Professional Documents

Culture Documents

United States Patent (19) : Spencer

Uploaded by

Kevin Villacis0 ratings0% found this document useful (0 votes)

17 views5 pagesOriginal Title

US4658712

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views5 pagesUnited States Patent (19) : Spencer

Uploaded by

Kevin VillacisCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

United States Patent (19) (11) Patent Number: 4,658,712

Spencer 45 Date of Patent: Apr. 21, 1987

54 COFFEE DEPULPNG MACHINE 1,496,265 6/1924 Grant .................................... 99/609

1,710,459 4/1929 Romero ...... ... 99/622 X

76) Inventor: Stanley L. Spencer, Route 3, Box 2,230,790 2/1941 Anderson .............................. 99/574

129-A, Gray, Ga. 31.032 4,131,061 12/1978 Skeen ................................ 99/621 X

k Notice: The portion of the term of this patent Primary Examiner-Timothy F. Simone

subsequent to Aug. 21, 2000 has been Attorney, Agent, or Firm-Roylance, Abrams, Berdo &

disclaimed. Goodman

(21) Appl. No.: 228,998 57 ABSTRACT

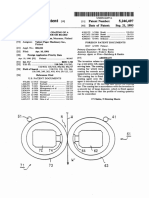

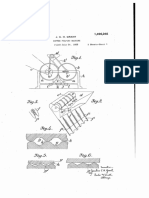

22 Fied: Jan. 27, 1981 A depulping machine comprises a frame, a shaft

mounted on the frame and at least one circular disk

51 Int. Cl." ........................ A23N 5/00; A23N 15/10 mounted for rotation on the shaft. The shaft passes

52 U.S. Cl. ........................................ 99/576; 99/574; perpendicularly through the disk. The disk tapers in a

99/579; 99/610; 99/622 radially outward direction of the shaft and has spirally

(58) Field of Search .................. 99/568, 520, 574-576, radiating ribs projecting laterally from opposite faces of

99/600, 609, 610,521, 612-615, 617-623, the disk. A hopper is supported on the frame above the

635-639, 567; 241/260, 251, 261.1-261.3, disks. Adjustable depulping plates are attached to the

296-298

frame adjacent to, but spaced from the disks, and have

(56) References Cited cutting edges which cooperate with independently ad

U.S. PATENT DOCUMENTS justable guide brackets and the disk faces and ribs to

force pulp between the disk and the plates and to push

232,714 9/1880 Henington ............................ 99/622 beans, pits and the like on the plates along the edges,

777,877 12/1904 Abele ................................ 99/610 X and out the machine.

879,211 2/1908 Tebyrica et al. ................. 99/622 X

1,066,344 7/1913 Urgelles ............................ 99/610 X

1,342,692 6/1920 Pape ...................................... 99/575 16 Claims, 2 Drawing Figures

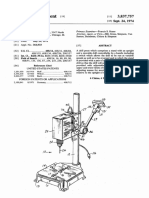

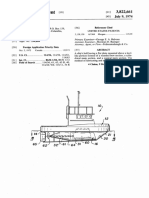

U.S. Patent Apr. 21, 1987 Sheet 1 of 2 4,658,712

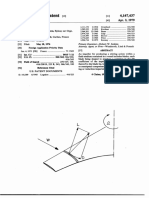

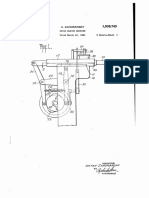

U.S. Patent Apr. 21, 1987 Sheet 2 of 2 4,658,712

4,658,712 2

1

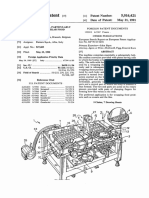

hopper 13. The shields 19 also serve to reinforce the

COFFEE DEPULPING MACHINE hopper 13 thus making it a more suitable truss like struc

ture for stabilizing the tops of the two A-frames 11. A

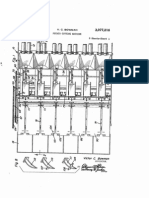

This invention relates to an apparatus used to remove series of stationary feeders 20 serve to guide the coffee

the cherry pulp from the coffee bean at the time the 5 to the depulping plates 21 being closely located adja

coffee is picked from the plant. It has been proven diffi cent and adjustable to the disks 14. Depulping plates 21

cult to produce a conventional coffee depulping ma are located between disks 14 and are tapered toward

chine that is economical to fabricate and efficient in shaft 15 providing generally triangular spaces that fit

operation. the taper of the disks. Adjustment of the depulping

The primary objects of the present invention are to O plates 21 are achieved by moving the wedge-shaped

provide solutions to problems commonly encountered plates 21 closer to or away from the shaft 15 of the

when depulping coffee in a conventional machine. machine 10. Adjustment of the plates toward and away

