Professional Documents

Culture Documents

Coco Inven PDF

Uploaded by

sushil-funOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coco Inven PDF

Uploaded by

sushil-funCopyright:

Available Formats

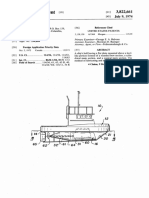

United States Patent 119]

[111

4,383,479

Hill

[45]

May 17, 1983

[54] COCONUT HUSK REMOVING TOOL

Primary ExaminerPhilip R. Coe

[76] Inventor:

Assistant ExaminerTimothy F. Simone

Attorney, Agent, or Firm--Wilson, Fraser, Barker &

Clemens

Edward D. Hill, 11212 Edgewater

Dr., Cleveland, Ohio 44102

[21] App]. No.: 297,428

[57]

,[22] Filed:

A device for forcefully removing husks from coconuts

Aug. 28, 1981

[51]

Int. Cl; ........................ .. A23N 5/03; A23N 5/08

[52]

u.s.c1. ................................... ..99/572;30/120.1;

[58]

Field of Search ................ .. 99/s14,515,537-541,

99/574; 99/582; 99/583; 99/591

99/547, 557, 567, 568, 571-575, 579-583, 584,

588, 590593, 646 R; 30/1201, 120.5; 83/570;

7/129, 110, 113; D7/98, I05, 106

[56]

References Cited

2/1911

provided with a pair of hingedly connected wedge

blades adapted to be inserted into the coconut husk.

One blade is stationary and the other blade has a handle

to enable it to be rocked for pryirlg the husk away from

the seed. Two or more operations are required for re

moving the entire husk. The so-called stationary blade

is ?xed to a vertically movable cross bar, the ends of

which slide on spaced rods forming part of a frame. The

frame is intended to be mounted upright on a support,

such as a post.

U.S. PATENT DOCUMENTS

983,631

ABSTRACT

Marot ...................... .., ......... .. 99/591

10 Claims, 3 Drawing Figures

22

.01

""9

US. Patent

May 17, 1983

,2

4,383,479

MG. Q35

4,383,479

cocoNu'r Husk REMOYING I6? I:

BACKGROUND AND SUMMARY oiljrn

7.

INVENTION,

operating handle for moving the wedge blade 26 up

w'ardly and outwardly as shown by the broken lines on

FIG. 2. A suitable grip 38'is on the outer end of the

handle. -A wooden bowl 40 rests on the base rail 10 to

receive the coconut to be stripped.

The husking of coconuts isa'laborious, time-consum

ing and somewhat risky undertaking. No set formula

seems to exist for handling'this operation, but usually it

is carriedout' with 'a 'lhatchetglknife, or machete. To a 1

novice, these canbe dangerous especially in dealing

with a coconut due to its being ungainly. Additionally,

it required considerable time to do the job, so that it has

not been a pro?table operation.

This invention provides a relatively simple tool for

husking coconuts and one which does not pose risks and

can be achieved easily quickly and without the neces

Inoperation, a coconut to be husked is placed in the

in the proper-position and then the cross bar 20

is manually lowered? to forcefully cause the pointed

ends of the husking blades 24 and 26 to enter the coco

nut-husk; as indicated on FIG. 2. Then by grasping the

handle grip 38, the handle is lifted thereby causing the

blade 26 to divide the husk and one half is torn loose.

The blade 24 is held stationary and retains the coconut

in position. Thereafter the coconut is turned sidewise

and that part is halved, leaving a narrow section that the

blades can easily remove from the coconut.

sity of prior training. The tool includes wedge blades

Carried by and depending from the cross bar 20 is a

which are forced into the husk and then one of the

punch 42 which upon forcefully lowering the cross bar

can pierce the eye of the coconut for removing the

blades is shifted away from the other, thereby to tear

loose a portion of the ?brous husk. This is repeated until

the entire husk is forced from the seed. The entire oper

husk.

