,“ Angew.

Chem., vol. 48, p. 394, 1935.

If the initial value ΣGbeg is not known, the residual lifetime is [10] IEC 60814, “Insulating liquids–Oil-impregnated paper and

calculated based on regular analyses as: pressboard–Determination of water by automatic coulometric Karl

Fischer titration”, Aug 1997.

rres = ∆τ(ΣGend – ΣGτ2)/(ΣGτ2 – ΣGτ1), (24) [11] ASTM D1533, “Standard Test Method for Water in Insulating

Liquids by Coulometric Karl Fischer Titration”, 2005.

where τ2 and τ1 designate the calculation of the total amount of

water during the current and previous measurements, and ∆τ is

the interval of time, in years, between measurements.

Thus, both monitoring and laboratory data of humidity of

insulating oils become the important diagnostic components of

oil-filled equipment in service [29].

Conclusions [14] H. Borsi, “Gassing behavior of different insulating liquids for

Our investigations, based on scientific representations of the transformers,” Electra vol. 188, pp. 21–41, 2000.

states of water in insulating liquids; show the advantage of di- [15] V. G. Arakelian, “The long way to the automatic chromatographic

verse methods for measuring humidity in insulating liquids, and analysis of gases dissolved in insulating oil,” IEEE Elect. Insul.

a variety of analytical expressions for calculating the condition Mag., vol. 20, no. 6, pp. 8–25, 2004.

of solid insulation. Solid insulation is the most vulnerable link [16] Vaissala Company, “Vaissala HMP228: Moisture and temperature

transmitter for qil,” User’s Guide, M210282en-A, Helsinki, Finland,

of all the insulations, as it is most susceptible to the degrading

May 2002.

influence of water. We propose the analysis of water content of oil

[17] Doble Engineering Company, “Domino and IDD® Intelligent

either by direct or indirect methods. In addition, we also propose Diagnostic Device for On-Line Moisture in Oil Analysis,” MKT-

analytical expressions for automated decision making for the tasks SL-IDDMO-09/04, Watertown, MA 02472-4037, U.S.A.

in the operative diagnostics of oil-filled equipment. [18] IEC 60733, “Method for determination of water in insulating oils,

The proposed analytical relations allow automating the deci- and in oil-impregnated paper and pressboard”, 1982.

sion making of tasks in the operative diagnostics of the oil-filled

equipment for use in a system of monitoring.

Acknowledgment

The authors express deep gratitude to Michel Duval for revis-

ing the English text and for his help in finding suitable terminol- [21] T. Oshi, S. Tsukao, T. Ishii, S. Itahashi, and M. Kamba, “Properties

ogy. of aged oil impregnated paper power capacitor,” in Proc. 7th Inter.

Conf. Properties Appl. Dielect. Mat., vol.1, pp. 246–249, June 1–5,

2003.

References

[22] A. Seytashmehr, I. Fofana, A. Akbari, H. Borsi and E. Gockenbach,

[1] V. G. Arakelian and I. Fofana, “Water in oil-filled high-voltage

“Effects on temperature on the dielectric response of transformer,”

equipment part I: States, solubility and equilibrium in insulating

in Proc. 15th Int. Symp. High-Voltage Eng., ISH 2007, Ljubljana,

materials,” IEEE Elect. Insul. Mag., vol. 23, no. 4, pp. 15–27,

Slovenia, Paper T8-537, Aug. 27–31, 2007.

2007.

September/October 2007 — Vol. 23, No. 5 23

[23] W.S. Zaengl, “Application of dielectric spectroscopy in time and 1997 to August 1999) at the Schering Institute of High Voltage

frequency domain for HV power equipment,” IEEE Elec. Insul. Engineering Techniques (University of Hanover, Germany). He

Mag., vol. 19 no. 6, pp. 9–22, Nov./Dec. 2003.

joined the Université du Québec à Chicoutimi (UQAC) as an as-

[24] Y. Du, M. Zahn, B.C. Lesieutre and A.V. Mamishev and S.R. Lind-

gren “Moisture equilibrium in transformer paper-oil systems,” IEEE

sociate researcher in 2000. He is currently associate professor at

Elect. Insul. Mag., vol. 15, no. 1, pp. 11–20, 1999. the UQAC, Quebec, Canada.