Briefly described the invention uses one or more circu from the shaft will decrease or increase, respectively,

lar disks mounted on a shaft, the disks being thicker in the lateral spacing between the disks and the shearing

the center part near the shaft and gradually becoming 15 edges of plates 21. Slots through which the mounting

thinner in the outer perimeter. Embossed veins radiat screws 22 and 23 pass allow for this simple in and out

ing spirally from the centers of the disks provide the adjustment. The stationary feeders 20 are fastened to

depulping action by shearing the pulp away from the the hopper 13 by machine screws 24 and a third longer

coffee bean and pulling the pulp through an adjustable screw 22 aids to secure the nose of the feeder 20 to a

shearing edge and out the bottom of the machine while 20 mounting plate 25 which in turn is fastened to the two

pushing the exposed coffee bean along the shearing A-frames thus making for a more integral simplified

edge and through an adjustable guide bracket fitted construction. Adjustable guide brackets 26 which serve

against the disks so as to allow sufficient passage for the to hold the coffee the correct distance from the rotating

coffee bean but not the pulp surrounding it. The ex disks 14 during depulping and guide the coffee beans

posed beans are then pushed out the openings in the 25 out of the machine 10 are secured above the depulping

front of the machine. The hopper into which the coffee plates 21 and mounting plate 25 by means of a machine

is first introduced is designed to guide the coffee to the screw 23 and the longer machine screw 22 passing

thicker center part of the disks where depulping begins. through the nose of the feeder 20. The guide brackets 26

The obvious advantage is that depulping near the shaft are independently adjustable from the depulping plates

requires much less force than the conventional machine 30 21 thus allowing an additional degree of flexibility of

which depulps at the perimeter of a cylinder. Shields adjustment not possible in the cast iron breastplate of

located inside the hopper cover the outer perimeter of the conventional machine. The guide brackets 26 also

the rotating disks thus channeling the coffee still in the provided with slots through which the mounting

cherry to stationary feeders located over the shaft and screws 22 and 23 pass are adjusted in the same manner

as the depulping plates 21. As compared with the con

between the disks where the spirally radiating veins pull 35

the coffee into the depulping chambers. Feeding is auto ventional machine with four openings which occupies

matic thus eliminating two gears, a feeder bar and four 0.245 cubic meters of space and weighs approximately

flat bars found in the conventional machine. 80 kilograms the present machine 10 with the same

Other and further objects, features and advantages of number of openings is less bulky and lighter, occupying

the present invention will become apparant from the 40 approximately 0.036 cubic meters of space and weigh

detailed description of the preferred form thereof read ing approximately 19 kilograms. The present machine

in conjunction with the following drawings, in which: 10 is more versatile in that it is possible to have from one

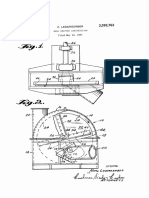

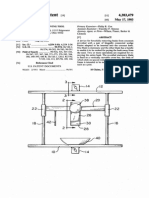

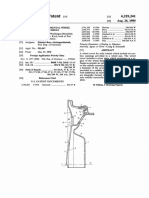

FIG. I is a front elevation of a machine having four up to six or eight openings per machine according to the

disks; depulping capacity required instead of the usual two,

FIG. II is a sectional view along lines "A-A' of 45 three or four openings of the conventional machine.