_ Changes in details of construction, operation and

ation can be accomplished quickly and easily.

choice of materials may be made without departing

from the invention.

BRIEF DESCRIPTION OF THE DRAWINGS

What is claimed is:

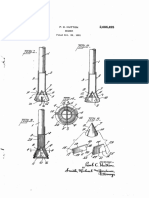

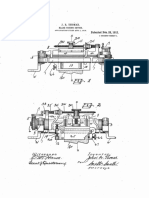

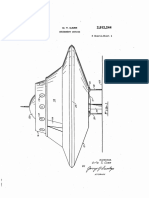

FIG. 1 is a front elevational of a frame provided with 25

1. A device for removing the husk from a coconut

a vertical reciprocatory slide carrying a tool for remov

comprising a pair of blades arranged ?atwise against

ing the husk from a coconut;

each other, means for forcing said blades into the coco

_ FIG. 2 is a sectional view on the line 2-2 of FIG. 1

nut husk, a hinged connection between end portions of

showing the husk removing tool and an associated co

said blades, means to hold one blade stationary, and

30

conut in broken lines; and

7

means for pivoting the other blade away from the one

FIG. 3 is a sectional view on the line 33 of FIG. 1.

blade about said hinged connection thereby to tear

away a portion of the husk.

DESCRIPTION OF PREFERRED EMBODIMENT

2. A coconut husk removing device as claimed in

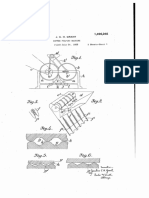

The illustrated embodiment of the invention com

claim 1 comprising wedge means on the blades for en

prises an upright frame having a transverse metal base

rail 10 and an upwardly spaced top metal rail 12. On

each of the rails 10 and 12 is a centrally disposed aper

tured angle iron bracket 14, which is shown in FIG. 3

spaces the frame laterally to afford working clearance.

Suitable fasteners connect these brackets to a post (not

shown) at a convenient height. A pair of laterally

spaced welded on cylindrical metal upright guide rods

16 and 18, respectively, connect the rails 10 and 12,

thereby forming a rigid frame. Between the guide rods

is a transverse metal tool-carrying bar 20 to the ends of 45

which are secured vertical tubular guide 22, which

slidingly engage the guide rods 16 and 18 respectively,

thereby enabling the bar 20 to be manually raised or

lowered, as desired.

A coconut husk removing tool is secured to the cen-.

tral portion of the cross bar 20 and comprises a pair of

metal plates, or blades 24 and 26 constituting wedge

members. The plates or blades 24 and 26 are of substan

tial width and thickness and the normal position ?atwise

abut against each other. The lower end of each blade is,

tering the husk.

3. A coconut husk removing device as claimed in

claim 1 wherein said means for pivoting includes a han

dle connected to said other blade.

4. A coconut husk removing device as claimed in

claim 3 comprising downwardly and inwardly inclined

lower end portions of said blades which when in abut

ting relation provide a pointed end to be forced into the

husked end of a coconut.

5. A coconut husk removing device as claimed in

claim 4 comprising a detachable connection between

said handle and the respective blade adjacent said hinge

connection.

6. A coconut husk removing device as claimed in

claim 1 comprising a cross bar to which one blade is

?xed to hold same stationary during husk removing, a

pair of spaced upright rods, and sliding connections

between end portions of said cross bar and said rods.

7. A coconut husk removing device as claimed in

champfered downwardly and inwardly to form oppo

claim 6, comprising a pair of vertically spaced bars to

which end portions of said rods are ?xed respectively,

of the blade 24 is welded to the front face of the cross

bar 20 so that the blade 24 is retained stationary while

the blade 26 can pivot or rock relative to the blade 24.

For this purpose the upper'ends of the plates or blades ~

are connected by a suitable hinge 32. Near the upper 65

said vertically spaced bars to receive a coconut to be

husked.

