Professional Documents

Culture Documents

IR 10 Years LCC and OPEX Cost

Uploaded by

er_bhavinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IR 10 Years LCC and OPEX Cost

Uploaded by

er_bhavinCopyright:

Available Formats

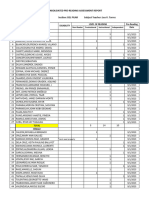

Particular- .

Life cycle cost(LCC) based on energy consumption and estimated consumables and

S. No. Details

overhauling for 10 years of running.

1 Compressor R90n

2 Sp. Power 0.19

3 Power Consumed per hr @ 560 cfm 106.4

4 Power for Dryer operation (power equivalent for Purge + system, etc) 3.4

5 Power Consumed by Compressor for unloaded Run (KW) 0

6 Power Consumed Compressor + Dryer System @ 560 cfm (KW) 109.8

Avg Power Consumed per hour i.e. Compressor + Dryer System @ 560 cfm, with below assumption :

25% operation @ 560 cfm (i.e. 100% design load)

7 74.48

30% time operation @ 70% design load &

30% time operation @ 40% design load

10% at no load / unload due to low variable load requirement.

8 Maintenance cost (Consumables) considering 1W + 1S compressor system 100000

9 Airend life 40000

10 Airend Rebuilding cost 265000

11 Power cost for 10 year @ avg power consumption (from S.No 7.) & power cost @ Rs. 7 per KWH 41708800

12 Maintenance cost (Consumables) 1W + 1S for 10 years 1000000

13 AMC Cost (4 visit per year - 2 scheduled + 2 breakdown) at present cost 720000

Cost of Airend repaid in 10 years

14 265000

assuming 1# rebuilding after 40K hrs i.e. after 5 years

15 Total OPEX cost for 10 years 43693800

16 Initial investment discounted rates

17 Total Cost of Ownership for 10 years #VALUE!

Exclusions

Incidental Expenses, consideration of consumable life is basis recommendation which may vary as per

1). actual site conditions. Above cost may vary depending upon actual running of air compressor, site

conditions .

AIL had to carry out maintenance schedule as per IR O & M and will utilize genuine spares from Ingersoll

2).

Rand through out .

3). AMC charges are excluding first year being warranty.

4). Insurance spares, airend repair considered after 5 years.

5). Package care charges.

6). Anything else not mentioned above.

7). Above considerations are assuming 1W + 1S compressor system.

8). Considering customer requirement is with VFD so .

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Calculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A PumpDocument4 pagesCalculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pumper_bhavinNo ratings yet

- Pump SizingDocument4 pagesPump SizingNikunj100% (5)

- AS/ISO 9906:2018 pump performance standard now in effectDocument3 pagesAS/ISO 9906:2018 pump performance standard now in effecter_bhavinNo ratings yet

- Tri P10Document10 pagesTri P10Dvd Davide La CruzNo ratings yet

- K-Reference DataDocument37 pagesK-Reference DataMonglen Z. CasiñoNo ratings yet

- SP 3 DDocument24 pagesSP 3 DPatel ChiragNo ratings yet

- Compressed Air Treatment Diagrams For Rotary Screw CompressorsDocument4 pagesCompressed Air Treatment Diagrams For Rotary Screw Compressorser_bhavin100% (1)

- LCC KaeserDocument1 pageLCC Kaeserer_bhavinNo ratings yet

- The Mathematics of Pumping Water PDFDocument9 pagesThe Mathematics of Pumping Water PDFOualid LamraouiNo ratings yet

- 65-125 Ton Water Cooled ChillerDocument2 pages65-125 Ton Water Cooled Chillerer_bhavinNo ratings yet

- DSDDocument15 pagesDSDIvan KokićNo ratings yet

- Life Cycle Cost CalculationDocument2 pagesLife Cycle Cost Calculationer_bhavinNo ratings yet

- Capex VS Opex CHiller - 27-05-2020 DaikinDocument8 pagesCapex VS Opex CHiller - 27-05-2020 Daikiner_bhavinNo ratings yet

- ZR 75 90 VSD FF Product Description EN AntwerpDocument9 pagesZR 75 90 VSD FF Product Description EN Antwerper_bhavinNo ratings yet

- Running Cost and Lifecycle Cost of ChillerDocument2 pagesRunning Cost and Lifecycle Cost of Chillerer_bhavinNo ratings yet

- Selection Sheet PFS1101DBRYV CEWT Final RevisedDocument1 pageSelection Sheet PFS1101DBRYV CEWT Final Reviseder_bhavinNo ratings yet

- 65-125 Ton Water Cooled ChillerDocument2 pages65-125 Ton Water Cooled Chillerer_bhavinNo ratings yet

- Capex Vs Opex Compariosn For Chiller YorkDocument9 pagesCapex Vs Opex Compariosn For Chiller Yorker_bhavinNo ratings yet

- Energy Analysis OPEX - 10 YearsDocument1 pageEnergy Analysis OPEX - 10 Yearser_bhavinNo ratings yet

- Capex vs Opex comparison for 100 TR chillerDocument4 pagesCapex vs Opex comparison for 100 TR chillerer_bhavinNo ratings yet

- Aquaforce: Detailed Performance Summary For Untitled1Document3 pagesAquaforce: Detailed Performance Summary For Untitled1er_bhavinNo ratings yet