[25] J. Aubin and B. D. Sparling, “Moisture in paper assessment from Since 2005, Dr Fofana has been the Chairholder of the Canada

continuous monitoring of moisture in oil,” Weidmann ACTI 4th Research Chair, tier 2, on Insulating Liquids and Mixed Dielec-

Annu. Tech. Conf., San Antonio, TX, November 28, 2005. trics for Electrotechnology (ISOLIME). He has been appointed

[26] M. Koch, S. Tenbohlen and T. Stirl, “Advanced online moisture to the Technical Committee on Energy and Power Systems of

measurements in power transformers,” CMD 2006 Int. Conf. Condi- the International Association of Science and Technology for

tion Monitoring Diagnosis, Changwon, Korea, April 2–5, 2006. Development (IASTED), a member of the IEEE Task Force on

[27] http://en.wikipedia.org/wiki/Thermodynamic_equilibrium#Local_

Atmospheric Icing performance of line insulators, and a member

thermodynamic_equilibrium (June 15th 2007).

[28] R. A Meyers, “Encyclopedia of physical science and technology”,

of the ASTM Committee D27 on Electrical Insulating Liquids and

Orlando Academic Press, 1992. Gases. He authored/co-authored more than 80 scientific publica-

[29] V. G. Arakelian, “Effective diagnostics for the condition of oil-filled tions and has three patents.

equipment,” IEEE Elect. Insul. Mag., vol. 18, no. 6, pp. 26–38,

2002.

Erratum

In the feature article, Water in Oil-Filled High-Voltage Equip-

ment Part I: States, Solubility, and Equilibrium in Insulating

Vadim Gareginovich Arakelian is a Materials, published in the July-August issue of IEEE Electrical

leading research worker of All-Russia Elec- Insulation Magazine, vol. 23, no. 4, pp. 22 and 23, Figures 3 and

trotechnical Institute, Moscow. In 1961 he 5 had errors. The figures should appear as follows:

graduated from Moscow Institute of Fine

Chemical Technology (M. V. Lomonosov).

In 1969 he defended his dissertation in the

field of theory and practice of gas chroma-

tography. When he joined the All-Russia

Electrotechnical Institute in 1969, his scien-

tific interests were reoriented from analytical

chemistry into the area of electrical engineering, especially in the

development of bases of creation of SF6 electrotechnical equip-

ment and in the application of gas chromatography for diagnostics

of damage to oil-filled electrotechnical equipment.

Dr. Arakelian has generated a new branch of knowledge in

electrical engineering, which was the basis of his doctor’s dis-

sertation “Physical Chemistry of Electrotechnical Equipment,”

which he defended in 1995. This was the first dissertation in the

field of physical chemistry of electrotechnical equipment. He Figure 3. Relative water content isotherms of mineral oil.

is the author of more than 100 published works, more than

80 of those in the field of electrical engineering. He is au-

thor of a monograph,

2002 (“Physical

chemistry of SF6 electrotechnical equipment,” Moscow, 2002).

He may be contacted at: arakelva@mtu-net.ru.

Issouf Fofana received an electrome-

chanical engineering degree in 1991 from

the University of Abidjan (Côte d’Ivoire),

a master and Ph.D. degrees, respectively in

1993 and 1996, from the Ecole Centrale de

Lyon, France, where he was a postdoctoral

researcher in 1997. From 1998 to 2000, he

was a researcher (Fellow of the Alexander Figure 5. Relative amount of excess water (versus the total

von Humboldt Stiftung from November amount of water) in mineral oil versus the relative humidity of

air.

24 IEEE Electrical Insulation Magazine

View publication stats

You might also like

- 810 1644 04 - C Transformer Monitor TM Series Installation GuideDocument35 pages810 1644 04 - C Transformer Monitor TM Series Installation GuideMohammed NouzalNo ratings yet

- Bill of Materials: JIGCC Power Block Project (Package 4)Document3 pagesBill of Materials: JIGCC Power Block Project (Package 4)Mohammed NouzalNo ratings yet

- Clark Reliance: Bill of MaterialDocument3 pagesClark Reliance: Bill of MaterialMohammed NouzalNo ratings yet

- DV-ESGT0001-79066023 - B - Data SheetsDocument5 pagesDV-ESGT0001-79066023 - B - Data SheetsMohammed NouzalNo ratings yet

- Aquarian 3000 Mini Ip DrumDocument29 pagesAquarian 3000 Mini Ip DrumMohammed NouzalNo ratings yet