9. A coconut husk removing device as claimed in

claim 8, comprising a punch on said cross bar for use in

piercing the eye of a coconut for removing the milk.

and mounting brackets on said bars for spacing same

sitely included wedge surfaces 28 and 30 on the blades

from a support to afford working clearance.

24 and 26, respectively. The bottom bevel edge of each

8. A coconut husk removing device as claimed in

blade is sharp and the edge portion of blade 24 is slightly

longer than that of the blade 26. The upper edge portion 60 claim 7, comprising receptacle means on the lower of

end of the outer side of the plate 26 andropposite the

cross bar 20 is rigidly ?xed a screw socket 34 to receive

the threaded end portion of a pipe 36 providing the

10. A coconut husk removing device comprising:

a-a pair of vertically disposed blades disposed ?at

wise against each other,

4,383,479

fa frame having vertically spaced, horizontal bars

bpointed wedge means at the lower ends of said

blades to be forced into the husk,

ca hinge connection between the upper ends of said

to which laterally spaced vertical rods are secured

at their ends,

g-a slidable connection between each end of said

blades,

cross bar and said vertical rods to enable the cross

d-a laterally projecting handle connected to the

upper end portion of one blade adjacent said hinge

connection,

bar to be moved up or down,

hmeans on the lower of said horizontal bars to hold

a coconut to be husked,

iand means for connecting said frame to an upright

e-~a cross bar to which the upper end portion of the

support,

.

t

other blade is ?xed,

15

25

'30

35

45

50

55

65

It

You might also like

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- Dau TomDocument6 pagesDau TomPham LoiNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- 19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Document5 pages19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Azri LunduNo ratings yet

- Us2218783 PDFDocument4 pagesUs2218783 PDFlandagoNo ratings yet

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Document7 pages"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- US2099314Document3 pagesUS2099314Jhonnatan E Avendaño Florez100% (1)

- United States Patent (191 1111 Patent Number: 4,991,386: Dirksen (45) Date of Patent: Feb. 12, 1991Document6 pagesUnited States Patent (191 1111 Patent Number: 4,991,386: Dirksen (45) Date of Patent: Feb. 12, 1991James LindonNo ratings yet

- Title - Wood Chipper ConstructionDocument4 pagesTitle - Wood Chipper Constructionمحمد عبدالدايمNo ratings yet

- taibl1 صورةDocument26 pagestaibl1 صورةAyham MhannaNo ratings yet

- Title - Wood Chipper Disc and Knife MountingDocument5 pagesTitle - Wood Chipper Disc and Knife Mountingمحمد عبدالدايمNo ratings yet

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocument3 pagesData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateJaymar ManualNo ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- A. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .Document4 pagesA. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .AGUAVIVANJNo ratings yet

- United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986Document3 pagesUnited States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986wahaha06No ratings yet

- US2126921Document5 pagesUS2126921Jhonnatan E Avendaño Florez100% (1)

- H. J. Smith: Potato Cutting Machine 28 Filed 00Document3 pagesH. J. Smith: Potato Cutting Machine 28 Filed 00RodrigoPomaNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- LL-LLL'LL-FLL: 31, 1940. E. C. MmleanDocument7 pagesLL-LLL'LL-FLL: 31, 1940. E. C. MmleanKrozeNo ratings yet

- United States Patent (19) : SpencerDocument5 pagesUnited States Patent (19) : SpencerKevin VillacisNo ratings yet

- US1685447Document5 pagesUS1685447Redirecting DecoyNo ratings yet

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Document7 pagesSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNo ratings yet

- United States Patent (19) : Filed: July 27, 1976 57Document3 pagesUnited States Patent (19) : Filed: July 27, 1976 57Alexandre Magno Bernardo FontouraNo ratings yet

- Fig. Ib: Oct.8,1968 M - ,. - A. - KER - 3,404,545Document6 pagesFig. Ib: Oct.8,1968 M - ,. - A. - KER - 3,404,545Thiru MuruganNo ratings yet

