Professional Documents

Culture Documents

P&G's Key Distribution Decisions

Uploaded by

Amit Biswal0 ratings0% found this document useful (0 votes)

102 views2 pagesP&G case first question

Original Title

Assignment 1_Question 1

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentP&G case first question

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

102 views2 pagesP&G's Key Distribution Decisions

Uploaded by

Amit BiswalP&G case first question

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Q1. What were the key decisions taken by P&G in relation to distribution channel?

Could a mid-sized manufacturer have used such an approach?

In order to optimize their supply chain by reducing costs and improve the service level, P&G

launched several projects in the mid-1980s. The following are the key decisions taken by the

firm.

1. EDI (Electronic data exchange)

This is a new approach that is used for replenishment ordering which was

started in 1985.

Transmits data daily from retailer to P&G on warehouse product shipments to

each store.

The quantity of orders to be shipped based now depends on shipment

information rather than retailer generated orders.

Product Order quantities are computed such that sufficient safety stock is

assured, minimization of total logistic cost and also elimination of excess

inventory available in Retailers ware house.

This approach resulted in the reduction of labour costs and improvement in

service level.

But this process is expensive when compared to that of the earlier one.

During the second trial, P&G changed the way of ordering in such a way that

there will be as less retail store stockouts and product acquisition costs as

possible.

2. Just in Time basis shipment

Shipping products simply on JIT basis, by using retailer’s actual sales data

whenever required.

Improve consistency and overall service levels by integrating many separate

systems that did not work well together across functions and product sectors.

Current processes were automated and flexibility was added in order to meet

the needs of different sectors and functions.

They started using a common data base for product pricing and specifications

to accomplish the vision of “Simplify, Standardize, then Mechanize”

3. Restructuring of Pricing

Change from “high-low pricing” to “Value Pricing”

Reducing the complexity in the pricing system in order to improve the quality

of the ordering process

Eliminated the incentives for retailer’s forward buying

4. CRP Implementation, Pricing Restructure, ECR System and OSB Changes

Encouraging CRP adoption by providing benefits to retailers.

Reduction in the number of pricing changes from 55 per day in 1992 to less

than 1 per day in 1994.

The flow of information between supplier, distributor, retailer and consumer

went paperless, timely and accurate.

The product lines standardization was the result of changing from brand to

category.

P&G by 1985 was a multinational consumer good manufacturer which had almost $4 billion

in international sales alone. By 1993 it increased to $30 billion which accounted for fifty per

cent of their overall sales. This increase in their sales all over the world was a result of their

changes bought about in the field of supply chain management and value creation for their

consumers by their efficiency improvements and pricing policy changes.

These facts alone are enough to prove that P&G is financially much more capable compared

to a normal mid-sized manufacturer. Having deep pockets during the times when the supply

chain was gradually evolving to a much more fluid and efficient version was a huge

advantage in favour of P&G.

P&G had the first mover advantage by realising the importance of efficient distribution,

pricing, logistics and data management systems which served as a blue ocean for the

untapped demand of low and stable pricing by the end consumers. Being financially capable

at this point was a great advantage for P&G above mid-sized manufacturers. The approach

that P&G took would be much more difficult for a mid-sized manufacturer to implement in

the following ways:

During the early logistics improvement trials with a moderate-sized grocery chain and

their test with initial EDI to transmit data from the retailer about their order details

was great in inventory reductions for the retailer, but the cons outweighed the pros for

P&G as this proved to be much more costly than the old one.

For a mid-sized manufacturer costs like these would place a huge burden on their

finances and therefore would be difficult for them to implement and perfect. P&G

took many trial and errors before bringing their logistics to todays level and it would

be impossible for a mid-sized manufacturer to keep up with that.

P&G followed JIT shipment which provided a huge advantage for not only them but

also their retailers. This was a major implementation under the Continuous

Replenishment Programme. As this made use of information sharing from the retailers

to the manufacturers to replenish their orders for them, this could be easily adopted by

mid-sized manufactures as it only made use of fax and phone in the initial days.

But as it was faulty with manual data inputs and potential delays of processing EDI

had to improve parallelly along with it. This would require the mid-size

manufacturers to invest in improvement of EDI and upgradation of existing systems

which would prove to be difficult for them.

These changes also required major management and policy changes which would be

challenging for any organisation.