- Cross Cetion Details: JIGCC Power Block Project (Package 4)Document3 pagesCross Cetion Details: JIGCC Power Block Project (Package 4)Mohammed NouzalNo ratings yet

- Cross Cetion Details: JIGCC Power Block Project (Package 4)Document3 pagesCross Cetion Details: JIGCC Power Block Project (Package 4)Mohammed NouzalNo ratings yet

- SA1042 Jazan: Request For Information (Rfi) FormDocument2 pagesSA1042 Jazan: Request For Information (Rfi) FormMohammed NouzalNo ratings yet

- Elevation Layout: JIGCC Power Block Project (Package 4)Document5 pagesElevation Layout: JIGCC Power Block Project (Package 4)Mohammed NouzalNo ratings yet

- Bill of Materials: JIGCC Power Block Project (Package 4)Document3 pagesBill of Materials: JIGCC Power Block Project (Package 4)Mohammed NouzalNo ratings yet

- Elevation Layout: JIGCC Power Block Project (Package 4)Document5 pagesElevation Layout: JIGCC Power Block Project (Package 4)Mohammed NouzalNo ratings yet

- MV Cable RepairDocument17 pagesMV Cable RepairMohammed NouzalNo ratings yet

- Elevation Layout: JIGCC Power Block Project (Package 4)Document5 pagesElevation Layout: JIGCC Power Block Project (Package 4)Mohammed NouzalNo ratings yet

- Inspection Release Certificate For Part Shipment 3021&3022Document1 pageInspection Release Certificate For Part Shipment 3021&3022Mohammed NouzalNo ratings yet

- 29.10.3.05 Central 70 ITS Integration and Testing PlanDocument51 pages29.10.3.05 Central 70 ITS Integration and Testing PlanbelhaskaNo ratings yet

- GPS Cable Installation and SurgeDocument6 pagesGPS Cable Installation and SurgeMohammed NouzalNo ratings yet

- Wired Tracker GPS InstallationDocument2 pagesWired Tracker GPS InstallationMohammed NouzalNo ratings yet

- Scotch® 70 Self-Fusing Silicone Rubber Electrical Tape: Data SheetDocument3 pagesScotch® 70 Self-Fusing Silicone Rubber Electrical Tape: Data SheetMohammed NouzalNo ratings yet

- Bracket Extension ModelDocument1 pageBracket Extension ModelMohammed NouzalNo ratings yet

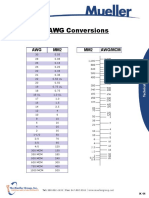

- MM2 AWG ConversionsDocument1 pageMM2 AWG ConversionsMohammed NouzalNo ratings yet

- Bracket Extension ModelDocument1 pageBracket Extension ModelMohammed NouzalNo ratings yet

- Wired Tracker GPS InstallationDocument2 pagesWired Tracker GPS InstallationMohammed NouzalNo ratings yet

- GPS Cable Installation and SurgeDocument6 pagesGPS Cable Installation and SurgeMohammed NouzalNo ratings yet

- Electrical Engineering FormulasDocument4 pagesElectrical Engineering Formulassanjay975No ratings yet

- ABB Oil Filling Method of StatementDocument8 pagesABB Oil Filling Method of StatementAbdullah GhannamNo ratings yet

- 29.10.3.05 Central 70 ITS Integration and Testing PlanDocument51 pages29.10.3.05 Central 70 ITS Integration and Testing PlanbelhaskaNo ratings yet

- TR Interface Work Permit HFW-31001Document2 pagesTR Interface Work Permit HFW-31001Mohammed NouzalNo ratings yet

- Tranformer Oil Sampling MethodsDocument68 pagesTranformer Oil Sampling MethodsMohammed NouzalNo ratings yet

- Scotch® 70 Self-Fusing Silicone Rubber Electrical Tape: Data SheetDocument3 pagesScotch® 70 Self-Fusing Silicone Rubber Electrical Tape: Data SheetMohammed NouzalNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Radiant Ceiling CoolingDocument2 pagesRadiant Ceiling CoolingAmit BharadwajNo ratings yet

- Japan: EDI CT OF GovernmentDocument14 pagesJapan: EDI CT OF GovernmentTuanbk NguyenNo ratings yet