- Zsi DT 0025 - 1 PDFDocument1 pageZsi DT 0025 - 1 PDFer_bhavinNo ratings yet

- Capex VS Opex CHiller - 27-05-2020 TraneDocument8 pagesCapex VS Opex CHiller - 27-05-2020 Traneer_bhavinNo ratings yet

- Myths and Facts of Hvac Refrigerants: Fact: HCFCS, Including R123, Are Being Phased OutDocument4 pagesMyths and Facts of Hvac Refrigerants: Fact: HCFCS, Including R123, Are Being Phased OutSiva SivaNo ratings yet

- Capex vs Opex comparison for 100 TR chillerDocument4 pagesCapex vs Opex comparison for 100 TR chillerer_bhavinNo ratings yet

- Vendor data requirements for equipment drawingsDocument1 pageVendor data requirements for equipment drawingser_bhavinNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- City Montessori School, Lucknow Syllabus 2020 - 2021 Class IXDocument20 pagesCity Montessori School, Lucknow Syllabus 2020 - 2021 Class IXBsp Secl100% (1)

- Secure File Storage On Cloud Using CryptographyDocument13 pagesSecure File Storage On Cloud Using CryptographyIJRASETPublicationsNo ratings yet

- New Ford Endeavour Brochure Mobile PDFDocument13 pagesNew Ford Endeavour Brochure Mobile PDFAnurag JhaNo ratings yet

- Maestro-Ko: IGP - Tshirt Printing ProjectDocument4 pagesMaestro-Ko: IGP - Tshirt Printing ProjectAxel Nicerio RoveloNo ratings yet

- World Policy Journal: Bangladesh: A Labor ParadoxDocument11 pagesWorld Policy Journal: Bangladesh: A Labor ParadoxPranto BaraiNo ratings yet

- Et in Arcadia EgoDocument5 pagesEt in Arcadia Ego69telmah69No ratings yet

- Jaiib Made Simple Legal & Regulatory Aspects of BankingDocument8 pagesJaiib Made Simple Legal & Regulatory Aspects of BankingChatur ReddyNo ratings yet

- Y Oughal Ne WsDocument48 pagesY Oughal Ne WsmwmccarthyNo ratings yet

- Vedanta KesariDocument56 pagesVedanta Kesarigeo_unoNo ratings yet

- CIMA's Background as Malaysia's Third Largest Cement ManufacturerDocument47 pagesCIMA's Background as Malaysia's Third Largest Cement ManufacturerApom LenggangNo ratings yet

- Tracking DepEd Division Funds for Disaster MonitoringDocument2 pagesTracking DepEd Division Funds for Disaster MonitoringMamad Tomara BatingoloNo ratings yet

- IndiaMart Research ProjectDocument15 pagesIndiaMart Research ProjectbusinessideasNo ratings yet

- Marketing Strategies of AdidasDocument58 pagesMarketing Strategies of Adidasjassi7nishadNo ratings yet

- What Is Occupational Health and Safety?Document3 pagesWhat Is Occupational Health and Safety?flex gyNo ratings yet

- Seismic Vulnerability of Structures in Sikkim During 2011 EarthquakeDocument20 pagesSeismic Vulnerability of Structures in Sikkim During 2011 EarthquakeManpreet SinghNo ratings yet

- Military History of Slovenians, by Janez J. Švajncer, 2001Document5 pagesMilitary History of Slovenians, by Janez J. Švajncer, 2001Slovenian Webclassroom Topic Resources100% (1)

- 49 People V RamosDocument7 pages49 People V RamosIsagani CastilloNo ratings yet

- Seirei Tsukai No Blade Dance - Volume 12 - Releasing The Sealed SwordDocument284 pagesSeirei Tsukai No Blade Dance - Volume 12 - Releasing The Sealed SwordGabriel John DexterNo ratings yet

- Heirs vs Garilao (2009) Land Retention RightsDocument2 pagesHeirs vs Garilao (2009) Land Retention RightsTrek AlojadoNo ratings yet

- Re-appropriation of Rs. 3.99 lakh for publicationsDocument1 pageRe-appropriation of Rs. 3.99 lakh for publicationsAshish Singh Negi100% (1)

- PaperDocument4 pagesPaperAnne ChenNo ratings yet

- General Defences Shortest (Last Minute)Document23 pagesGeneral Defences Shortest (Last Minute)Raj DasNo ratings yet

- Lesson Plan Template: DirectionsDocument3 pagesLesson Plan Template: Directionsapi-612420884No ratings yet

- Summary National Policy Strategy For Infrastructure and Spatial PlanningDocument24 pagesSummary National Policy Strategy For Infrastructure and Spatial Planningandre turnerNo ratings yet

- Reading Report G9Document50 pagesReading Report G9Grade9 2023No ratings yet

- Trump University Asset Protection 101 Trump University PDFDocument4 pagesTrump University Asset Protection 101 Trump University PDFThumper Kates0% (2)

- Ugc Good PracticesDocument21 pagesUgc Good PracticesIngryd Lo TierzoNo ratings yet

- Letter Sa Mga Panel Inag FinalsDocument7 pagesLetter Sa Mga Panel Inag FinalsCHENNY BETAIZARNo ratings yet

- ACCOUNTS RECEIVABLES 7-8 - Sheet1-2Document3 pagesACCOUNTS RECEIVABLES 7-8 - Sheet1-2Astrid AboitizNo ratings yet

- Project - OmDocument30 pagesProject - OmSesha Sai KumarNo ratings yet