The OSD systems changed the system completely and took many years along with

million of dollars to complete. This required upgrading to the already old system form

1960s. Changing the system and upgrading the hardware with a learning curve

involved would have been difficult for any mid-sized manufacturing organisation.

The bottom line is that P&G invested a lot of resources to bring about these changes. These

steps required not only huge monetary investments but time was also one of the key factors

along with it. This required technological innovation with constant improvement over time to

achieve the results that we see today. Mid-sized manufacturer would be more at an advantage

from technology adoption than competing on the same level as P&G.

You might also like

- Operations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationFrom EverandOperations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationNo ratings yet

- The Strategy Machine (Review and Analysis of Downes' Book)From EverandThe Strategy Machine (Review and Analysis of Downes' Book)No ratings yet

- P&G Case Study on Improving Consumer Value Through Process RedesignDocument13 pagesP&G Case Study on Improving Consumer Value Through Process RedesignShaheer ShahNo ratings yet

- Case 1 Procter & GambleDocument3 pagesCase 1 Procter & GambleThe Gas Cast LiveNo ratings yet

- MIS Procter & Gamble Q2 AndQ3 by WatieDocument7 pagesMIS Procter & Gamble Q2 AndQ3 by WatieAtielia De SamsNo ratings yet

- P&GDocument7 pagesP&GAli Jibran100% (1)

- 5 TH Module of Supply Chain ManagementDocument18 pages5 TH Module of Supply Chain ManagementSunil ChauhanNo ratings yet

- 2A VMI Kellogg ReportDocument12 pages2A VMI Kellogg ReportPrafull MalviyaNo ratings yet

- P&G Case: Improving Customer Value Through Process RedesignDocument12 pagesP&G Case: Improving Customer Value Through Process RedesignParambrahma Panda86% (7)

- A Simpler Way To Modernize Your Supply ChainDocument23 pagesA Simpler Way To Modernize Your Supply ChainragerahulNo ratings yet

- Vendor Managed Inventory (Vmi)Document10 pagesVendor Managed Inventory (Vmi)France ParodiNo ratings yet

- Innovative Inventory and Production Management TechniquesDocument24 pagesInnovative Inventory and Production Management TechniquesPatricia Anne BolivarNo ratings yet

- Production and Performance ManagementDocument12 pagesProduction and Performance ManagementhidehelpNo ratings yet

- Evolution or Revolution?Document16 pagesEvolution or Revolution?jpiris215No ratings yet

- A Framework To Speed Manufacturing's Digital Business TransformationDocument17 pagesA Framework To Speed Manufacturing's Digital Business TransformationCognizant100% (1)

- P&GDocument12 pagesP&GKarthik ArumughamNo ratings yet

- P&G SCM InitiativesDocument29 pagesP&G SCM InitiativesKunal Singh100% (2)

- GSCM-23-The Role of Information Sharing in Global Supply Chain OperationsDocument13 pagesGSCM-23-The Role of Information Sharing in Global Supply Chain Operationsabdul rehmanNo ratings yet

- Case Study - Channel Partnership Between Walmart and P&G: Made By: Group 4Document12 pagesCase Study - Channel Partnership Between Walmart and P&G: Made By: Group 4Arpit GuptaNo ratings yet

- Operation Management: Project Report E-Commerce in The NhsDocument15 pagesOperation Management: Project Report E-Commerce in The NhsShivam SarohaNo ratings yet

- Top 5 Challenges Facing The Food and Beverage Industry: September, 2013Document7 pagesTop 5 Challenges Facing The Food and Beverage Industry: September, 2013erza scarletNo ratings yet

- Postponement For Profitability 065283Document14 pagesPostponement For Profitability 065283akashkrsnaNo ratings yet

- ONM4201E. I22022258 .JUN2022.Document8 pagesONM4201E. I22022258 .JUN2022.Joan 夏No ratings yet

- HW - Chapter 4Document7 pagesHW - Chapter 4Yến NhưNo ratings yet

- Untapped Potential Digital Transformation in Mid & Downstream Industries 10th Oct 19 - FinalDocument2 pagesUntapped Potential Digital Transformation in Mid & Downstream Industries 10th Oct 19 - FinalashispNo ratings yet