- WFA Equipment SpecificationsDocument21 pagesWFA Equipment SpecificationsSanjayan MaratNo ratings yet

- Painting Procedure GlobalDocument15 pagesPainting Procedure GlobalUbed KudachiNo ratings yet

- Vent Holes at Spandrel PDFDocument21 pagesVent Holes at Spandrel PDFtroyel99No ratings yet

- 8.1 Basic AerodynamicsDocument11 pages8.1 Basic Aerodynamicsame_ravisinghNo ratings yet

- Operating Manual - Dehumidifier TTK 31 EDocument17 pagesOperating Manual - Dehumidifier TTK 31 EEşanu ViorelNo ratings yet

- 04 - Sanjana B - Sem 5 - Elective - Interpretation - Assignment 4Document21 pages04 - Sanjana B - Sem 5 - Elective - Interpretation - Assignment 4Sanjana BhandiwadNo ratings yet

- RS-1R Electric Feeder Manual - RF04 - InstructionManual - Rev01 - EDocument43 pagesRS-1R Electric Feeder Manual - RF04 - InstructionManual - Rev01 - ERamil100% (1)

- Heat and Mass Transfer Unit OperationsDocument5 pagesHeat and Mass Transfer Unit OperationsFran LeeNo ratings yet

- Hempathane Topcoat 55210: Product CharacteristicsDocument4 pagesHempathane Topcoat 55210: Product CharacteristicsJohn Brian TagbagoNo ratings yet

- Classification and Selection of Industrial Dryers: January 2000Document56 pagesClassification and Selection of Industrial Dryers: January 2000TEEO INDIANo ratings yet

- Cooling TowerDocument2 pagesCooling TowerLance Darren GalorportNo ratings yet

- Megger Book The Complete Guide To Electrical Insulation TestingDocument35 pagesMegger Book The Complete Guide To Electrical Insulation TestingTimmyJuriNo ratings yet

- Blasting Painting ProcedureDocument10 pagesBlasting Painting ProcedureMohamed RizwanNo ratings yet

- Rac Gtu SumsDocument8 pagesRac Gtu SumsNainesh SorathiyaNo ratings yet

- Dehumidifying Dryer - SDD ESDocument51 pagesDehumidifying Dryer - SDD ESEndri SudrajatNo ratings yet

- P 6Document51 pagesP 6Mark Darcy UngsonNo ratings yet

- Factors Affecting Weather 10Document24 pagesFactors Affecting Weather 10Jaypee CarlNo ratings yet

- AC Smart 5 NCA Admin Bldg. Acs5 Instance Number Bacnet 20.11.17Document666 pagesAC Smart 5 NCA Admin Bldg. Acs5 Instance Number Bacnet 20.11.17luxusNo ratings yet

- TGA 50 Brochure C160 E012BDocument4 pagesTGA 50 Brochure C160 E012BRajesh KumarNo ratings yet

- Aan 008Document2 pagesAan 008MD FASIUDDINNo ratings yet

- ATPL - EASA2016 - MeteorologyDocument70 pagesATPL - EASA2016 - MeteorologyNuno Arnaud100% (1)

- Effect of Pad Geometry and Material On Performance of Evaporative CoolerDocument11 pagesEffect of Pad Geometry and Material On Performance of Evaporative CoolerNavsumeet Singh SandhuNo ratings yet

- Carbothane 133 HB: Selection & Specification DataDocument5 pagesCarbothane 133 HB: Selection & Specification DatalavekushNo ratings yet

- Smart Garden Water Sprinkler: Tariq Taha Ali Awad Falah Nasih Safar MustafaDocument5 pagesSmart Garden Water Sprinkler: Tariq Taha Ali Awad Falah Nasih Safar Mustafaعلو الدوري100% (1)

- TDP-201 Psychrometrics Level 1 IntroductionDocument71 pagesTDP-201 Psychrometrics Level 1 IntroductionChiu Tak Shing100% (1)

- User Manual - Heraeus - Heracell 150 - Rev. D - 50075549 - D - EnglischDocument86 pagesUser Manual - Heraeus - Heracell 150 - Rev. D - 50075549 - D - Englischluroguita-1100% (2)

- Spray Drier Lab ManualDocument11 pagesSpray Drier Lab ManualJay Wong100% (1)

- 2014 FALL FrostByte FinalLowResDocument8 pages2014 FALL FrostByte FinalLowResJOHNNo ratings yet