FIG. I. The spirally radiating veins in the disks 14 enable the

In the drawings the coffee depulping machine of the machine 10 to operate at a faster velocity thus increas

present invention is designated generally by the refer ing depulping capacity without imparting damage to

ence number 10. Like parts are indicated by similar the coffee bean. A smaller drive pulley 17 is required

characters of reference in both views. The invention 50 thus saving materials and occupying less space.

can best be described with reference to the accompany In operation, the edges of plates 21 are slightly spaced

ing drawings. The machine illustrated is supported by a from the ribs on the disks to permit the pulp to pass

pair of A-frames 11 secured at the bottom by threaded downwardly between the plates and disks, but are suffi

rods 12 and at the top by the hopper 13 being bolted in ciently close to the faces of the disks to prevent the

place at both sides. The disks 14 are mounted on a shaft 55 beans from passing between the plates and the faces of

15 which passes through a sealed bearing 16 at either the disks during depulping. The beans or nuts are

extremity. The bearings 16 are set in the two A-frames pushed along the plates adjacent their edges by the ribs

11 from the inside and the shaft 15 is turned down so as on the rotating disks with the aid of guide brackets 26

to form a shoulder which holds the bearings 16 in place which hold the coffee cherries or nuts close enough to

once the machine is assembled thus eliminating the need the faces of the disks to remove the husk, but are suffi

for bearing retainers. A drive pulley 17 is used to turn ciently spaced to allow the bean to pass through the

the shaft 15 in a clockwise rotation as viewed in FIG. II machine unharmed. Shields 19 assist in directing the

section "A-A'. A handle 18 may be installed near the coffee beans toward a lateral side of a disk. The feeders

perimeter of the drive pulley 17 for manual operation. also assist in this function since they slant toward the

The freshly picked coffee is first introduced into the 65 shaft and the disk.

hopper 13 and is guided down into the machine 10 by From the above description it will be apparent that

shields 19 placed over the disks 14 to prevent premature there is thus provided a device of the character de

depulping and leakage of pulp out the front of the scribed possessing the particular features of advantage

4,658,712 4.

3

previously stated as desirable, but which obviously is 5. A depulping machine according to claim 1 wherein

susceptible of modification in its form, proportions, said6. shaft is mounted by bearings on said frame.

detail construction and arrangement of parts without said Aframe depulping machine according to claim 1 wherein

departing from the principle involved or sacrificing any ports beingcomprise two supports with legs, said sup

secured at tops thereof by said hopper.

of its advantages. 7. A depulping machine according to claim 2 wherein

While in order to comply with the statute the inven said hopper is formed of sheet metal, and comprises

tion has been described in language more or less specific reinforcing shields over said disks and stationary feed

as to structural features, it is to be understood that the ing mechanisms over said shaft and between said disks.

invention is not to be limited to the specific features 10 8. A depulping machine according to claim 1 wherein

shown, but that the means and construction herein dis said depulping plates are adjustably mounted on said

closed comprise but one of several modes of putting the frame to vary spacing relative to said disk.

invention into effect. The following claim is to be read 9. A depulping machine according to claim 1 wherein

as encompassing all modifications and adaptations fall guide brackets are mounted on opposite sides of said

ing in the same category of the aforementioned. 15 disks adjacent said edges.

Having thus described my invention, I claim: 10. A depulping machine according to claim 9

1. A depulping machine, comprising: wherein said depulping plates are adjustably mounted

a frame; on said frame to vary spacing relative to said disk.

a shaft supported on said frame; 11. A depulping machine according to claim 10

20 wherein said depulping plates and said guide brackets

at least one circular disk mounted on said shaft, said are coupled to a mounting plate secured to said frame

shaft passing perpendicularly through a center and traversing the width of the machine.

portion of said disk, said disk tapering in a radially 12. A depulping machine according to claim 10

outward direction of said shaft and having spirally wherein said guide brackets and said depulping plates

radiating ribs projecting laterally from opposite 25 are independently adjustable. .

faces of said disk; 13. A depulping machine, comprising:

a hopper supported on said frame above said disk; and a first member having an outer face with at least one

depulping plates attached to said frame adjacent to protruding rib;

but spaced from said disk, said plates having edges a second member with a edge adjacent to but spaced

which cooperate with said disk faces and ribs to 30 from said face and said rib, said rib and said edge

force pulp between said disk and said plates and to being oriented at an angle; and

push beans, pits and the like on said plates along drive means for moving one of said members relative

said edges and out a discharge opening. to the other member such that said angle remains

2. A depulping machine according to claim 1 wherein 35 substantially constant as said rib moves along said

a plurality of disks are mounted on said shaft; and de

edge during relative movement and an optimum

pulping plates are mounted on said frame adjacent each

shearing force is applied.