- Untapped Potential Digital Transformation in Mid & Downstream Industries 10th Oct 19 - FinalDocument2 pagesUntapped Potential Digital Transformation in Mid & Downstream Industries 10th Oct 19 - FinalashispNo ratings yet

- Impact of IT on Supply Chain & ManufacturingDocument3 pagesImpact of IT on Supply Chain & ManufacturingPiyush PDNo ratings yet

- Module 2 Enabliers of BPR IN MANUFACTURINGDocument7 pagesModule 2 Enabliers of BPR IN MANUFACTURINGneyom bitvooNo ratings yet

- 03 Filling The GapDocument6 pages03 Filling The GapBrenda Gallardo MuñizNo ratings yet

- Modernize Supply Chains in Under $5MDocument3 pagesModernize Supply Chains in Under $5Mmanshi choudhuryNo ratings yet

- I2 & Continental Tire Case StudyDocument4 pagesI2 & Continental Tire Case StudyAniket RathodNo ratings yet

- WESCODocument2 pagesWESCODushyant PandaNo ratings yet

- Micro link Information Technology and Business College Campus Department of MBA Post graduate Program Supply Chain Management Course Strategic Fit in a Global Supply ChainDocument7 pagesMicro link Information Technology and Business College Campus Department of MBA Post graduate Program Supply Chain Management Course Strategic Fit in a Global Supply ChainKalayou TekleNo ratings yet

- Bhupesh Negi (OM Articles)Document6 pagesBhupesh Negi (OM Articles)Bhupesh NegiNo ratings yet

- Procter & Gamble: Using Agent Based Modeling and RFID: Supply Chain ManagementDocument18 pagesProcter & Gamble: Using Agent Based Modeling and RFID: Supply Chain ManagementJames KudrowNo ratings yet

- Supply Chain MnagementDocument5 pagesSupply Chain MnagementDanish AhsanNo ratings yet

- Strategic Importance of Supply Chain ManagementDocument6 pagesStrategic Importance of Supply Chain ManagementCharlie MaineNo ratings yet

- The Seven Keys To World-Class ManufacturingDocument8 pagesThe Seven Keys To World-Class ManufacturingSherif El-SherifNo ratings yet

- Supply ChainDocument21 pagesSupply ChainAnam KhanNo ratings yet

- SCM and Its EffectsDocument4 pagesSCM and Its EffectsfatimaNo ratings yet

- WBF - Integrating Shop PDFDocument13 pagesWBF - Integrating Shop PDFPutra Saleh SiregarNo ratings yet

- BUS 2011A Financial Management and Control Activity Based Costing and Management Accounting Technique ReportDocument14 pagesBUS 2011A Financial Management and Control Activity Based Costing and Management Accounting Technique ReportJoe FarringtonNo ratings yet

- Research Paper On Supply Chain ManagementDocument6 pagesResearch Paper On Supply Chain Managementp0zikiwyfyb2100% (1)

- Solution Manual For Supply Chain Management 5th Edition by Chopra MeindlDocument36 pagesSolution Manual For Supply Chain Management 5th Edition by Chopra Meindloweltyswiller.28sh100% (11)

- CRP Walmart & Procter and GambelDocument8 pagesCRP Walmart & Procter and Gambelمعتز العطارNo ratings yet

- Changing The Game in Strategic Sourcing at Procter & Gamble: Expressive Competition Enabled by OptimizationDocument14 pagesChanging The Game in Strategic Sourcing at Procter & Gamble: Expressive Competition Enabled by OptimizationJavier Garcia ParedesNo ratings yet

- Moore Medical - Need of Information (Erp, CRM, Bolt Ons)Document8 pagesMoore Medical - Need of Information (Erp, CRM, Bolt Ons)Deeksha SharmaNo ratings yet

- Case Study SCM 507 & 607 International SCMDocument5 pagesCase Study SCM 507 & 607 International SCMDas ApurboNo ratings yet

- UPS FINAL - Print ReadyDocument15 pagesUPS FINAL - Print Readyapi-19464015No ratings yet

- Decision EngineeringDocument7 pagesDecision EngineeringutorrentNo ratings yet

- Supply Chain and Materials ManagementDocument23 pagesSupply Chain and Materials Managementgeorge calNo ratings yet