- April 27, 1948. E. A. Bender 2,440,427: Filed Jan. 12, 1945 2 Sheets-SheetDocument6 pagesApril 27, 1948. E. A. Bender 2,440,427: Filed Jan. 12, 1945 2 Sheets-SheetAbu SayedNo ratings yet

- US2128620 - Bending MachineDocument5 pagesUS2128620 - Bending MachinedevheadbotNo ratings yet

- Foldable Boat FlierDocument5 pagesFoldable Boat FlierRakeshNo ratings yet

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDocument7 pagesCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitNo ratings yet

- Us2018240 PDFDocument4 pagesUs2018240 PDFPolygrapack SA DE CVNo ratings yet

- United States Patent (191: Andersen Et A1Document5 pagesUnited States Patent (191: Andersen Et A1khoagleNo ratings yet

- 1,138,232. Patented May 4, 1915,: 0, J, McgannDocument3 pages1,138,232. Patented May 4, 1915,: 0, J, McgannVyacheslavNo ratings yet

- June 23, 1925.: F . I: ZacherDocument3 pagesJune 23, 1925.: F . I: ZachershamsNo ratings yet

- Us 5546957Document7 pagesUs 5546957SurgaveryNo ratings yet

- US2125697Document3 pagesUS2125697davarniyaalirezasepehrelectricNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- Dec. 14, 1948. O. G. Reske 2,456,446: - 2Z 2. 77zzvezzoDocument4 pagesDec. 14, 1948. O. G. Reske 2,456,446: - 2Z 2. 77zzvezzoAngelica Mae LargaNo ratings yet

- Patente TrituradoraDocument11 pagesPatente TrituradoraDany ChimborazoNo ratings yet

- United States Patent 1191: MasuyamaDocument7 pagesUnited States Patent 1191: MasuyamaAbdullah AljabriNo ratings yet

- Ulllted States Patent (19) (11) Patent Number: 5,901,540: Vella (45) Date 0f Patent: May 11, 1999Document12 pagesUlllted States Patent (19) (11) Patent Number: 5,901,540: Vella (45) Date 0f Patent: May 11, 1999James LindonNo ratings yet

- I Set: II. F TaxaDocument6 pagesI Set: II. F Taxafrank saruhanNo ratings yet

- Target Kite (1944)Document7 pagesTarget Kite (1944)CAP History LibraryNo ratings yet

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDocument4 pagesMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniNo ratings yet

- US2447117Document6 pagesUS2447117MahnooshNo ratings yet

- Us 2912244Document9 pagesUs 2912244alexhkiNo ratings yet

- US2009857 FORMADOR SOBRES PotdevinDocument3 pagesUS2009857 FORMADOR SOBRES PotdevinJhonnatan E Avendaño FlorezNo ratings yet

- Mica DescrptionDocument8 pagesMica DescrptionmpkkbtechNo ratings yet

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduNo ratings yet

- United States Patent: SimpsonDocument5 pagesUnited States Patent: Simpsonاحمد عبدالكريمNo ratings yet

- W, B. Kidder. : Tree Climbing MotorDocument4 pagesW, B. Kidder. : Tree Climbing Motormonem2014No ratings yet

- Braiding MachineDocument7 pagesBraiding Machinejojaberi100% (1)

- US2228469Document4 pagesUS2228469George AcostaNo ratings yet

- Unidad IV Intercambiadores de CalorDocument4 pagesUnidad IV Intercambiadores de CalorRafael CórdobaNo ratings yet

- European Patent Application: 22.06.2011 Bulletin 2011/25 A01D 45/02Document13 pagesEuropean Patent Application: 22.06.2011 Bulletin 2011/25 A01D 45/02Lenti TiborNo ratings yet

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- ZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Document5 pagesZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Edikan AkpanNo ratings yet

- Catering Menu: Reakfast Ower AndwichesDocument3 pagesCatering Menu: Reakfast Ower Andwichessushil-funNo ratings yet