14. A depulping machine according to claim 13

of said disks. wherein said second member is relatively fixed and said

3. A depulping machine according to claim 1 wherein first member is moved by said drive means.

said shaft is coupled to drive means for rotating said 40 15. A depulping machine according to claim 14

disks, said drive means including a drive pulley on said wherein said first member is rotated.

shaft. 16. A depulping machine according to claim 3

4. A depulping machine according to claim 3 wherein wherein said second member is adjustably mounted

said drive pulley comprises a handle for optional man relative to said first skmember. k se e k

ual operation. 45

50

55

60

65

You might also like

- Us3432107 PDFDocument3 pagesUs3432107 PDFasssssNo ratings yet

- US2099314Document3 pagesUS2099314Jhonnatan E Avendaño Florez100% (1)

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Document7 pages"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNo ratings yet

- US2126921Document5 pagesUS2126921Jhonnatan E Avendaño Florez100% (1)

- US4335764Document7 pagesUS4335764Jorge ArbelaezNo ratings yet

- United States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsDocument8 pagesUnited States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsUvxtalNo ratings yet

- US4827759Document7 pagesUS4827759jonyNo ratings yet

- United States Patent: (45) July 4, 1972Document4 pagesUnited States Patent: (45) July 4, 1972Lidya SimatupangNo ratings yet

- Title - Wood Chipper ConstructionDocument4 pagesTitle - Wood Chipper Constructionمحمد عبدالدايمNo ratings yet

- United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986Document3 pagesUnited States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986wahaha06No ratings yet

- Coco Inven PDFDocument4 pagesCoco Inven PDFsushil-funNo ratings yet

- United States Patent (19) : 11 Patent Number: 45 Date of PatentDocument12 pagesUnited States Patent (19) : 11 Patent Number: 45 Date of Patentعلی ربانیNo ratings yet

- Sept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetDocument4 pagesSept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetLucas RaithsNo ratings yet

- United States Patent (19) : (54) Coating Device For Coating OfaDocument10 pagesUnited States Patent (19) : (54) Coating Device For Coating OfaNiccolast Adnandito SaputraNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- A BY - 4 The: May 23, 1961 B. J. Parmele 2,985,391Document5 pagesA BY - 4 The: May 23, 1961 B. J. Parmele 2,985,391Eloquent EloquentNo ratings yet

- United States PatentDocument8 pagesUnited States PatentClaudinei MayerNo ratings yet

- United States Patent (19) : TinkerDocument12 pagesUnited States Patent (19) : TinkerJoel AndradeNo ratings yet

- United States Patent (19) : PreticDocument5 pagesUnited States Patent (19) : Pretic63No ratings yet

- Us 2543888Document5 pagesUs 2543888Juan Sebastian PrietoNo ratings yet

- United States Patent (19) : Gazalel, 72 8Document7 pagesUnited States Patent (19) : Gazalel, 72 8Mihai RobertNo ratings yet

- Diseño ElectricoDocument5 pagesDiseño ElectricoemernelsonmanNo ratings yet

- US2447117Document6 pagesUS2447117MahnooshNo ratings yet

- US3921555Document6 pagesUS3921555Muhammad TalhaNo ratings yet

- Diseño de Impulsores para Mezcla de SuspensionesDocument9 pagesDiseño de Impulsores para Mezcla de SuspensionesrwtoorresdNo ratings yet

- Dec. 13, 1960 I, Tubbs 2,964,084: Z2S SLDocument5 pagesDec. 13, 1960 I, Tubbs 2,964,084: Z2S SLstv ravaNo ratings yet

- United States Patent To: Crompton (45) Jun. 28, 1983Document6 pagesUnited States Patent To: Crompton (45) Jun. 28, 1983aliathnofficeNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 7,610,957 B2Document8 pagesUlllted States Patent (10) Patent N0.: US 7,610,957 B2lfilippiniNo ratings yet