- Question & Answers Question No.1: How JIT Approach Can Help Dell Inc. To Meet Customer Demand On Time With Effective Inventory Management?Document2 pagesQuestion & Answers Question No.1: How JIT Approach Can Help Dell Inc. To Meet Customer Demand On Time With Effective Inventory Management?Arooj HectorNo ratings yet

- 008Document8 pages008Jonathan SantiagoNo ratings yet

- Assignment PGDM Batch 2018-2020Document5 pagesAssignment PGDM Batch 2018-2020Mack RaoNo ratings yet

- The Challenges of Managerial Accounting 2Document5 pagesThe Challenges of Managerial Accounting 2therhine100% (2)

- Less Stock, More Profit: Inventory Optimization: IBS White PaperDocument17 pagesLess Stock, More Profit: Inventory Optimization: IBS White PaperFreddy VargasNo ratings yet

- Supply Chain ManagementDocument25 pagesSupply Chain ManagementshikinNo ratings yet

- Homework 1 - Vinicio-Parra PDFDocument2 pagesHomework 1 - Vinicio-Parra PDFVinicio ParraNo ratings yet

- Group1 - GE and The Industrial InternetDocument2 pagesGroup1 - GE and The Industrial InternetNishiGogia100% (2)

- Diagnose The Underlying Cause of The Difficulties That The JITD Program Was Created To Solve. What Are The Benefits and Drawbacks of This Program?Document2 pagesDiagnose The Underlying Cause of The Difficulties That The JITD Program Was Created To Solve. What Are The Benefits and Drawbacks of This Program?SARTHAK NAVALAKHA100% (1)

- Forecasting 2Document18 pagesForecasting 2Amit BiswalNo ratings yet

- NotesDocument1 pageNotesAmit BiswalNo ratings yet

- Textiles CalculationsDocument28 pagesTextiles CalculationsAmit BiswalNo ratings yet

- Class NotesDocument11 pagesClass NotesAmit BiswalNo ratings yet

- Virtual Pooling of Inventory. Makes The Illusion That All The Product Online Is in One LocationDocument7 pagesVirtual Pooling of Inventory. Makes The Illusion That All The Product Online Is in One LocationAmit BiswalNo ratings yet

- Session 1Document9 pagesSession 1Amit BiswalNo ratings yet

- Inputs - Costs, Capacities, DemandsDocument5 pagesInputs - Costs, Capacities, DemandsAmit BiswalNo ratings yet

- Forecasting 2Document18 pagesForecasting 2Amit BiswalNo ratings yet

- Strategic Human Resource Management - A Process of Defining The Organization Goals AchievedDocument2 pagesStrategic Human Resource Management - A Process of Defining The Organization Goals AchievedAmit BiswalNo ratings yet

- Hola KolaDocument3 pagesHola KolaAmit BiswalNo ratings yet

- McKinsey & Company - Sec2 - Group7Document8 pagesMcKinsey & Company - Sec2 - Group7Amit BiswalNo ratings yet

- IndCo: Designing customised trainingDocument8 pagesIndCo: Designing customised trainingAmit BiswalNo ratings yet

- PPT_Capital budgeting under uncertainity NPV AnalysisDocument15 pagesPPT_Capital budgeting under uncertainity NPV AnalysisAmit BiswalNo ratings yet

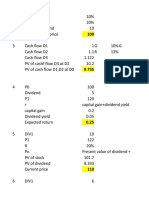

- Valuation of StocksDocument5 pagesValuation of StocksAmit BiswalNo ratings yet

- Real Options and Decision TreesDocument20 pagesReal Options and Decision TreesAmit BiswalNo ratings yet

- Asahi Case SolutionDocument1 pageAsahi Case SolutionAmit BiswalNo ratings yet

- Sec2 - Group4 - Hola KolaDocument2 pagesSec2 - Group4 - Hola KolaAmit BiswalNo ratings yet

- Section 2 Group 13Document12 pagesSection 2 Group 13Amit BiswalNo ratings yet

- HW2Document17 pagesHW2Amit BiswalNo ratings yet

- MR AnalysisDocument8 pagesMR AnalysisAmit BiswalNo ratings yet

- Section 2 Group 13Document12 pagesSection 2 Group 13Amit BiswalNo ratings yet

- 2019W.PAT - Syll.472.Kuuskoski 2018.12.12Document8 pages2019W.PAT - Syll.472.Kuuskoski 2018.12.12Wilson PlonkNo ratings yet