- Romeo OnDocument2 pagesRomeo Onsushil-funNo ratings yet

- David Che TractDocument1 pageDavid Che Tractsushil-funNo ratings yet

- Wednesday Night Dinner "Special"Document2 pagesWednesday Night Dinner "Special"sushil-funNo ratings yet

- Pahdo PDFDocument15 pagesPahdo PDFsushil-funNo ratings yet

- White Wines: New WorldDocument4 pagesWhite Wines: New Worldsushil-funNo ratings yet

- Wid DumeDocument39 pagesWid Dumesushil-funNo ratings yet

- Martinis: CocktailsDocument4 pagesMartinis: Cocktailssushil-funNo ratings yet

- Valentine's Day Menu February 14: A Glass of Champagne On ArrivalDocument2 pagesValentine's Day Menu February 14: A Glass of Champagne On Arrivalsushil-funNo ratings yet

- SundenuDocument2 pagesSundenusushil-funNo ratings yet

- Horizo PDFDocument2 pagesHorizo PDFsushil-funNo ratings yet

- NubguDocument2 pagesNubgusushil-funNo ratings yet

- Flowers and Dinr Spots in HDocument5 pagesFlowers and Dinr Spots in Hsushil-funNo ratings yet

- Catering: Whole Foods MarketDocument5 pagesCatering: Whole Foods Marketsushil-funNo ratings yet

- H Y S T R W - L ?: AVE OU EEN Hese ARE Ater IliesDocument3 pagesH Y S T R W - L ?: AVE OU EEN Hese ARE Ater Iliessushil-funNo ratings yet

- Origami Lily PrintDocument1 pageOrigami Lily Printrenden_harriedNo ratings yet

- Mindfulness in Freeding PDFDocument9 pagesMindfulness in Freeding PDFsushil-funNo ratings yet

- Order at or Call (410) 772-1072 For Delivery From The Greene Turtle!Document4 pagesOrder at or Call (410) 772-1072 For Delivery From The Greene Turtle!sushil-funNo ratings yet

- Lily (Lilium) Care SheetDocument1 pageLily (Lilium) Care Sheetsushil-funNo ratings yet

- The Laugh of The Water NymphDocument3 pagesThe Laugh of The Water Nymphsushil-funNo ratings yet

- The Laugh of The Water NymphDocument3 pagesThe Laugh of The Water Nymphsushil-funNo ratings yet

- Origami Lily PrintDocument1 pageOrigami Lily Printrenden_harriedNo ratings yet

- Breads BDocument1 pageBreads Bsushil-funNo ratings yet

- How To Make OrigDocument35 pagesHow To Make Origsushil-funNo ratings yet

- Nutrition Facts Nutrition Facts Nutrition Facts Nutrition FactsDocument8 pagesNutrition Facts Nutrition Facts Nutrition Facts Nutrition Factssushil-funNo ratings yet

- Bakery Cafe MenuDocument2 pagesBakery Cafe MenuamsterdamageNo ratings yet

- Idk What Is ThisDocument2 pagesIdk What Is Thishi im a fecking penguinNo ratings yet

- Idk What Is ThisDocument2 pagesIdk What Is Thishi im a fecking penguinNo ratings yet

- Fish Fy MeDocument1 pageFish Fy Mesushil-funNo ratings yet

- RenuDocument1 pageRenusushil-funNo ratings yet

- MTC Bus RoutesDocument133 pagesMTC Bus Routesinnovativedeepak8784% (19)

- The Iranian Mannerbund Revisited Iran A PDFDocument12 pagesThe Iranian Mannerbund Revisited Iran A PDFDeep StateNo ratings yet

- Cix Content Index PDFDocument2 pagesCix Content Index PDFJohn ReyNo ratings yet

- Single Mode Optical Fiber Cable Specification (GYTS53) : No. FT-S20103 Version: A-2 Issued: Sept. 08, 2020Document6 pagesSingle Mode Optical Fiber Cable Specification (GYTS53) : No. FT-S20103 Version: A-2 Issued: Sept. 08, 2020Aung Thein OoNo ratings yet