- US527955Document5 pagesUS527955moonstarNo ratings yet

- Glue GunDocument9 pagesGlue GunNaranLoganNo ratings yet

- United States Patent: SimpsonDocument5 pagesUnited States Patent: Simpsonاحمد عبدالكريمNo ratings yet

- United States Patent: 72 Inventor Richard F. ReinkeDocument13 pagesUnited States Patent: 72 Inventor Richard F. Reinkeعبد الحليم رغدةNo ratings yet

- United States Patent (19) : Filed: Feb. 14, 1972Document5 pagesUnited States Patent (19) : Filed: Feb. 14, 1972zgregzNo ratings yet

- US5180284Document7 pagesUS5180284vishal pandeyNo ratings yet

- United States Patent: (54) SailboatDocument5 pagesUnited States Patent: (54) Sailboat155No ratings yet

- (1966, May 3) US3248803 Rotary Drum Heat ExchangerDocument6 pages(1966, May 3) US3248803 Rotary Drum Heat ExchangeraegosmithNo ratings yet

- A. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .Document4 pagesA. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .AGUAVIVANJNo ratings yet

- USRE29603Document7 pagesUSRE29603PUVAN TSTNo ratings yet

- United States Patent: Primary Examiner-Richard A. GaudetDocument8 pagesUnited States Patent: Primary Examiner-Richard A. GaudetcanishtainNo ratings yet

- US6581308Document5 pagesUS6581308PUVAN TSTNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- Tesla Gas Turbine PatentDocument3 pagesTesla Gas Turbine PatentHasan Murat SolmazNo ratings yet

- United States Patent (191: (73) AssigneeDocument6 pagesUnited States Patent (191: (73) AssigneeRodrigoPomaNo ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- United States Patent (19) : Hood Et Al.Document5 pagesUnited States Patent (19) : Hood Et Al.8787No ratings yet

- United States Patent (19) : Filed: July 27, 1976 57Document3 pagesUnited States Patent (19) : Filed: July 27, 1976 57Alexandre Magno Bernardo FontouraNo ratings yet

- Dau TomDocument6 pagesDau TomPham LoiNo ratings yet

- Unidad IV Intercambiadores de CalorDocument4 pagesUnidad IV Intercambiadores de CalorRafael CórdobaNo ratings yet

- United States Patent 19Document9 pagesUnited States Patent 19Claudinei MayerNo ratings yet

- Tesla Turbine Patent 1922 B..Document3 pagesTesla Turbine Patent 1922 B..zekau100% (1)

- United States Patent (19) : HermannsDocument3 pagesUnited States Patent (19) : HermannsIvan ReyesNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- US4219241Document7 pagesUS4219241aungkyawzoreNo ratings yet

- United States Patent (113,565,212: 3. AFE No. 1969 3,454,131 7/1969 Johnson....................... 182/115Document5 pagesUnited States Patent (113,565,212: 3. AFE No. 1969 3,454,131 7/1969 Johnson....................... 182/115Jesus Antonio Esquivel HernandezNo ratings yet

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocument3 pagesData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateJaymar ManualNo ratings yet

- Ezzaz Lar Qway7% /7/47ss?-Fé: Q. H. Massaro 3,057,386Document4 pagesEzzaz Lar Qway7% /7/47ss?-Fé: Q. H. Massaro 3,057,386Guillermo Avila RiveraNo ratings yet

- Folding AparatusDocument4 pagesFolding AparatusUbunterNo ratings yet

- United States Patent (191: Sullivan Et A1Document21 pagesUnited States Patent (191: Sullivan Et A1fghdfjerNo ratings yet

- Cultural Diversity in Vikram Seth's A Suitable Boy'Document3 pagesCultural Diversity in Vikram Seth's A Suitable Boy'Sneha PradhanNo ratings yet

- Manual Diagrama Detector de MetalesDocument18 pagesManual Diagrama Detector de MetalesEdmundo Cisneros0% (1)

- Avenger 220 Cruise Street BS IVDocument79 pagesAvenger 220 Cruise Street BS IVShubham AatopartsNo ratings yet