- IntroductionDocument7 pagesIntroductionChristian DaytoNo ratings yet

- BSBMKG417 Assessment Task-1Document2 pagesBSBMKG417 Assessment Task-1Teerapol KhoonburanNo ratings yet

- Ukay-Ukay Business - Is It Still FeasibleDocument7 pagesUkay-Ukay Business - Is It Still FeasibleJayPee De GuzmanNo ratings yet

- Men's Grooming Products: Presented byDocument19 pagesMen's Grooming Products: Presented byPiyush ThakarNo ratings yet

- A Persuasive MessageDocument16 pagesA Persuasive Messageaneeza jamilNo ratings yet

- Emergence of Communication As A Key Concept in The Corporate and Global WorldDocument3 pagesEmergence of Communication As A Key Concept in The Corporate and Global WorldVaibhavNo ratings yet

- Tuscan Lifestyles Case, Customer Lifetime ValueDocument4 pagesTuscan Lifestyles Case, Customer Lifetime ValueJeff Lien100% (4)

- Revlon's vision and SWOT analysis in 40 charactersDocument8 pagesRevlon's vision and SWOT analysis in 40 charactersAnantaNo ratings yet

- INSEAD Case Book Template v0.2Document8 pagesINSEAD Case Book Template v0.2Louis Giacomo Pranlas DescoursNo ratings yet

- Mckercher2020 Cultural Tourism Market A Perspective PaperDocument4 pagesMckercher2020 Cultural Tourism Market A Perspective PaperHà ThiNo ratings yet

- Planning, Metrics & Forecasting for Marketing ImplementationDocument13 pagesPlanning, Metrics & Forecasting for Marketing ImplementationMEGA NURWANINo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word Documentrapworld66No ratings yet

- Is Store or Service Satisfaction More Important To Customer Loyalty?Document15 pagesIs Store or Service Satisfaction More Important To Customer Loyalty?zZl3Ul2NNINGZzNo ratings yet

- Customer Relationship Management at PantaloonsDocument5 pagesCustomer Relationship Management at Pantaloonssharmaishan100% (1)

- Makadok and Ross (2013) - Taking Industry Structuring Seriously - A Strategic Perspective On Product Differentiation PDFDocument42 pagesMakadok and Ross (2013) - Taking Industry Structuring Seriously - A Strategic Perspective On Product Differentiation PDFCrhistian GarciaNo ratings yet

- Marketing StrategiesDocument78 pagesMarketing Strategiesanuja_solanki89030% (1)

- Company Name: Nestle: Executive SummaryDocument11 pagesCompany Name: Nestle: Executive SummaryWaleed AhmadNo ratings yet

- BA9223 - MARKETING MANAGEMENTDocument14 pagesBA9223 - MARKETING MANAGEMENTLords PorseenaNo ratings yet

- GlobalCPRSectorOverview Dec2020Document48 pagesGlobalCPRSectorOverview Dec2020Karthik KeyanNo ratings yet

- Talentship BoudreauDocument8 pagesTalentship BoudreauBiluNo ratings yet

- Significance of Qualifying Examination in The Retention Program of Bsa Students in Saint Vincent College of CabuyaoDocument18 pagesSignificance of Qualifying Examination in The Retention Program of Bsa Students in Saint Vincent College of CabuyaoGenRev SamaniegoNo ratings yet

- Chapter 22 - Marketing Mix - PlaceDocument29 pagesChapter 22 - Marketing Mix - PlaceKanishq BawejaNo ratings yet

- Mobile Data AnalysisDocument34 pagesMobile Data AnalysisAswathy Ashokan50% (8)

- Rural Market EnvironmentDocument12 pagesRural Market EnvironmentAkhil SuriNo ratings yet

- Lesson 1 Om-TqmDocument3 pagesLesson 1 Om-TqmDeanne GuintoNo ratings yet

- Five LadiesDocument14 pagesFive Ladiesfaredj rsNo ratings yet

- Company Project: 2.business PlanDocument7 pagesCompany Project: 2.business PlanandreaNo ratings yet

- Five Ways To Maintain and Grow Your Business DuriDocument1 pageFive Ways To Maintain and Grow Your Business DuriMa Katherine Gomer QuimoyogNo ratings yet

- Chapter 13Document54 pagesChapter 13butterfly_irinaNo ratings yet