- Compassion and GratitudeDocument45 pagesCompassion and GratitudeIrfan AbubakarNo ratings yet

- Cwcheat Monster Hunter Freedom Unite EU (ULES 01213)Document5 pagesCwcheat Monster Hunter Freedom Unite EU (ULES 01213)Shahmi Alidin67% (9)

- The Healing School Magazine - November 2019Document16 pagesThe Healing School Magazine - November 2019Healing School NewsNo ratings yet

- JK Wall PuttyDocument4 pagesJK Wall PuttyChander Mohan0% (1)

- Week 9 - Worship and Prophecy - Psalm 63Document4 pagesWeek 9 - Worship and Prophecy - Psalm 63kishtal17No ratings yet

- English 3 Unit 11 QUIZ NameDocument1 pageEnglish 3 Unit 11 QUIZ NameOllian300No ratings yet

- Peeking - Backstage - Shattering The Narrative and Parabolizing The Fitna in Ibn Al - Adīm's Bughyat Al TalibDocument21 pagesPeeking - Backstage - Shattering The Narrative and Parabolizing The Fitna in Ibn Al - Adīm's Bughyat Al TalibAnonymous JWUsx1No ratings yet

- Manual Panasonic Ny MDDocument3 pagesManual Panasonic Ny MDPopescu IonutNo ratings yet

- The Paper Craft BookDocument164 pagesThe Paper Craft BookMagdalena Alejandra PIERA91% (22)

- Degrees of ComparisonDocument8 pagesDegrees of ComparisonUmaDevi Yarasu DeviNo ratings yet

- Aerial PhotographyDocument45 pagesAerial Photographypavan hiranNo ratings yet

- Finlay Park PresentationDocument6 pagesFinlay Park PresentationWIS Digital News StaffNo ratings yet

- Most Interesting Man in The WorldDocument1 pageMost Interesting Man in The Worldlarson hermanNo ratings yet

- Homonyms - Lesson PlanDocument5 pagesHomonyms - Lesson PlanJefferson McKing FlorNo ratings yet

- Ireland AmyDocument7 pagesIreland Amymarcelo grosmanNo ratings yet

- Kabanata 27 El FilibusterismoDocument4 pagesKabanata 27 El FilibusterismoAsher BelenNo ratings yet

- Elle Decor 2009-09 PDFDocument134 pagesElle Decor 2009-09 PDFTran Tuan AnhNo ratings yet

- Gulliver's Travels More Than An AdventureDocument2 pagesGulliver's Travels More Than An AdventureAbdulRehman75% (4)

- Transcript - Episode 180: Live From The Lilly Library (I Hear of Sherlock Everywhere)Document30 pagesTranscript - Episode 180: Live From The Lilly Library (I Hear of Sherlock Everywhere)Scott MontyNo ratings yet

- Waltz de Chocobo From Final FantasyDocument4 pagesWaltz de Chocobo From Final FantasyGoRacerGoNo ratings yet

- Colombia Is A Wonderful Country For Its Natural DiversityDocument2 pagesColombia Is A Wonderful Country For Its Natural DiversityNathaliaNo ratings yet

- Saxos AltosDocument2 pagesSaxos AltosJOSE VICENTENo ratings yet

- Revolution On Animal FarmDocument46 pagesRevolution On Animal FarmAkshansh BhadouriyaNo ratings yet

- Aristotle's Definition of TragedyDocument2 pagesAristotle's Definition of TragedyChandrashri ChoudhuryNo ratings yet

- Total Number of Items Remembering Understanding Applying Analyzing Evaluating Creating 5Document16 pagesTotal Number of Items Remembering Understanding Applying Analyzing Evaluating Creating 5erma rose hernandezNo ratings yet

- JI Pitch NotationDocument4 pagesJI Pitch NotationEl Roy M.T.No ratings yet