- Revise Chap 12Document14 pagesRevise Chap 12RACHEL DAMALERIONo ratings yet

- Education During The Ancient Period Primitive EducationDocument5 pagesEducation During The Ancient Period Primitive EducationEn CyNo ratings yet

- Complete-Crp SPC Shamli r01-1562323540Document291 pagesComplete-Crp SPC Shamli r01-1562323540p nandyNo ratings yet

- One Word SubstitutionDocument5 pagesOne Word SubstitutionPranaykant Singh PanwarNo ratings yet

- 1-Perceived Threat of Covid-19 and T.I (Reference Article)Document10 pages1-Perceived Threat of Covid-19 and T.I (Reference Article)Hassan NadeemNo ratings yet

- Precast Concrete ConstructionDocument37 pagesPrecast Concrete ConstructionRuta Parekh100% (1)

- Activity On The Layers of The Earth 1Document1 pageActivity On The Layers of The Earth 1Ian MarianoNo ratings yet

- 16 Advantages & 10 Disadvantages of Solar Panels in 2022Document29 pages16 Advantages & 10 Disadvantages of Solar Panels in 2022xaxinev359100% (1)

- Upload Infotype 2006 (Absence Quotas) - Code Gallery - SCN WikiDocument3 pagesUpload Infotype 2006 (Absence Quotas) - Code Gallery - SCN WikiArun Varshney (MULAYAM)No ratings yet

- Lab 5 (... )Document10 pagesLab 5 (... )Zeeshan JuttNo ratings yet

- The Complete MARILLION Discography V2 PDFDocument13 pagesThe Complete MARILLION Discography V2 PDFtotalmenteprovisorioNo ratings yet

- Title of The Training Program Regional Training of Grades 4-8 Reading Teachers On Care For Non-Readers (CNR) Program Module No., Day & Session NoDocument18 pagesTitle of The Training Program Regional Training of Grades 4-8 Reading Teachers On Care For Non-Readers (CNR) Program Module No., Day & Session Nomarvin susminaNo ratings yet

- UntitledDocument44 pagesUntitledFrancesco TauroNo ratings yet

- Proc.-02 GTAW - PAWDocument37 pagesProc.-02 GTAW - PAWRaghu vamshiNo ratings yet

- AYLS Annual Report 2019 LampDocument136 pagesAYLS Annual Report 2019 LampHigh FourNo ratings yet

- Refraction Through A Lens PDFDocument3 pagesRefraction Through A Lens PDFPrudhvi JoshiNo ratings yet

- Cop4600 Exam1 sp13Document2 pagesCop4600 Exam1 sp13chavNo ratings yet

- Pre-Placement Training Program: Sample Profiling (All About You)Document2 pagesPre-Placement Training Program: Sample Profiling (All About You)RISHAV RAJ GUPTANo ratings yet

- 4363 112 Heat TransferDocument6 pages4363 112 Heat Transferyogesh_b_kNo ratings yet

- Probability and Statistics Ii Assignment I July 2019 PDFDocument3 pagesProbability and Statistics Ii Assignment I July 2019 PDFDanielNo ratings yet

- When A Transformer Has Stomach Pain and Wants ToDocument4 pagesWhen A Transformer Has Stomach Pain and Wants ToRobert GalarzaNo ratings yet

- 4naa7 4eeDocument2 pages4naa7 4eeDorottya HózsaNo ratings yet

- Dramix: Dramix Economic Concrete Reinforcement For Safe Floors On PilesDocument9 pagesDramix: Dramix Economic Concrete Reinforcement For Safe Floors On PilesMohammad IqbalNo ratings yet

- Education and Learning: Good Study HabitsDocument3 pagesEducation and Learning: Good Study Habitsزهرة ZaraNo ratings yet

- Adient Managment CSRDocument68 pagesAdient Managment CSRClaudia PEÑANo ratings yet

- Khairro SanfordDocument2 pagesKhairro SanfordJezreel SabadoNo ratings yet

- Purchasing Process Models Inspiration For Teac 2019 Journal of Purchasing ADocument11 pagesPurchasing Process Models Inspiration For Teac 2019 Journal of Purchasing ASunita ChayalNo ratings yet